System for pyrolyzing and burning sludge at low temperature

A low-temperature pyrolysis and low-temperature cracking technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of complex equipment, large maintenance, low efficiency, etc., and achieve low operating costs, transportation costs, and energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

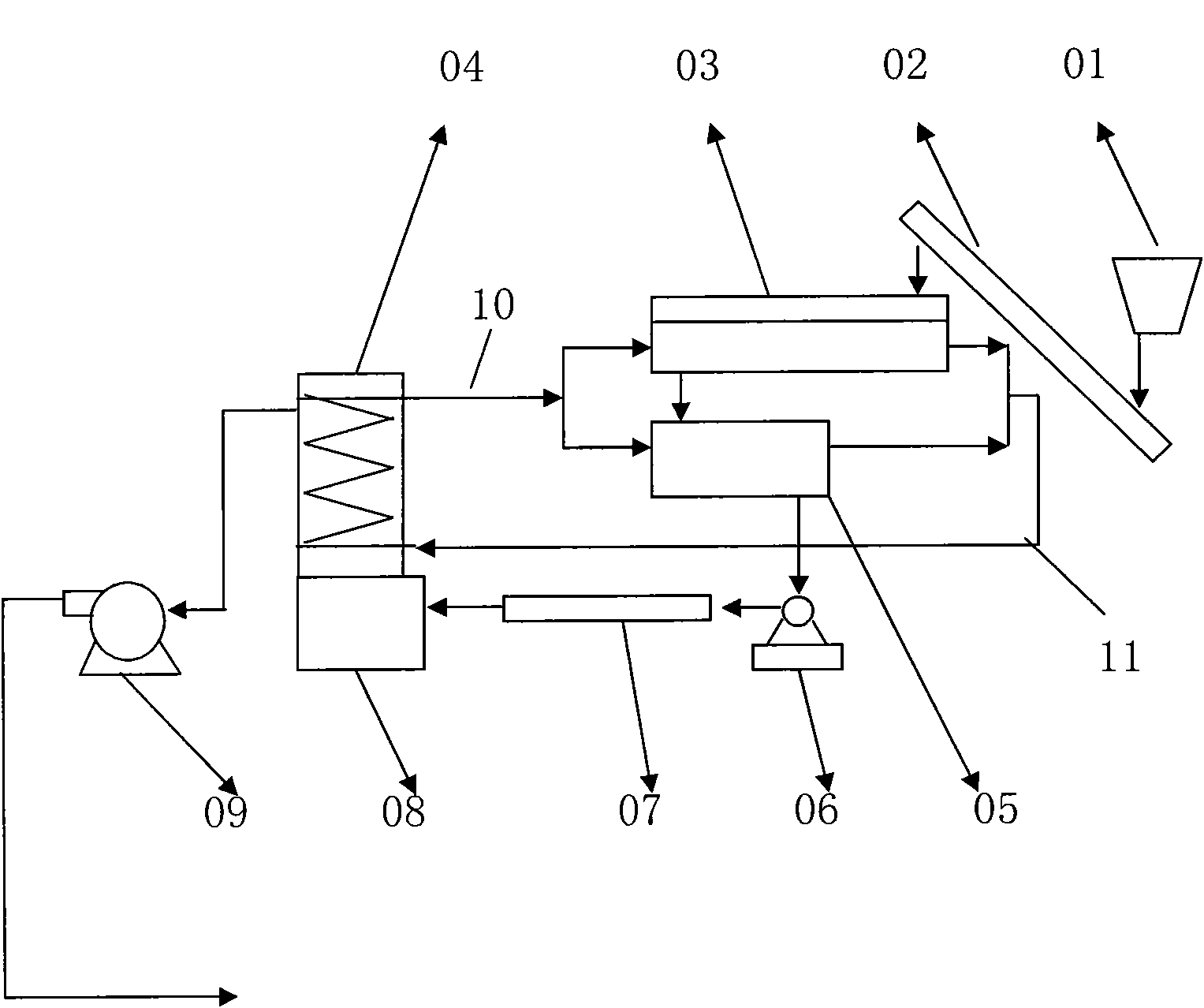

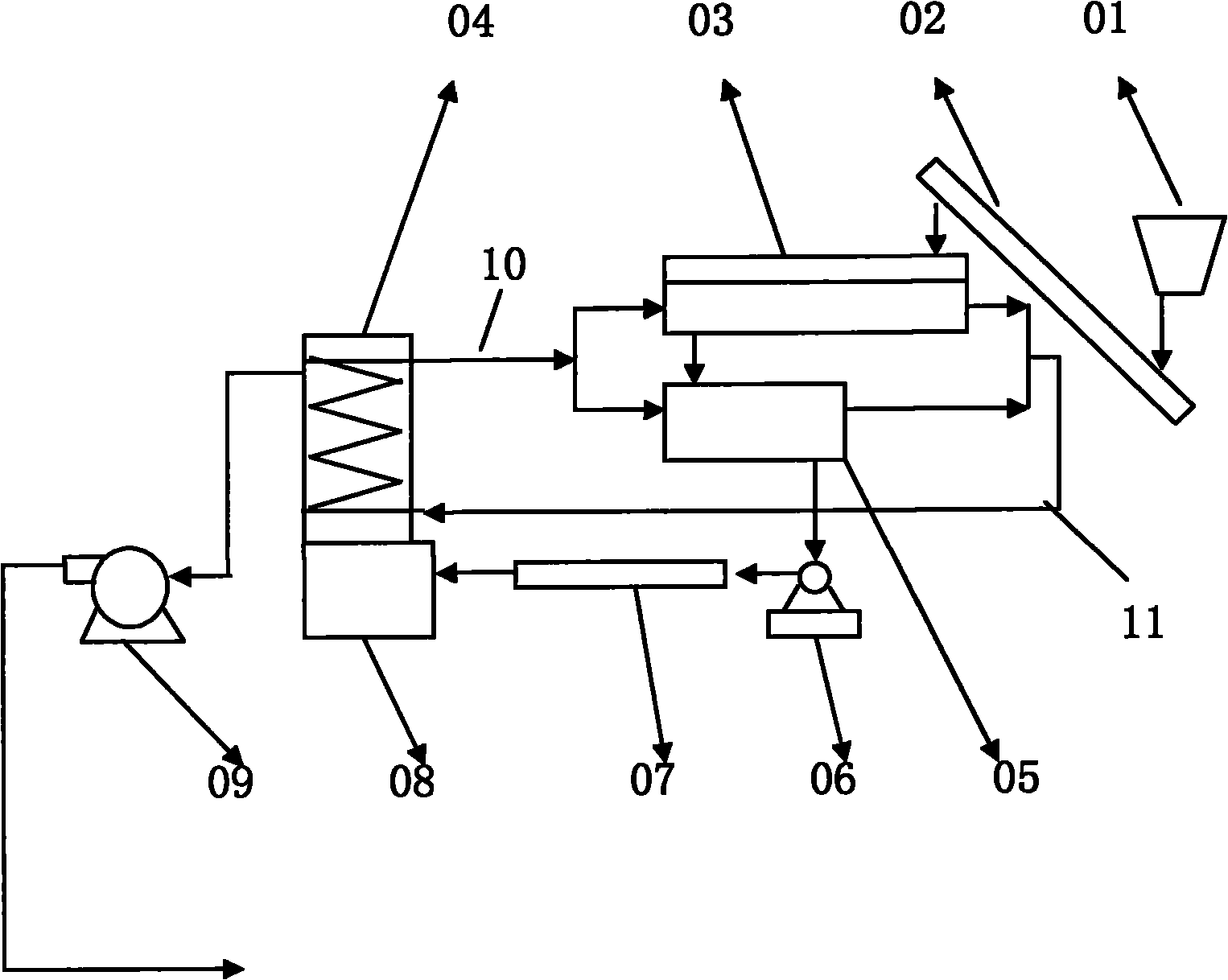

[0022] figure 1 It shows the flow chart of the embodiment of the present invention, the sludge low-temperature pyrolysis incineration system, which includes a sludge hopper 01, a dryer 03, and a device for transporting the sludge output from the sludge hopper 01 to the feed port of the dryer 03 Screw conveyor 02, low-temperature pyrolysis reactor 05 with stirring device connected to the discharge port below the dryer 03, extrusion molding machine 06 connected to the discharge port of the low-temperature pyrolysis reactor, through a conveyor 07 The incinerator 08 with the waste heat boiler 04 connected to the extrusion molding machine, the induced draft fan 09 connected with the waste heat boiler, the upper part of the waste heat boiler 04 is respectively connected with the dryer 03 and the low temperature pyrolysis reactor 05 through the waste heat input pipe 10, The dryer 03 and the low-temperature pyrolysis reactor 5 are respectively connected to the lower part of the waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com