Fermentation device for sludge compost treatment and treatment method using same

A technology of fermentation device and treatment method, applied in fertilization device, sewage/sludge fertilizer, application and other directions, can solve the problems such as the inability of sludge to achieve safe land use, the reduction of sludge moisture content, and the low inactivation rate of pathogenic bacteria. Realize the effect of nearby utilization, promoting sludge decomposing and increasing abundance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

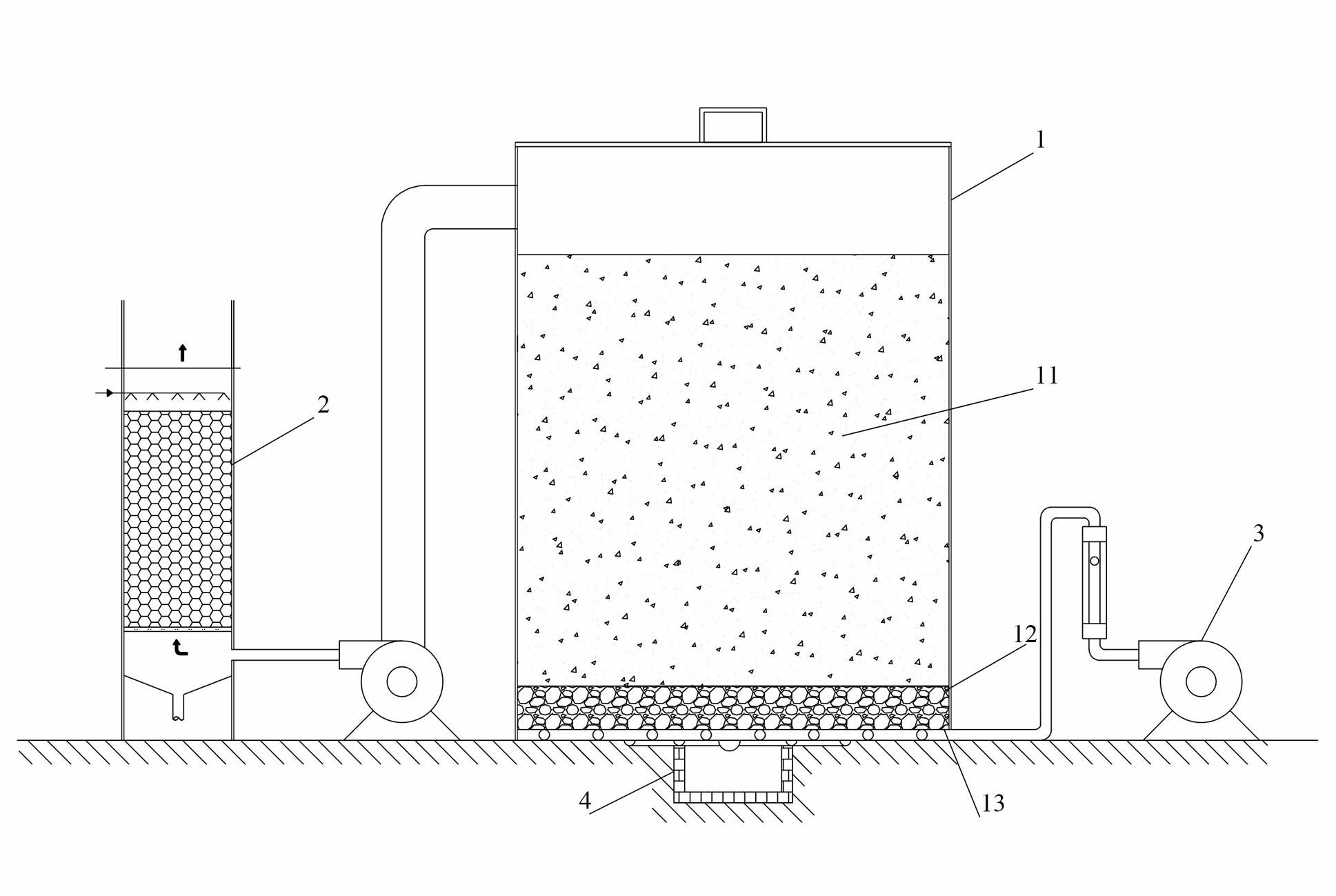

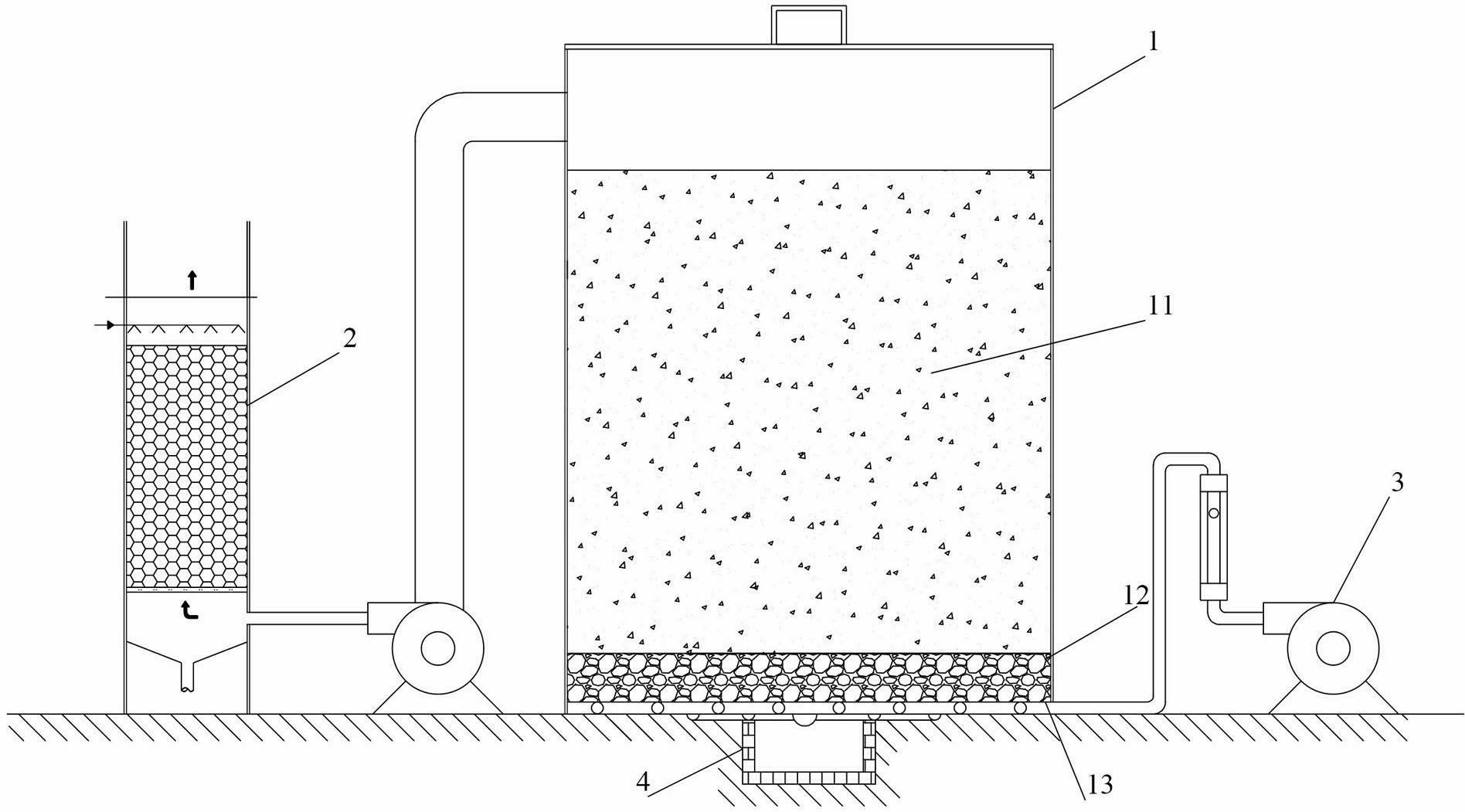

[0030] Embodiment 1: Fermentation device for sludge composting treatment.

[0031] a kind of like figure 1As shown in the fermentation device for sludge composting treatment of the present invention, the fermentation device in this embodiment is designed according to the processing capacity of 5 t of sludge with a moisture content of 80% (can be adjusted according to the amount of sludge produced in a single day) ). The fermentation device for sludge composting treatment of the present invention includes a fermentation bin body 1, and the fermentation bin body 1 is a steel plate welded angle iron reinforced cylindrical closed type fermentation bin (diameter d=2 m, height h=2.75 m); The bottom of the body 1 is externally connected with a forced ventilation device 3 (this embodiment is an intermittent static forced ventilation device); a filter layer is laid on the bottom of the fermentation bin body 1, and the filter layer includes a 20 cm thick crushed stone layer 12 (the d...

Embodiment 2

[0032] Embodiment 2: the processing method of sludge composting.

[0033] A sludge composting treatment method of the present invention, the sludge raw material to be treated is collected from Qianfeng Sewage Plant, Shiqi Town, Panyu District, Guangzhou City, which is a typical small sewage treatment plant, and the sludge raw material is dehydrated by a belt filter press Finally, dewatered sludge with a moisture content of about 80% was obtained, and the dewatered sludge was dried in an oven at 105°C for 24 hours to obtain dry sludge. The content of volatile organic compounds in the dry sludge was 52.90%, and the C / N ratio was about is 8.5. Composting the dewatered sludge with a moisture content of 80% using the treatment method of the present invention and the fermentation device in Example 1, specifically comprising the following steps:

[0034] (1) Adding an organic conditioner: Add an organic conditioner to the dewatered sludge to adjust the water content, texture and C...

Embodiment 3

[0039] Embodiment 3: Sludge composting treatment method.

[0040] A sludge composting treatment method of the present invention, the sludge raw material to be treated is collected from Qianfeng Sewage Plant, Shiqi Town, Panyu District, Guangzhou City, which is a typical small sewage treatment plant, and the sludge raw material is dehydrated by a belt filter press Finally, dewatered sludge with a moisture content of about 80% was obtained, and the dewatered sludge was dried in an oven at 105°C for 24 hours to obtain dry sludge. The content of volatile organic compounds in the dry sludge was 52.90%, and the C / N ratio was about is 8.5. Composting the dewatered sludge with a moisture content of 80% using the treatment method of the present invention and the fermentation device in Example 1, specifically comprising the following steps:

[0041] (1) Adding an organic conditioner: Add an organic conditioner to the dewatered sludge to adjust the water content, texture and C / N of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com