Method for high-valued recycling of wastes of diamond wire silicon wafer cutting

A technology of silicon wafer cutting and diamond wire, applied in chemical instruments and methods, silicon compound, polycrystalline material growth and other directions, can solve the problems of difficult to ensure silicon recovery rate, increase of particle melting point, high surface activity, and achieve added value of products High, low cost, simple equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

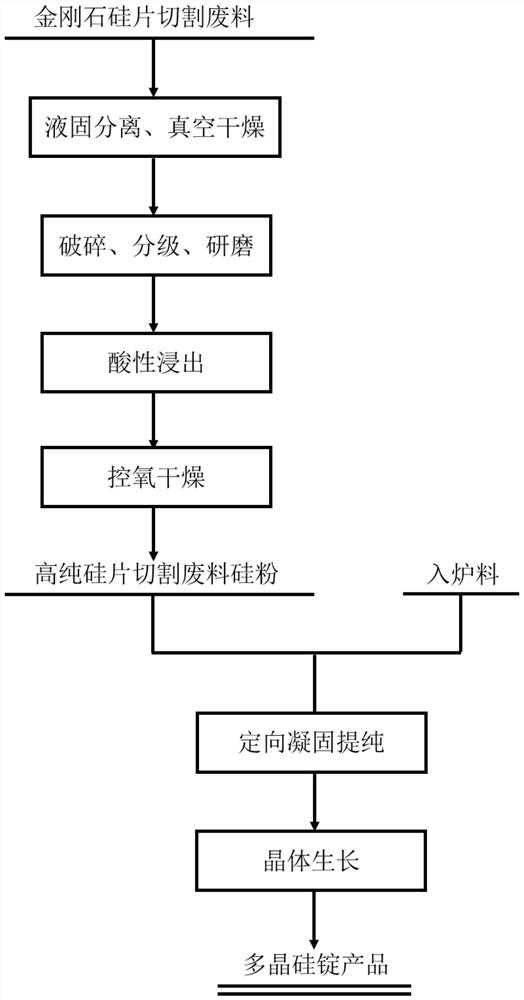

[0027] Embodiment 1: A kind of method of high-value recycling of diamond wire silicon chip cutting waste (see figure 1 ),Specific steps are as follows:

[0028] (1) The crystalline silicon diamond wire cutting scraps in a certain place in Yunnan are subjected to plate and frame press filtration to remove liquids such as water-based lubricants to achieve liquid-solid separation, and the filter block is vacuum-dried for diamond wire silicon wafer cutting waste solid blocks, and the diamond Wire silicon wafer cutting waste solid blocks are crushed, classified, and ground to obtain silicon fine-grained powder; the average particle size of silicon fine-grained powder is 45 μm, and the total content of metal impurities in silicon fine-grained powder is 11503ppm: Al 7738ppm, Ca 2877ppm , Fe 531ppm, Mg212ppm, Ni 145ppm, in terms of mass percentage, the water content of the silicon fine particle powder is 6%;

[0029] (2) Add the silicon fine particle powder into the hydrochloric acid...

Embodiment 2

[0035] Embodiment 2: A kind of method of high-value recycling of diamond wire silicon chip cutting waste (see figure 1 ),Specific steps are as follows:

[0036](1) The crystalline silicon diamond wire cutting scraps in a certain place in Yunnan are subjected to plate and frame press filtration to remove liquids such as water-based lubricants to achieve liquid-solid separation, and the filter block is vacuum-dried for diamond wire silicon wafer cutting waste solid blocks, and the diamond Wire silicon wafer cutting waste solid blocks are crushed, classified, and ground to obtain silicon fine-grained powder; the average particle size of silicon fine-grained powder is 40 μm, and the total content of metal impurities in silicon fine-grained powder is 710ppm: Al 1ppm, Fe 596ppm , Mg 47ppm, Ni 58ppm, Ti5ppm, Cu 2ppm, V1ppm, in terms of mass percentage, the water content of the silicon fine particle powder is 8%;

[0037] (2) Add silicon microparticles powder into hydrochloric acid s...

Embodiment 3

[0043] Embodiment 3: A method for high-value recycling of diamond wire silicon wafer cutting waste, the specific steps are as follows:

[0044] (1) The crystalline silicon diamond wire cutting scraps in a certain place in Yunnan are subjected to plate and frame press filtration to remove liquids such as water-based lubricants to achieve liquid-solid separation, and the filter block is vacuum-dried for diamond wire silicon wafer cutting waste solid blocks, and the diamond Wire silicon wafer cutting waste solid blocks are crushed, classified, and ground to obtain silicon fine-grained powder; the average particle size of silicon fine-grained powder is 40 μm, and the total content of metal impurities in silicon fine-grained powder is 6692.7ppm: Al 6400ppm, Fe 6.7ppm, Mg 58ppm, Ni68ppm, in terms of mass percentage, the moisture content of the silicon fine particle powder is 5%;

[0045] (2) Add silicon fine particle powder into hydrochloric acid solution for a section of mechanical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com