Electric field aided silicon through hole etching process

An electric field-assisted, through-silicon via technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as affecting surface quality, difficulty in etching through holes, and difficulty in achieving deep etching of micron-scale patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

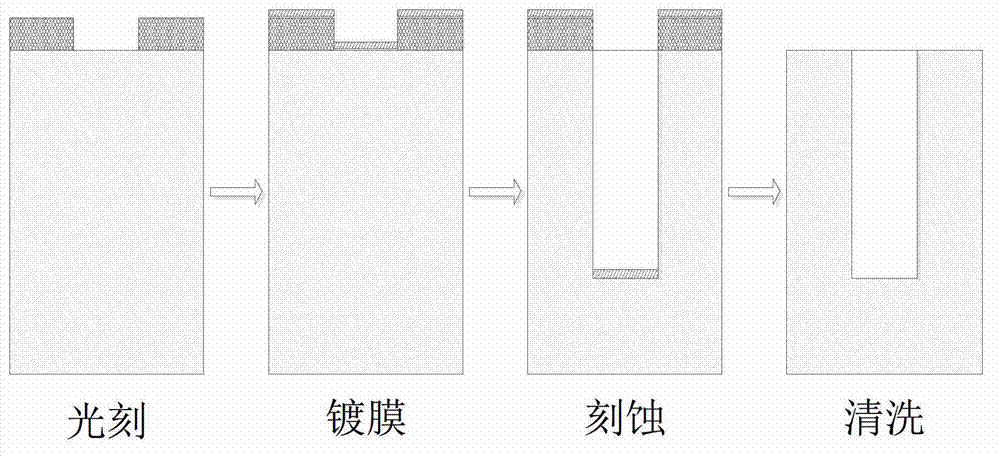

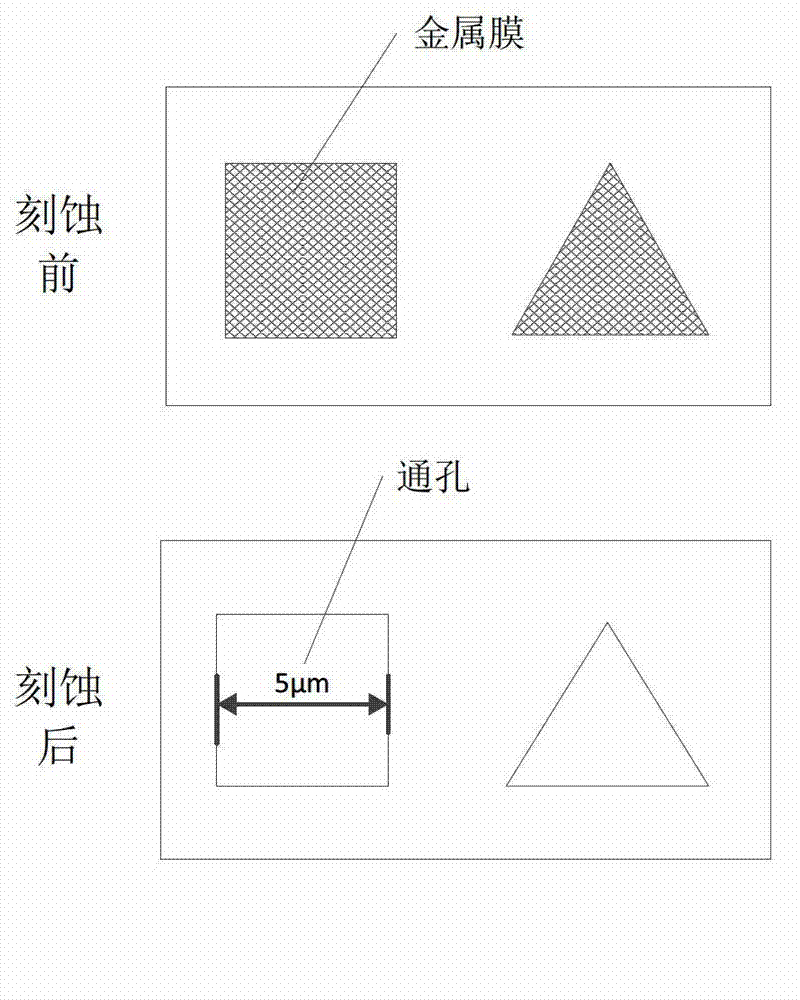

[0027] see figure 1 and figure 2 , figure 1 It is a process block diagram of the inventive method. figure 2 It is a schematic diagram of the through-hole structure made according to Embodiment 1 of the present invention, such as figure 1 and figure 2 As shown in , the electric field-assisted TSV metal-catalyzed etching process in this example includes the following specific steps:

[0028] (a) Clean the single crystal silicon wafer, then spin-coat photoresist on its surface, and transfer the micron-scale pattern on the mask corresponding to the square hole and triangular hole structure with the required characteristic size of 5 microns by photolithography process onto the photoresist, thereby forming a photoresist pattern with micron holes.

[0029] (b) On the single crystal silicon wafer formed with the above-mentioned photoresist with micron holes, a 40nm gold film is plated by using a magnetron sputtering process.

[0030] (c) Using HF, H 2 o 2 The mixed solution...

Embodiment 2

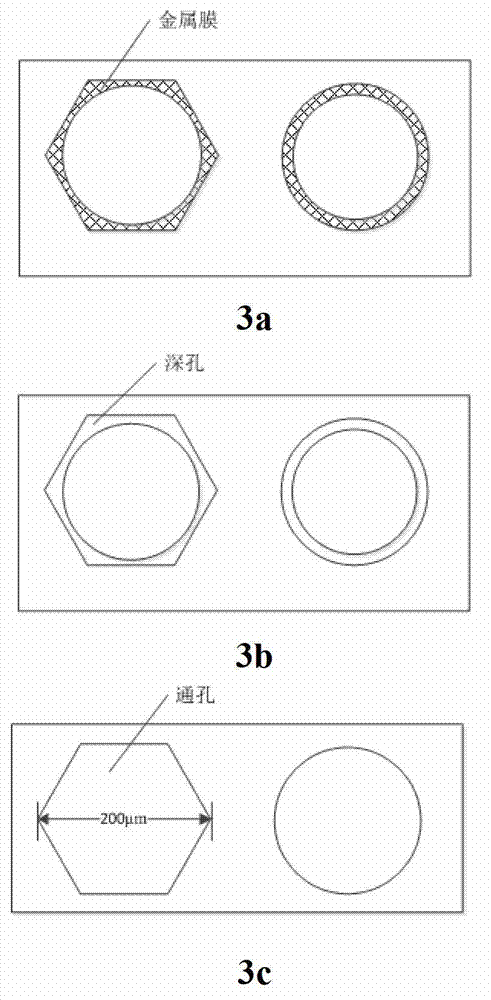

[0034] see figure 1 and image 3 , image 3 It is a schematic diagram of the structure of the large-sized through hole prepared according to the second embodiment of the present invention. Its specific manufacturing process steps include:

[0035] (a) Clean the single crystal silicon wafer, then spin-coat photoresist on its surface, and transfer the ring-like pattern with a diameter of about 200 microns on the mask to the photoresist by photolithography process, thereby forming a micron Photoresist pattern for ring holes.

[0036] (b) On the single-crystal silicon wafer formed with the above-mentioned micron ring holes, a 50nm silver film is plated by electron beam evaporation process.

[0037] (c) Using HF, H 2 o 2 The mixed solution of deionized water and deionized water is used as an etchant to carry out metal-catalyzed etching on a single crystal silicon wafer. The etching reaction is in an electric field with a strength of 500v / m, and the direction of the electric f...

Embodiment 3

[0041] see figure 1 and Figure 4 , Figure 4 It is a schematic diagram of the structure of the nanoscale through-hole array prepared according to the third embodiment of the present invention. Its specific manufacturing process steps include:

[0042] (c) Clean the single crystal silicon wafer, then spin-coat photoresist on its surface, and form a photoresist pattern corresponding to the 50 nanometer hole array by electron beam lithography.

[0043] (d) On the single crystal silicon wafer formed with the above-mentioned nanohole photoresist pattern, a 20nm silver film was plated by using a magnetron sputtering process.

[0044] (c) Using HF, H 2 o 2 A mixed solution of deionized water and deionized water is used as an etchant to carry out metal-catalyzed etching on a single crystal silicon wafer. The etching reaction is in an electric field with a strength of 10v / m, and the direction of the electric field is perpendicular to the surface of the silicon wafer. The mixed so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com