Mercapto-functionalized organic inorganic hybrid ordered mesoporous silicon material and preparation method thereof

A functionalized, mesoporous silicon technology, applied in the field of materials, can solve problems such as limitations, low content, and difficulty in maintaining an ordered structure, and achieve the effects of good complexation ability, large specific surface area, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] At 40°C, 4.00g F127 (0.32mmol) was dissolved in 15.00g anhydrous ether and stirred for 1 hour to obtain solution A; 2.384g of organosilicon source 3-mercaptopropyltriethoxysilane (10mmol) at 1.0 Hydrolyzed under the condition of g (0.2mol / L) hydrochloric acid for 30 minutes to obtain solution B.

[0038] The two solutions were mixed, 1.8 g of soluble resole resin (4.5 mmol) was added, and the reaction was stirred for 2 hours at 40°C. Then spread the mixture evenly in a petri dish and place it at room temperature for 7 hours to evaporate the organic solvent.

[0039] Finally, it is transferred to an oven at 100°C, and after low-temperature thermosetting for 24 hours, the product is refluxed in a 48wt% sulfuric acid solution at 85°C for 48 hours to remove the surfactant.

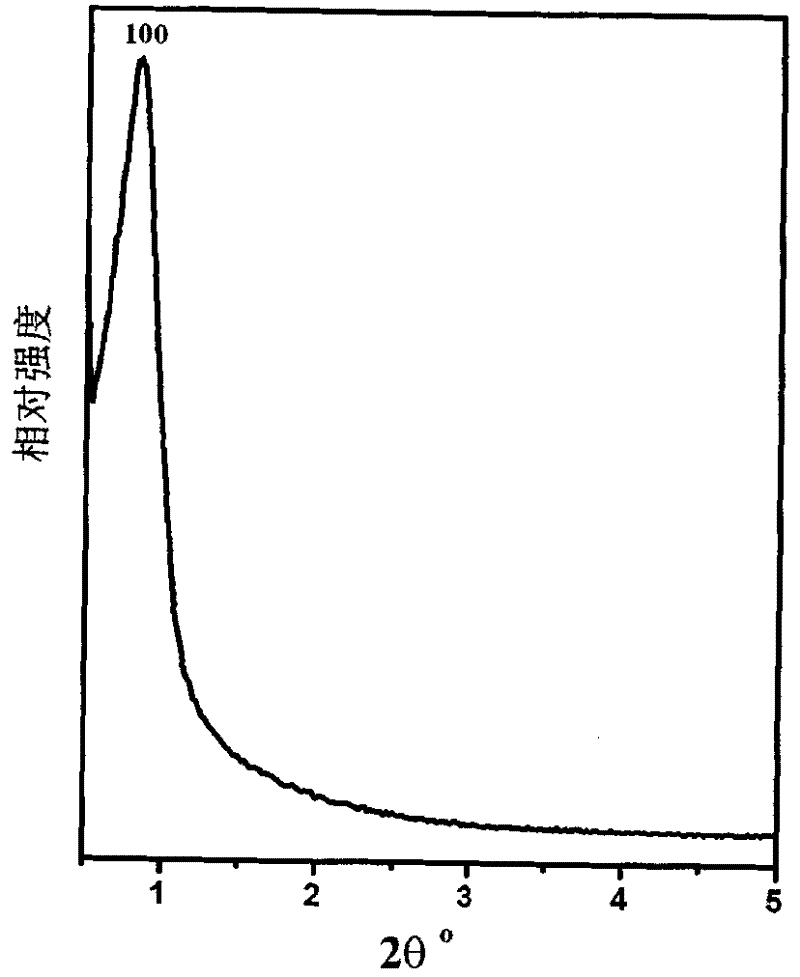

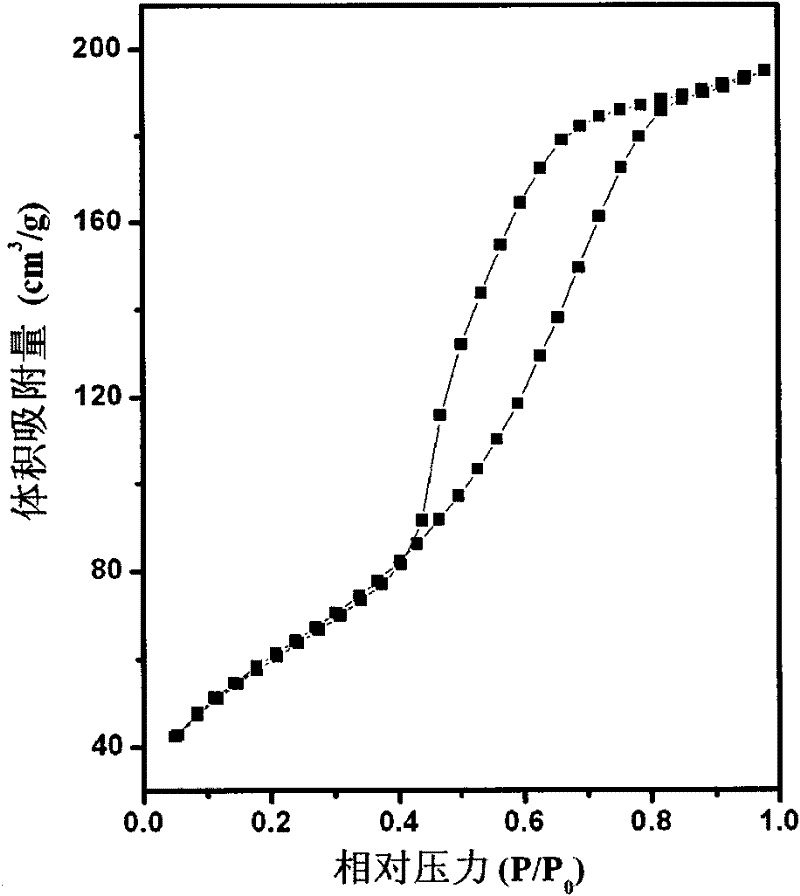

[0040] The obtained material has a two-dimensional hexagonal mesoscopic structure (space group p6mm), a pore diameter of 5.4nm, and a pore volume of 0.30cm 3 / g, the specific surface area is 223m 2 / g, sulfhy...

Embodiment 2

[0043] At 40°C, 1.60g F127 (0.13mmol) was dissolved in 10.00g absolute ethanol and stirred for 1 hour to obtain solution A; 0.405g organosilicon source 3-mercaptopropyltriethoxysilane (1.7mmol) and 1.729 g of inorganic silicon source TEOS (8.3 mmol) was hydrolyzed under 1.0 g (0.2 mol / L) hydrochloric acid for 30 minutes to obtain solution B.

[0044] The two solutions were mixed, 1.0 g of soluble resole resin (2.5 mmol) was added, and the reaction was stirred for 2 hours at 40°C. Then spread the mixture evenly in a petri dish and place it at room temperature for 7 hours to evaporate the organic solvent.

[0045] Finally transferred to a 100 ℃ oven, after low temperature thermosetting for 24 hours, the product was refluxed in a 48wt% sulfuric acid solution at 95 ℃ for 48 hours to remove the surfactant.

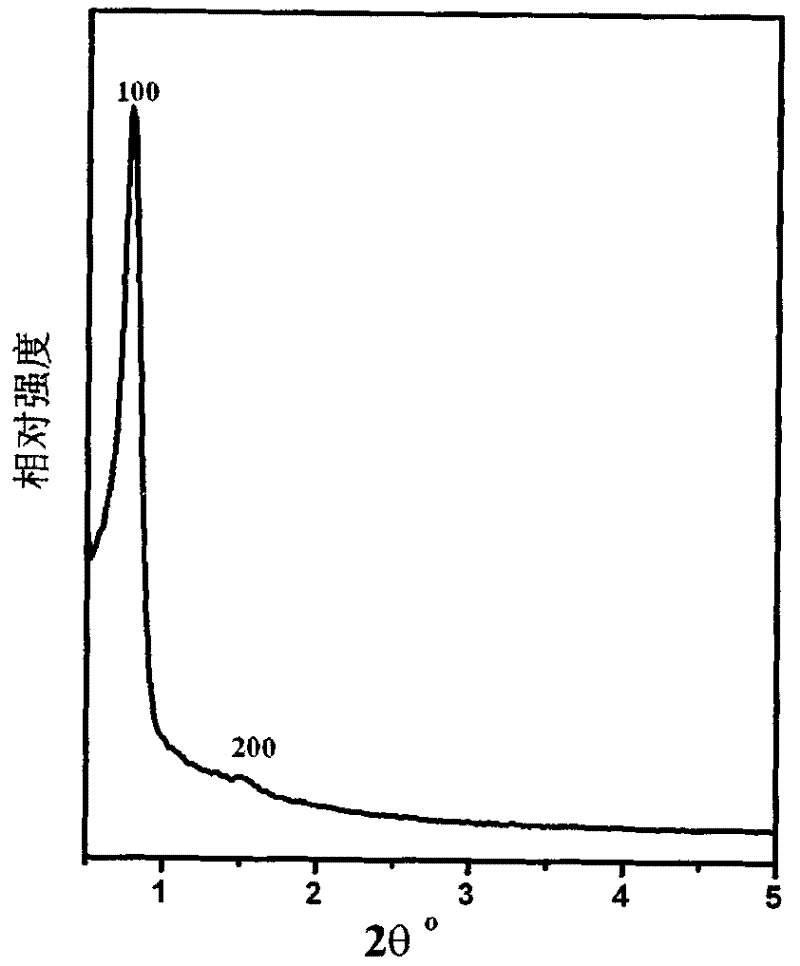

[0046] The obtained material has a two-dimensional hexagonal mesoscopic structure (space group p6mm), the pore diameter is 5.8nm, and the pore volume is 0.3cm 3 / g, the specific surf...

Embodiment 3

[0048] At 40°C, dissolve 2.0 g of F127 (0.16 mmol) in 10.00 g of absolute ethanol and stir for 1 hour to obtain solution A; 0.654 g of organosilicon source 3-mercaptopropyltrimethoxysilane (3.3 mmol) and 1.396 g of inorganic silicon source TEOS (6.7 mmol) was hydrolyzed under 1.0 g (0.2 mol / L) hydrochloric acid for 30 minutes to obtain solution B.

[0049] Mix the two solutions, add 1 g of soluble resole (2.5 mmol), and stir and react at 40°C for 2 hours. Then spread the mixture evenly in a petri dish and place it at room temperature for 7 hours to evaporate the organic solvent.

[0050] Finally, it is transferred to an oven at 100°C, and after low-temperature thermosetting for 24 hours, the product is refluxed in a 48wt% sulfuric acid solution at 85°C for 48 hours to remove the surfactant.

[0051] The obtained material has a two-dimensional hexagonal mesoscopic structure (space group p6mm), the pore diameter is 4nm, and the pore volume is 0.18cm 3 / g, the specific surface area is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com