Nano zinc oxide-doped powder and preparation method thereof

A technology of nano zinc oxide powder and zinc oxide, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., can solve the problem of affecting the uniformity of zinc oxide-based conductive materials, reducing the purity of zinc oxide-based conductive materials, zinc oxide Problems such as particle growth and agglomeration, to achieve excellent light stability and transparency, small zinc ion dissolution, and reduce the effect of particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

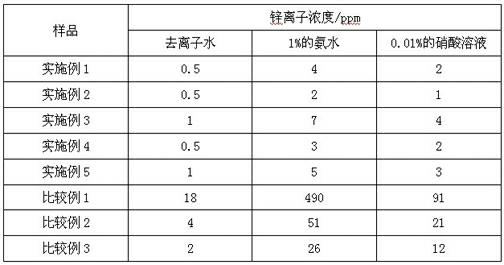

Examples

Embodiment 1

[0022] Embodiment 1: the ZnSO of 28.76g 4 ·7H 2 0 and 6.66g of Al 2 (SO4) 3 18H 2 0 was added to deionized water to form a mixed salt solution with a total concentration of 1.0 mol / L. Control the temperature of the mixed salt solution at 50°C, add 1.5 mol / liter of ammonium bicarbonate solution to the mixed salt solution while stirring, when the pH value of the system reaches 3.8, suspend adding the ammonium bicarbonate solution, and add it to the coprecipitated product Add 24 ml of 0.5 mol / L sodium silicate aqueous solution. After adding the sodium silicate aqueous solution, continue to add 1.5 mol / L ammonium bicarbonate solution to adjust the pH of the system to 7.5, raise the temperature to 75°C, and stir for 2 hours. Filter the obtained co-precipitation product, wash repeatedly with deionized water to remove soluble salts, when the conductivity of the filtrate is 200 μS / cm, end the washing, dry to obtain a white product, calcinate the white product at 800°C for 2 hours,...

Embodiment 2

[0023] Embodiment 2: the ZnSO of 28.76g 4 ·7H 2 0 and 1.998g of Al 2 (SO4) 3 18H 2 0 was added to deionized water to form a mixed salt solution with a total concentration of 0.2 mol / L. Control the temperature of the mixed salt solution at 30°C, add 3 mol / liter of ammonium carbonate solution to the mixed salt solution while stirring, when the pH value of the system reaches 3.5, suspend adding the ammonium carbonate solution, and add 1.0 18 ml of mol / L potassium silicate aqueous solution. After adding the potassium silicate aqueous solution, continue to add 3.0 mol / L ammonium carbonate solution to adjust the pH value of the system to 7.0, raise the temperature to 90°C, and stir and mature for 0.5h. Filter the obtained co-precipitation product, wash repeatedly with deionized water to remove soluble salts, when the conductivity of the filtrate is 260 μS / cm, end the washing, dry to obtain a white product, calcinate the white product at 700°C for 5 hours, and grind it to obtain ...

Embodiment 3

[0024] Embodiment 3: the Zn of 29.75g (NO 3 ) 2 ·6H 2 O and 6.75g Al (NO 3 ) 3 9H 2 0 was added to deionized water to form a mixed salt solution with a total concentration of 2.0 mol / L. Control the temperature of the mixed salt solution at 60°C, add 0.2 mol / liter of sodium carbonate solution to the mixed salt solution while stirring, when the pH value of the system reaches 4.0, suspend adding the sodium carbonate solution, and add 0.1 mol / liter of sodium carbonate solution to the coprecipitated product 30 ml of mol / L sodium silicate aqueous solution. After adding the sodium silicate aqueous solution, continue to add 0.2 mol / L sodium carbonate solution to adjust the pH of the system to 8.0, raise the temperature to 70°C, and stir for 4 hours. Filter the obtained co-precipitation product, wash repeatedly with deionized water to remove soluble salts, when the conductivity of the filtrate is 150 μS / cm, end the washing, dry to obtain a white product, calcinate the white produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com