Fertilizer utilization method for rotten vegetable leaves

A technology of tail vegetables and fertilizer, which is applied in the field of fertilization and utilization of tail vegetables, can solve the problems of non-standard retting technology, poor retting effect, high labor cost, etc., and achieve the effects of improving treatment utilization efficiency, reducing non-point source pollution, and avoiding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

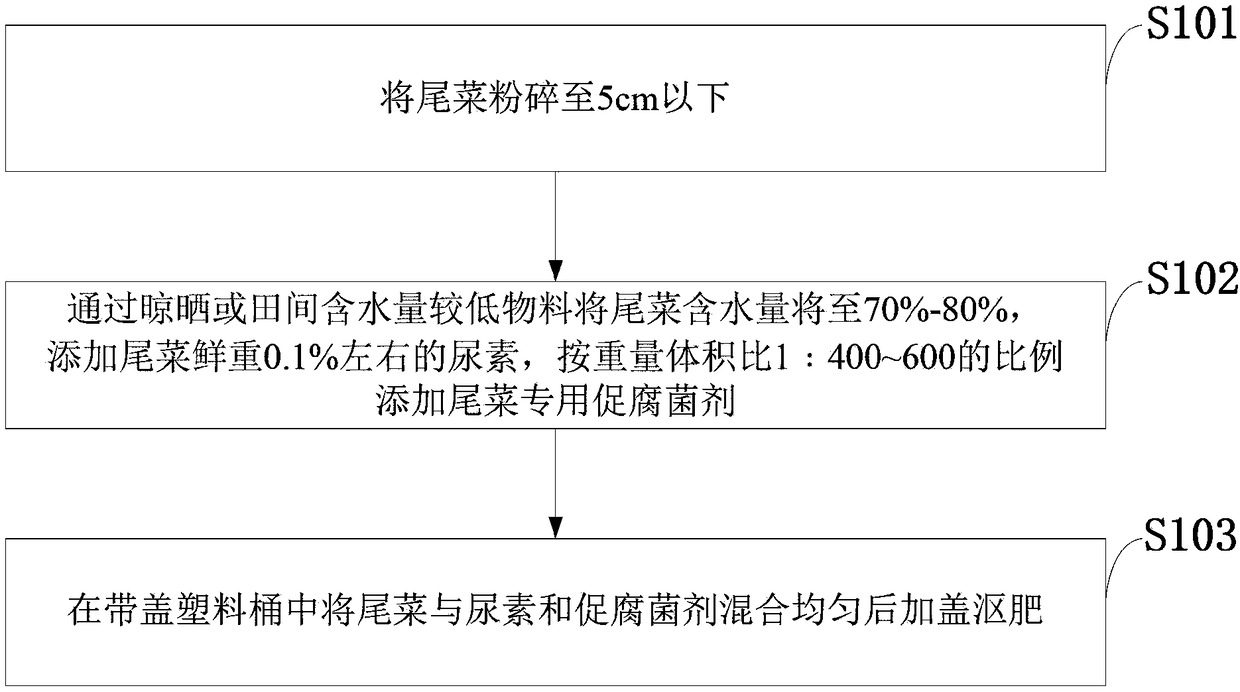

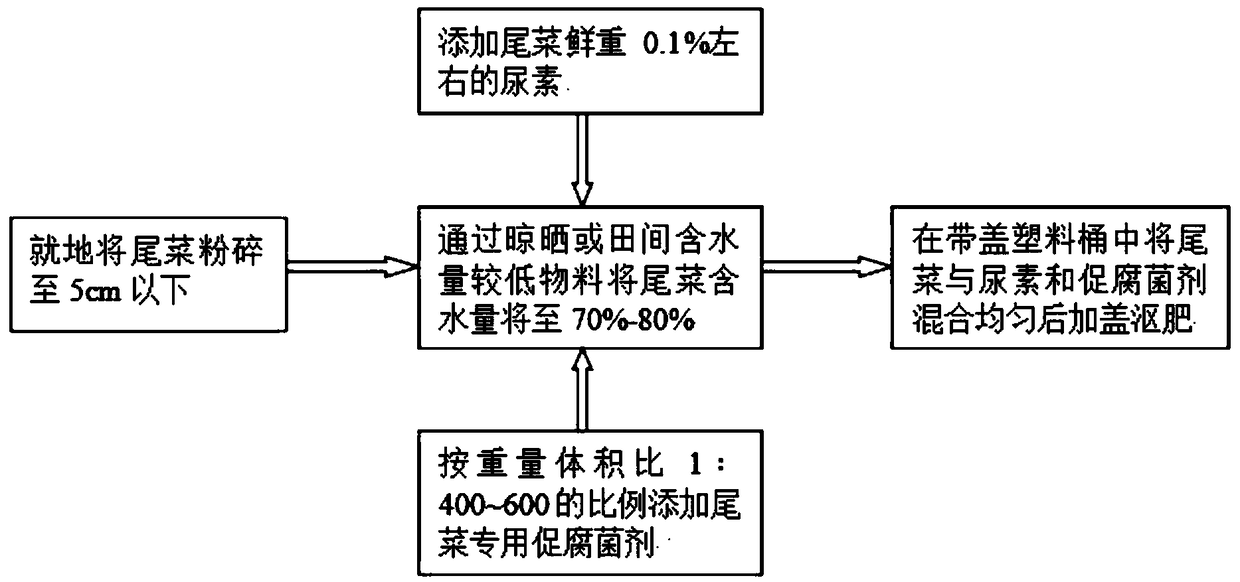

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: after vegetables such as eggplant, tomato, capsicum are harvested, the rhizome with the higher degree of fibrosis is pulverized to below 5cm with a movable small pulverizer, and the tail vegetables after pulverization and the waste fruit of eggplant, tender branches and leaves etc. are flatly aired , until the tail dish can be squeezed with both hands to form a ball and slowly rebound, but the extent of squeezing the fingers will not drip. At this time, the water content of the tail dish is about 70-80%. Put the tail dish into a covered In plastic barrels, add a special rot-promoting agent for tail vegetables at a ratio of 1:400 by weight to volume, and add urea of about 0.1% of the fresh weight of the processed tail vegetables at the same time; add a cover for retting, and release the exhaust gas in the barrel from time to time until the smell of retting Disappeared, no obvious plant residues were visible, and the retting was successful.

Embodiment 2

[0035]Example 2: After the cauliflower is harvested, dig out the stumps with high degree of fibrosis in the field, crush them to below 5cm with a movable small-sized pulverizer, spread the crushed tail vegetables in the air, until the tail vegetables can be squeezed with both hands to form The balls will rebound slowly, but squeeze the fingers hard enough that water will not drip. At this time, the water content of the tail vegetables is about 70-80%. Put the tail vegetables into a plastic bucket with a lid, and the ratio of weight to volume is 1:600 At the same time, add about 0.1% urea of the fresh weight of the processed tail vegetables; add a cover for retting, release the waste gas in the barrel from time to time during the period, until the smell of retting disappears, no obvious plant residues can be seen, and retting success.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com