High-temperature pyrolysis and oxygen-rich incineration treatment process and system for medical waste

A high-temperature pyrolysis technology for medical waste, which is applied in the field of high-temperature pyrolysis to treat medical waste, can solve problems such as inability to treat medical solid waste on site, excessive storage time of medical waste, and omissions in the collection, storage and transportation process, and achieve The effect of improving the enthusiasm of the hospital, reducing the cost of purchasing and storage, and reducing the temperature of the flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

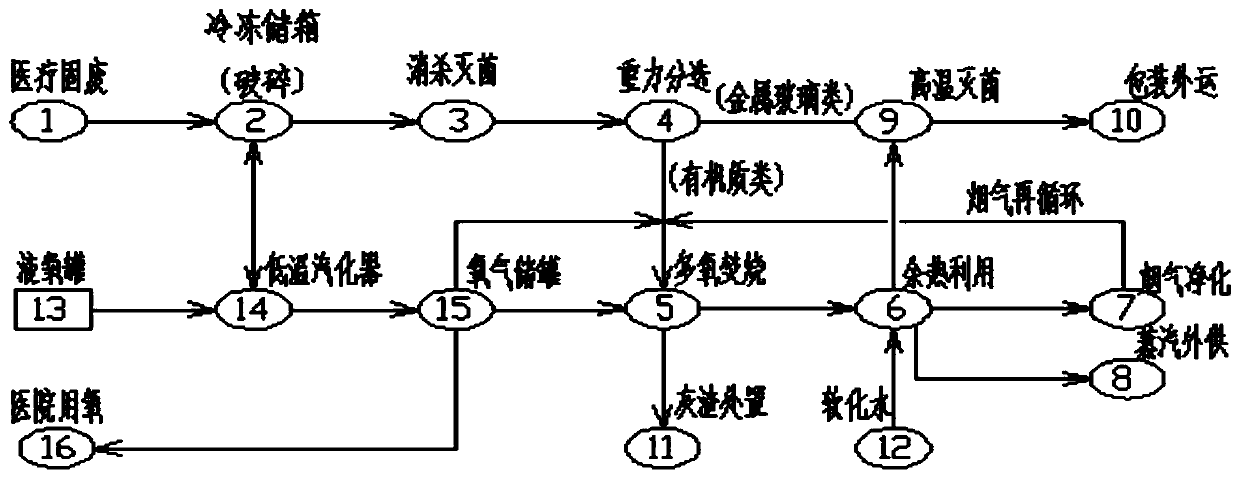

[0049] According to the above process, this embodiment provides a high-temperature pyrolysis polyoxygen incineration treatment system for medical waste. This system utilizes the residual energy of liquid oxygen refrigeration commonly used in hospitals to make the medical waste storage tank into a storage tank with a freezing function (-10°C The following), on the one hand, reduces the activity of germs, on the other hand, the collection is timely, does not involve transportation and storage, and reduces costs; through the design of a crushing mechanism at the lower part of the garbage storage box, the frozen medical waste is crushed and sterilized with ozone; Automatic screening, to separate a very small amount of metal, glass and other sundries among them, and then discharge the system after further high-temperature steam sterilization, and then dispose of it separately; the medical waste that has been crushed and sterilized by ozone is airtightly transported to the anti-burnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com