A multi-directional nozzle assembly vehicle

An assembly car, multi-directional technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of nozzle transfer position, different assembly cars, single function, etc., to achieve good economy, convenient assembly, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

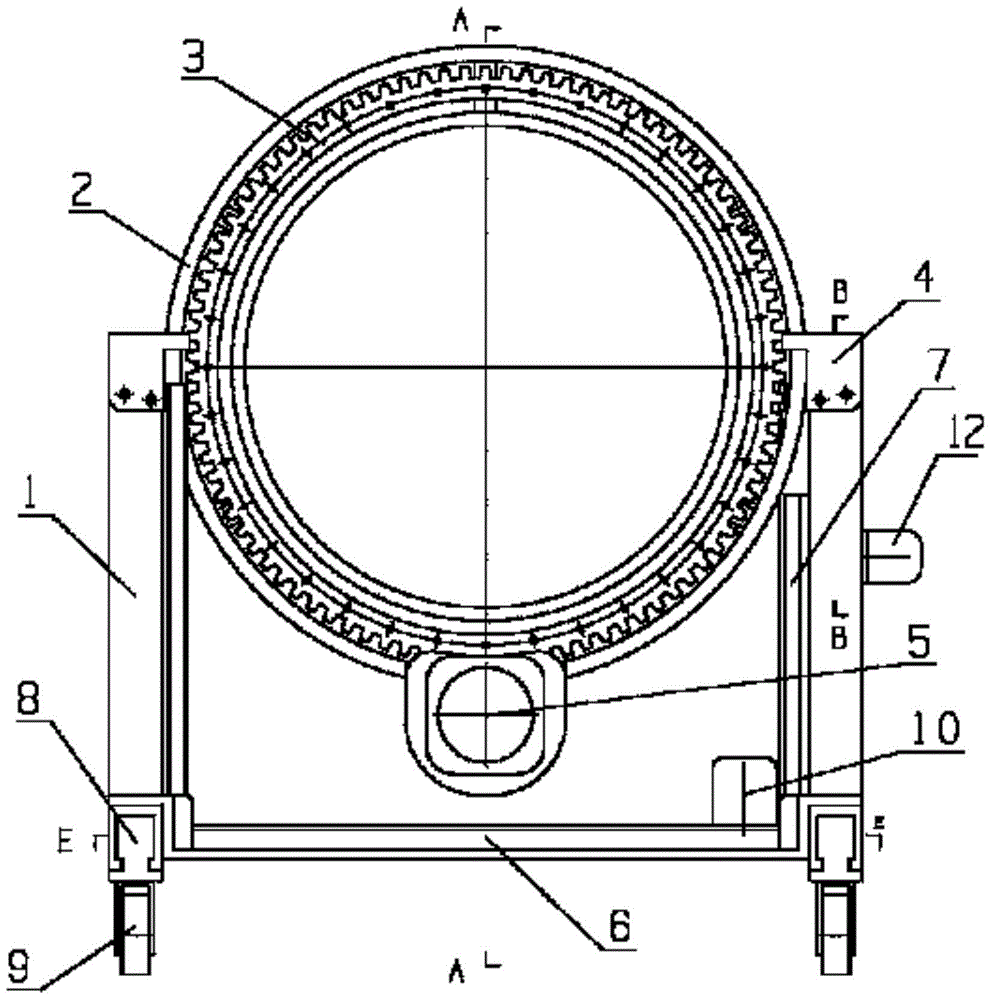

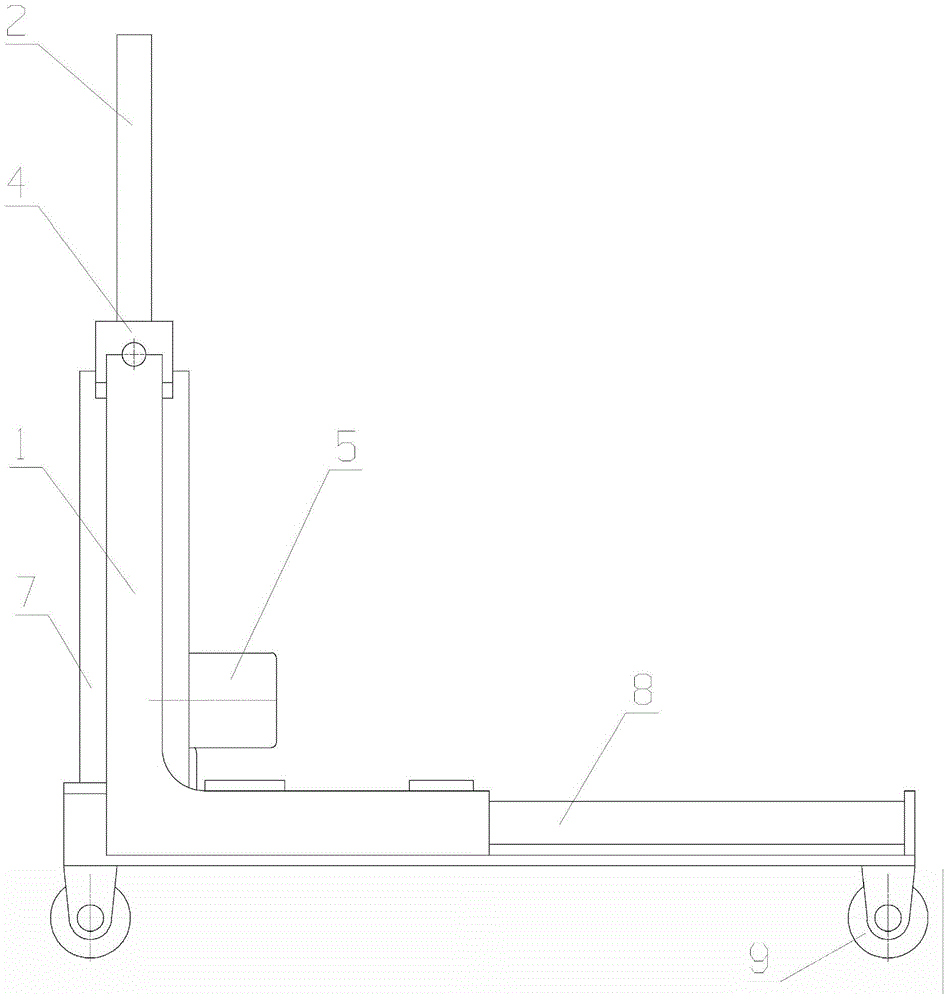

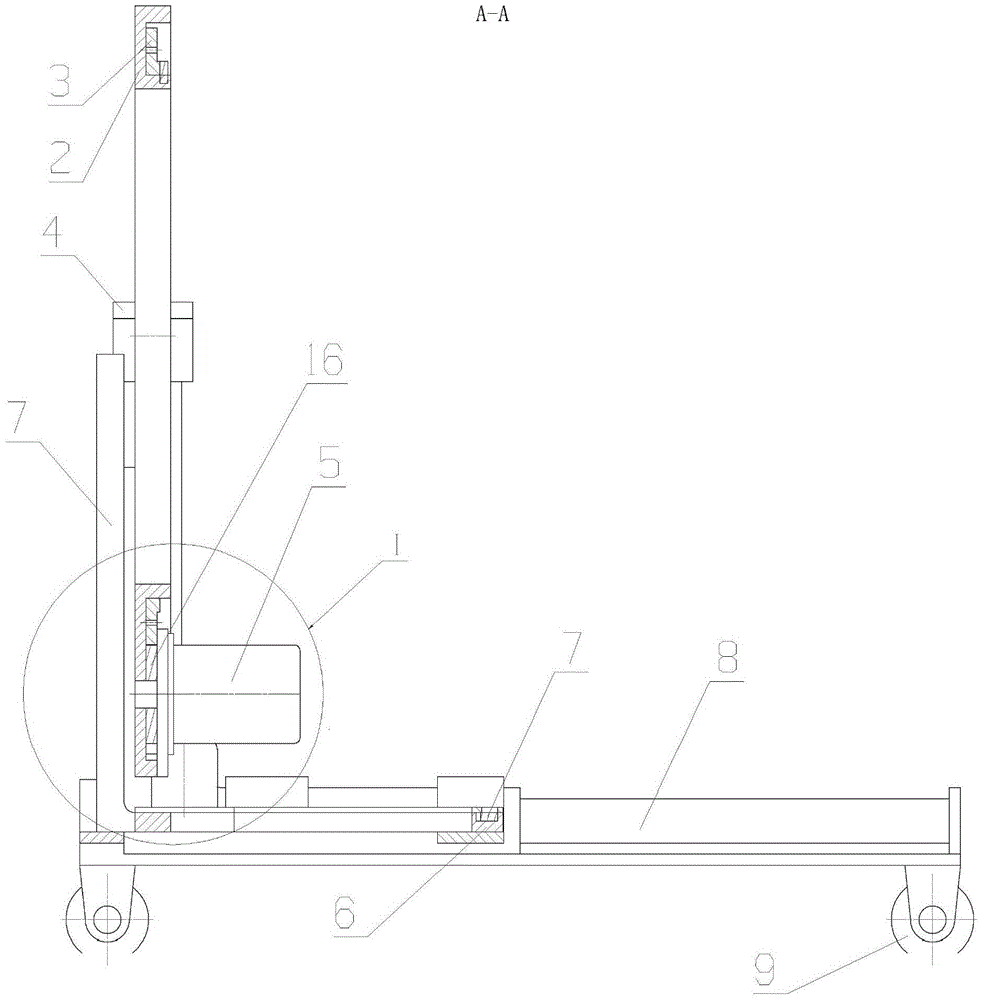

[0029] This embodiment provides a multi-directional nozzle assembly vehicle, which is characterized in that it includes a support base 1, an auxiliary support structure, a multi-directional rotation adjustable mechanism and a limit fixing member, which are specifically:

[0030] The supporting seat 1 is used as the main support bearing member, located on both sides of the whole mechanism, and used to support the whole mechanism;

[0031] The auxiliary support mechanism includes a support box 6 and a support rod 7, wherein the support box 6 is fixed on the support base 1. It is a box-shaped structure with a circular slide groove for supporting the support rod 7 and enables the support rod 7 to be supported along the The circular chute of the box 6 slides; the support rod 7 is a strip structure with vertical ends and a semi-circular ring in the middle, which is mainly used for supporting the assembly vehicle in the vertical state;

[0032] The multi-directional rotating adjustable mech...

Embodiment 2

[0043] This embodiment provides a multi-directional nozzle assembly vehicle, which is characterized in that it includes a support base 1, an auxiliary support structure, a multi-directional rotation adjustable mechanism and a limit fixing member, specifically:

[0044] The supporting seat 1 is used as the main support bearing member and is located on both sides of the whole mechanism to support the whole mechanism;

[0045] The auxiliary support mechanism includes a support box 6 and a support rod 7, wherein the support box 6 is fixed on the support base 1. It is a box-shaped structure with a circular slide groove for supporting the support rod 7 and enables the support rod 7 to be supported along the The circular chute of the box 6 slides; the support rod 7 is a strip structure with vertical ends and a semi-circular ring in the middle, which is mainly used for supporting the assembly vehicle in the vertical state;

[0046] The multi-directional rotating adjustable mechanism mainly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com