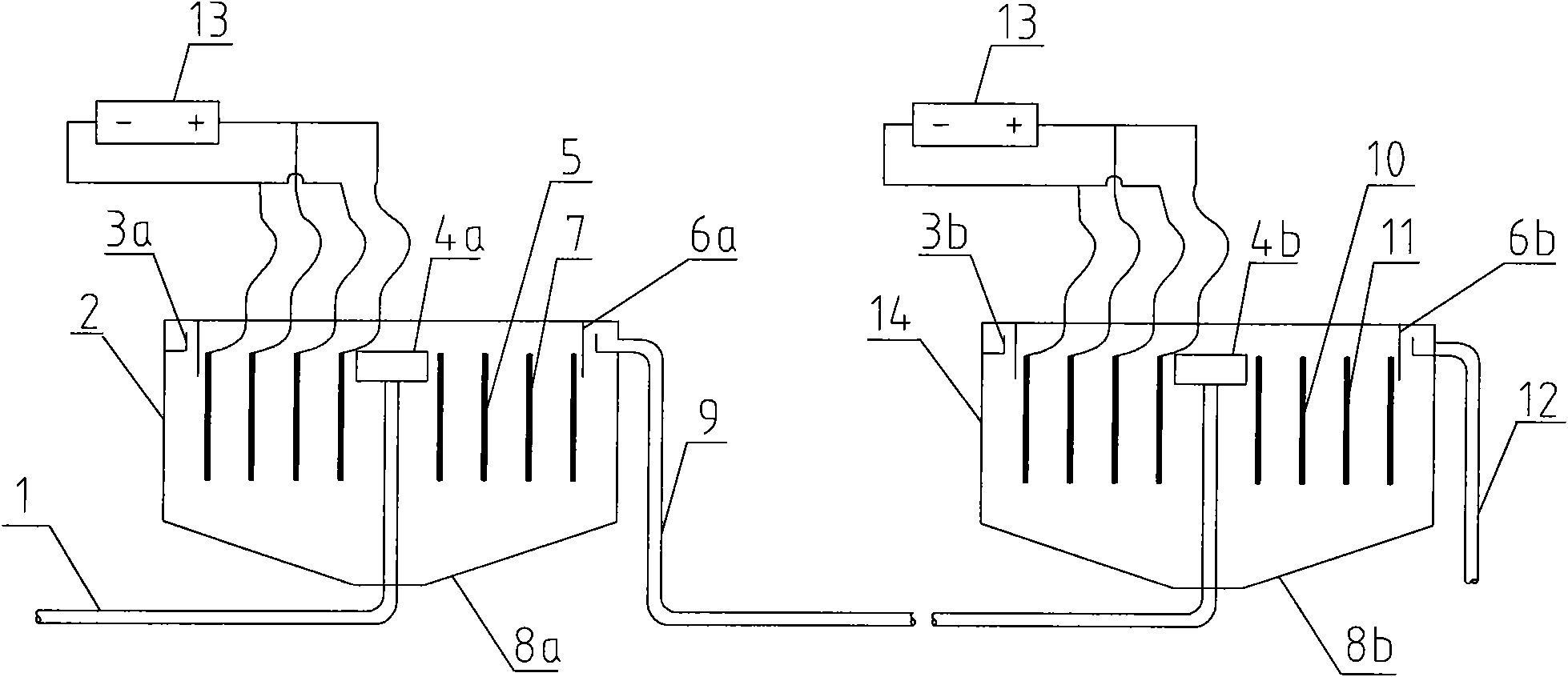

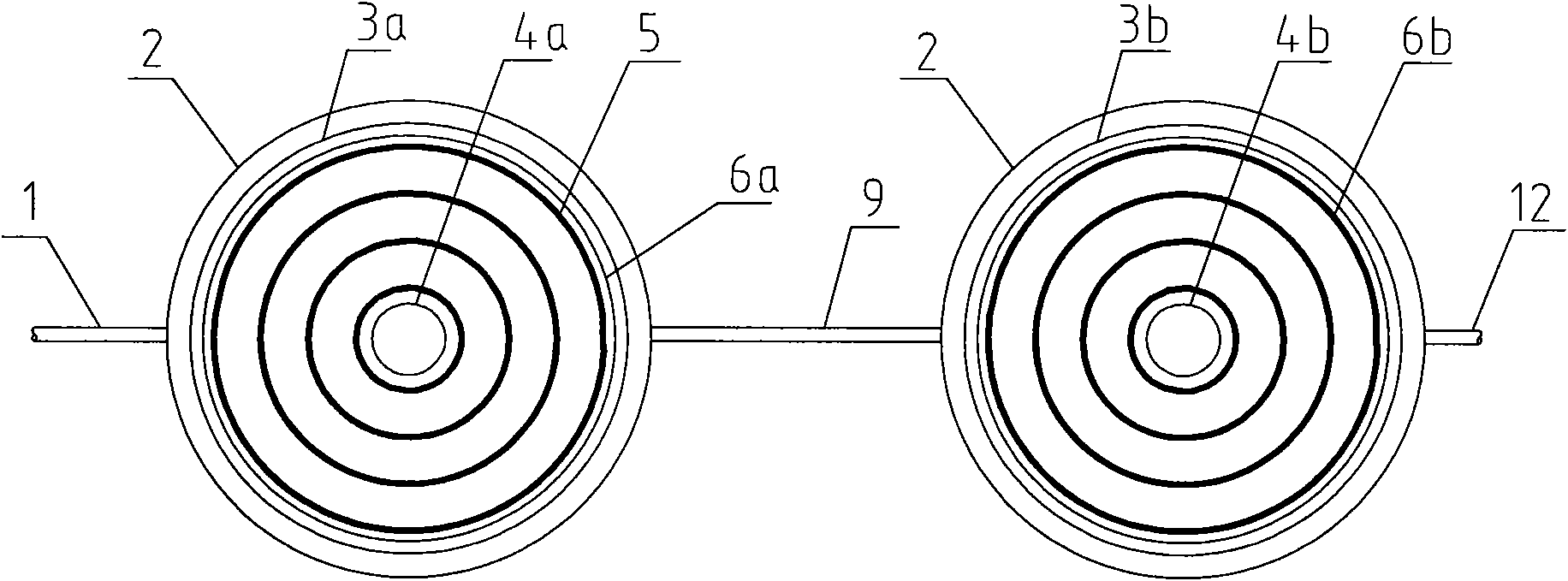

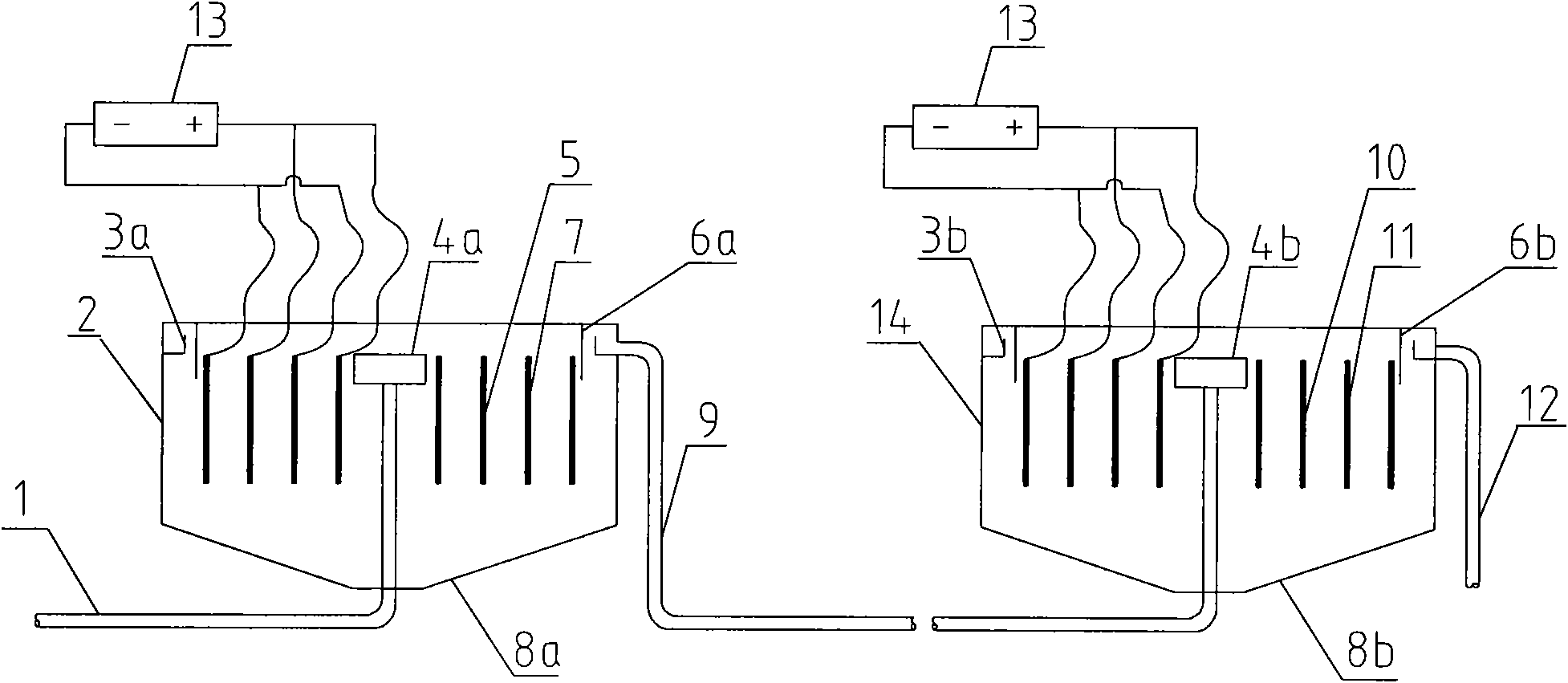

Method for processing effluent by two-stage electrolysis and device thereof

An electrolysis, two-stage technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems that cannot be solved and affect water flow, and achieve small-scale treatment and high-response The effect of mild conditions and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Treat the waste water containing ammonia nitrogen with the method and device of the present invention, the concentration of ammonia nitrogen in the waste water raw water is 480mg / L, the electric current of the first electrolyzer 2 is set to 4.5A, the electrolytic treatment time is 10min, and the removal rate of ammonia nitrogen is 23%.

Embodiment 2

[0037] The electrolytic treatment time in Example 1 was extended to 20 minutes, and other conditions remained unchanged, and the removal rate of ammonia nitrogen reached 35%.

Embodiment 3

[0039] The electrolytic treatment time in Example 1 was extended to 30min, and other conditions remained unchanged, and the removal rate of ammonia nitrogen reached 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com