Integrated sewage treatment technology and system for tin-removing wastewater

A tin stripping wastewater and treatment system technology, applied in water/sewage treatment, light water/sewage treatment, neutralized water/sewage treatment, etc., can solve water resources and ecological environment pollution, hazardous waste leakage, treatment difficulties, etc. problems, to achieve the effect of strong sewage treatment capacity, small footprint and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] [Example 1] Comparison and analysis of technical solutions

[0050] By analyzing the tin stripping waste liquid aimed at by the present invention, the raw water quality has the following characteristics:

[0051] 1) The pH of raw water is low, and the types of heavy metals are complex;

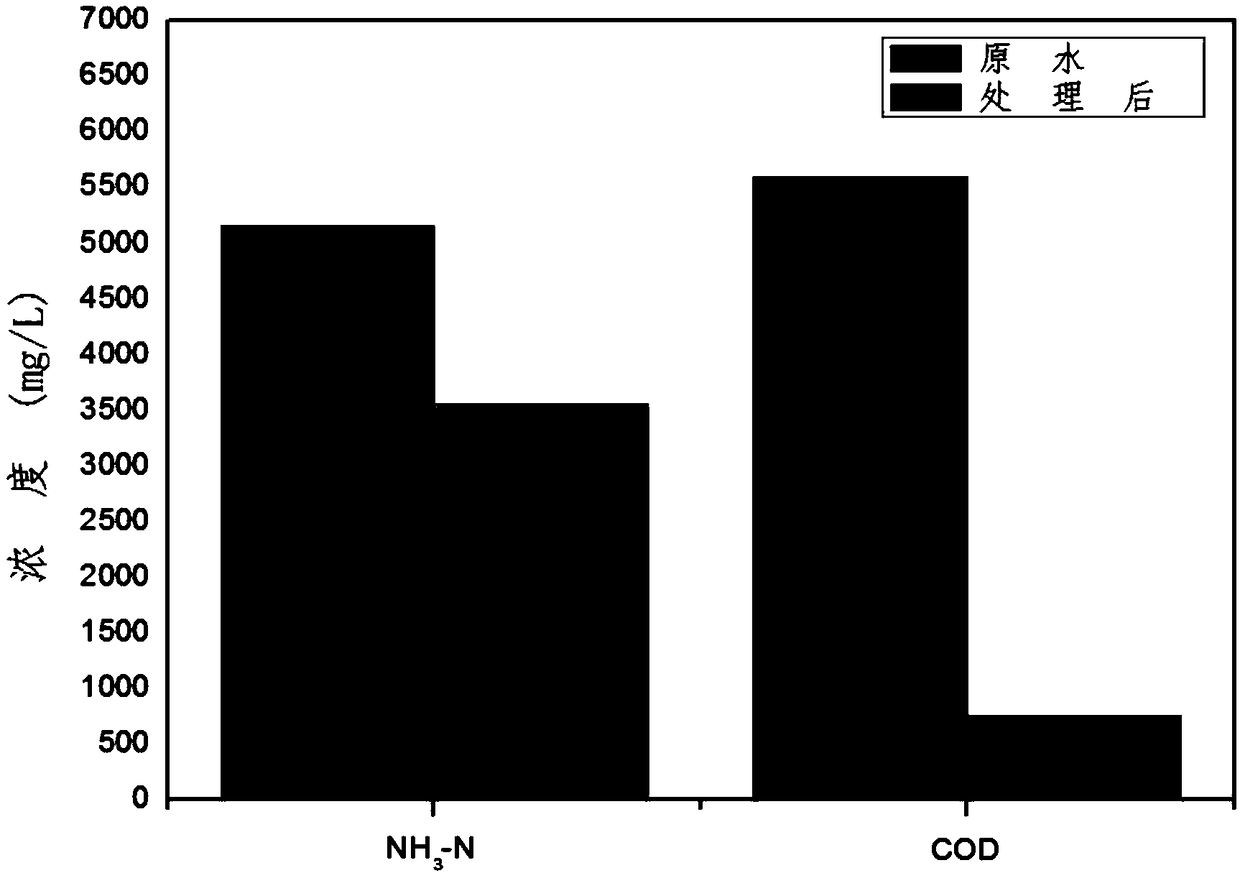

[0052] 2) High content of COD and ammonia nitrogen;

[0053] 3) The tin content in the waste water is high, and the solubility product of tin is small, and the pH corresponding to the precipitation is low;

[0054] 4) The types of organic matter in wastewater are complex, mostly surfactants, complexing agents, etc., with poor biochemical properties.

[0055] The present invention formulates following scheme on the basis of analyzing raw water quality:

[0056] 1. Recovery of metal tin by neutralization precipitation method

[0057] The initial pH of the wastewater is -0.51, and the tin in the solution is mainly Sn 2+ form, a small amount is Sn 4+ ; Iron is mainly Fe 2 + form, a ...

Embodiment 2

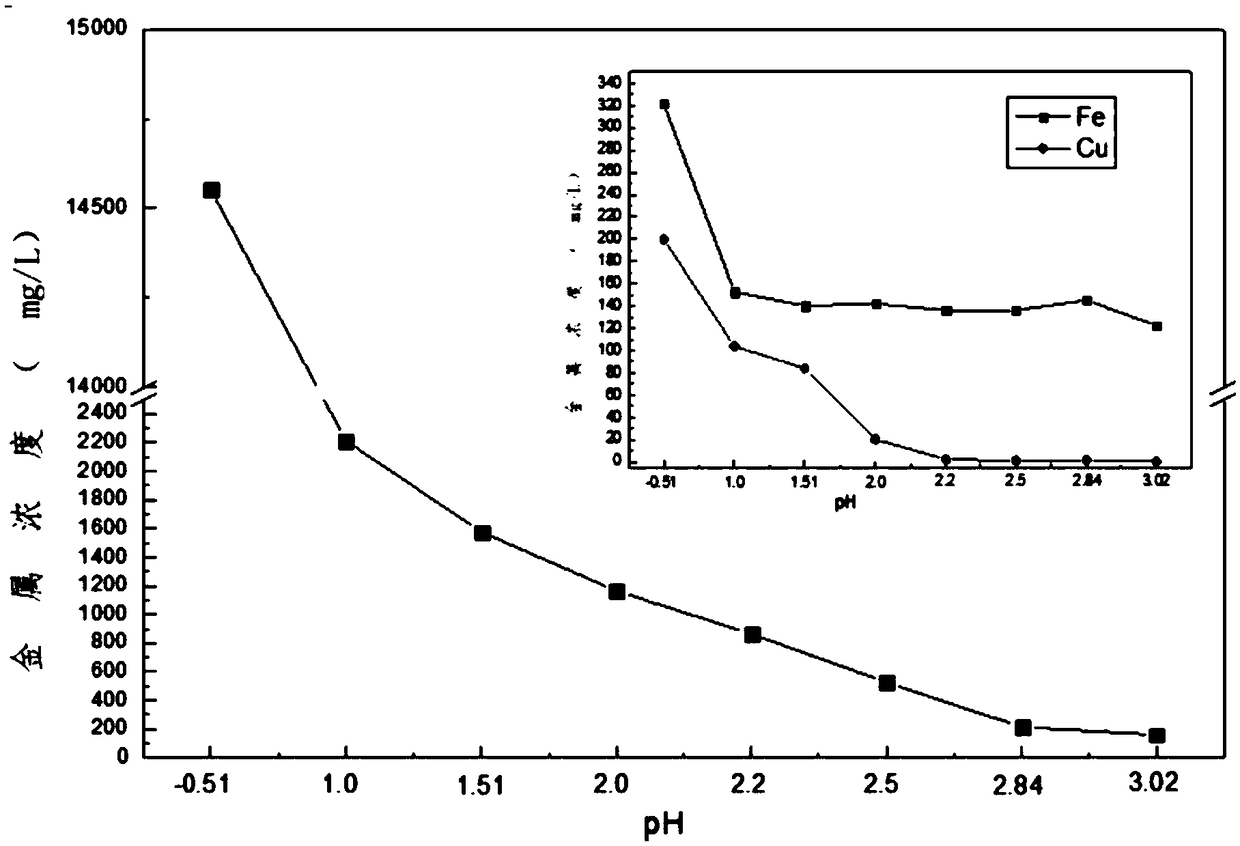

[0084] [Example 2] Small-scale experimental demonstration of the technical scheme

[0085] In the process of tin stripping wastewater treatment, in the first step of neutralizing the precipitated metal step, Sn 2+ and Sn 4+ It can completely precipitate between pH 2-3, and the experimental design adjusts pH=1-3 to measure the remaining content of metal elements in the supernatant after precipitation. Such as figure 1 As shown, the experimental results show that as the pH increases, the tin content in the supernatant presents a gradual downward trend. At the same time, copper and iron elements in the supernatant also form precipitates and are removed as the pH increases. When the pH reaches 2.2 When pH = 3.02, the content of copper in the supernatant decreased to below 3 mg / L, and decreased to 0.445 mg / L when pH = 3.02. When the pH=1.0, the remaining iron content in the supernatant is 152.58mg / L, and then the iron content tends to be stable as the pH increases, and the preci...

Embodiment 3

[0090] [Example 3] process design

[0091] 1. Integrated tin metal recovery and UV synergistic oxidation treatment station

[0092] The process flow of the integrated sewage treatment system for stripping tin wastewater of the present invention is as follows: Figure 6 As shown, the layout of the integrated tin metal recovery and UV synergistic oxidation treatment station is shown in Figure 7 As shown, the treated water volume: 7m 3 / d.

[0093] Raw water (wastewater to be treated) 1 enters the first adjustment tank 10, after adjusting the pH precipitation reaction, enters the first sedimentation tank 20 for filtration, and the precipitated tin sludge 2 is recovered through the bottom discharge port 21; the filtered supernatant is transported To the UV / Fenton reaction tank 30 for oxidation treatment, and then the wastewater after the oxidation treatment is transported to the second regulating tank 40 through the circulation pump 31;

[0094] The UV / Fenton reaction tank 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com