Gel ball type rubidium/caesium ion adsorbent, and preparation method and application thereof

A cesium ion and gel ball technology, applied in the field of selective separation of inorganic metal ions, can solve the problems of lack, lack of extraction and utilization of rubidium and cesium resources, etc., and achieves low production cost, good thermal stability and mechanical strength, adsorption High volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The gel spherical rubidium and cesium ion adsorbents directly separated from calcium chloride or strontium chloride solutions generally contain calcium, strontium, and other impurity ions, which may affect the adsorption performance of the adsorbent on rubidium and cesium ions or Adsorption capacity, therefore, the preparation method of the present invention may also include the step of washing the gel spherical rubidium and cesium ion adsorbent with water to remove impurity ions. Specifically, the gel balls can be washed directly with pure water.

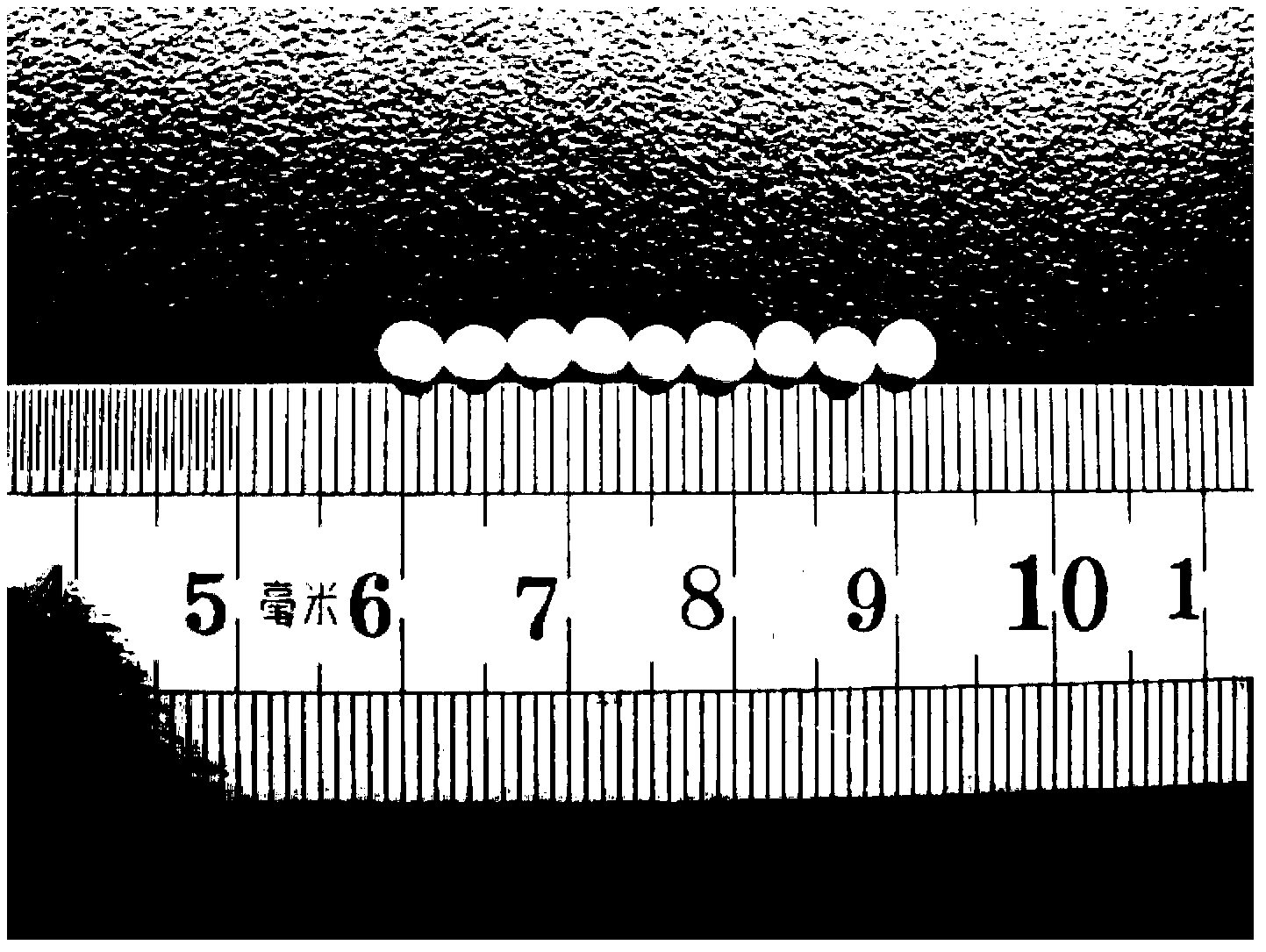

[0029] The gel spherical rubidium and cesium ion adsorbent prepared by the method of the present invention can generally have a particle diameter of 2-4mm. It should be understood that the smaller the particles, the more fully the contact between the gel ball and the adsorbed solute ions, and the greater the adsorption capacity, but if the particles are too small, it may be difficult to prepare due to the influence of the vi...

Embodiment 1

[0039]Preparation of gel spherical rubidium and cesium ion adsorbents: prepare sodium alginate hydrosol with a mass fraction of 2%; mix sodium alginate hydrosol and potassium tetraphenylborate powder at a mass ratio of 10:1 to form a sol Mixed solution: drop the sol mixed solution into 4% calcium chloride solution, age the gel for 48 hours, obtain gel balls after solid-liquid separation, and wash with distilled water until there is no impurity ion.

[0040] The particle diameter of the gel spherical rubidium and cesium ion adsorbent is 2-4mm.

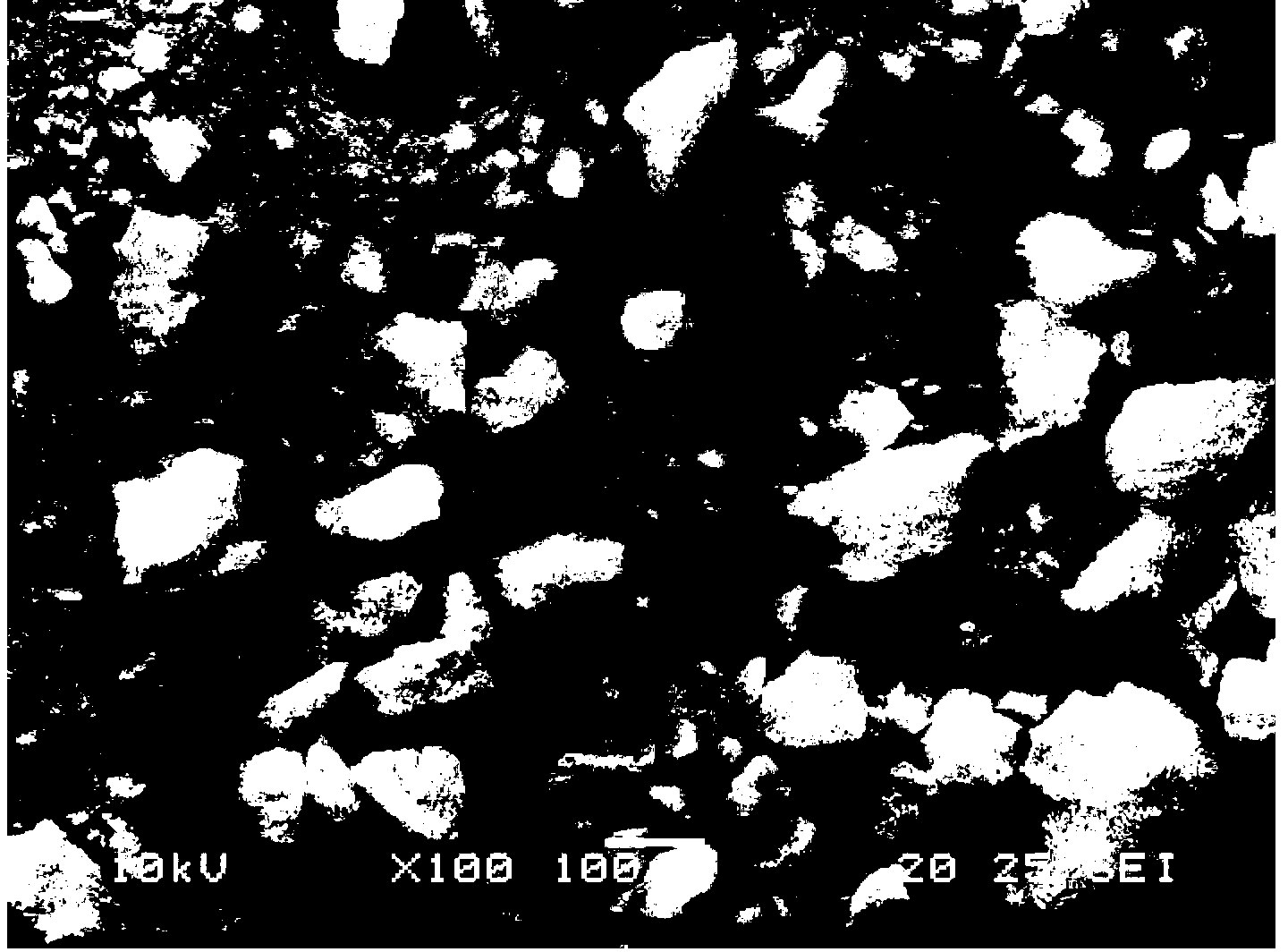

[0041] figure 1 Shown is the SEM image of the gel spherical rubidium and cesium ion adsorbent obtained in this embodiment, as can be seen from the figure, the surface morphology of the obtained gel spherical rubidium and cesium ion adsorbent is uniform, and the potassium tetraphenylborate particles evenly distributed.

Embodiment 2

[0043] Preparation of gel spherical rubidium and cesium ion adsorbents: prepare sodium alginate hydrosol with a mass fraction of 2%; mix sodium alginate hydrosol and potassium tetraphenylborate powder at a mass ratio of 5:1 to form a sol Mixed solution: drop the sol mixed solution into 0.5% calcium chloride solution, age the gel for 48 hours, and separate the solid and liquid to obtain gel balls. Wash the gel beads with distilled water until free of impurity ions.

[0044] The particle diameter of the gel spherical rubidium and cesium ion adsorbent is 2-4mm.

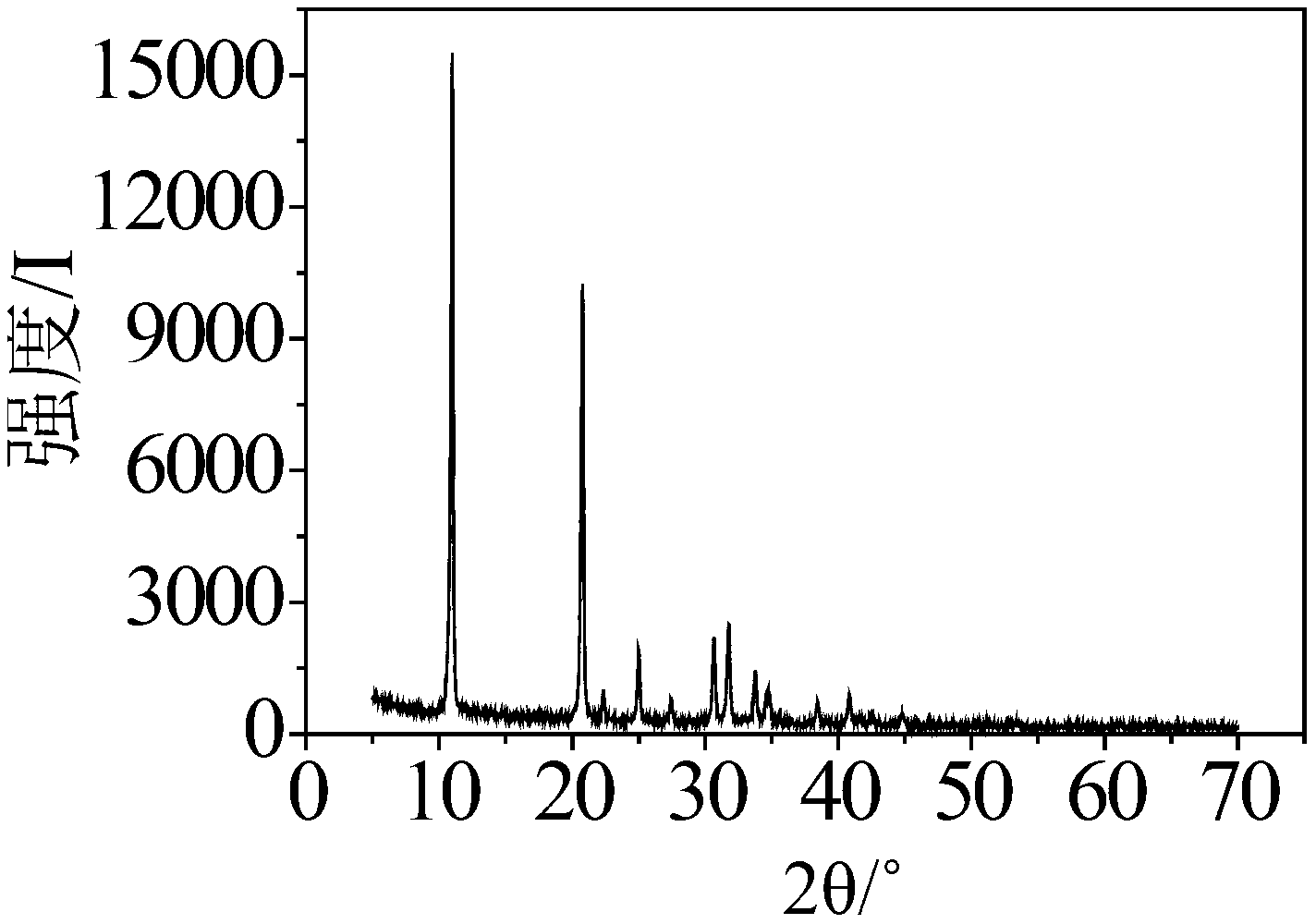

[0045] figure 2 Shown is the XRD pattern of the gel spherical rubidium and cesium ion adsorbent obtained in this embodiment. After the adsorbent gel balls are dried and ground, an XRD experiment is carried out. According to the XRD pattern, it can be confirmed that the adsorbent of the present invention contains potassium tetraphenylborate with relatively high purity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com