Magnetic iron-based composite catalyst and preparation method thereof

A catalyst and composite technology, applied in the field of magnetic iron-based composite catalyst advanced oxidation technology to treat printing and dyeing wastewater, can solve the problems of low iron leaching rate, difficulty, non-recyclable catalyst, etc., and achieve high surface activity, simple method, and reduced The effect of the possibility of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

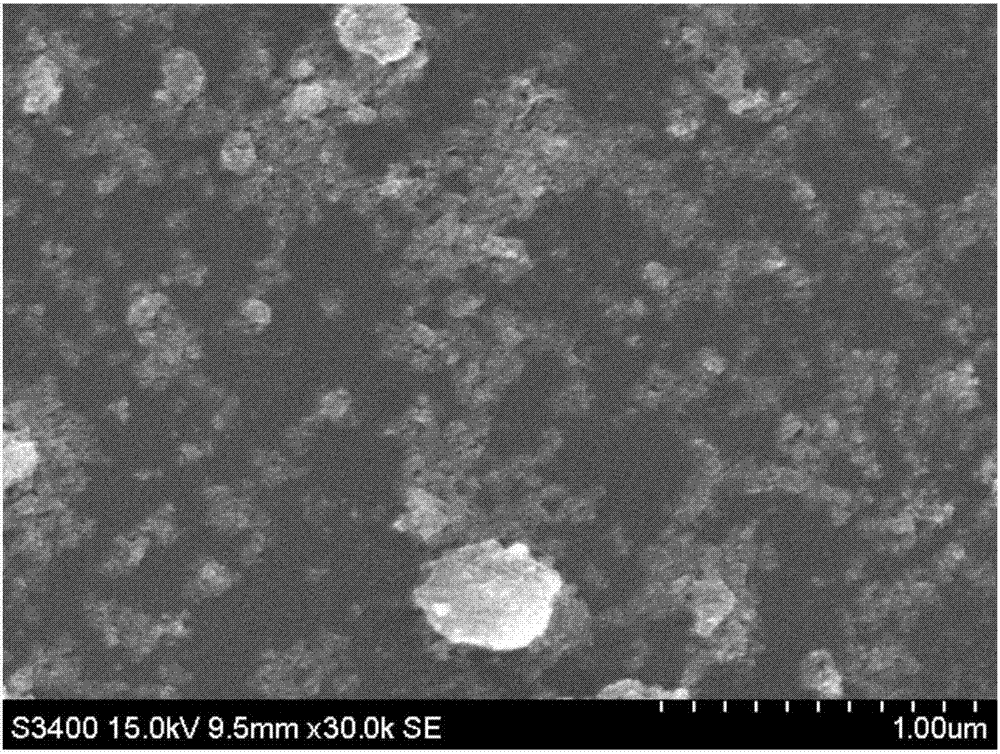

[0033] Embodiment 1: Magnetic iron-based Fe 3 o 4 / MnO 2 Preparation of composite catalyst

[0034] (1) 2.224g FeSO 4 ·7H 2 O and 1.0 g of polyethylene glycol 4000 were dissolved in 100 mL of deionized water, placed in a three-necked flask and heated to 70 ° C in a water bath, and 100 mL of 0.2 mol / L NaOH solution was added under electric stirring, and the reaction was maintained at 70 ° C for 5 minutes, and then continued Slowly add 12mL 0.2mol / L KMnO with stirring 4 solution, the color of the solution changed from dark green to dark brown at this time, and the reaction was maintained at 70° C. for 2 hours. After the reaction was completed, the solid powder was separated by an external magnetic field, and the obtained solid powder was washed three times with secondary water and ethanol by decantation, and the obtained product was vacuum-dried at 60°C for 12 hours, and finally the product was taken out and ground in a mortar, and weighed Measure the quality of the produc...

Embodiment 2

[0035] Example 2: Magnetic Fe-based Fe 3 o 4 / MnO 2 Preparation of composite catalyst

[0036] (1) 2.780g FeSO 4 ·7H 2 O and 1.0g of polyethylene glycol 4000 were dissolved in 100mL of deionized water, placed in a three-necked flask and heated to 75°C in a water bath, and 120mL of 0.2mol / L NaOH solution was added under electric stirring, and the reaction was maintained at 75°C for 5 minutes, and then continued Slowly add 14mL 0.2mol / L KMnO with stirring 4 solution, the color of the solution changed from dark green to dark brown at this time, and the reaction was maintained at 75° C. for 2 hours. After the reaction was completed, the solid powder was separated by an external magnetic field, and the obtained solid powder was washed three times with secondary water and ethanol by decantation, and the obtained product was vacuum-dried at 60°C for 12 hours, and finally the product was taken out and ground in a mortar, and weighed Measure the quality of the product and put it ...

Embodiment 3

[0037] Embodiment 3: a kind of magnetic iron-based Fe in this embodiment 3 o 4 / MnO 2 The method that composite catalyst activates persulfate treatment printing and dyeing wastewater comprises the following steps:

[0038] A kind of magnetic iron-based Fe prepared with embodiment 1 3 o 4 / MnO 2 Composite catalyst activated persulfate treatment of methylene blue in simulated dye wastewater. Take by weighing a certain amount (0.15g) of the catalyst prepared by embodiment 1, join in the simulated wastewater containing methylene blue, the simulated wastewater pH is 7.5, the volume is 250mL, the methylene blue concentration is 30mg / L, and the catalyst concentration is 0.6g / L, shake After 2 minutes, add a certain amount of potassium hydrogen persulfate (1.25g) to make the concentration of potassium hydrogen persulfate in the solution 5g / L, and place it in a constant temperature water bath oscillator at 25°C for oscillating reaction for 20 minutes. After the reaction, with the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com