Method for coking wastewater degradation and synchronous power generation by taking coking active bacterium as biocatalyst

A biocatalyst and coking wastewater technology, applied in biochemical fuel cells and other directions, can solve the problem of high energy consumption for aeration, and achieve the effects of low treatment efficiency, low investment, and both environmental and ecological benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

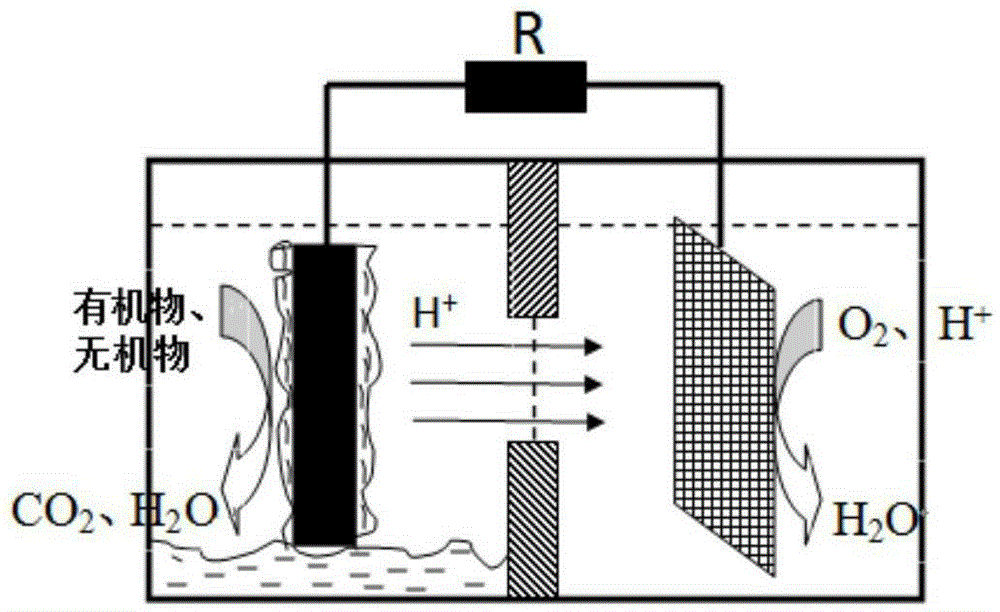

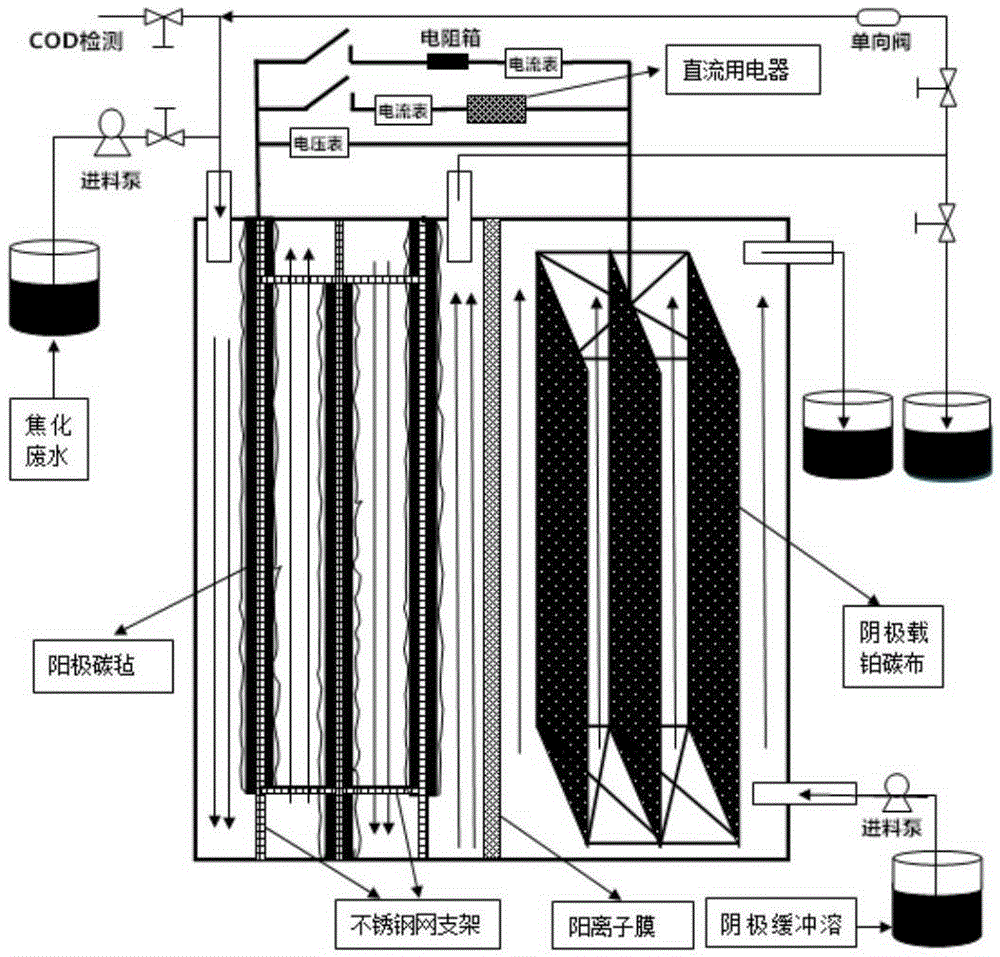

[0067] A method for synchronously generating electricity by using coking active bacteria as a biocatalyst to degrade coking wastewater by microbial fuel cells, the method is carried out according to the following steps.

[0068] 1. Electrochemical domestication of MFC phenol and glucose co-substrate system: Activated sludge was taken from the aerobic pool and anaerobic pool of the wastewater treatment workshop of a coking plant, and a dual-chamber microbial fuel cell device was built. The anode compartment used a phenol and glucose co-substrate system , the cathode chamber is potassium ferricyanide solution, the cathode is 20% platinum-carrying carbon cloth, maintain a constant temperature of 35°C, connect an external constant external resistance of 1000Ω, and measure the external voltage regularly. The battery adopts intermittent operation mode. When the output voltage is less than 0.1V, the anolyte and catholyte are replaced. Initially set the concentration of phenol to 0.2g...

Embodiment 2

[0079] The difference between this embodiment and Example 1 is that nickel-loaded carbon felt is used as the cathode, and other steps are the same as Example 1. In this example, the Coulombic efficiency is 62.1%, the COD removal rate of coking wastewater is 63.5%, and the maximum output power density is 509mW / m 2 .

Embodiment 3

[0081] This embodiment is different from Example 1 in that a graphite brush is used as the cathode, and other steps are the same as in Example 1. In this example, the coulombic efficiency is 49.6%, the COD removal rate of coking wastewater is 52.6%, and the maximum output is 611mW / m 2 .

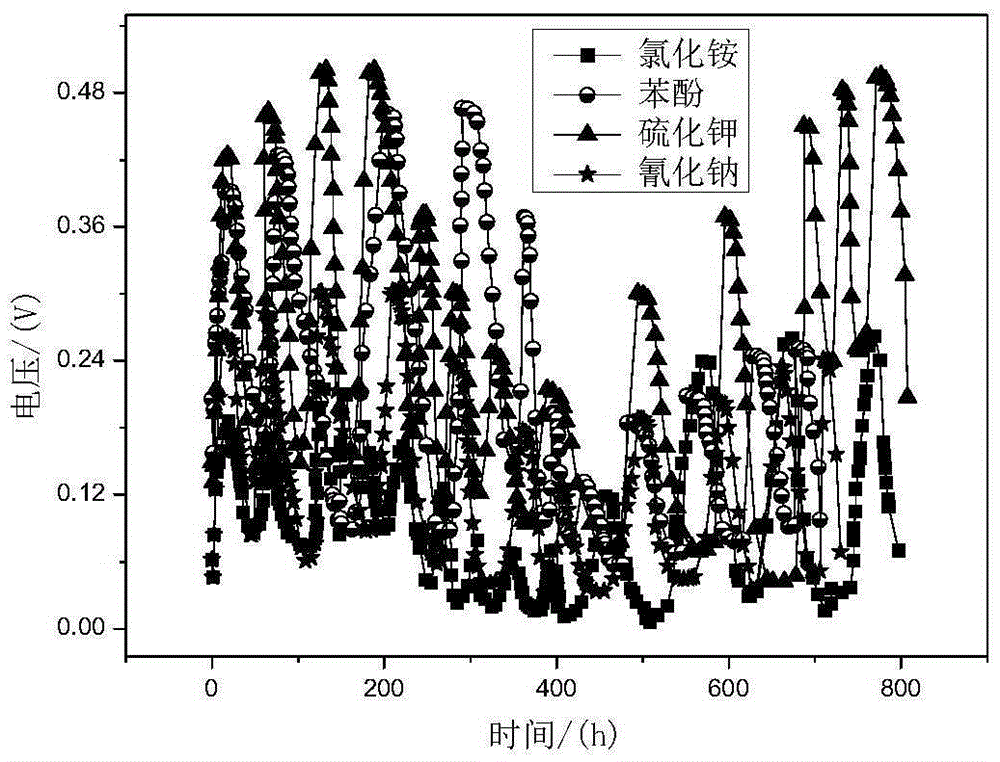

[0082] attached image 3 It is the relationship diagram of the output voltage with the acclimation time during the domestication process of phenol dominant bacteria, ammonia nitrogen dominant bacteria, sulfide dominant bacteria and cyanide dominant bacteria. When the output voltage is constant, it means that the biofilm is mature and the domestication of the strains is completed. The domestication time of phenol dominant bacteria is 705 hours, ammonia nitrogen dominant bacteria is 796 hours, sulfide dominant bacteria is 807 hours, and cyanide dominant bacteria is 729 hours.

[0083] attached Figure 4 The relationship between the output voltage and time during the acclimatization of coking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com