System for treating desulfurization wastewater of coal-fired power plant by magnetic coagulation

A technology for desulfurization wastewater and coal-fired power plants, which is applied in the fields of magnetic field/electric field water/sewage treatment, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc. Prospects, high sludge moisture content, to achieve the effect of improving practical applicability, improving particle settling characteristics, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means realized by the present invention, creative features, goals and effects easy to be understood, the present invention will be further elaborated below in conjunction with specific embodiments.

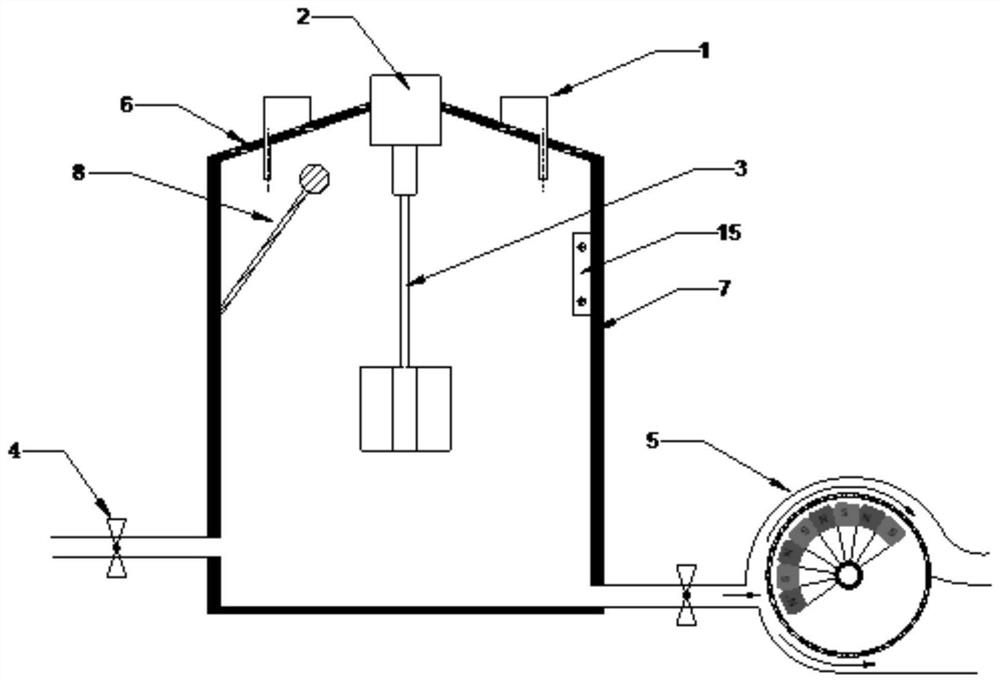

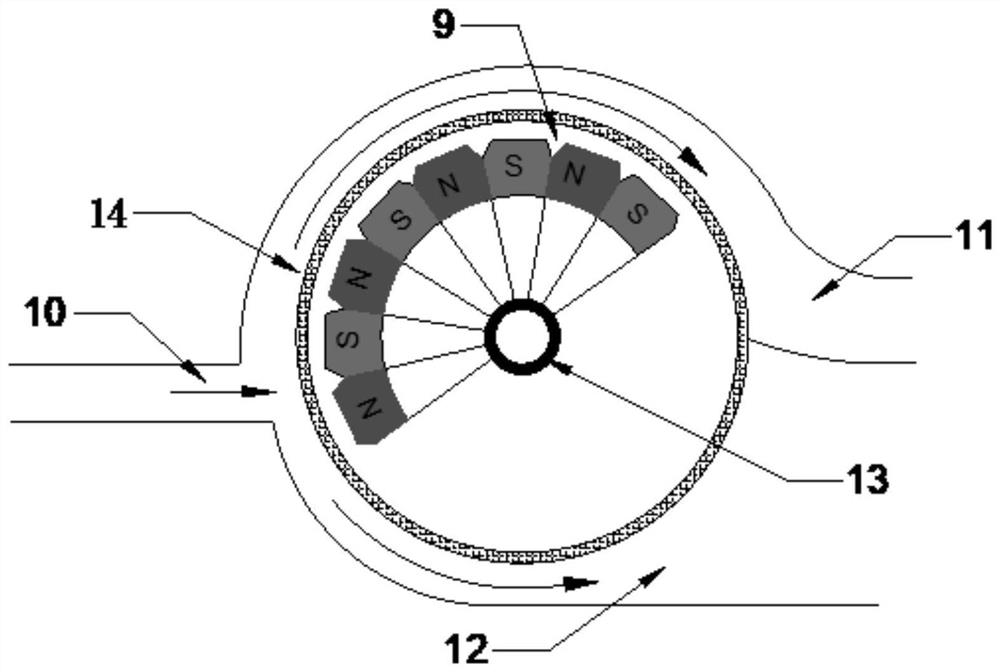

[0030] The technical solution adopted by the present invention to solve the technical problems is: a system for magnetic coagulation treatment of coal-fired power plant desulfurization wastewater, selects a coal-fired power plant containing high suspended matter desulfurization wastewater to process, and the specific steps are as follows:

[0031] The desulfurization waste water is transported to the reactor through the pipeline, and the tertiary reaction is carried out in the reactor.

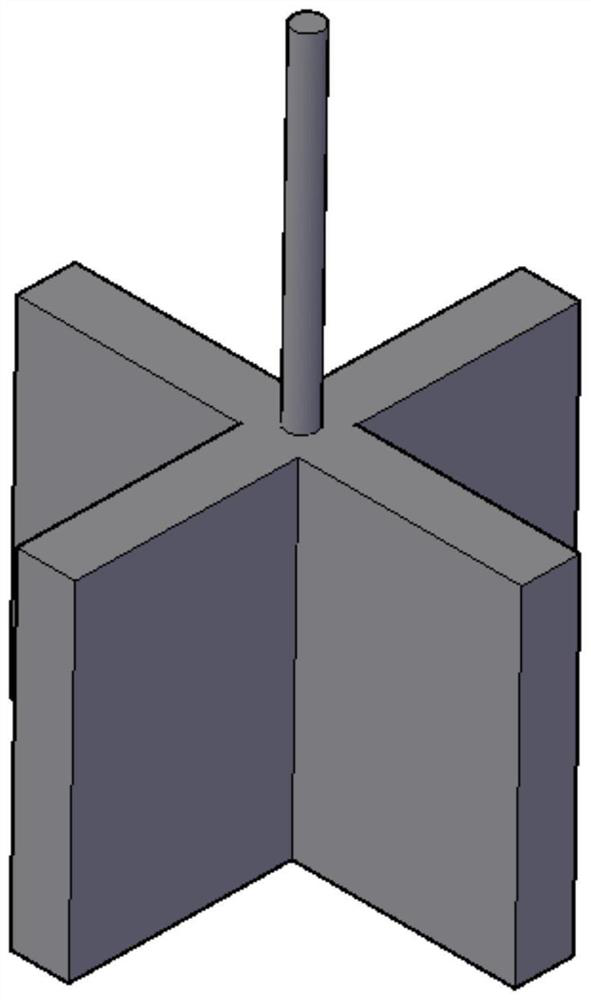

[0032] The first stage: After desulfurization wastewater is injected into the reactor, 30mg / L PAC coagulant and 6-8g / L magnetic powder are added through the dosing device (1), and stirred at a stirring speed of 50r / min for 1min.

[0033] The second stage: add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com