Carbon fiber surface treatment method based on ultrasonic strengthening

A surface treatment and ultrasonic strengthening technology, applied in ultrasonic/sonic fiber treatment, carbon fiber and other directions, can solve problems such as electrolyte corrosion of devices, low treatment efficiency, fiber body damage, etc., to achieve fast and efficient treatment speed, simple treatment equipment, Increase the effect of oxygen-containing functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

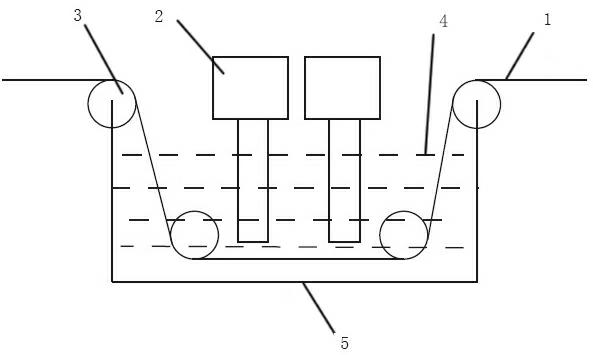

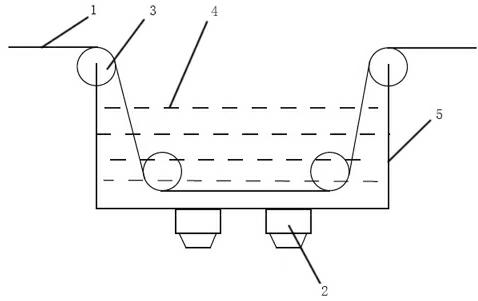

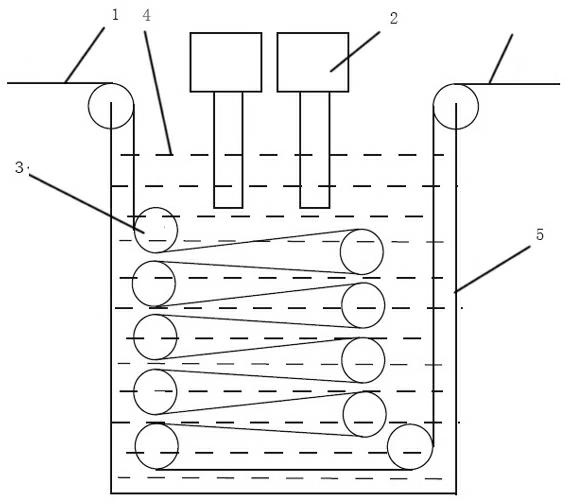

[0028] Ultrasonic strengthening surface treatment of carbon fiber is accomplished by a simple ultrasonic generator or its array, the ultrasonic generator 2 such as Figure 1-2 As shown, it is installed above or below the surface treatment tank 5, and the carbon fiber filament 1 is immersed in the liquid medium 4 in the surface treatment tank for drafting. At the same time, the ultrasonic generator radiates ultrasonic waves to the liquid medium for a period of time to reach The purpose of processing carbon fiber. The power of the generator is 1000W (the average ultrasonic intensity is 1W / cm 2 ), the ultrasonic frequency is 20kHz, the liquid medium is hydrogen peroxide solution (concentration 5%), the temperature of the liquid medium is 30 degrees, and the action time is 2 minutes. The action time here can be adjusted by the traction speed. It can be used for production lines that cannot adjust the traction speed Figure 3-4 The method mentioned in the method uses multiple rol...

Embodiment 2

[0032] A simple ultrasonic generator for ultrasonically enhanced surface-treated chopped carbon fibers can be obtained by Figure 5 or Image 6 The shown equipment is completed, the chopped carbon fiber 7 placed on the tray 6 is immersed in the liquid medium in the tank by pressure, and the ultrasonic generator is turned on to irradiate the liquid medium with ultrasonic waves for a period of time, so as to achieve the purpose of surface treatment of carbon fiber. The pressure condition is 0.1 MPa, the power of the ultrasonic generator is 2000 W (the average sound intensity is 2 W / cm 2 ), the ultrasonic frequency is 30 kHz, the liquid medium is degassed water, the liquid medium temperature is 30 degrees, and the action time is 20 minutes. The degree of surface treatment of chopped fibers can be controlled by adjusting the ultrasonic treatment time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com