Patents

Literature

182results about How to "Low radioactivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

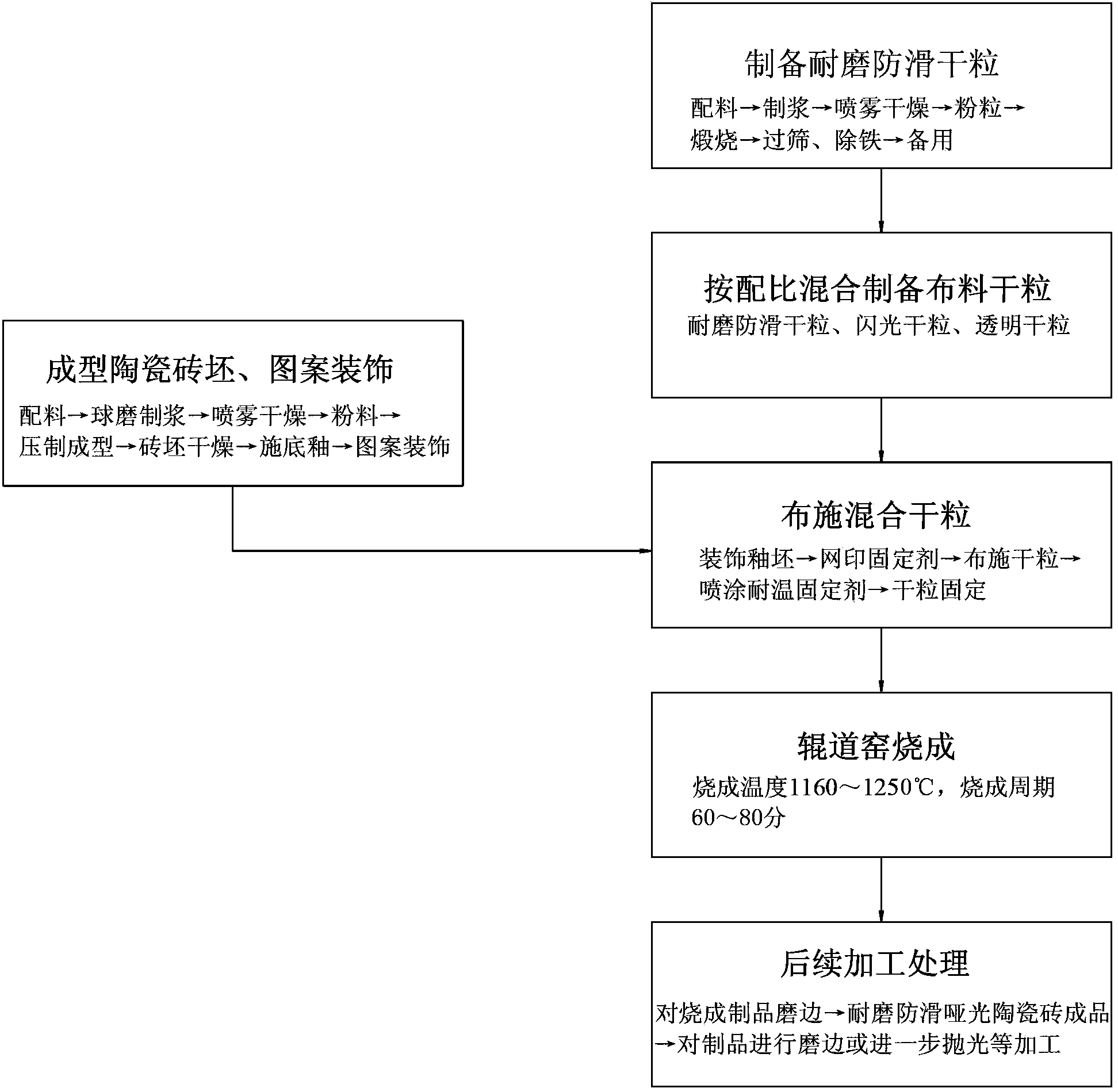

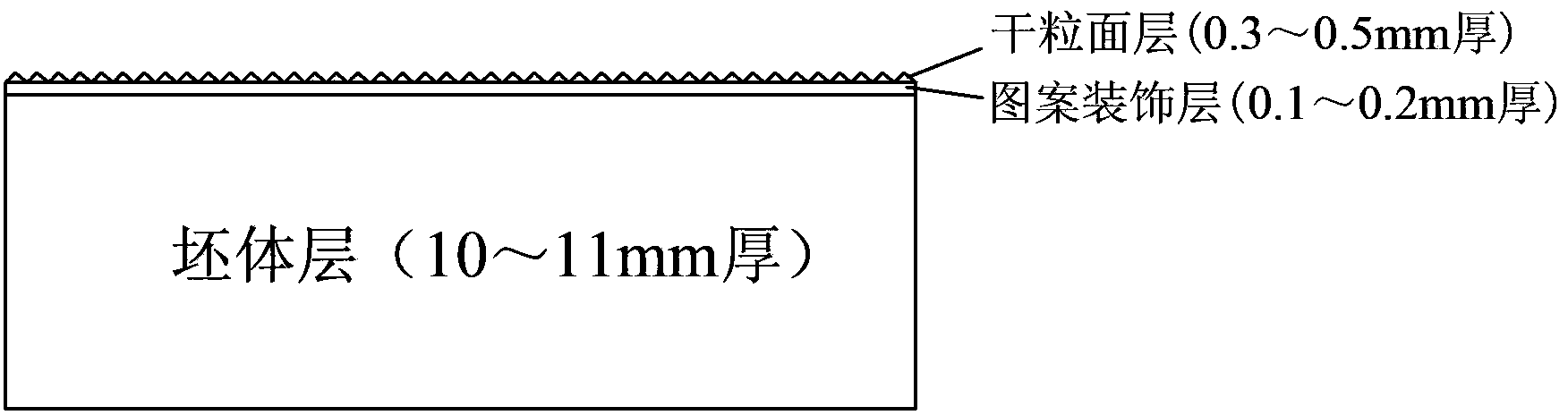

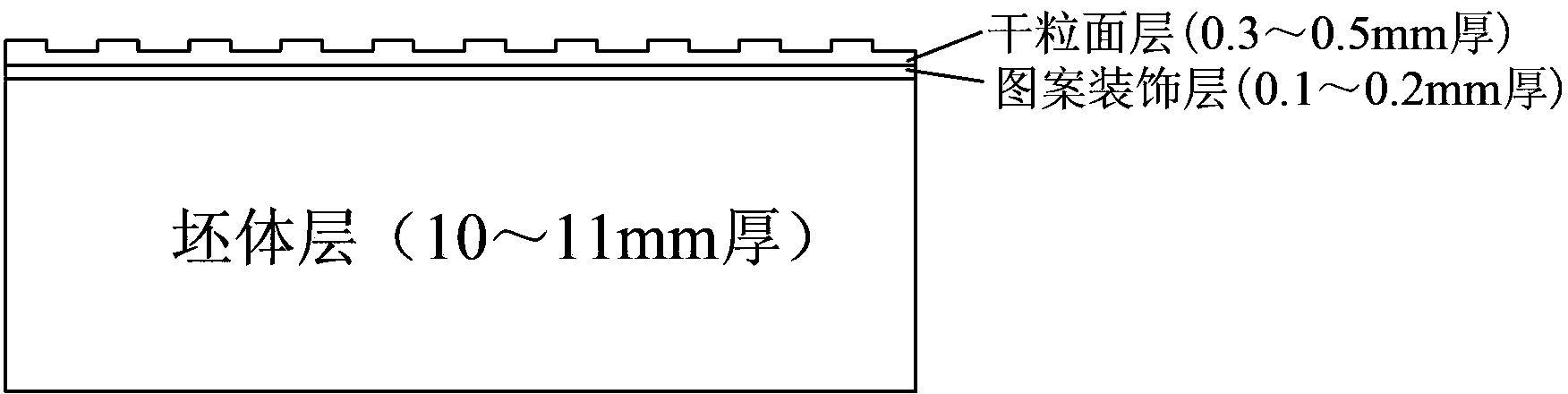

Method for manufacturing wear-resistant antiskid dry-particle ceramic tile

The invention relates to a method for manufacturing a wear-resistant antiskid dry-particle ceramic tile, which comprises the following steps: (1) forming a ceramic tile plane matrix and carrying out pattern decoration; (2) preparing dry particles with wear-resistant and antiskid properties; (3) mixing the wear-resistant antiskid dry particles, flashing dry particles and transparent dry particles according to a certain proportion for distribution; (4) applying the mixed dry particles to the surface of a decorative glazed body and spraying a temperature-resistant fixing agent; (5) conveying the obtained product to a roller kiln for firing and preparing the finished product of the ceramic tile through subsequent processes. According to the method for manufacturing the wear-resistant antiskid dry particle ceramic tile, the dry particles with good wear resistance are mixed with the transparent dry particles and the flashing dry particles, a dry powder distribution mode is adopted and the wear-resistant antiskid dry particles are bulged due to different melting performance of various dry particles in the firing process, so that the problems of wear resistance of the surface and thickness of a wear-resistant layer are solved; by distributing the transparent dry particles, a decorative pattern has a stereoscopic decorating effect under the covering of a glass layer, so that unification of wear-resistant and antiskid properties and decoration of the ceramic tile is achieved.

Owner:JIANGXI HEMEI CERAMICS

Separation of radium and rare earth elements from monazite

InactiveUS20100018347A1Efficiently recoversEfficient separationIon-exchange process apparatusAnion exchanger materialsRare-earth elementDecay product

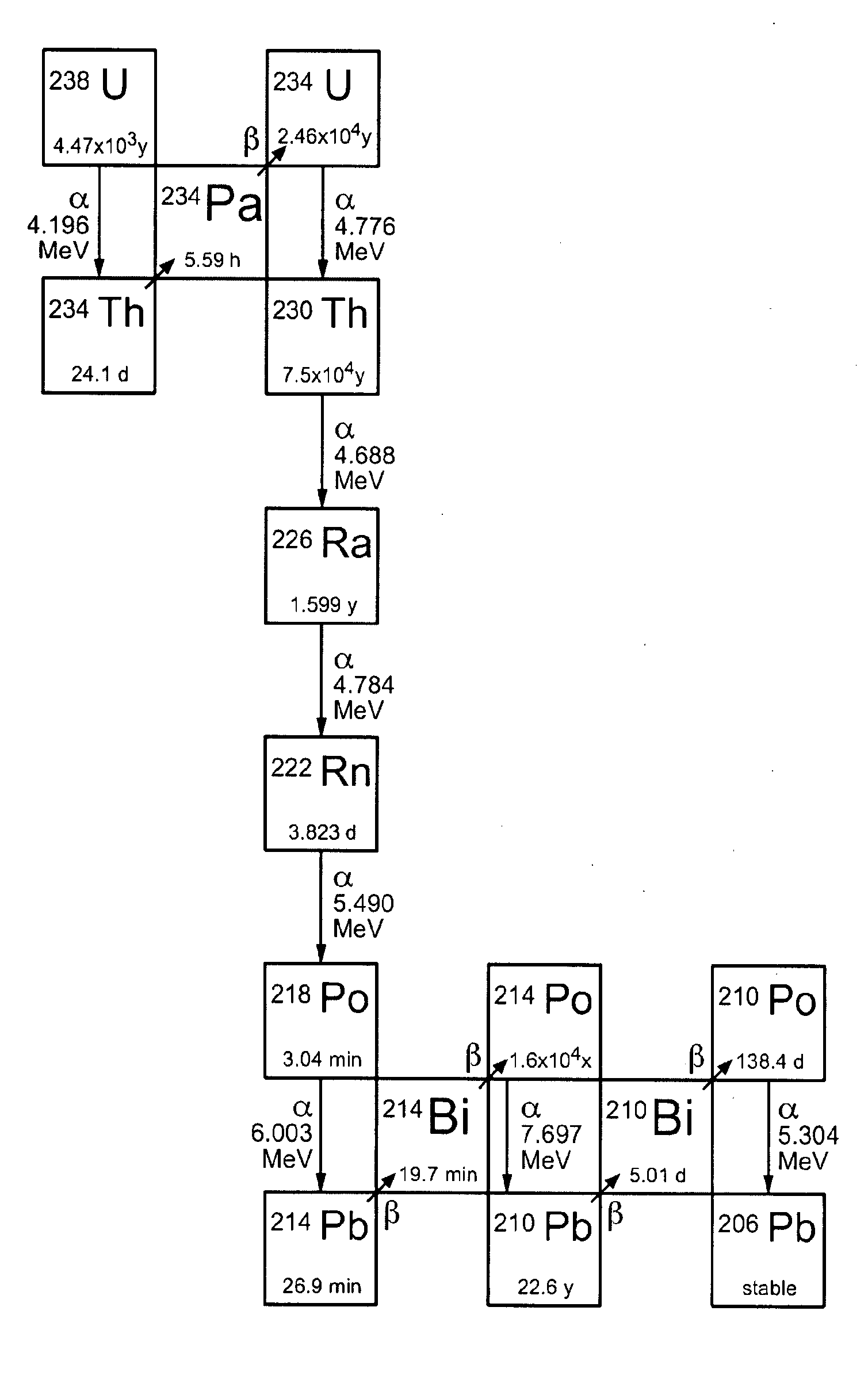

A method of chemically extracting radium-228, rare earth metals, thorium, the decay products of thorium, and phosphates from thorium-containing ores. The method involves breaking thorium-containing ore into fragments, wetting the fragments with a concentrated strong acid to make a slurry, heating the slurry, passing the heated solution through a first anion exchange column, retaining metals and radium-228 captured on the resin, allowing the radium-228 ions to decay to actinium-228, purifying the actinium-228 fraction, sending the actinium-228 fraction through a capture column, eluting the captured thorium-228 with acid, removing radium from the solution, retaining the radium-228 fraction for isomer in-growth, retaining decay products from the radium-228, separating the REEs from the process stream; and eluting and retaining the REEs.

Owner:HOLDEN CHARLES S +1

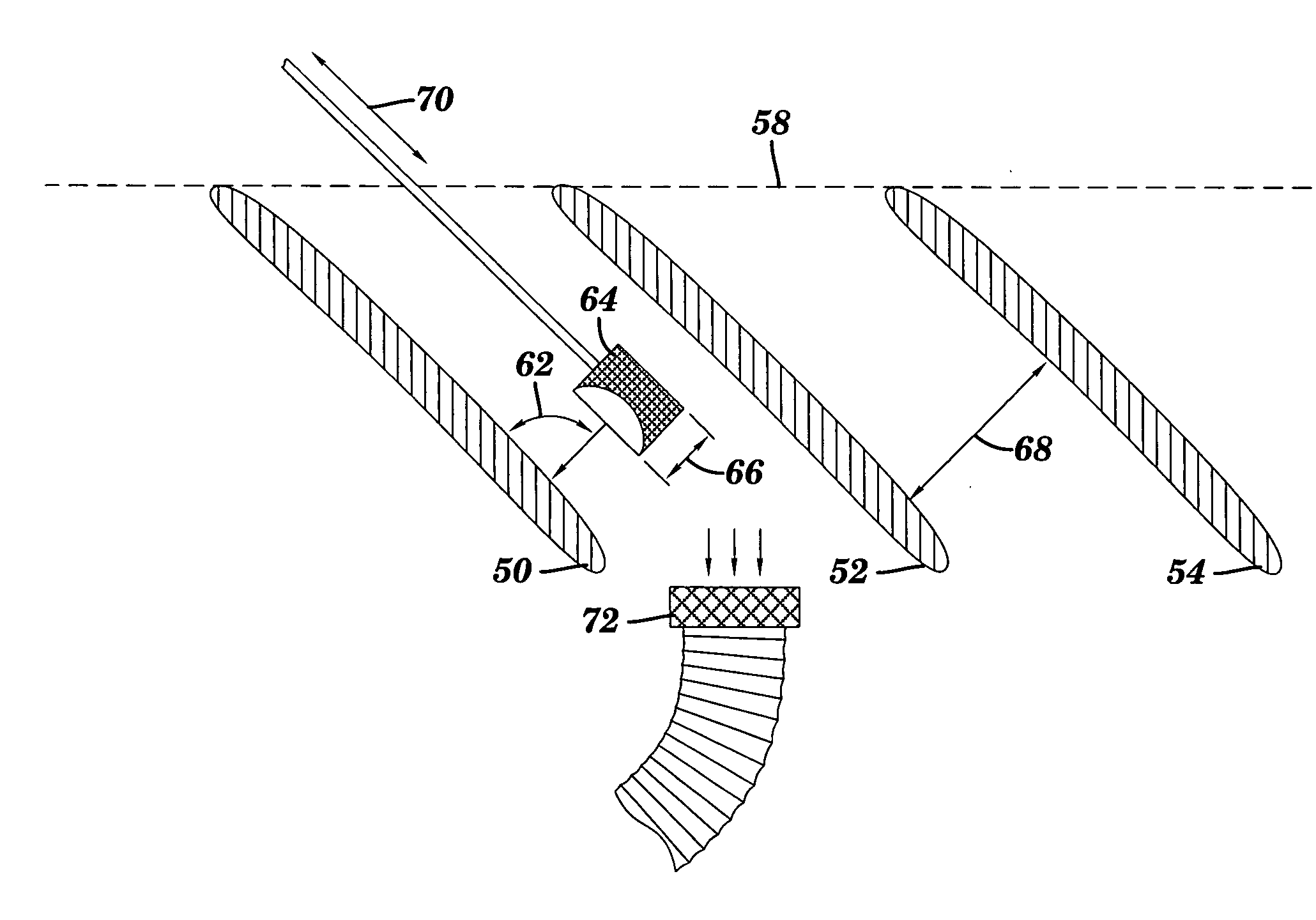

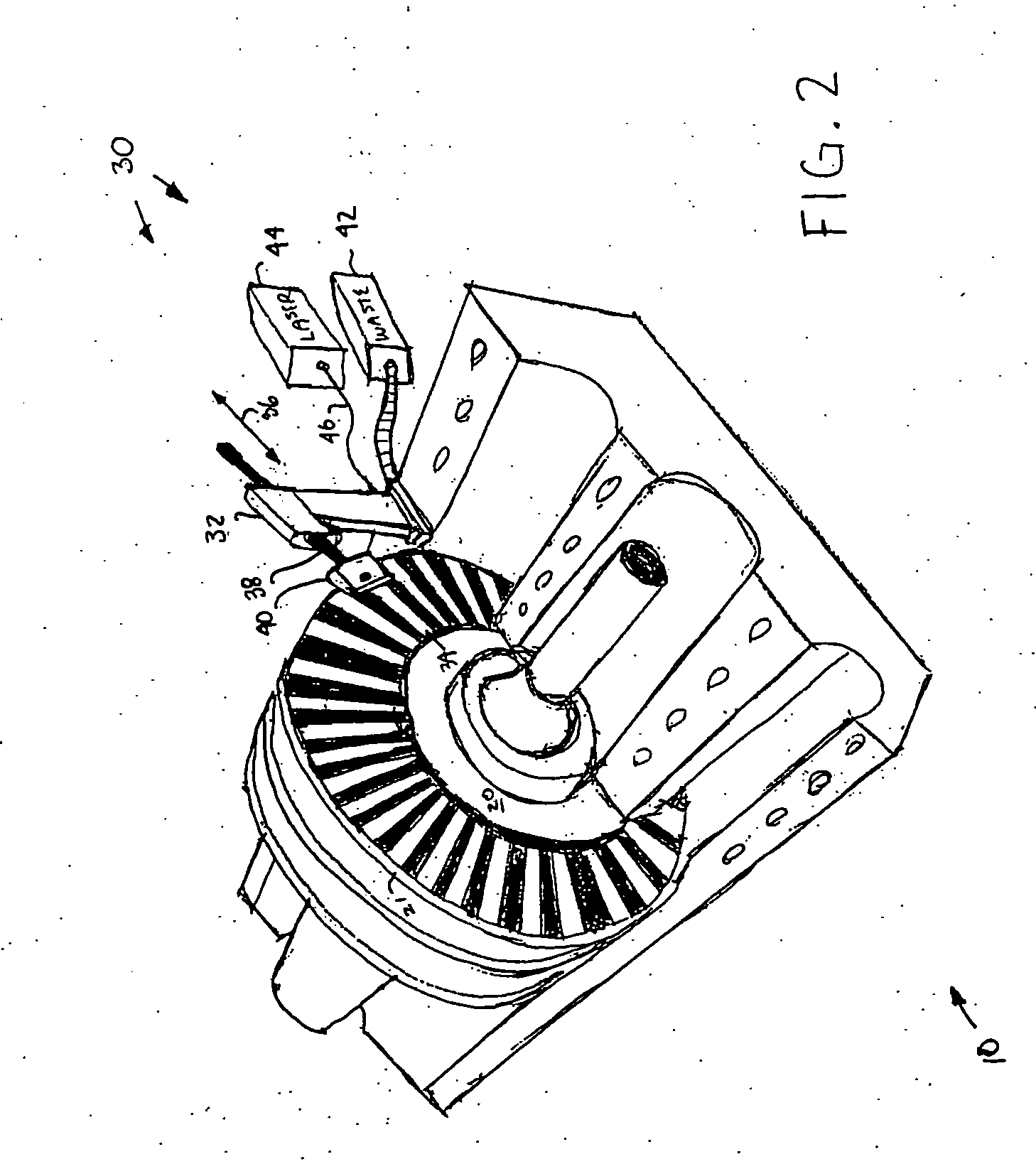

Method and apparatus for removing a thermal barrier coating from a power generation component

InactiveUS20050224474A1Low radioactivityTurbinesEfficient propulsion technologiesLight guideLight beam

The present invention provides a cleaning system and method that utilizes a portable workhead to direct a pulsed laser beam to a surface of a generator, turbine or boiler component or similar surface requiring cleaning and / or removal of a thermal barrier coating (TBC). In a first aspect, the invention provides a laser-based cleaning system for removing a thermal barrier coating from a power generation component, comprising a laser positioned remotely from the power generation component for generating a laser signal, a laser workhead capable of being positioned proximate the power generation component, wherein the laser workhead can deliver a laser beam onto the power generation component surface to cause the thermal barrier coating to be removed, and a light guide that delivers the laser signal from the laser to the laser workhead.

Owner:KILBURN CHRIS A

Structure steel material suitable for fusion reactor

InactiveCN1861825AImprove radiation resistanceImprove high temperature performanceHeat treatment process controlHalf-lifeAlloy

A structural steel material is suitable to fusion reactor, it is a martensite steel with low activation and is composed of element Fe, and it also contains the alloys Cr, W, V, Ta, Mn and C. It is suitable to use in the fusion reactor which has the resistance against the irradiation. The recipe of this steel replaces the elements Mo, Nb and Ni which are contained in the normal steels with W, Ta, V and Mn, so it assures the characteristic of low activation. Through optimization of the ingredients, the main nature of the steel increases. At the same time we strictly control the lever of long nuclear lifetime radioactive impurity which is created by irradiation with neutron. The half-life of the radioactive species which activated by irradiation with neutron is short, and the lever can be decreased to lower than the operational lever 10mSv / h in 100 years.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Cement lightweight mortar

The present invention provides a cement light mortar which is the thermal insulating material at the exterior wall surface of the building, the cement is taken as the base material, the mortar comprises a light weight aggregate, a polymer modified additive and a re-dispersible emulsion powder, the light weight aggregate is expanded perlite and lime dust, the polymeric additive is the combination of cellulose ether, lignocellulose, starch ether and the polypropylene short fiber, wherein, the expanded perlite is the organosilicon-modified expanded perlite. The invention has the following advantages: the thermal conducting coefficient of the invention is reduced greatly, the material has excellent heat preserving and heat insulating property, each strength index is increased greatly comparing with the conventional heat insulating mortar, has higher crushing strength for securing the safe using; the weight is light and the sole weight of the building and the burden to the base load are effectively reduced; the construction technique is same to the conventional coating mortar and the operation is rather simple; the physical property is stable and no empty projection or cracking will occur after construction. The activity is rather low. The mortar has a broad application field and has excellent compatibility and stick force to various wall bases, the product of the invention is nontoxic and smellless, inorganic and noncombustible.

Owner:上海中绿建材有限公司

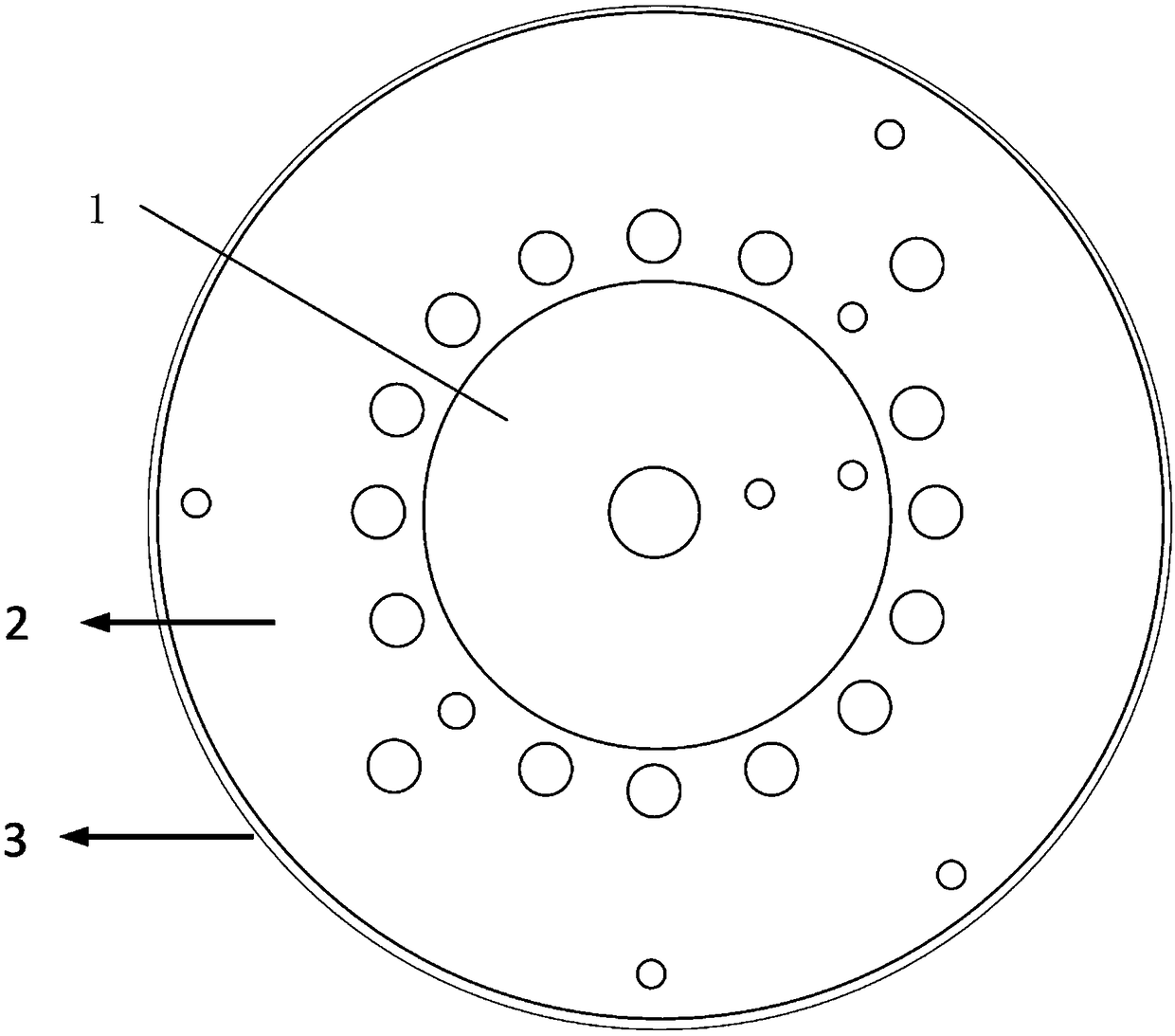

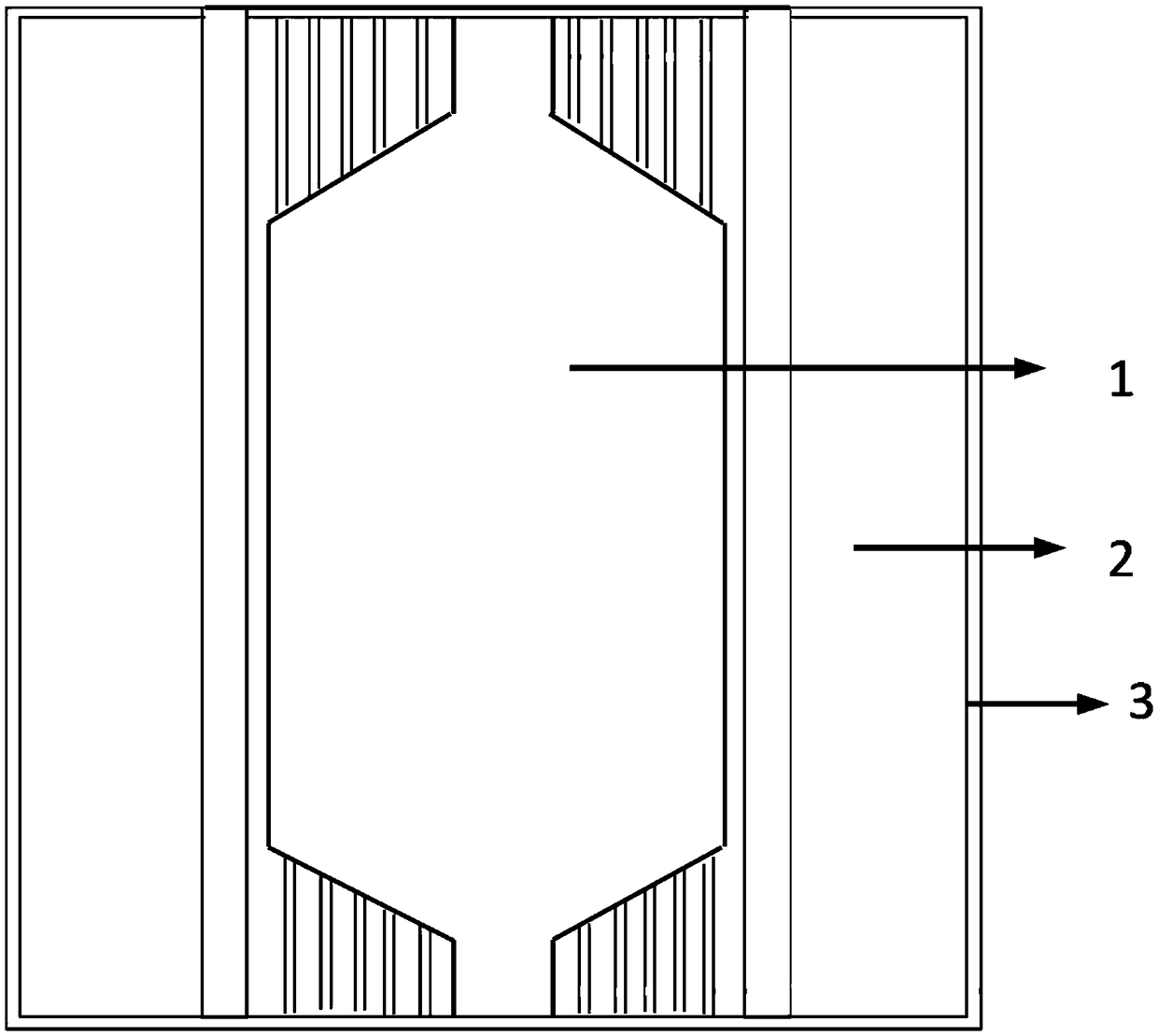

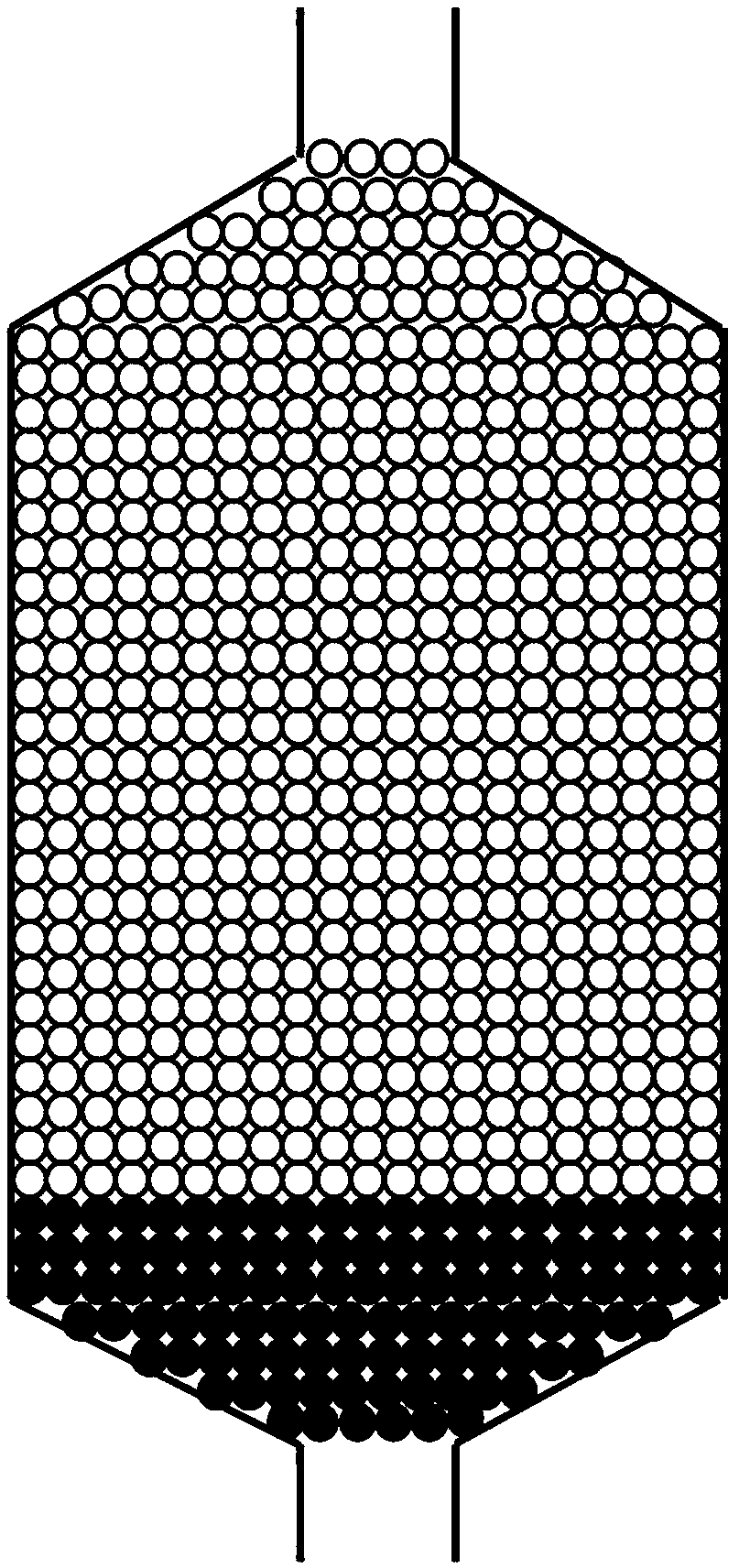

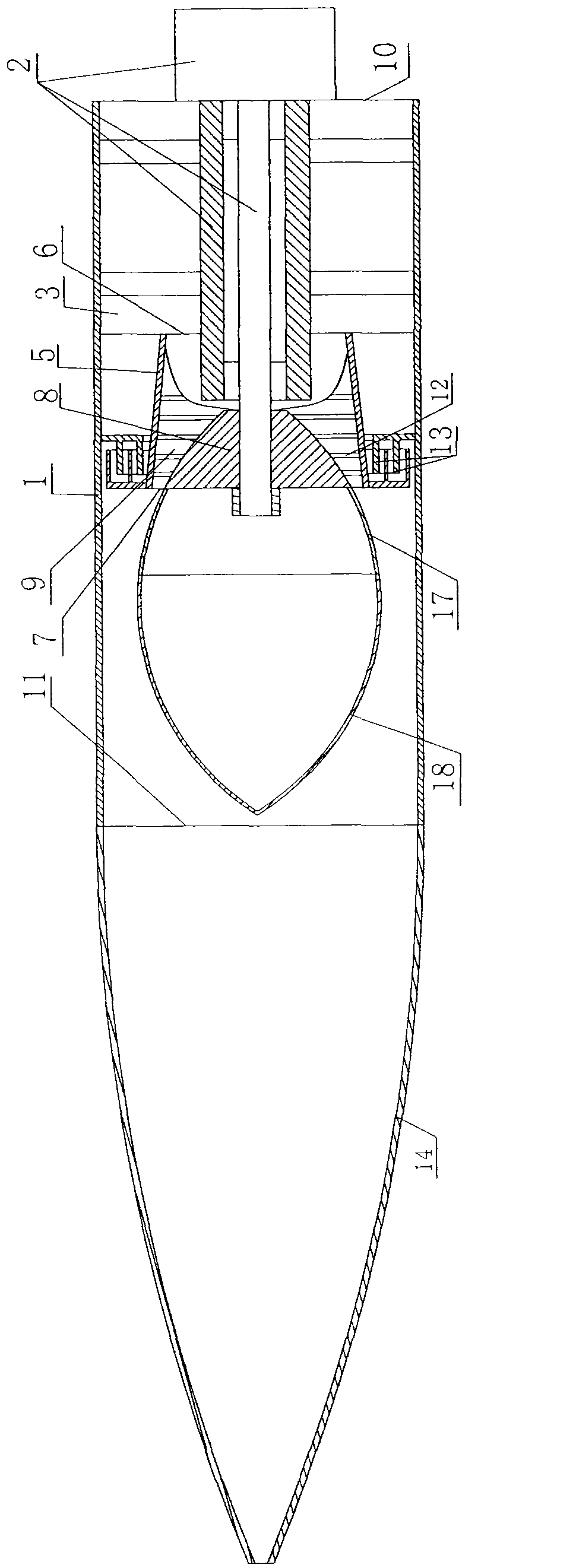

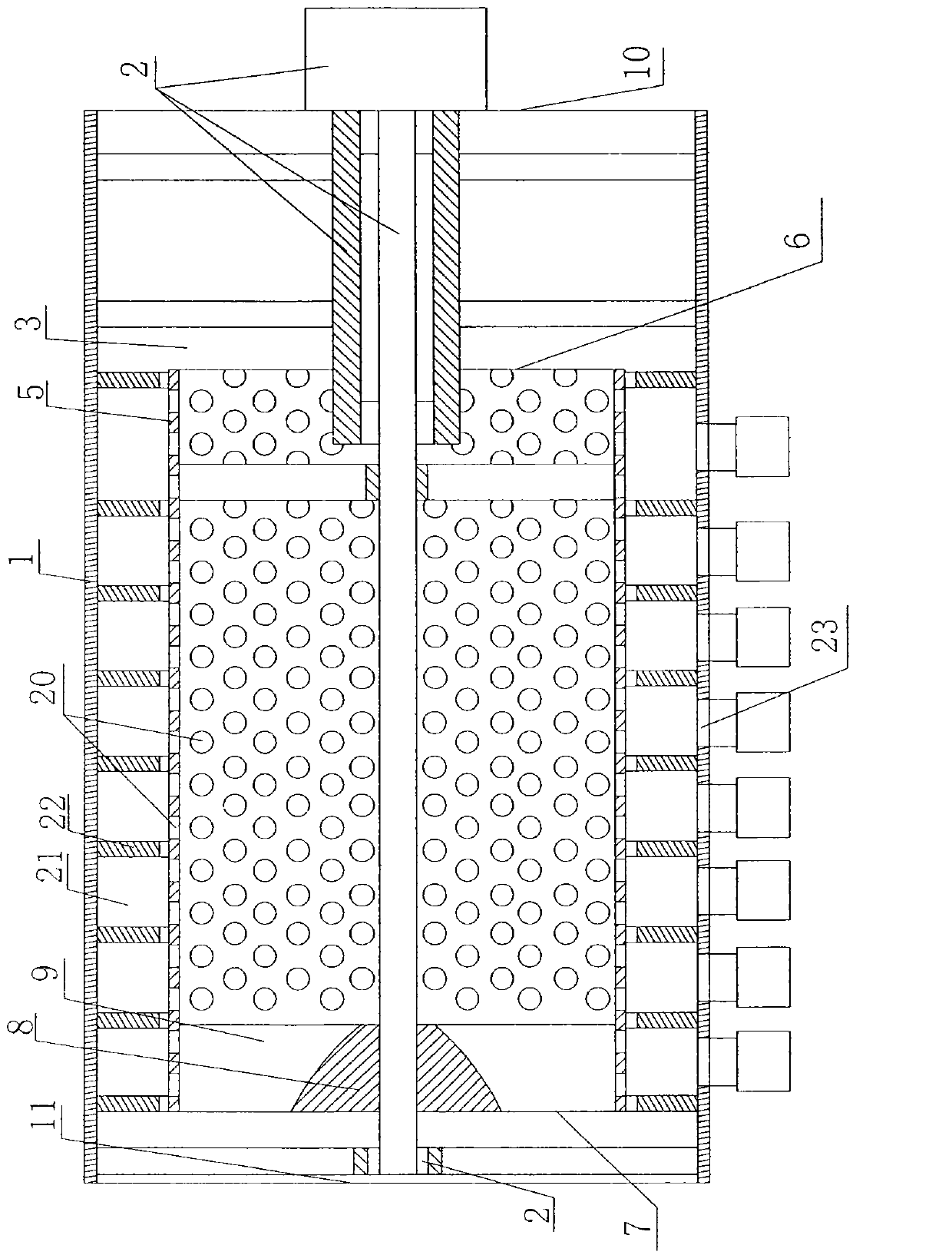

Reactor core structure, molten-salt pebble bed reactor and fuel management and reactor core loading method of molten-salt pebble bed reactor

PendingCN109509562AMinimize Reactor Control RisksMaintain core stabilityOptical rangefindersFuel elementsNuclear engineeringMolten salt

The invention discloses a reactor core structure, a molten-salt pebble bed reactor and a fuel management and reactor core loading method of the molten-salt pebble bed reactor. An active region of thereactor core structure is provided with a charging opening located at bottom and a discharging opening located at top, the density of fuel spheres in the active region is lower than that of a molten salt in the active region, and fuel inventory capable of being contained by the active region is greater than preset fuel inventory of full-power operating days. According to the reactor core structure, the global unloading of the fuel spheres at lifespan ends can be achieved, and components achieving an online reloading function are not required, so that the device can be simple; the fuel spheres,which are subjected to global unloading at the lifespan ends, have no need of being treated one by one and directly enter a spent fuel treatment system, so that radioactivity can be lowered, the reliability of the device is improved, and thus, the purification of the fuel spheres can become simple; due to the reactor core structure, the fuel management and reactor core loading method can have anadjusting margin, and a running target is guaranteed.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

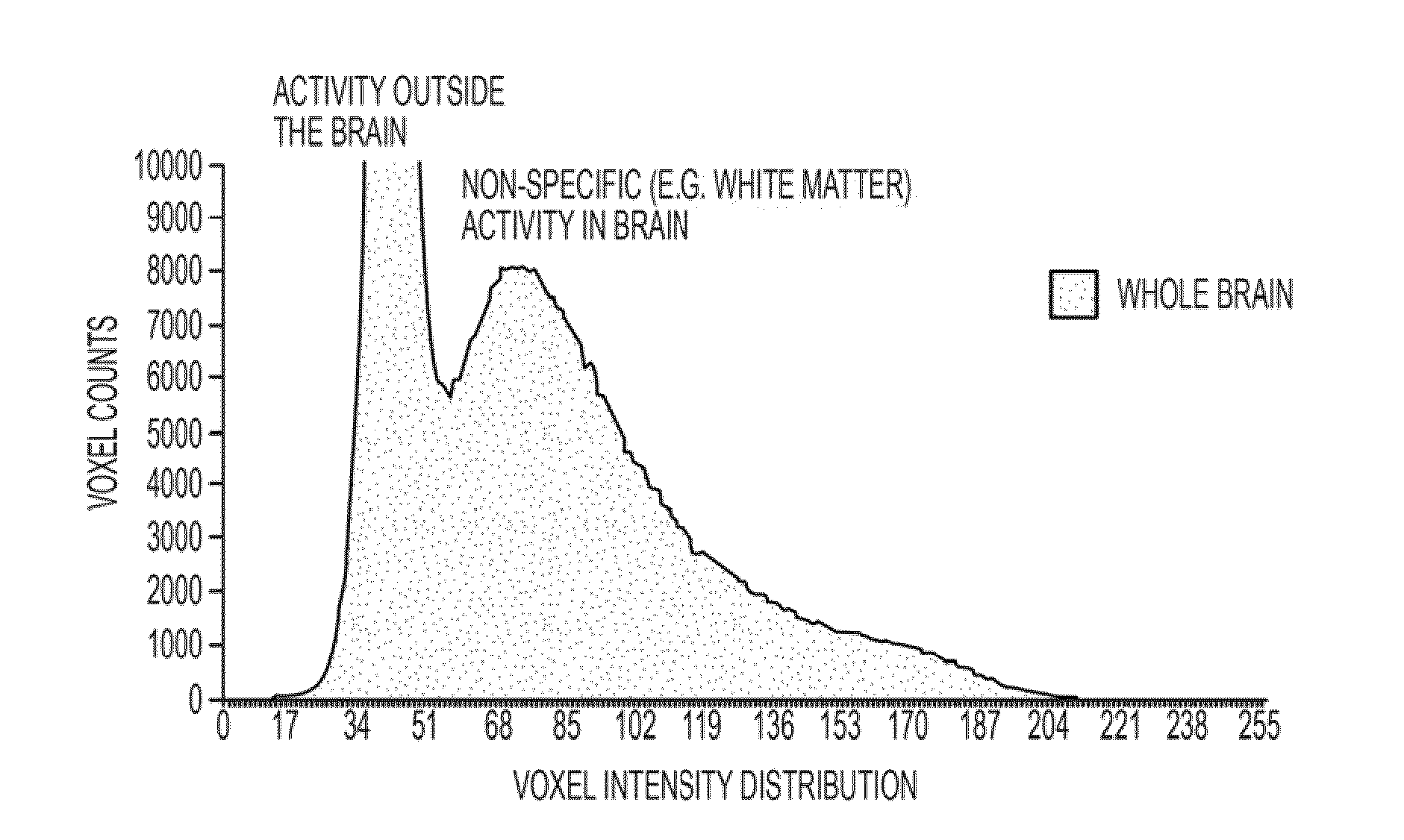

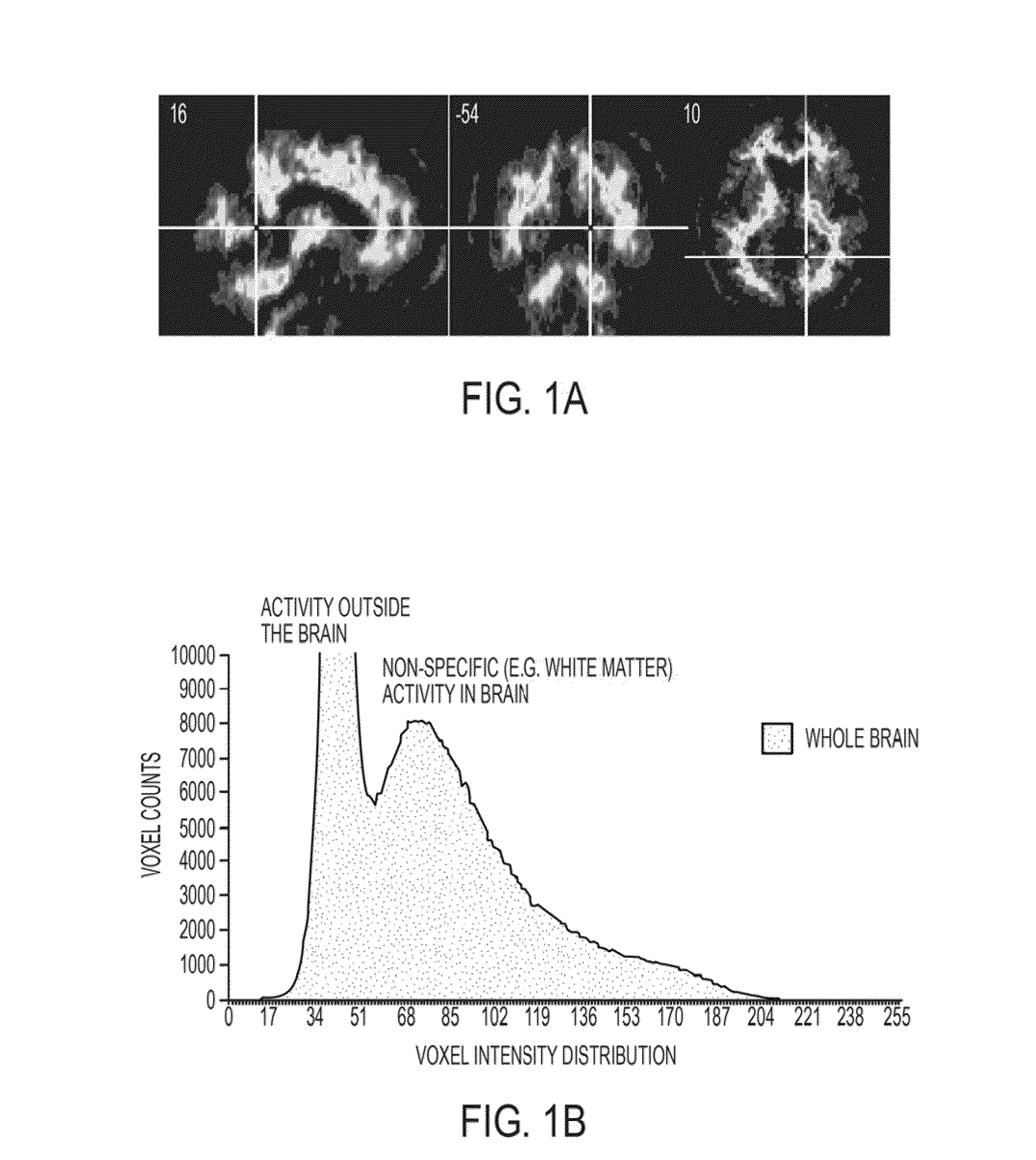

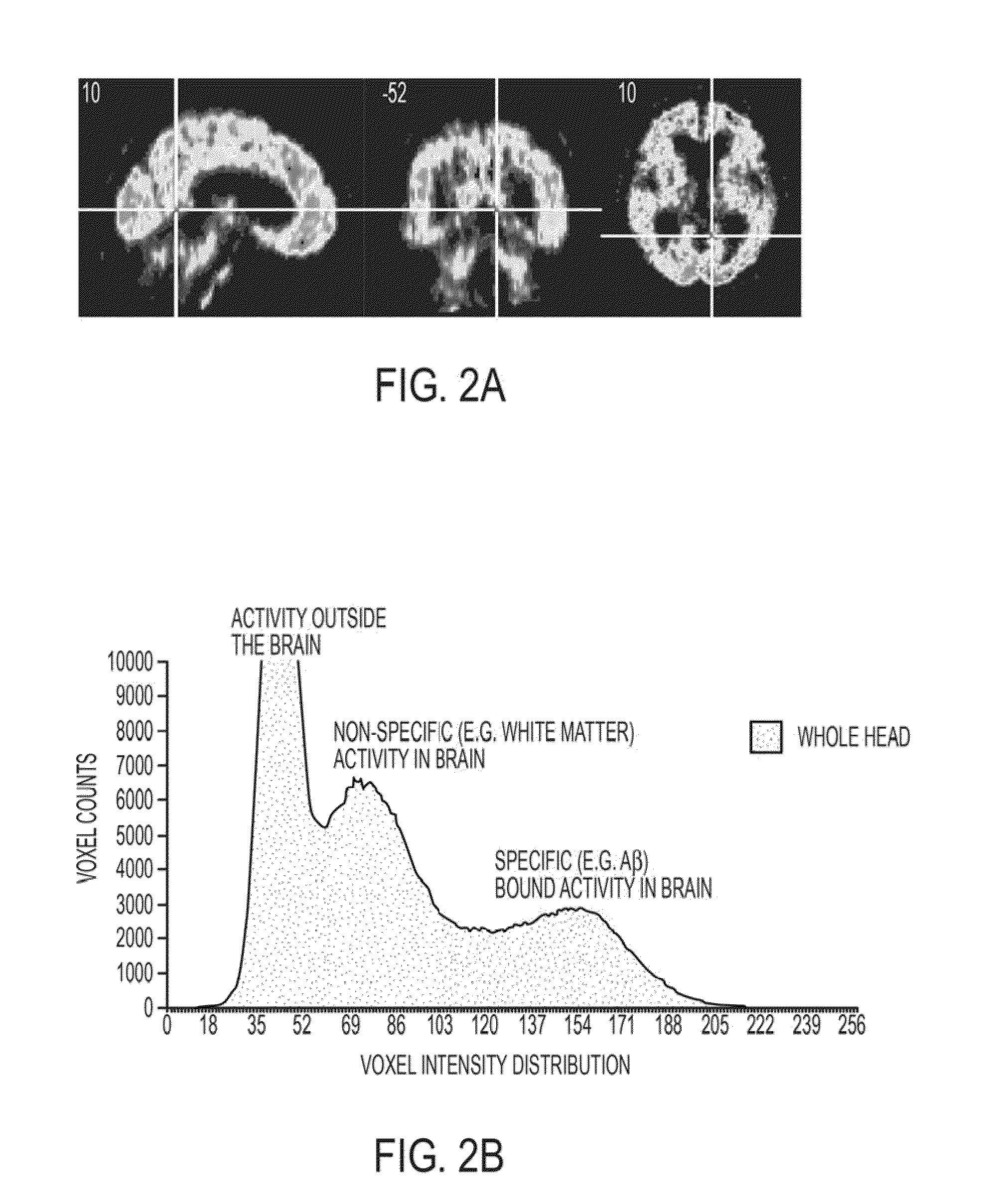

Histogram-based analysis method for the detection and diagnosis of neurodegenerative diseases

InactiveUS20100145194A1Reduce riskHigh riskDiagnostic recording/measuringSensorsAnalysis methodHistogram

An analysis method using histograms derived from positron emission tomography (PET) or single photon emission tomography (SPECT) images of the brain, which utilizes radiopharmaceuticals for the detection and diagnosis of pathological targets associated with neurodegenerative disease in a patient is provided.

Owner:AVID RADIOPHARMACEUTICALS

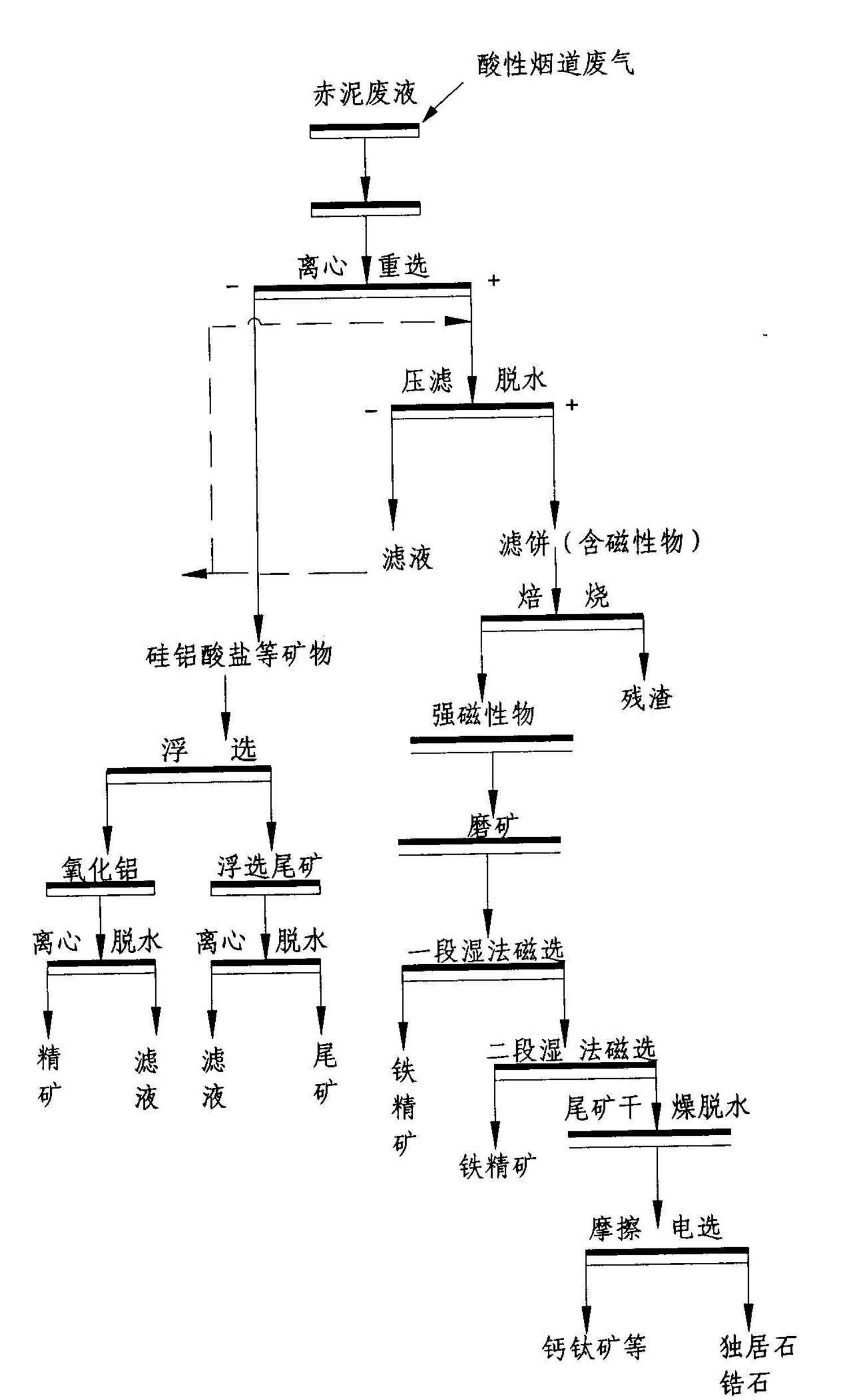

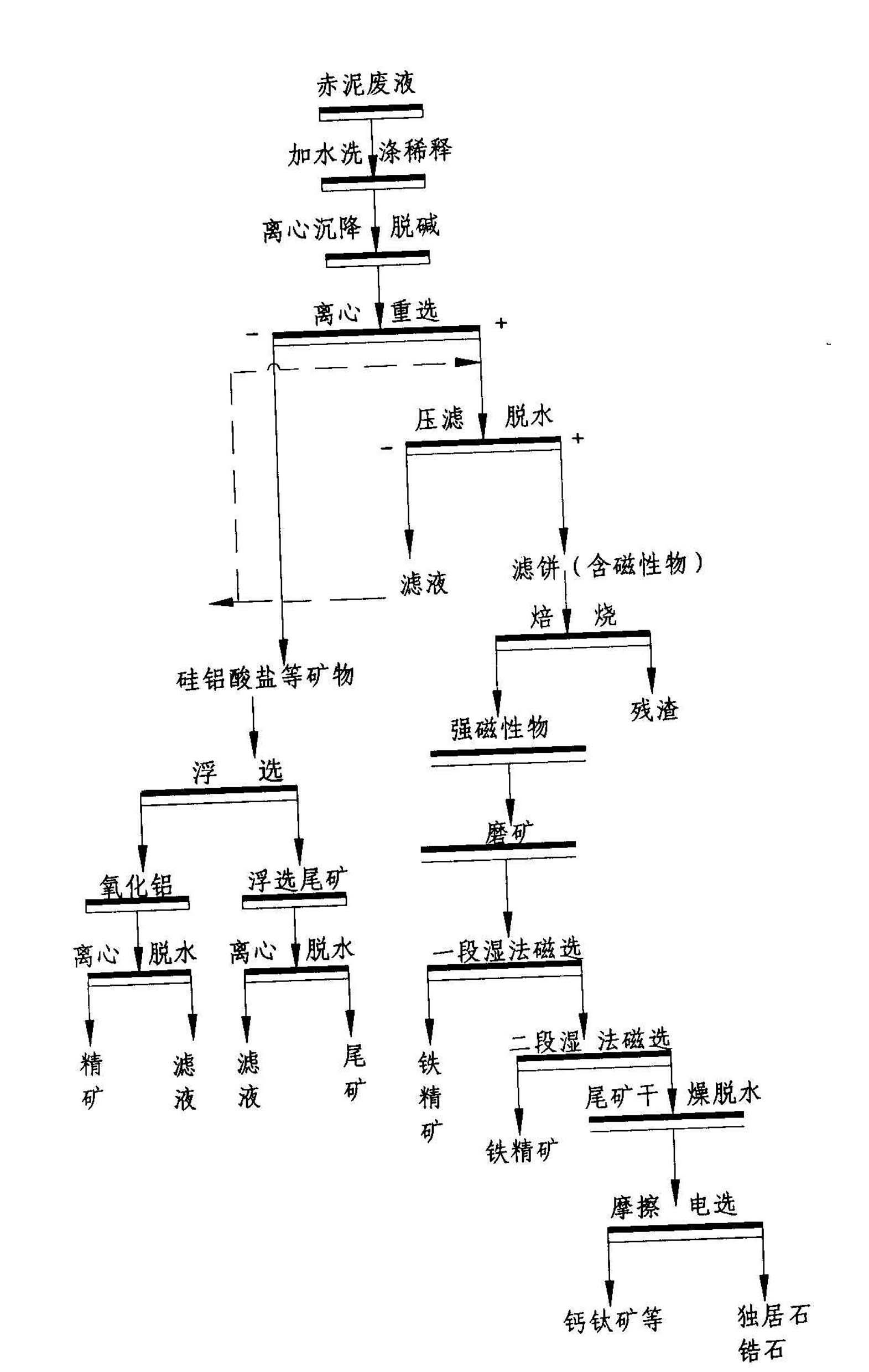

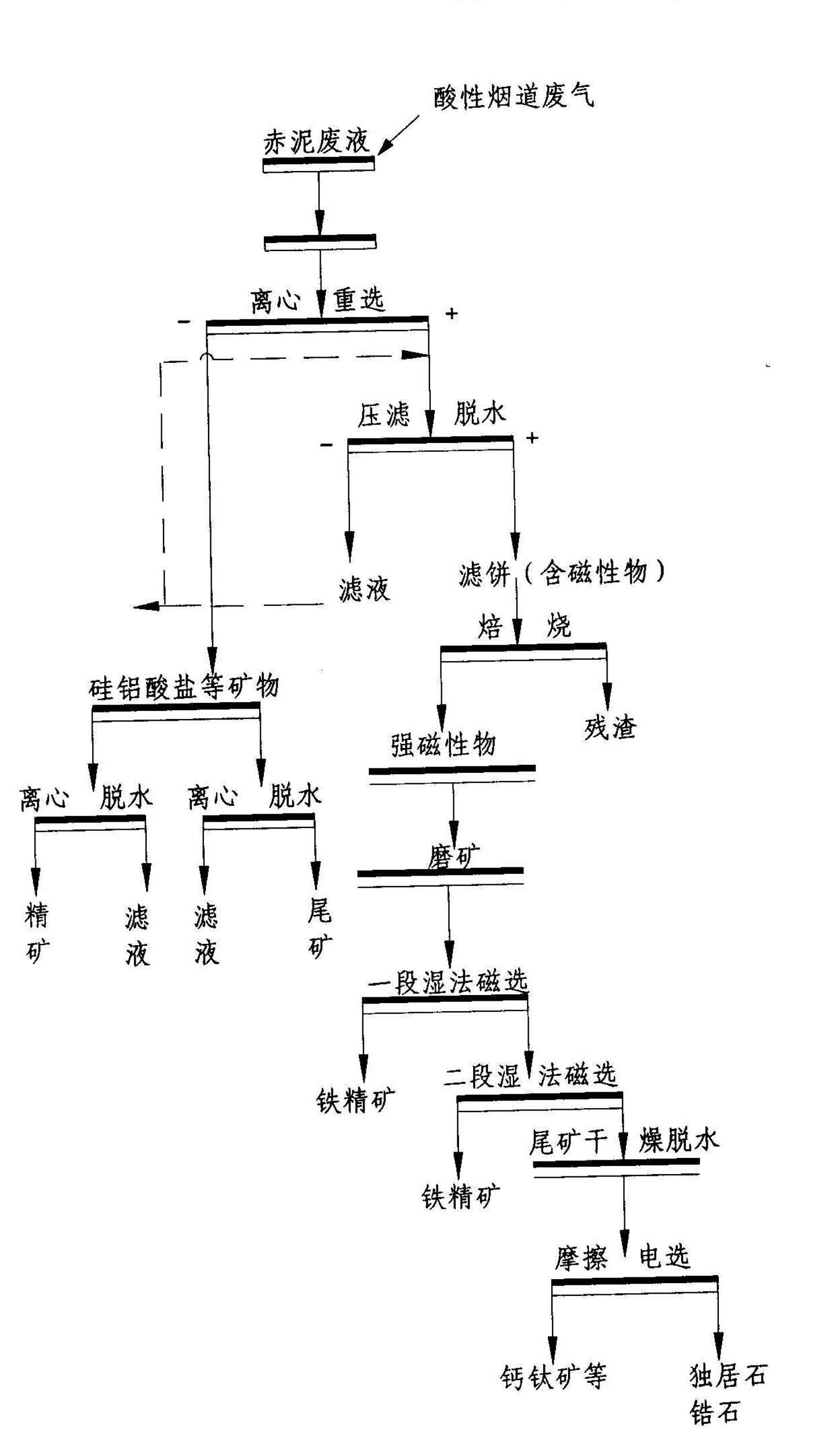

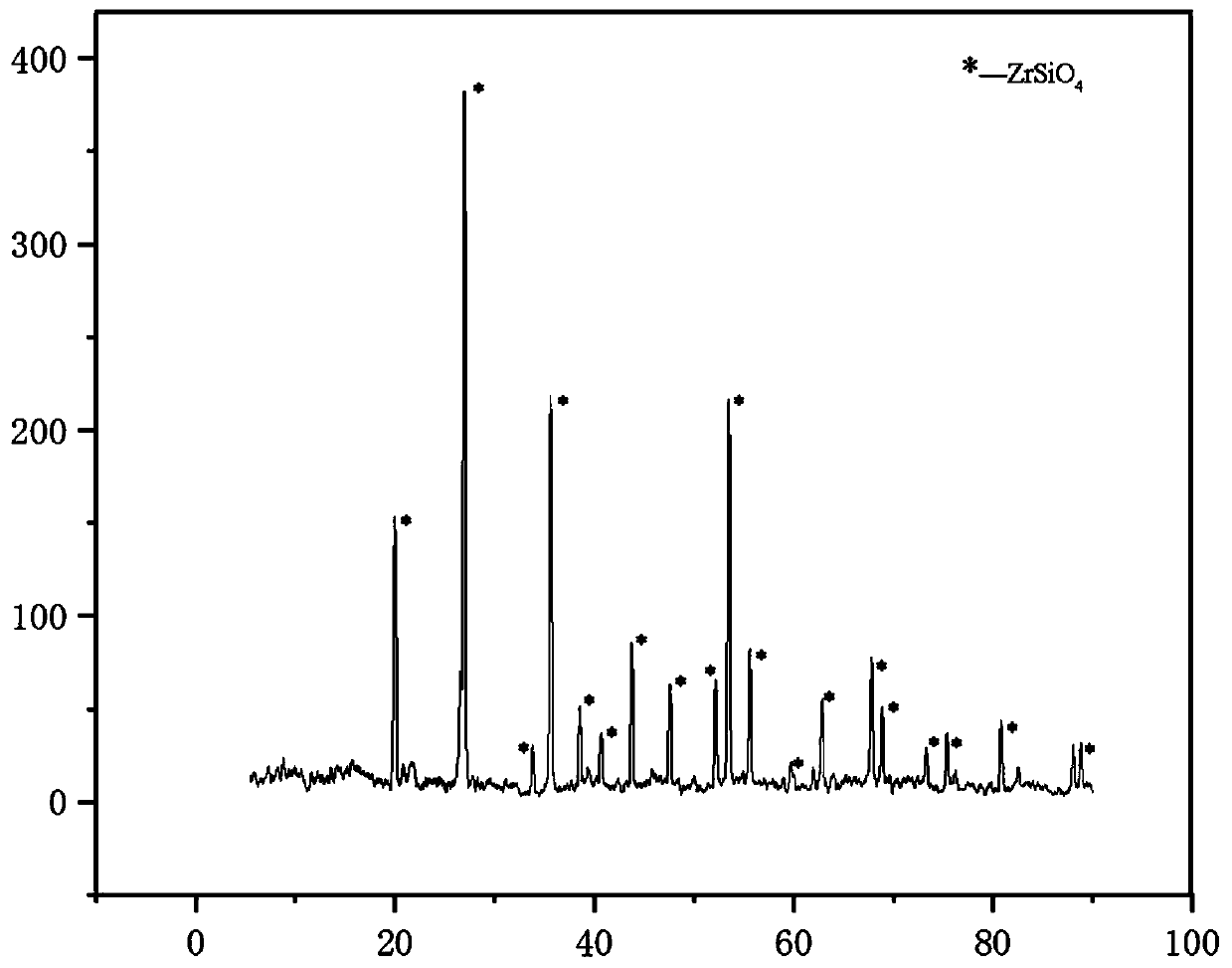

Red mud harmless comprehensive recycling technology suitable for Bayer process

The invention discloses a red mud harmless comprehensive recycling technology suitable for a Bayer process. The technology is mainly used for removing alkaline matters in the red mud and selecting a great quantity of iron minerals in the red mud through technical means while separating the radioactive minerals such as zircon, monazite and the like from the red mud at the same time; the separated red mud tailings are used as a large quantity of raw materials for cement processing, brick / tile firing, road building and the like, or used as mine filling materials and the like; the red mud minerals are turned into wealth and sufficiently used; large-scale resource utilization of red mud is realized; and a series of problems in resources and environment and potential safety hazard caused by red mud damming and stacking are fundamentally solved.

Owner:ANHUI UNIV OF SCI & TECH

Gypsum lightweight mortar

InactiveCN101239809ALow thermal conductivityImprove insulation effectSolid waste managementCelluloseHeat conducting

A gypsum light mortar is a heat-insulating material of the inner wall of the building, the gypsum powder is taken as the gelled material which comprises light weight aggregate, polymeric additive and retarder, the light weight aggregate comprises expanded perlite, the polymeric additive is the combination of cellulose ether, lignocellulose, starch ether and polyvinyl alcohol, wherein, the expanded perlite is a silicon-processing modified expanded perlite. The mortar of the invention has the following advantages: the heat conducting coefficient of the mortar of the invention is greatly reduced, and the mortar has excellent heat preserving and insulating property, greatly-increased strength index comparing with the conventional heat-insulating mortar, excellent compression strength, securing the safety using, light weight, effectively reducing the sole weight of the building and the burden of the base load, same construction technique with the conventional coating mortar, simple operation; stable physical property, no hollow injection or cracking after construction, low activity, broad application field, and excellent compatibility and sticking force to various wall bases, the product of the invention in nontoxic, smell-less, inorganic and non-combustible.

Owner:上海中绿建材有限公司

Light mortar inside and outside combined exterior wall heat-preserving system

InactiveCN101245613AMeet the requirements of building fire protectionEasy to adjustCovering/liningsWallsFire preventionMaterials science

An external wall insulation system of a lightweight screed inside and outside combination is formed by smearing plaster lightweight screed and cement lightweight screed on the external wall of a building; wherein, the inner side of the external wall is coated with the plaster lightweight screed and the outer side of the external wall is coated with the cement lightweight screed, and both the plaster lightweight screed and the cement lightweight screed comprise lightweight aggregate which contains organosilicone modified expanded perlite. The external wall insulation system has the advantages that: aiming at the different requirements of the inner side and the outer side of the external wall of the building, the inner side of the external wall adopts the plaster lightweight screed and the outer side adopts the cement lightweight screed so as to form the novel insulation structure, thus exerting the function of the two insulation sand pulps and being beneficial to humidity control and fire prevention in the building; the external wall insulation system has the advantages of low coefficient of heat conductivity, excellent intensity index of each item, ensuing safe use, effectively reducing the deadweight of the building and the burden of basis load, extremely simple construction technique, stable physical property, existing no hollowing and crazing after construction, extremely low radioactivity, ensuring the inhabited environment to be healthy and safe as well as wide application scope.

Owner:上海中绿建材有限公司

Heavy metal wastewater treatment technology, processing method thereof, and medicine production formula

InactiveCN103588319ARaise the ratioReduce manufacturing costBiocideSolid waste managementHeavy metal compoundSewage

The invention relates to a heavy metal wastewater treatment technology, a processing method thereof, and a medicine production formula. A certain proportion of an aqueous solution of a mixed acid is added to wastewater containing heavy metals and radioactive heavy metals, a special medicine for the heavy metal wastewater treatment is added, the obtained mixed solution undergoes a mixing and stirring reaction for precipitation, and the pH value of discharged water is controlled in a range of 6-9 through the quantity of the medicine addition amount in order to realize the copolymerization coagulation precipitation of reacted heavy metal compounds. The content of each of Pb, Cd, Hg, As, and radioactive elements comprising Co-60, Tl, Sr-90, Pu, Th and U235 is not greater than 0.0001-0.00001mg / l, and the CODcr is not greater than 20-50mg / l, so discharged water can be discharged to urban domestic sewage treatment plants or rivers, lakes and seas. Waste residues containing a non-overload amount of the radioactive elements can be processed to form non-fired termiticide bricks added with a color sign, the treatment cost is low, and the treatment problem of the worldwide heavy metal pollution and the radioactive heavy metal pollution of water is solved.

Owner:叶绍朋

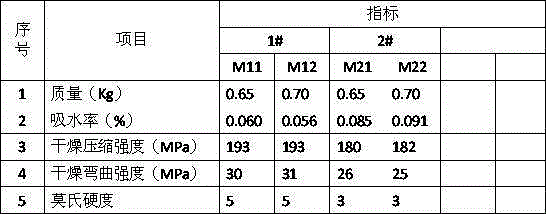

Microcrystalline glass stone material and preparation technology thereof

The invention provides a microcrystalline glass stone material and a preparation technology thereof, wherein the stone material comprises the following chemical components: silica, magnesium oxide or calcium oxide, phosphoric pentoxide or F, kali and / or sodium oxide. The preparation technology orderly comprises: mixing and stirring raw materials for preparing the stone material, seeding mixed raw materials into a glass tank furnace, and heating until a fusion state; casting the melt raw materials into a mould, and keeping temperature; cooling the mould; and opening the mould after cooling, to obtain a stone finished product. The preparation technology reduces chemical components of the microcrystalline glass stone material, and the preparation technology is simple, and it is convenient for adjusting the technology to obtain different cross section textures and patterns.

Owner:JIANGXI GOLDEN MAPLE JADE

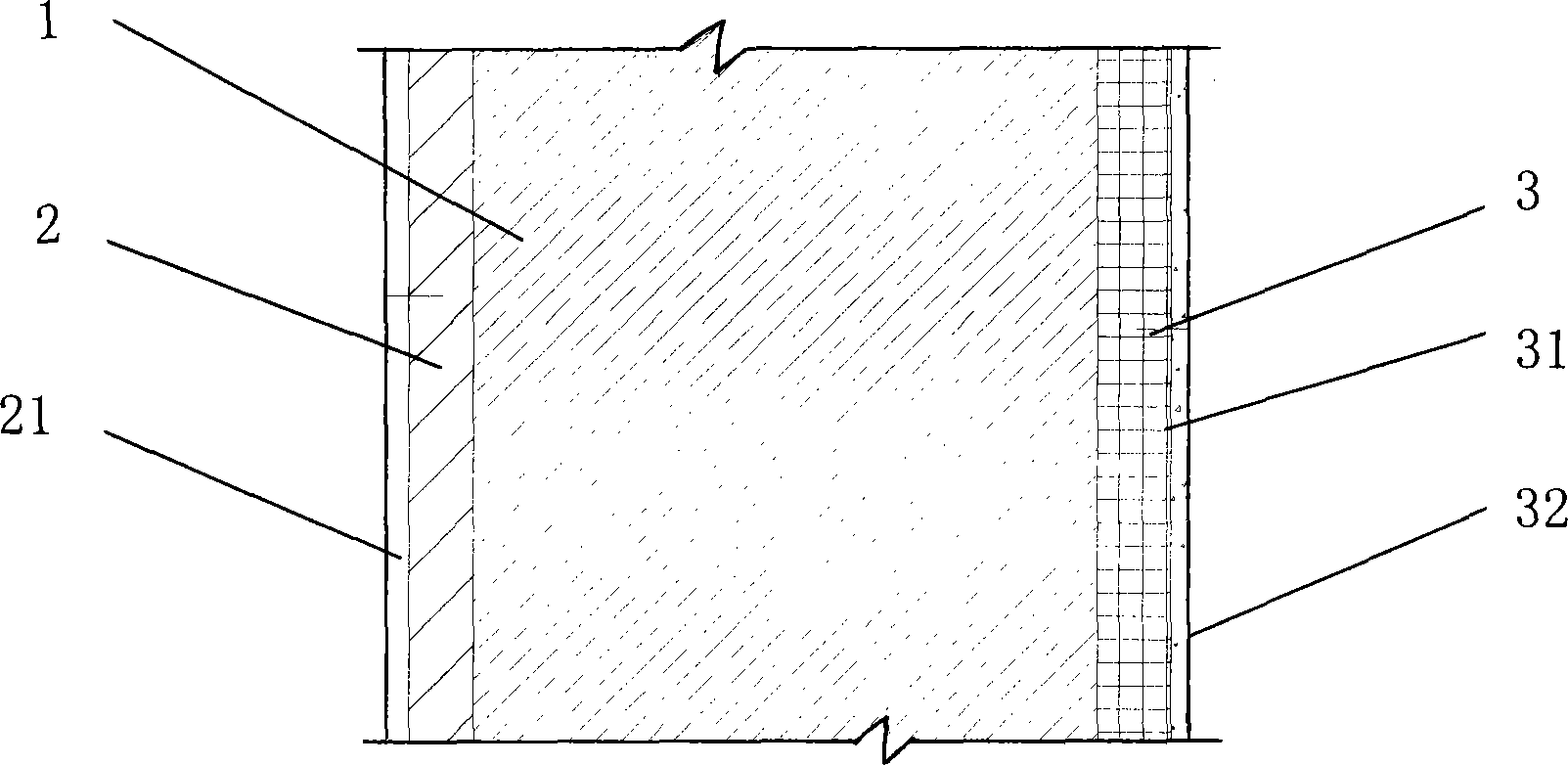

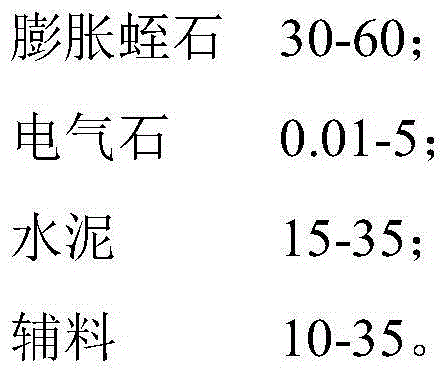

Expanded vermiculite cement board capable of releasing negative ions and preparation method thereof

The invention relates to an expanded vermiculite cement board capable of releasing negative ions and a preparation method thereof. The preparation method comprises the following steps: (1) weighing of raw materials: weighing the raw materials consisting of expanded vermiculite, cement, tourmalinite and an accessory by volume; (2) material mixing: uniformly mixing the raw materials under stirring by using a stirrer; (3) molding: allowing slurry obtained after uniform mixing under stirring to pass through a head box and then to be conveyed to running felt on a slurry-carrying felt conveying roller, carrying out natural dehydration and vacuum dehydration so as to form a material layer and winding the material layer onto a molding drum for molding by rolling; (4) maintenance: subjecting a molded product to normal-temperature maintenance for 3 to 6 h at first and then to steam maintenance in an autoclave at a pressure of 1 MPa and a temperature of 100 to 200 DEG C for 10 to 18 h; and (5) drying: carrying out drying at a temperature of 70 to 100 DEG C for 1 to 3 so as to obtain the expanded vermiculite cement board. Compared with the prior art, the expanded vermiculite cement board provided by the invention has the advantages of capacity of releasing negative oxygen ions, environment friendliness, good practicality and the like.

Owner:SHANGHAI CIMIC HEALTHY ENVIRONMENT TECH CO LTD

Gangue perforated brick and preparation method thereof

A gangue perforated brick and a preparation method thereof. The preparation method comprises the following steps: taking, by weight, 1 to 3 parts of shale, 1 to 3 parts of fly ash and 3 to 9 parts of gangue, respectively crushing the shale and the gangue, putting the crushed shale and gangue into a stirring mill, adding water in the process of stirring so as to control the water content of the mixture to be 12 to 13%, taking the mixture out and allowing the mixture to stand for more than 72 hours; putting the mixture into the stirring mill again, adding water, the amount of which is 0.5 to 1% of that of the mixture, and evenly mixing the water and the mixture; putting the obtained mixture into a brickmaking machine, adjusting the water content to be 10 to 12% so as to prepare adobes; putting the adobes into a dry kiln for drying and then into a roasting kiln for roasting, wherein the time for roasting is 48 to 55 hours and temperature in the process of roasting evenly increases from 100 DEG C to 1000 DEG C first and evenly decreases from 1000 DEG C to 100 DEG C next, and taking out the roasted adobes for cooling so as to obtain gangue perforated bricks. The gangue perforated brick prepared by the method has a hole density rate over 26%, produces holes of a circular shape, and has high strength and good weather resistance.

Owner:HENAN UNIV OF SCI & TECH

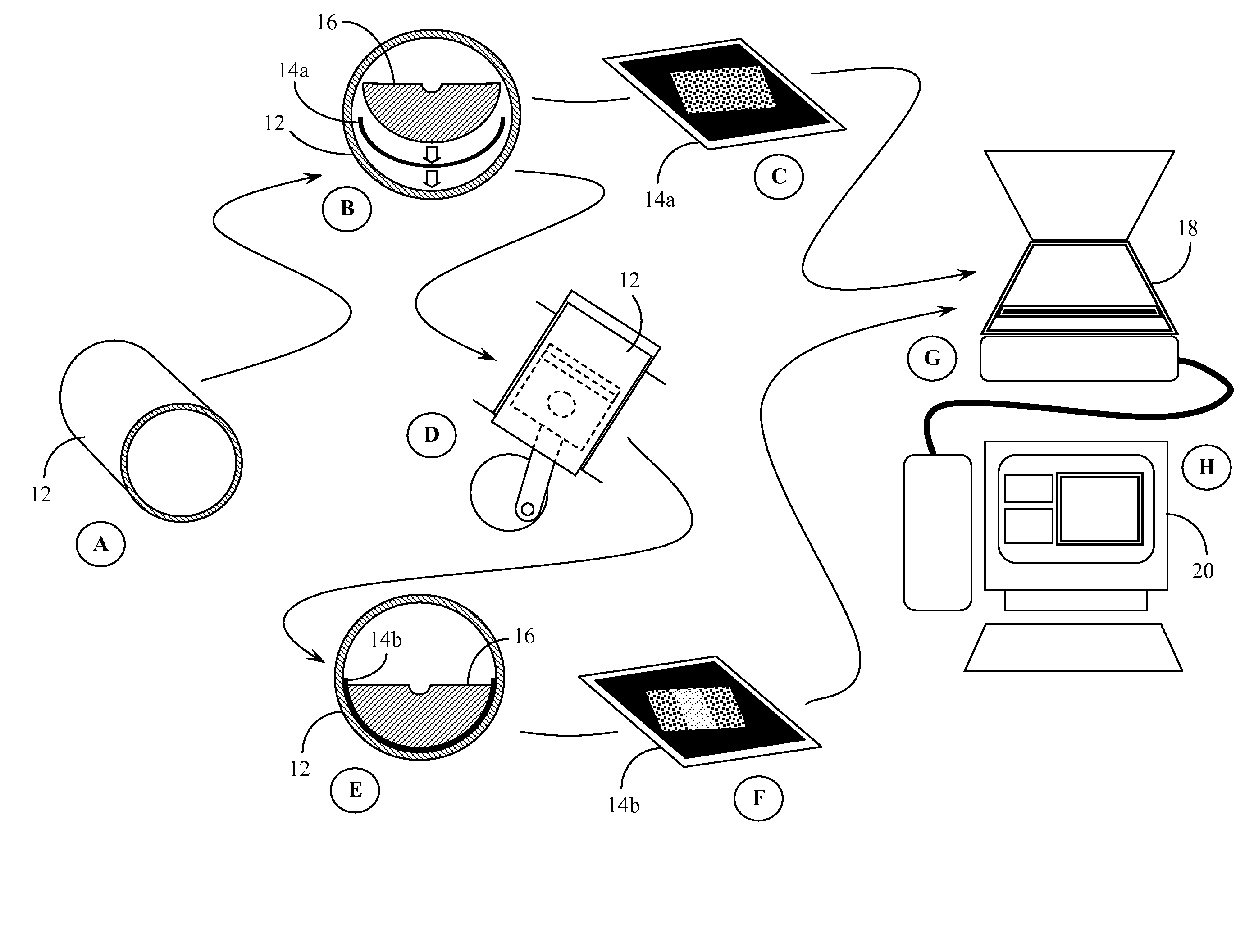

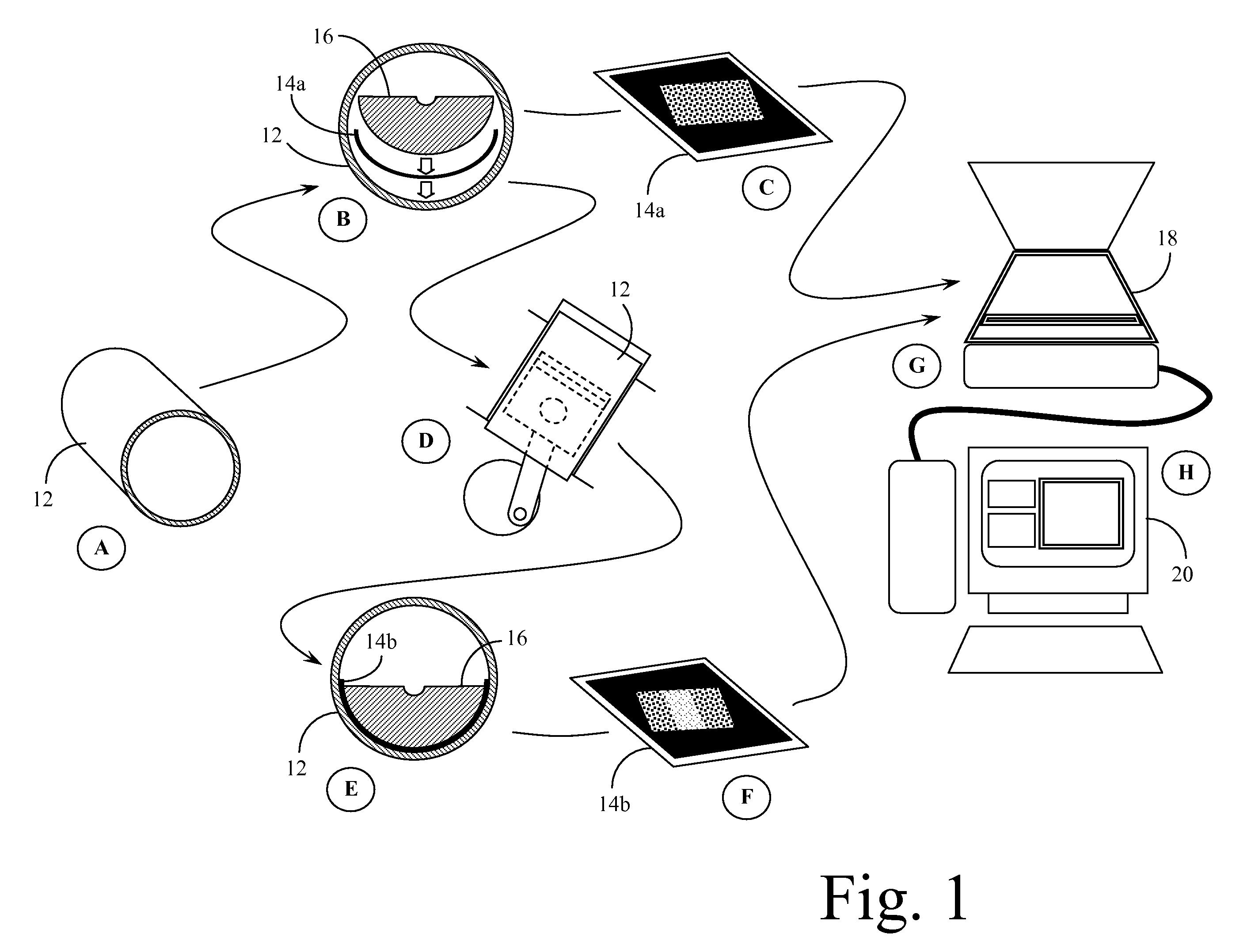

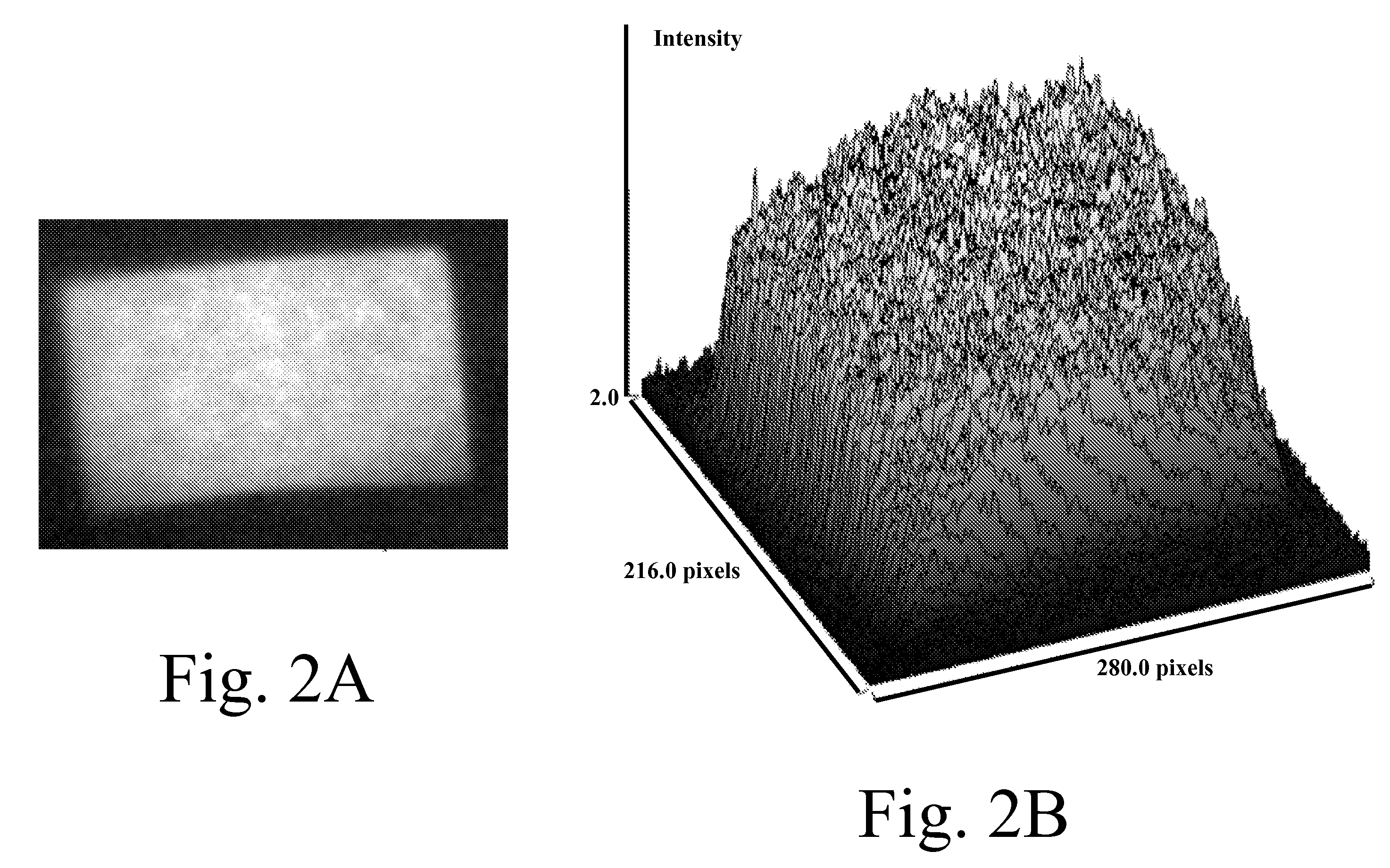

Autoradiography-based differential wear mapping

ActiveUS8050489B2Low radioactivityAvoid poor resultsElectric discharge tubesMaterial analysis by optical meansAutoradiographSurface layer

Methods and systems for the differential wear mapping of the surface of an object are described. The process involves establishing a radioactive wearing surface on the object through surface layer activation (SLA) and / or radioactive ion implantation (RII) and imaging the wearing surface with conformal photographic or x-ray film to produce a first autoradiograph providing a baseline profile of the wearing surface. After subjecting the object to wear during testing the wearing surface is again imaged with conformal photographic or x-ray film to produce a second autoradiograph providing a worn profile. The first and second autoradiographs of the wearing surface are digitized and compared to produce a differential wear map of the surface of the object.

Owner:SOUTHWEST RES INST

Method for recovery of stainless steel tailings and coal ash

The invention relates to a method for recovery of stainless steel tailings and coal ash, which comprises the following steps: first, the preparation of a base glass sample: I, mixing: mixing the following materials to be even; 33-42 stainless steel tailings, 10-23 coal ash, 25-35 quartz sand, 3-6 sodium carbonate and 3-5 barium oxide; II, melting: heating the mixture up to 1,400-1,500 DEG C until the mixture turns to glass metal, and preserving heat for 1.5-3h; III; pouring and annealing: pouring the glass metal into a stainless steel mould which is preheated to 600-700 DEG C, annealing for 1-2h under 650-700 DEG C; cooling along with the furnace, taking the mould out of the furnace and demolding the glass metal to the base glass sample; 2, nucleation and crystallization: heating the glass sample to 80-1030 DEG C for crystallization and then cooling the glass sample along with the furnace until the glass sample turns to a microcrystal glass sample; and 3, processing the microcrystal glass sample to be a finished product. The method makes use of the stainless steel tailings and the coal ash to produce microcrystal glass and thereby provides a novel approach for the recovery of stainless steel tailings.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

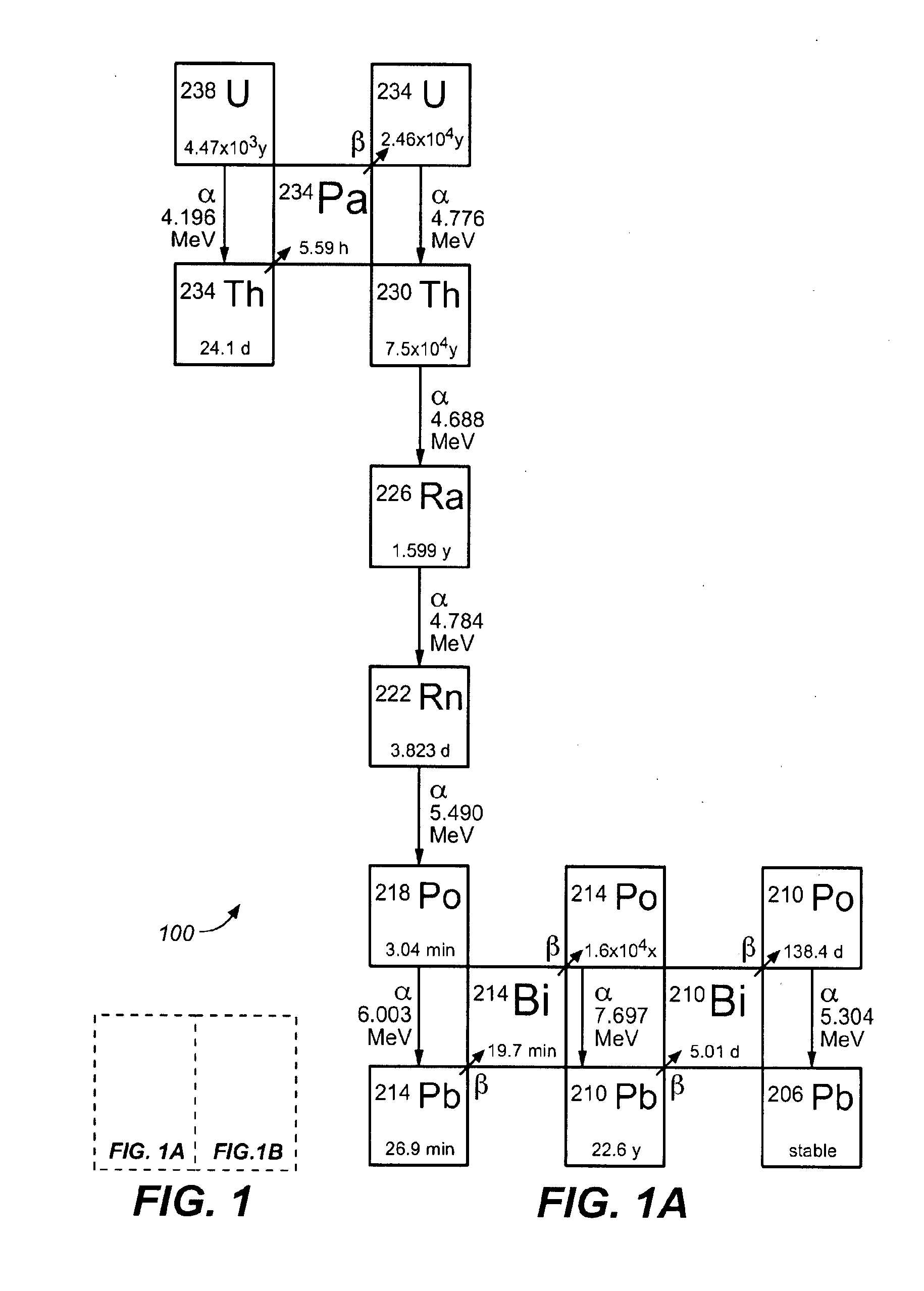

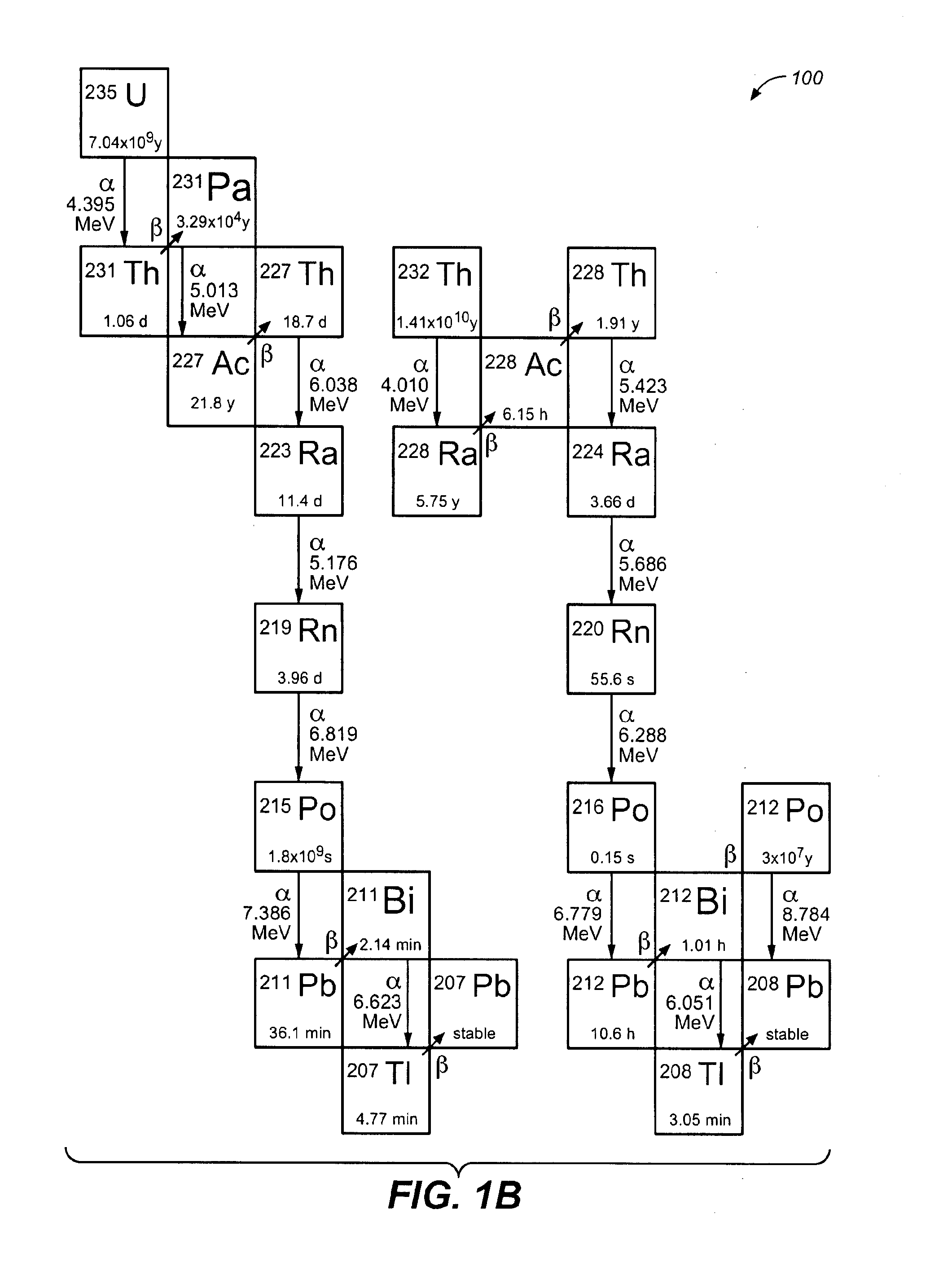

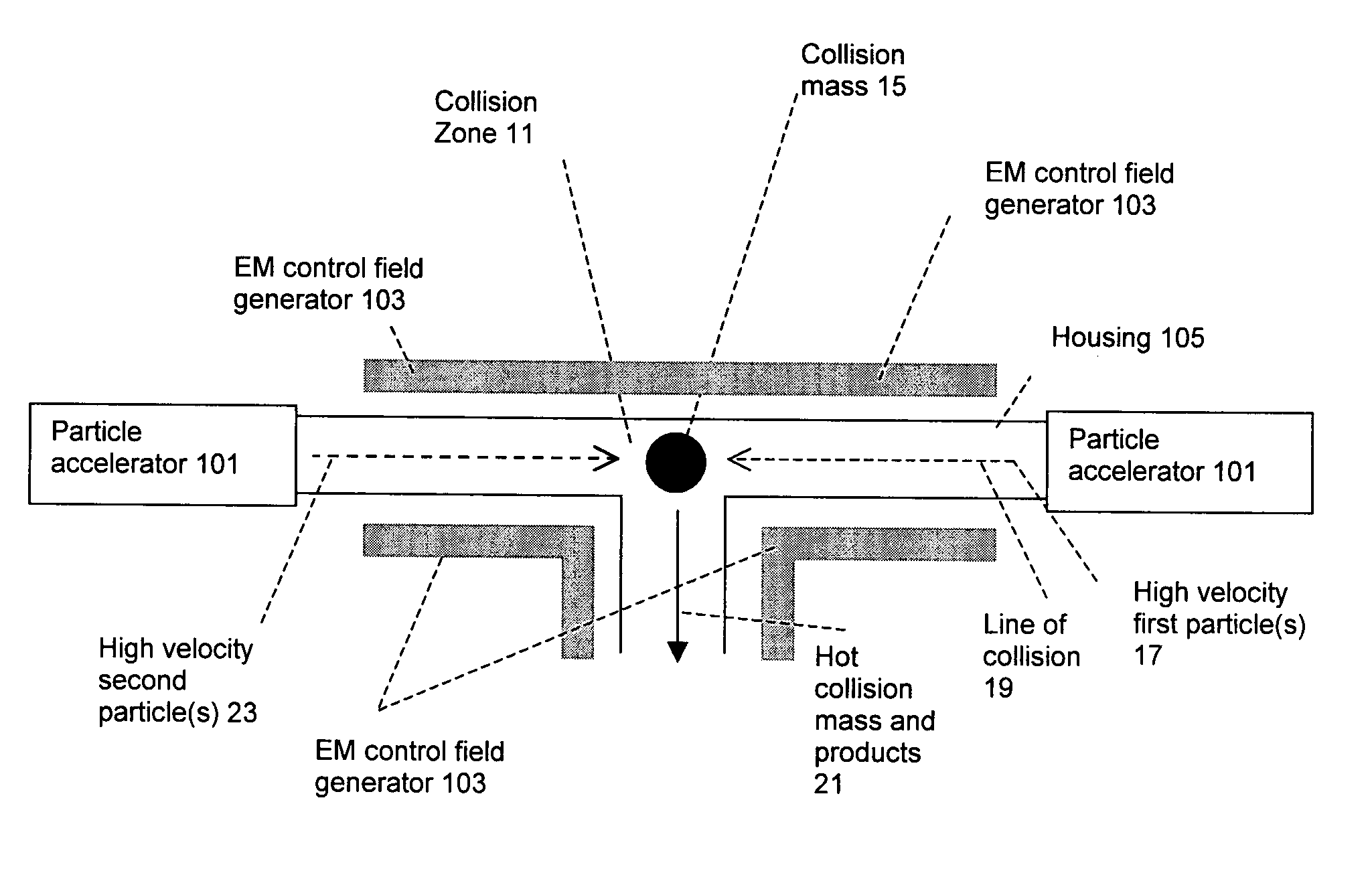

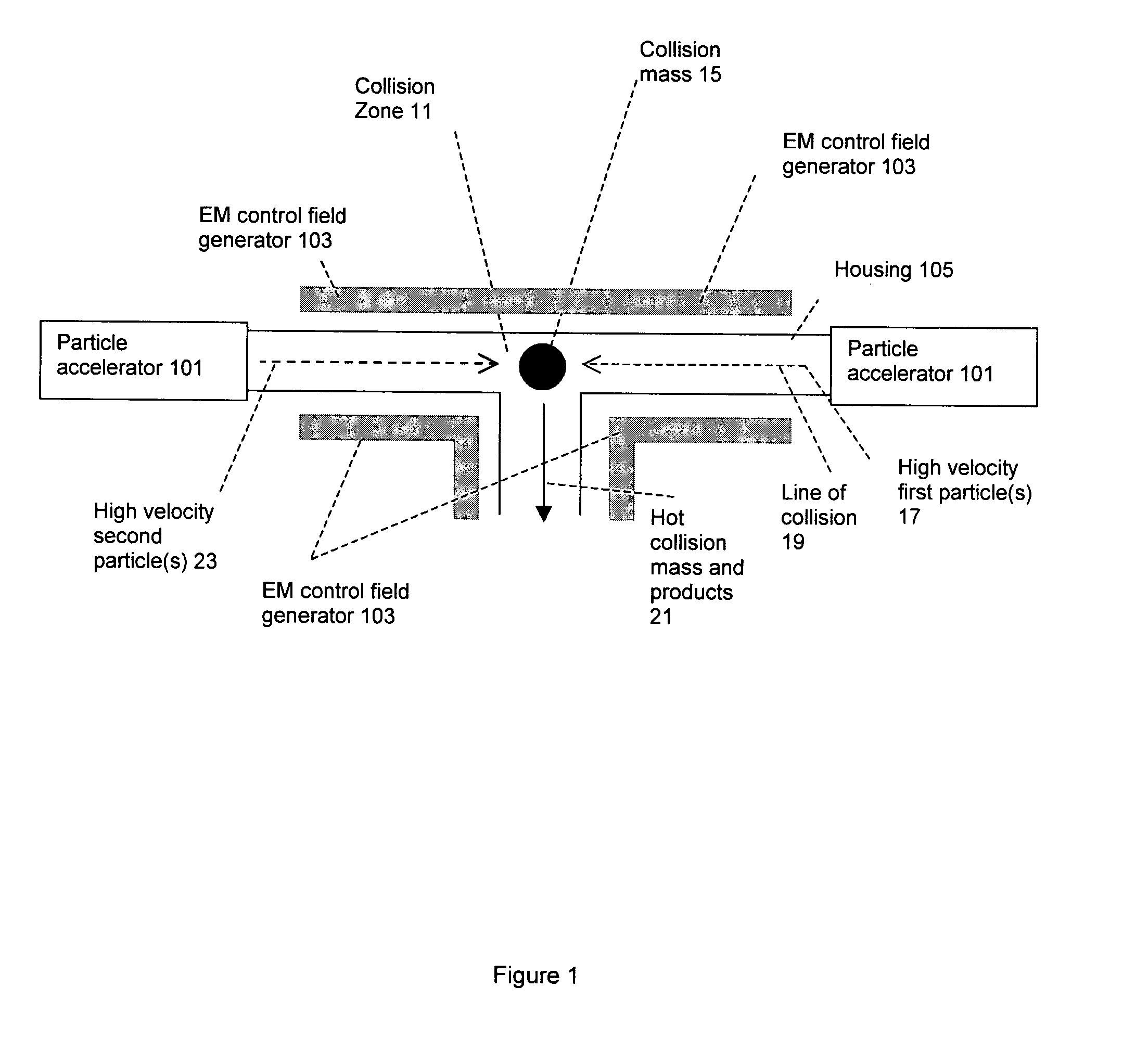

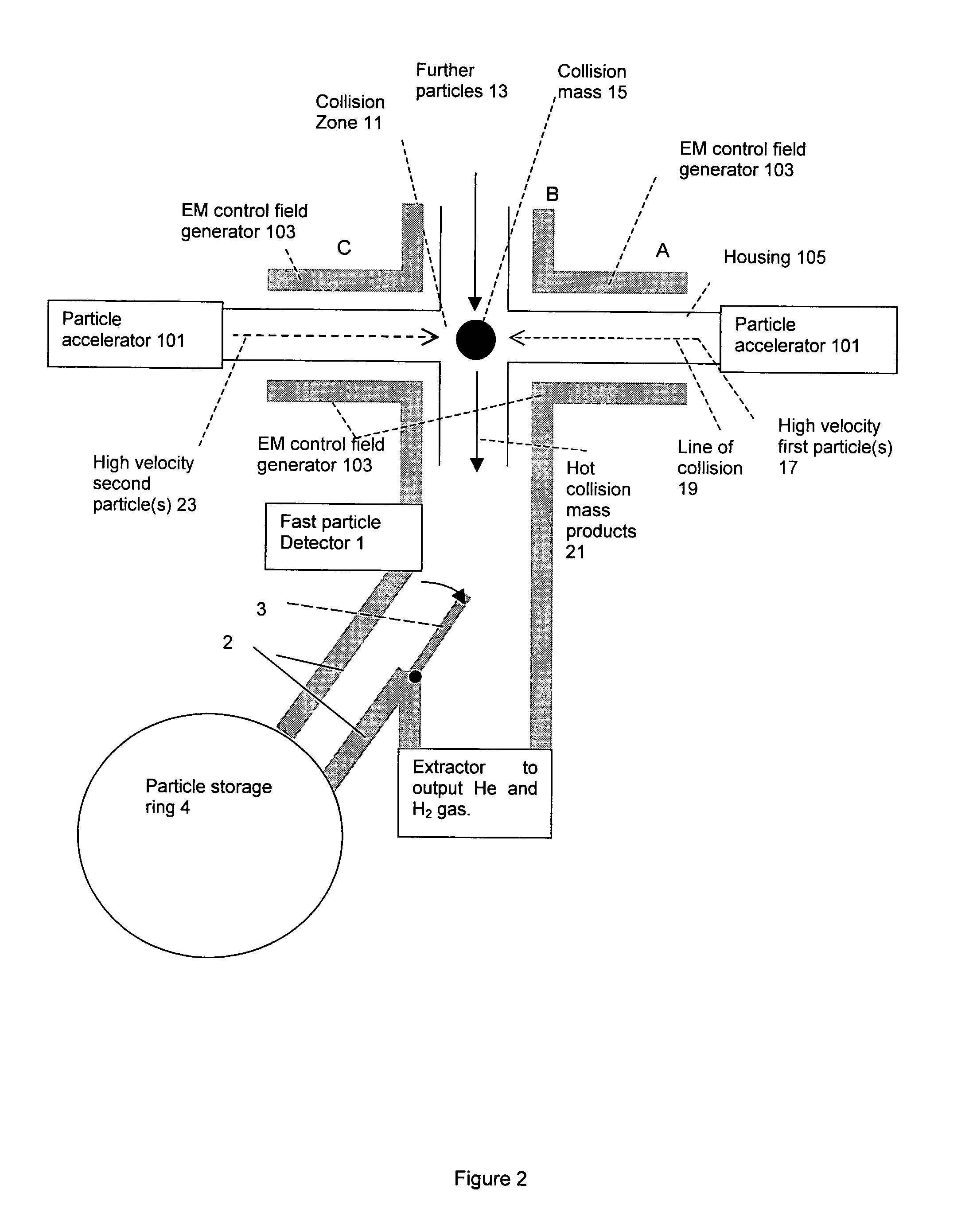

Method and apparatus for reducing the radioactivity of a particle

InactiveUS20100067639A1Low radioactivityReduce in quantityConversion outside reactor/acceleratorsNuclear energy generationAlpha particleProton

A method and apparatus for reducing the radioactivity of a particle is disclosed. The method comprises the steps of: accelerating one or more first particle(s) comprising one or more neutron(s), proton(s) and electron(s) to a first velocity; colliding the accelerated particles(s) with one or more second particles in a collision zone located within a housing causing the first particle(s) and second particle(s) to form one or more collision mass(es) comprising alpha particles and electrons or / and protons and electrons, and in which substantially all neutrons of the first or second particles are converted into alpha particles or / and protons and electrons as a result of the collision; controlling the position of the collision mass(es) with electric or / and magnetic fields; and exhausting the collision mass from the housing wherein the collision mass comprises substantially only alpha particles or / and protons and electrons.

Owner:STURT ALAN CHARLES

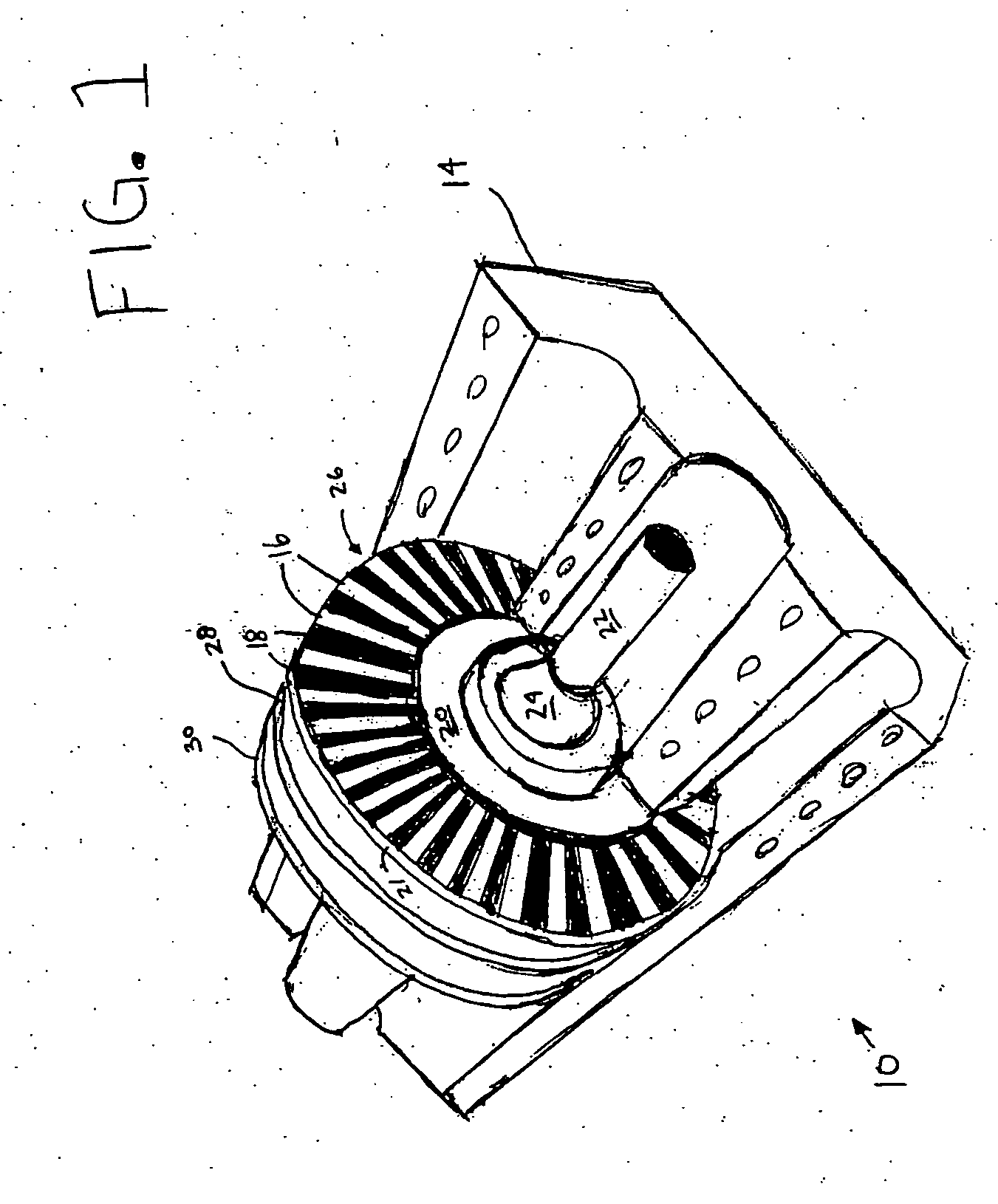

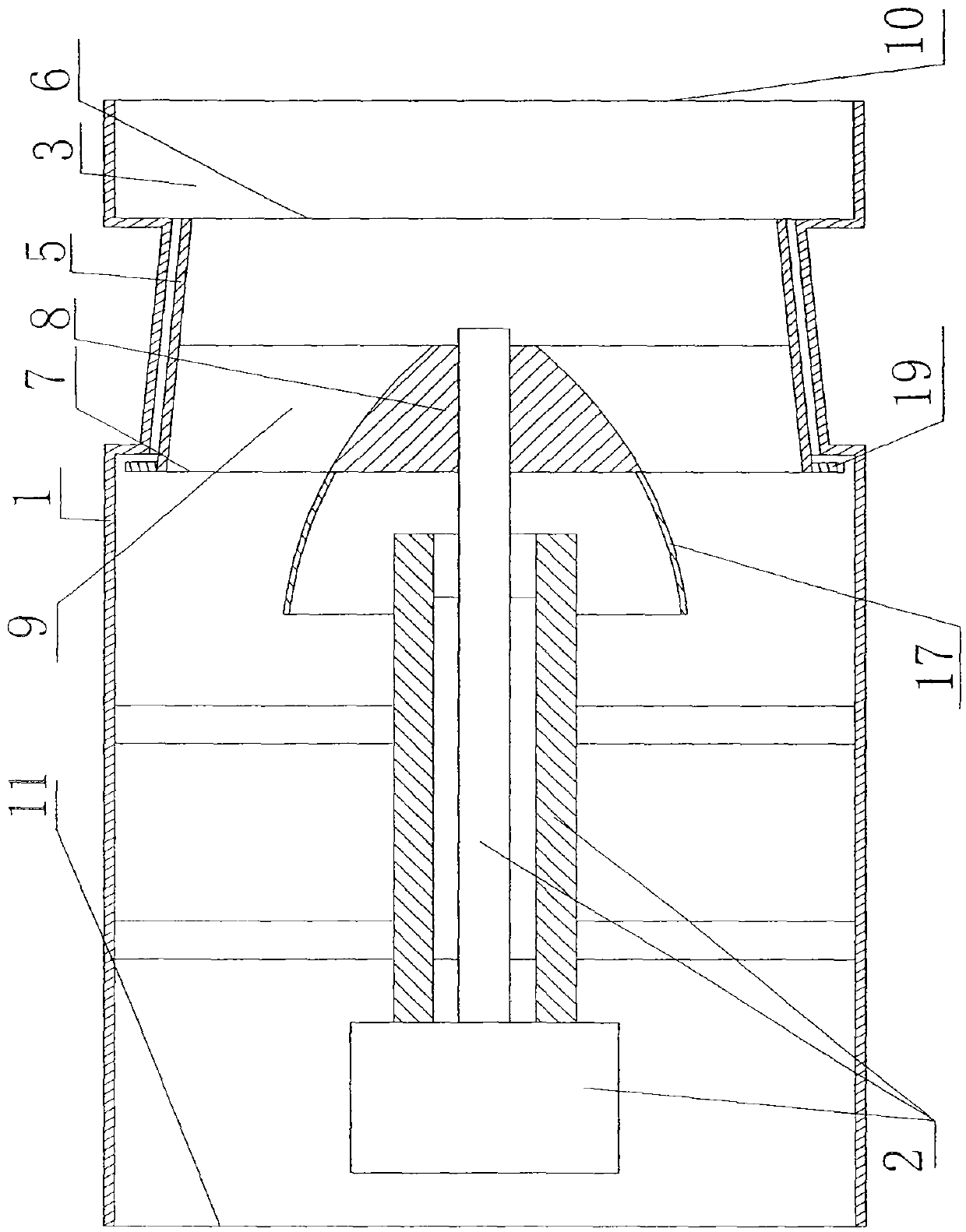

Axial flow device

InactiveCN102734175AUniform irrigationRealize micro-sprayPump componentsAxial flow pumpsImpellerSuction equipment

The invention provides an axial flow device comprising a shell and a transmission device. The shell is provided with the transmission device and is internally provided with a shell cavity; a vortex tube impeller is arranged in the shell cavity; the transmission device is connected with a vortex tube impeller; the vortex tube impeller is provided with a vortex tube which is provided with an impeller opening A and an impeller opening B and is internally provided with a wheel body, and the wheel body is provided with a guide blade; an inclined angle is formed between the guide blade and a rotating shaft of the vortex tube impeller; the guide blade is connected to the inner wall of the vortex tube; a shell cavity opening A is arranged at one end, which corresponds to the impeller opening A, of the shell cavity; and a shell cavity opening B is arranged at the other end of the shell cavity. The axial flow device is more energy-saving and can be used for pressurizing and conveying fluid. The axial flow device can serve as a water pump, vacuum equipment, air suction equipment, an air blower, a compressor, atomizing equipment, sprinkling equipment, a reactor, air blowing equipment, propelling equipment, a sewage processor, a dust remover, a dust collector, dressing equipment, a steam turbine, a water turbine, a wind turbine, a vortex pressurizing device utilizing residual heat of an engine, foam material manufacturing equipment, nano material manufacturing equipment and the like; and the axial flow device can be used for manufacturing a brand new foam material.

Owner:陈久斌

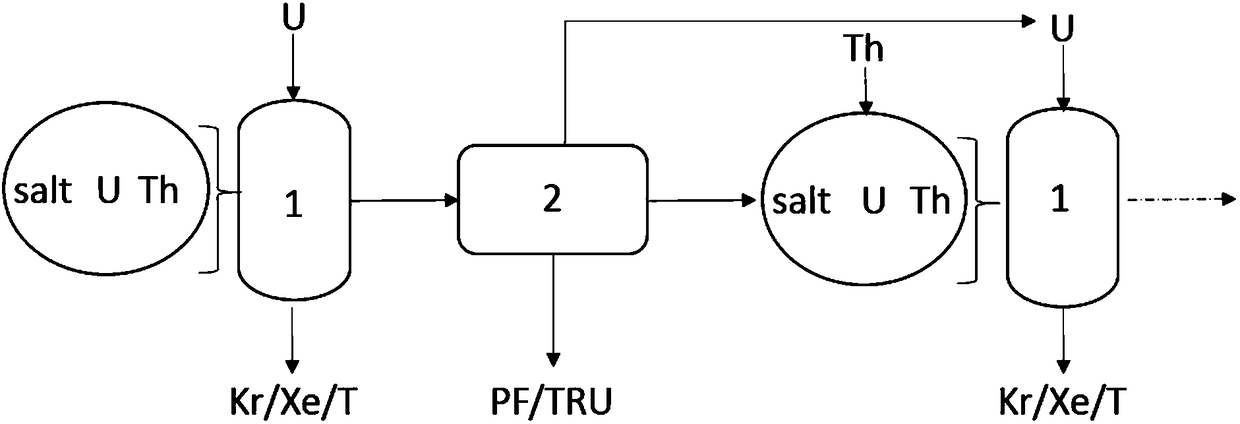

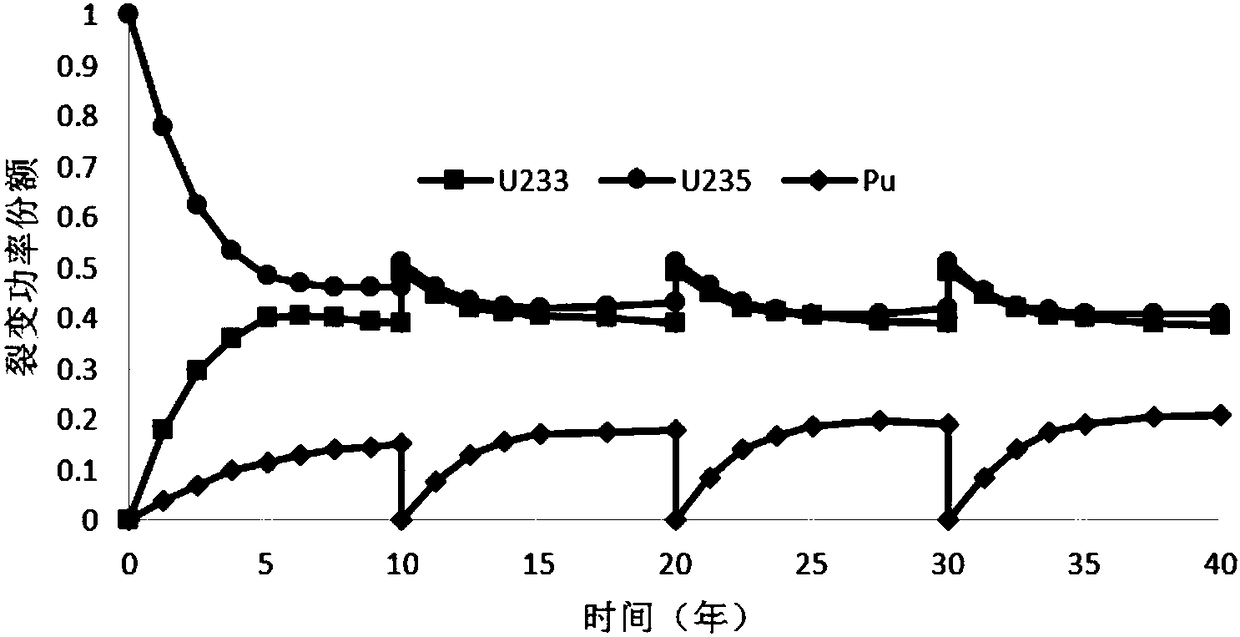

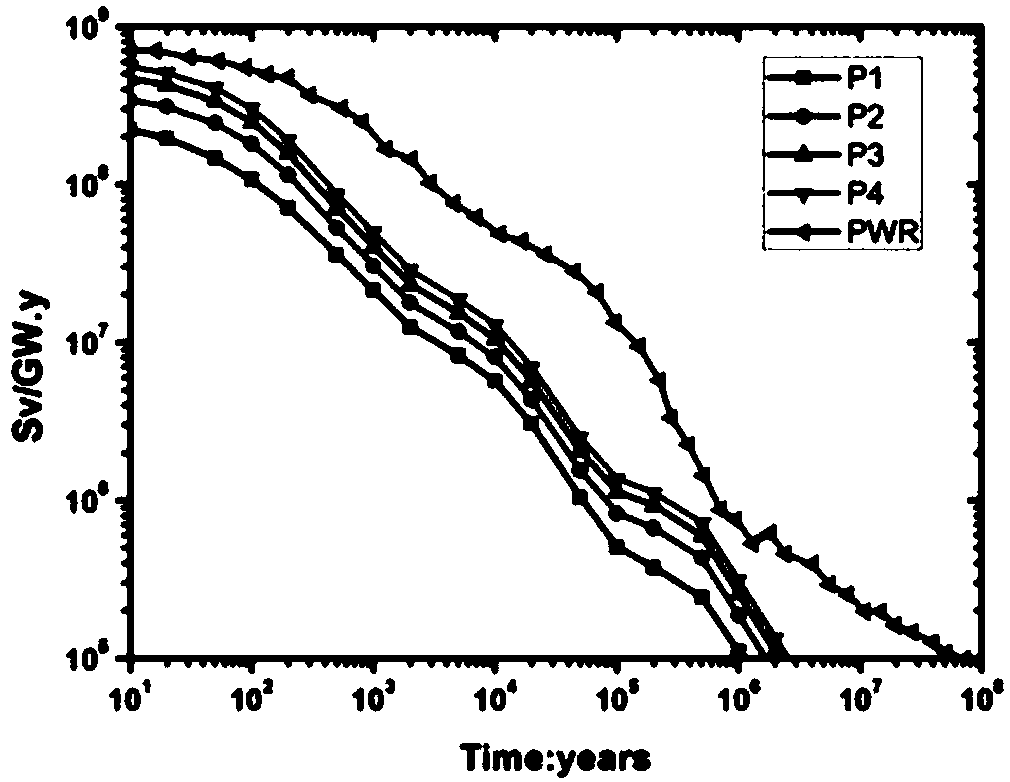

Molten salt reactor thorium fuel cyclic utilization method

InactiveCN108389634AIncrease profitLow radioactivityNuclear energy generationReactor fuel susbtancesEngineeringGraphite

The invention discloses a molten salt reactor thorium fuel cyclic utilization method. A reactor core comprises a graphite assembly and fuel molten salt, wherein the fuel molten salt is filled in a passage formed by the graphite assembly; the fuel molten salt comprises fuel salt and base salt; during operation, the on-line feeding is used; fission gas is cleared in a on-line way; reactor stopping off-line operation is performed, spent fuel is treated; recovered uranium, base salt and thorium are proportioned again and are then loaded into the reactor core for cyclic utilization, wherein the volume ratio of the fuel molten salt to the reactor core is 5 percent to 15 percent; the fuel salt is a mixture of ThF4 and UF4, wherein the U enrichment degree is 15 to 20 percent; the initial mole percentage of the fuel salt in the fuel molten salt is 6 percent to 8 percent; the initial mole percentage of ThF4 in the fuel salt is greater than 80 percent. The method has the advantages that under thecondition without depending an on-line treatment technology, the fission contribution of thorium fuel in the molten salt reactor is improved, so that the utilization rate of U-235 is improved; the radioactivity and the disposal quantity of the spent fuel are reduced.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

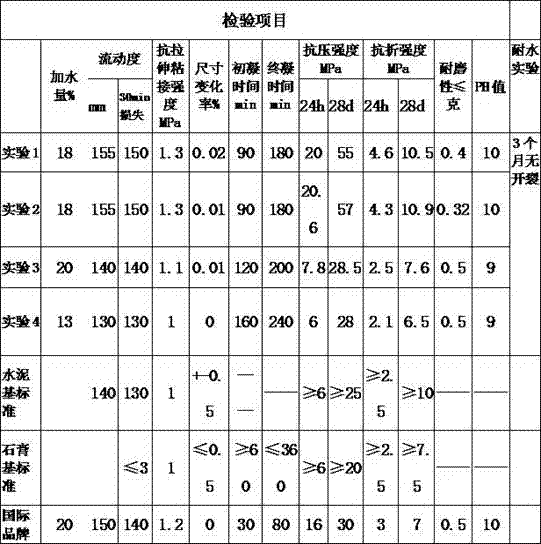

Novel self-leveling mortar and production technology thereof

The invention relates to novel self-leveling mortar and a production technology of the mortar. The mortar comprises the following components in percent by weight: 3-60% of modified cement, 10-66% of modified semi-hydrated gypsum, 0.1-8% of fly ash, 0.07-1.5% of a cement modifier, 0.05-1.5% of a gypsum modifier, 0.04-0.8% of a thickening time control agent, 0.01-0.1% of an anti-swelling agent, 0.01-0.2% of a stabilizer, 0.01-0.2% of a defoaming agent, 0.2-0.4% of toner, 0.05-0.13% of a smoother and 30-86% of aggregates. According to the novel self-leveling mortar, natural semi-hydrated gypsum and industrial solid gypsum are modified, and then subjected to modification and compounding with the fly ash and the cement to form a novel building material; a novel product which is better in production leveling property, higher in tensile strength, higher in compressive strength, adjustable in setting time, higher in construction efficiency, wide in application scope, low in cost and cracking-resistant is realized.

Owner:刘少伟

Reactor cooling treatment method after steam generator heat transfer pipe breakage accident

ActiveCN111540487ARadioactive release avoidanceRadioactive release noNuclear energy generationEmergency protection arrangementsNuclear engineeringPressurized water reactor

The invention discloses a reactor cooling treatment method after a steam generator heat transfer pipe breakage accident. The method is used for cooling and depressurizing a reactor to a cold shut-downstate after a steam generator heat transfer tube rupture accident occurs in a pressurized water reactor, and sequentially comprises the following steps: S1, stopping fluid leakage between a primary loop and a secondary loop after the accident, S2, cooling the primary loop by using a normally working steam generator, and reducing the pressure of the primary loop by using a pressure stabilizer on the primary loop, S3, when the pressure of the primary loop is lower than that of the secondary loop, reversely injecting a working medium on the secondary side of the damaged steam generator into theprimary side of the steam generator to further reduce the pressure and the temperature of the primary loop, and S4, connecting a residual heat removal system to enable the reactor to reach a cold shut-down working condition. By the adoption of the scheme, after an SGTR accident, cooling and pressure reduction are achieved, and meanwhile radioactive release can be eradicated or reduced to the minimum.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

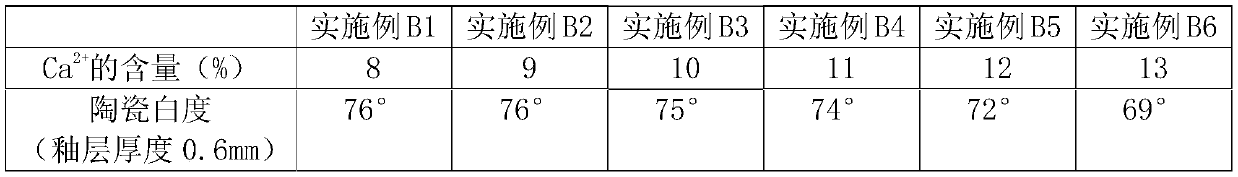

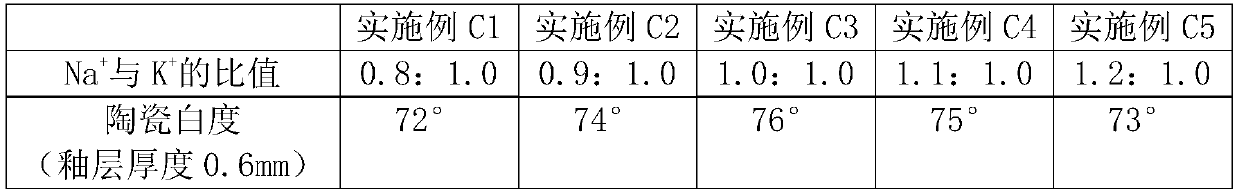

Low-zirconium white glaze for sanitary ceramic and preparation process of low-zirconium white glaze

The invention discloses a low-zirconium white glaze for a sanitary ceramic. The low-zirconium white glaze comprises the following raw materials in percentage by mass: 6.5-7.5% of zirconium silicate, 24-27% of quartz, 5-7% of kaolin, 2.5-3.5% of aluminum oxide, 12-18% of potassium feldspar, 9-15% of albite, 6-8.5% of calcite, 9-13% of wollastonite, 2-5% of dolomite, 2-3.5% of sintered talc, 2-3.5%of zinc oxide and 1.5-4% of frit. The low-zirconium white glaze is prepared by using a preparation process through operation of steps (1)-(3). Under a condition of a low zirconium silicate content, high glossiness, high ceramic whiteness, good high-temperature flowability and low radioactivity of the low-zirconium white glaze can be still maintained, and the low-zirconium white glaze has the effects of high glossiness, high ceramic whiteness, good high-temperature flowability and low radioactivity.

Owner:FOSHAN DONGPENG CERAMIC +3

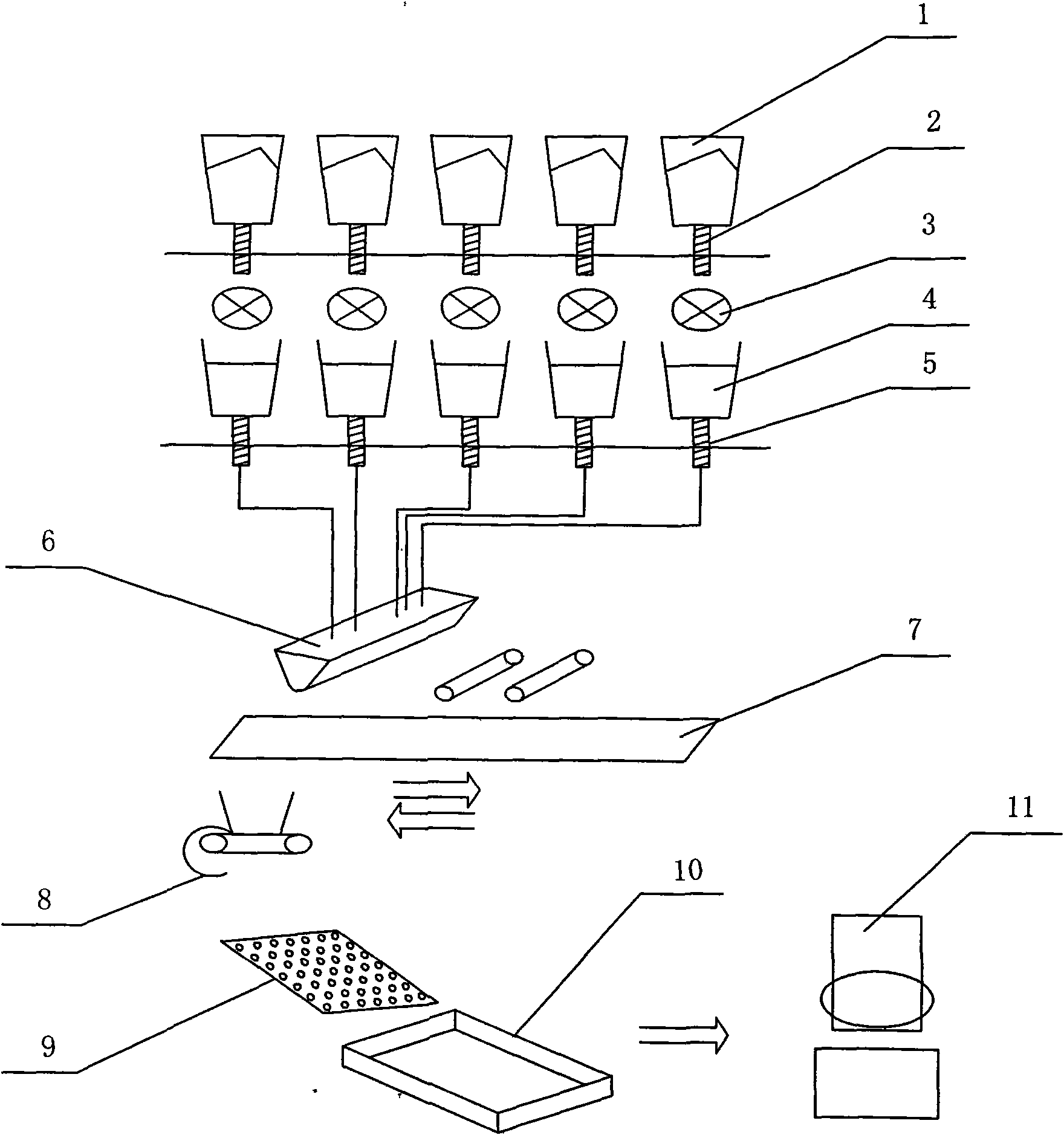

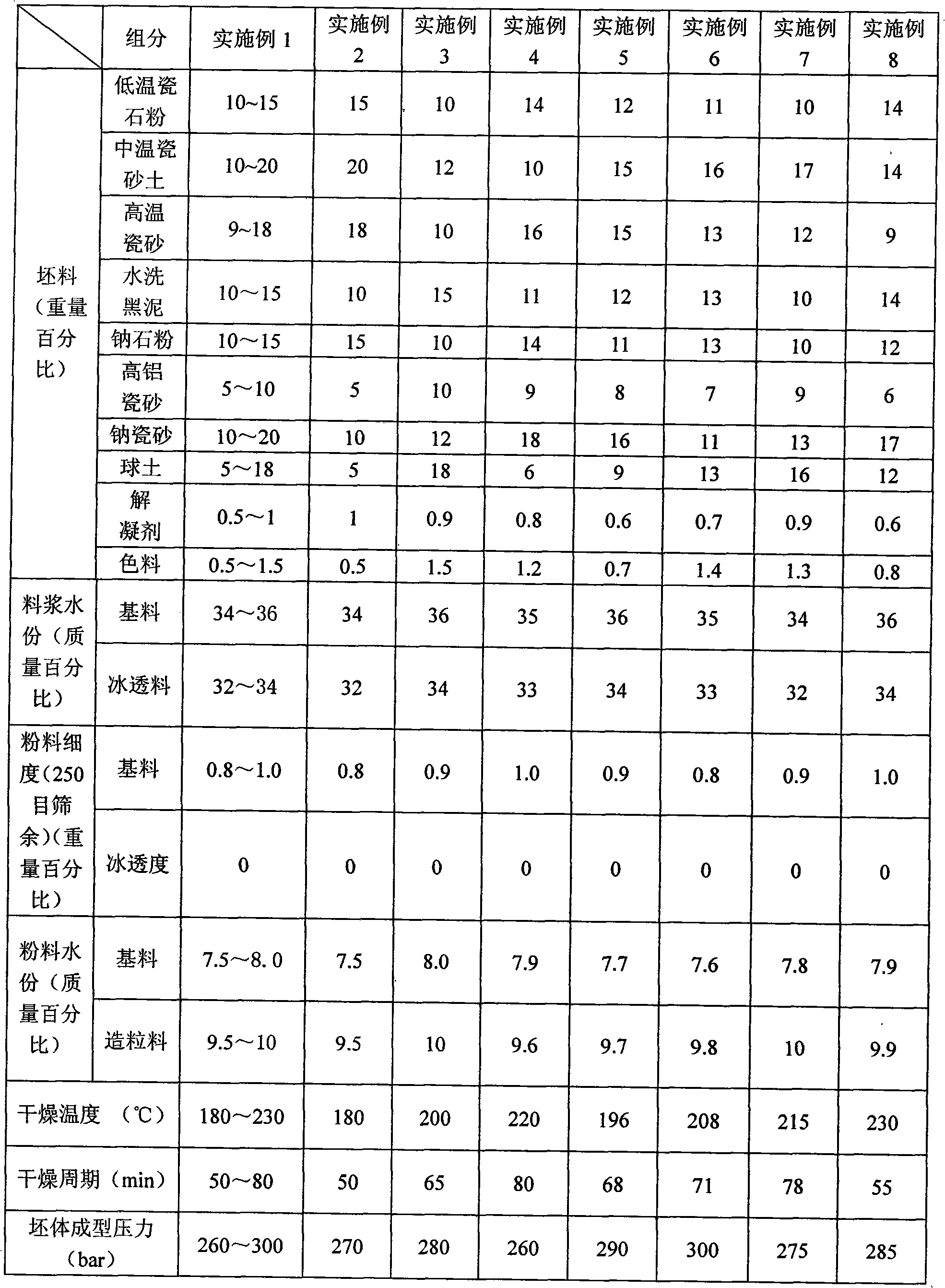

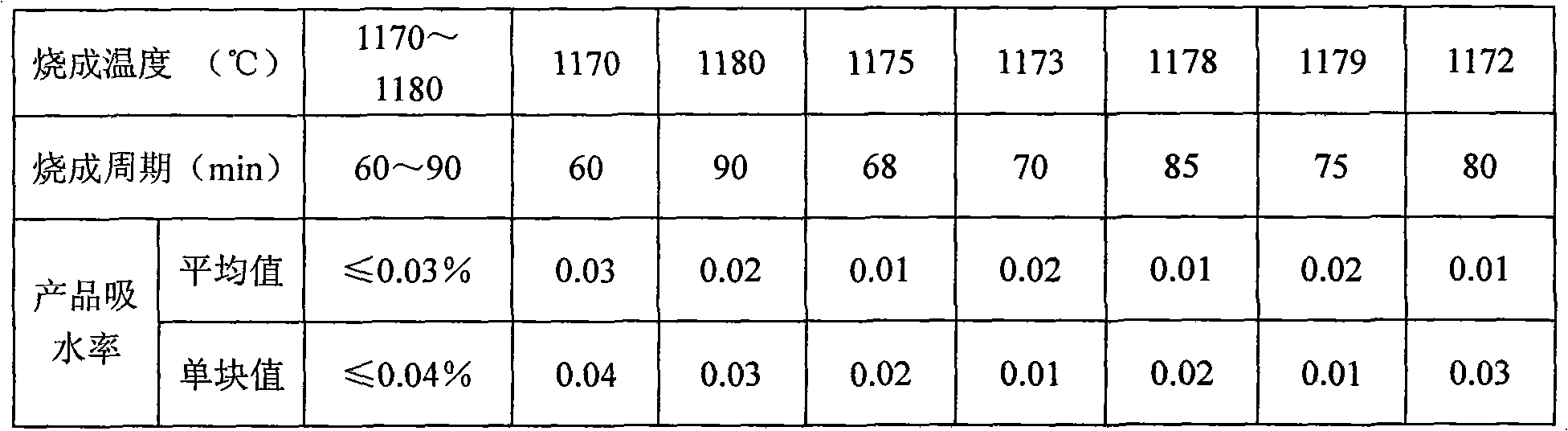

Method for manufacturing natural-like stone ceramic tile with clear color and luster and boundary

ActiveCN101613198AStrong stain resistanceLow water absorptionCeramic shaping apparatusClaywaresBall clayMoisture

The invention relates to a method for manufacturing a natural-like stone ceramic tile with clear color and luster and boundary. The ceramic tile comprises the following main raw materials in percentage by weight: 10 to 15 percent of low-temperature porcelain powder, 10 to 20 percent of medium-temperature porcelain sand soil, 9 to 18 percent of high-temperature porcelain sand, 10 to 15 percent of washed black mud, 10 to 15 percent of albite powder, 5 to 10 percent of alumina porcelain sand, 10 to 20 percent of sodium porcelain sand, 5 to 18 percent of ball clay, 0.5 to 1 percent of liquefaclent and 0.5 to 1.5 percent of pigment; a process flow of the manufacturing method comprises : material selection, material burdening, ball milling, toning, pulverization, cloth pressing, drying, sintering, polishing, sorting, packaging and warehousing; a sprayed micron antifouling coating process is added between a cloth pressing process and a drying process; the cloth pressing process comprises: powder crushing, full automatic computer-controlled vertical blanking, dropping of line micropowder cloth in a mould, distribution of a base material, and pressing and molding; slurry comprises the following components in percentage by moisture mass: 34 to 36 percent of base material and 32 to 34 percent of ice-thoroughly material; and powder (the fineness is about 250-mesh sieve ) comprises the following components in percentage by weight: 0.8 to 1.0 percent of base material and 0 percent of ice-thoroughly material.

Owner:广东能强陶瓷有限公司

Stone slab with patterns

The invention discloses a formula of a stone slab with artificial patterns. The formula comprises raw materials as follows: unsaturated polyester resin, a curing agent, quartz, glass fiber, color paste, an accelerant, a coupling agent, alloy powder, composite powder and water serving as a hydraulic bonding agent. The stone slab is energy-saving and environment-friendly due to the fact that the quartz and the glass fiber which are low in price and easy to obtain are taken as the raw materials of the formula and belongs to a novel environment-friendly building material, and various resources can be sufficiently used; the stone slab replaces natural quartz stone to serve as a high-grade decoration, over-exploitation of the natural quartz stone is effectively restrained, and environment protection and development of recycling economy and low-carbon economy are promoted; the stone slab has the advantages of non-toxic, tastelessness, non-radiation, no microcellular structure, dirt resistance, easiness in maintenance and high processability and can has a good lighting effect by the aid of projection of common light.

Owner:ZHUHAI SESALI HEALTH STONE CO LTD

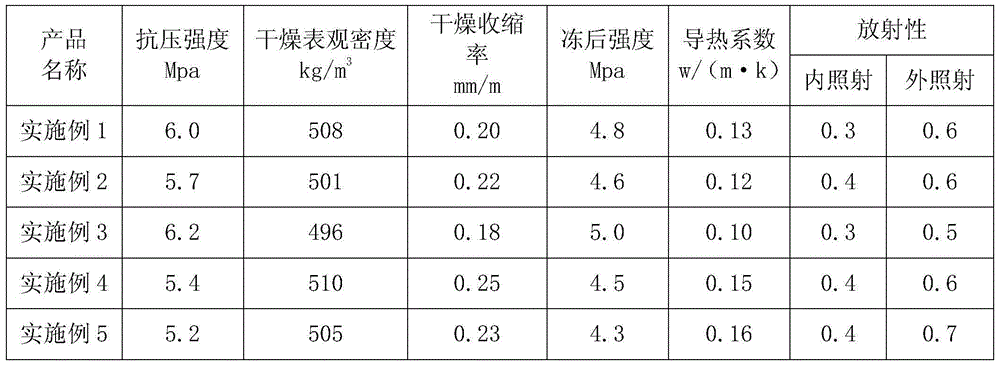

Aerated concrete block produced by dump-leached slags

ActiveCN103819217AGood weather resistanceHigh strengthSolid waste managementCeramicwareSlagSuperplasticizer

The invention relates to an aerated concrete block produced by dump-leached slags. The block comprises the following raw materials in parts by weight: 200 to 500 parts of dump-leached slags, 80 to 150 parts of quick lime, 50 to 200 parts of cement, 3 to 10 parts of gypsum, 0.4 to 1.2 parts of aluminium powder and 8 to 15 parts of superplasticizer, wherein the dump-leached slags are waste residues formed after silicate minerals are processed by acid. The aerated concrete block has the advantages of light weight, high strength, heat preservation, heat insulation and the like, utilizes wastes, is environmental-friendly, saves resources and is a green building material with excellent performance.

Owner:广西建筑材料科学研究设计院有限公司 +1

Tile with high whole body whiteness

ActiveCN105330256AConsistent whitenessImprove the decorative effectClaywaresAdditive ingredientWhole body

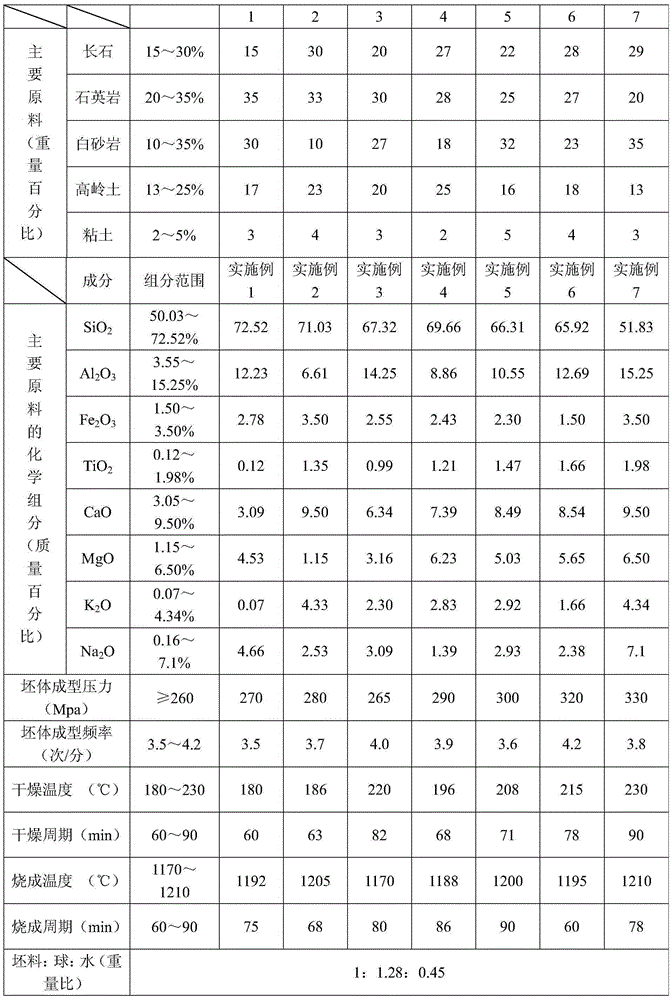

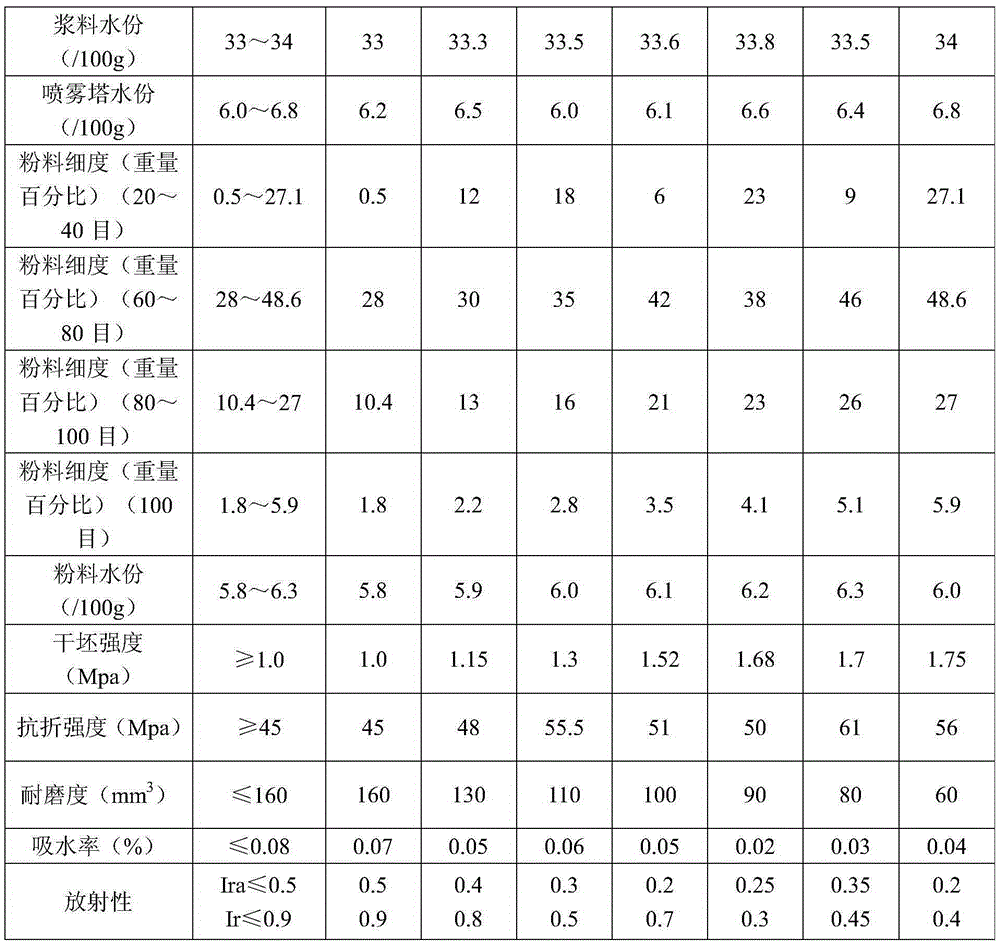

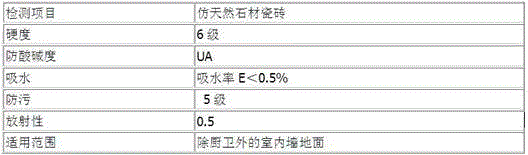

The invention discloses a tile with high whole body whiteness. The tile is prepared from the following main raw materials in percentage by weight: 15 to 30% of feldspar, 20 to 35% of quartzite, 10 to 35% of white sandstone, 13 to 25% of kaolin and 2 to 5% of clay. The main raw materials comprise the following chemical components in percentage by mass: 52.03 to 72.52% of SiO2, 3.55 to 15.25% of Al2O3, 1.50 to 3.50% of Fe2O3, 0.12 to 1.98% of TiO2, 3.05 to 9.50% of CaO, 1.15 to 6.50% of MgO, 0.07 to 4.34% of K2O and 0.16 to 7.1% of Na2O. A preparation method of the tile comprises the following steps: purchasing the raw materials, selecting the raw materials, making a formula, ball milling ingredients, preparing slurry, ageing the slurry, sieving and removing iron, spray drying, preparing powder, ageing the powder, distributing the powder, arranging a material, pressing and forming, drying, firing, edging, classifying, packing and putting products in a storehouse. The tile with the high whole body whiteness adopts the northern local raw materials, is smooth in texture, high in whole body whiteness, low in radioactivity and long in service life, and is energy-saving and environmentally-friendly.

Owner:内蒙古建亨能源科技有限公司

Natural stone imitated ceramic tile with clear color, luster and boundary and manufacturing method of natural stone imitated ceramic tile

ActiveCN106365612AUnique surface decoration effectHigh hardnessFeeding arrangmentsAuxillary shaping apparatusCanyonMetallurgy

The invention provides a natural stone imitated ceramic tile with clear color, luster and boundary and a manufacturing method of the natural stone imitated ceramic tile, and belongs to the technical field of building materials. The natural stone imitated ceramic tile is characterized in that a raw material formula contains ultrafine transparent powder; multi-pipeline material distribution and a plurality of types of slightly rubbing and laying are applied; a product is finely forged through four core technologies including vivid material distribution, color paste sketching, transparent material filling and dust particle deduction; natural vein effects including mountains, rivers and geographical positions, lava block masses, canyon ground cracks, crushed stone dispersion and the like are formed on the surface of the prepared product; natural scenes of rising, falling and stretching, repeated turning and being dangerously steep and elegant of a great canyon are perfectly imprinted, and extremely fine craftsmanship of the nature is extremely restored.

Owner:山东狮王陶瓷有限公司

Soft ceramic wall surface composite material and preparation method thereof

The invention belongs to the technical field of building walls and discloses a soft ceramic wall surface composite material. The soft ceramic wall surface composite material is prepared from, by mass,10-35 parts of polymer emulsion, 25-65 parts of inorganic filler, 0.1-0.2 part of a wetting agent, 0.2-0.4 part of an antifoaming agent, 0.1-0.3 part of cellulose, 10-15 parts of deionized water and0.1-0.3 part of polyvinyl alcohol fibers. The soft ceramic wall surface composite material has advantages of high water-repellency breathability, light weight, flexibility, acid-base resistance, freeze thawing resistance, aging resistance, quake resistance, crack resistance and high exterior wall external insulation system compatibility. The soft ceramic wall surface composite material overcomes potential safety hazards including proneness to falling to hurt people and the like of traditional ceramic tiles, mosaics and the like and is especially suitable for serving as an exterior wall facingmaterial for high-rise buildings and exterior wall external insulation systems. Especially, the soft ceramic material can be adhered directly to an old wall without knocking off old ceramic tiles andmosaics in old wall renovation or space renovation.

Owner:广东福莱特建筑材料有限公司

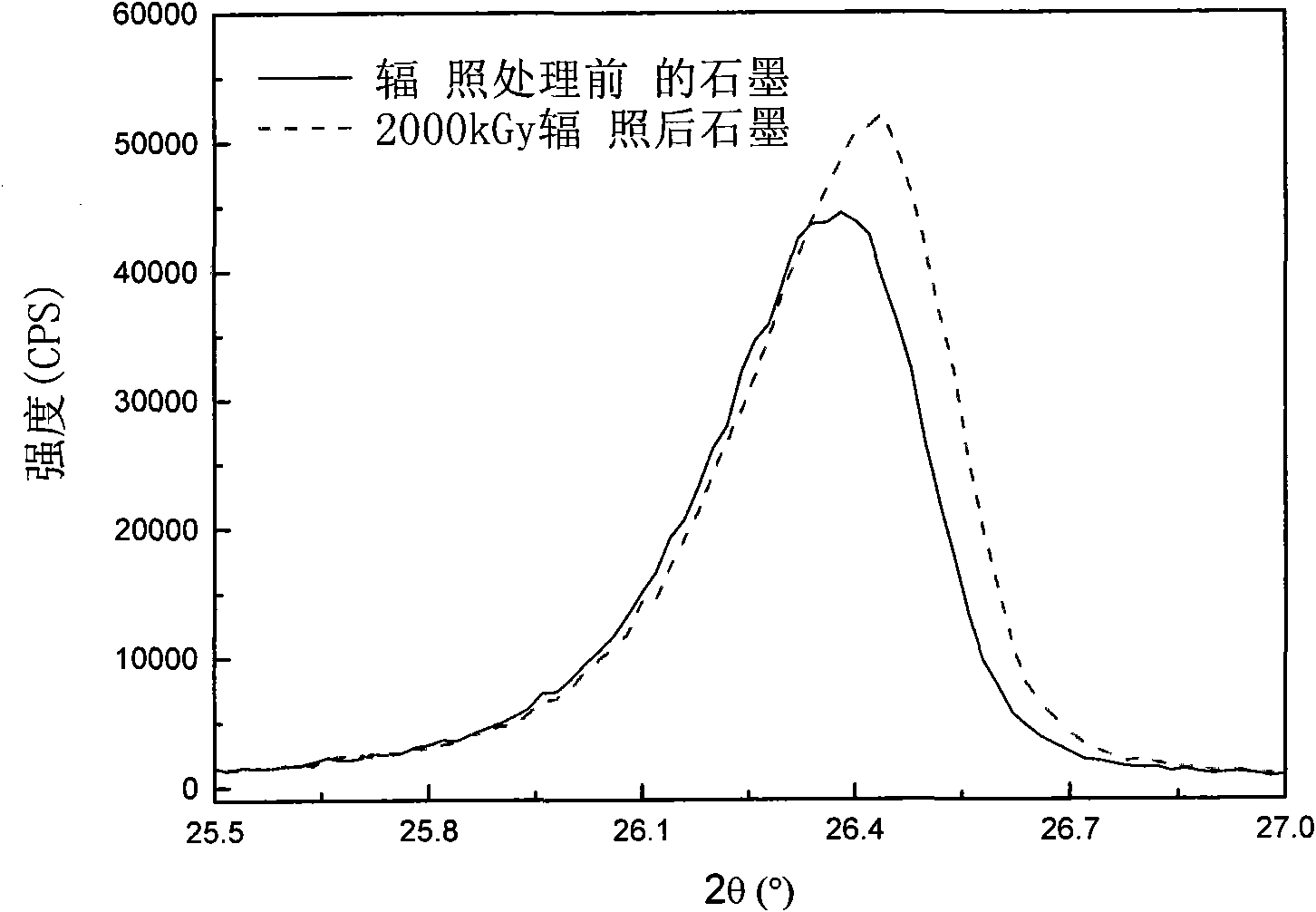

Method for improving degree of graphitization of graphite material

he invention relates to a method for improving degree of graphitization of graphite material, T comprising: the graphite material is placed inside a gamma ray radiation source chamber of Co and processed by gamma ray radiation under the conditions that the gamma ray radiation dose rate is 0.6*10Gy / h-6*10Gy / h, and the irradiation dose is 1*10Gy-6*10Gy. The method for improving the degree of graphitization of the graphite material utilizes the characteristics of high energy and strong penetrating power of gamma ray particles to initiate active points inside the graphite material, and leads the active points to react with medium around the material; meanwhile, the energy provided by the gamma ray is utilized to generate carbon free radicals at the defect part inside the graphite material, and stabler chemical bond can be formed among the carbon free radicals, thus the structure at the defect part inside the graphite material is rearranged to form stabler structure, the distance between graphite wafers becomes smaller and smaller, the microcrystal size in enlarged, and the degree of graphitization is improved.

Owner:TIANJIN POLYTECHNIC UNIV

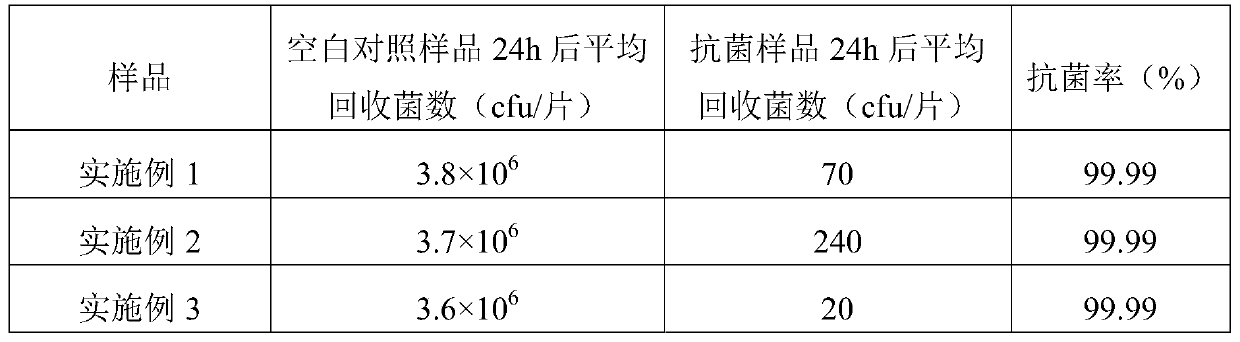

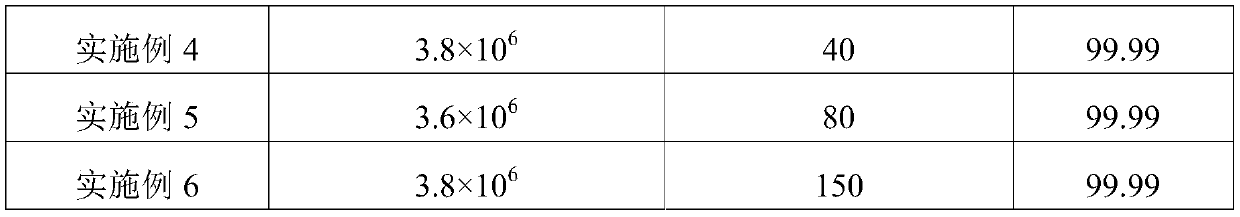

Long-service-life organic silicon polymer antibacterial liquid, preparation method thereof and preparation method of antibacterial coating

ActiveCN110054993AOvercome adhesionAchieve antibacterial and antifungal effectsAntifouling/underwater paintsPaints with biocidesSilanesAntibacterial coating

The invention belongs to the field of antibacterial materials and discloses long-service-life organic silicon polymer antibacterial liquid, a preparation method thereof and a preparation method of antibacterial coating. The long-service-life organic silicon polymer antibacterial liquid comprises, by weight, 60-80 parts of organosilicon quaternary ammonium salt, 3-8 parts of glacial acetic acid, 5-10 parts of methyltris(methylethylketoximino)silane, 0.1-3 parts of organic bismuth catalyst and 10-20 parts of amino-alkyl alkoxy silane. The organic silicon polymer antibacterial and anti-mildew liquid is simple in preparation process, safe, nontoxic, green, environmentally friendly, lasting and high in antibacterial effect, long in service life and capable of satisfying the living space requirements of safety, health and cleanness and conforms to the green and environment-friendly consumption concept of people.

Owner:筑迹(深圳)创新健康科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com