Natural stone imitated ceramic tile with clear color, luster and boundary and manufacturing method of natural stone imitated ceramic tile

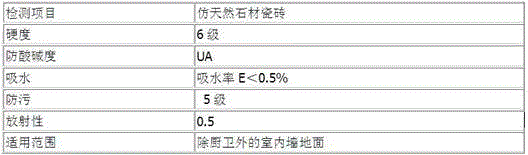

A technology for imitating natural stone and ceramic tiles, which is applied in the field of preparing imitation natural stone tiles, can solve the problems of chaotic colors, blurred boundaries, uneven cloth, etc., and achieves the effects of strong layering, high density and lower firing temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

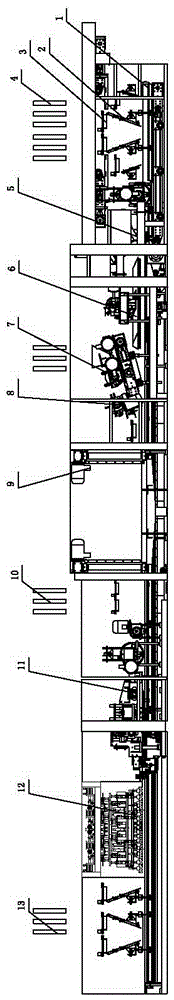

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of fabric slurry: According to the conventional method, talc, pyrophyllite, soft soil, quartz, albite, potassium albite, ball soil, ultra-permeable powder, water ingredients, and ball milling are used to prepare imitation natural stone tile body The fabric mud is used for standby; wherein the ultra-permeable powder is proportioned according to the following parts by weight: low-temperature feldspar: 35 parts, soft soil: 5 parts, ball soil: 18 parts, frit powder: 45 parts; wherein the frit powder is as follows Proportioning ingredients by weight: 17 parts of feldspar, 28 parts of quartz, 6 parts of zinc oxide, 12 parts of dolomite, 5 parts of potassium nitrate, 24 parts of borax, 2 parts of potassium carbonate;

[0035] (2) Pigment slurry preparation: Add golden yellow, orange yellow, coral red and other colorants to the fabric prepared by ball milling, and mix into low-temperature light yellow, low-temperature deep yellow, high-temperature yellow, super t...

Embodiment 2

[0055] Compared with Example 1, the types of raw materials are different, and the preparation process is the same, but the specific parameters of the preparation process are different, and the performance indicators of the obtained products are slightly different. The similarities will not be repeated, and the differences are as follows:

[0056] (1) Preparation of fabric slurry: According to the conventional method, talc, pyrophyllite, soft soil, potassium sodium feldspar, ball clay, cooked coke, ultra-permeable powder, water ingredients, and ball milling are used to prepare the natural stone tile body fabric slurry, Standby; wherein the proportioning ingredients in the ultra-permeable powder are according to the following parts by weight: low-temperature feldspar: 45 parts, soft soil: 11 parts, ball soil: 8 parts, frit powder: 35 parts; wherein the frit powder is in the following parts by weight Ingredients: 19 parts of feldspar, 30 parts of quartz, 8 parts of zinc oxide, 8 p...

Embodiment 3

[0064] Compared with Example 1, the types of raw materials are different, and the preparation process is the same, but the specific parameters of the preparation process are different, and the performance indicators of the obtained products are slightly different. The similarities will not be repeated, and the differences are as follows:

[0065] (1) Preparation of fabric slurry: According to conventional methods, talc, pyrophyllite, soft soil, quartz, albite, potassium albite, ball soil, ultra-permeable powder, water ingredients, and ball milling are used to prepare imitation natural stone tile body fabrics Slurry, for subsequent use; wherein the proportioning ingredients in the ultra-permeable powder are as follows: low-temperature feldspar: 40 parts, soft soil: 8 parts, ball soil: 11 parts, frit powder: 40 parts; wherein the frit powder is as follows Proportioning ingredients in parts by weight: 18 parts of feldspar, 29 parts of quartz, 7 parts of zinc oxide, 10 parts of dol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com