Separation of radium and rare earth elements from monazite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

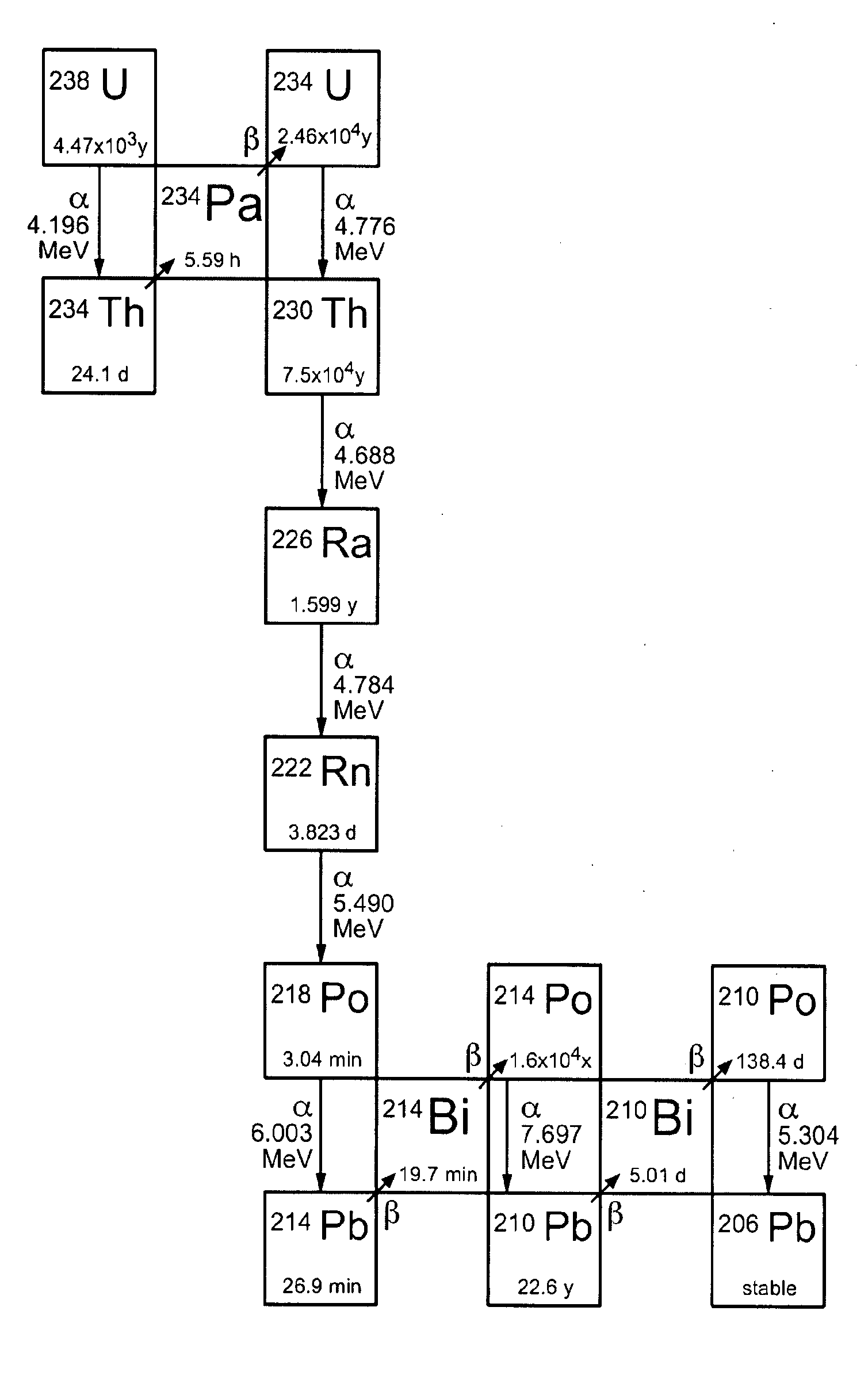

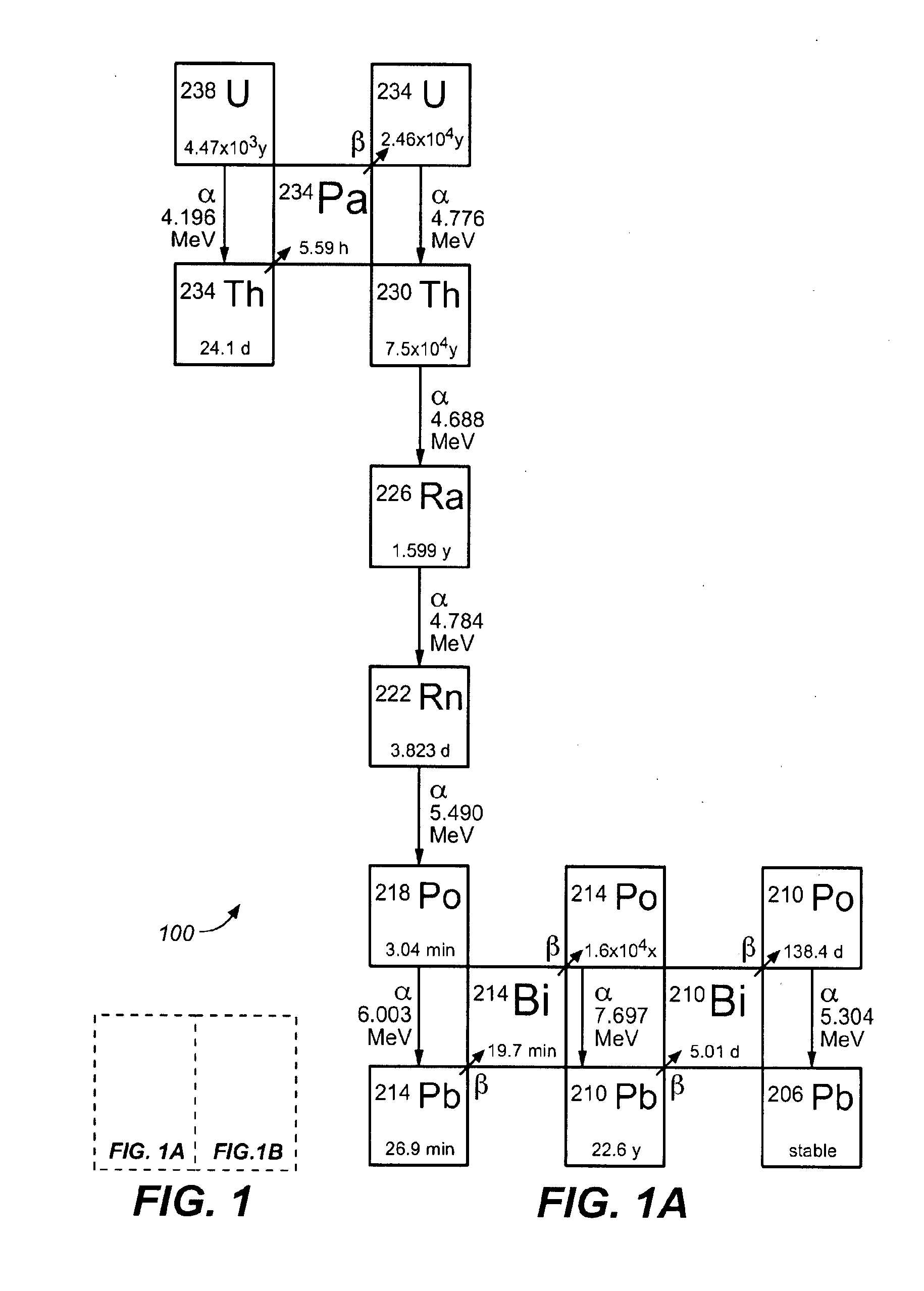

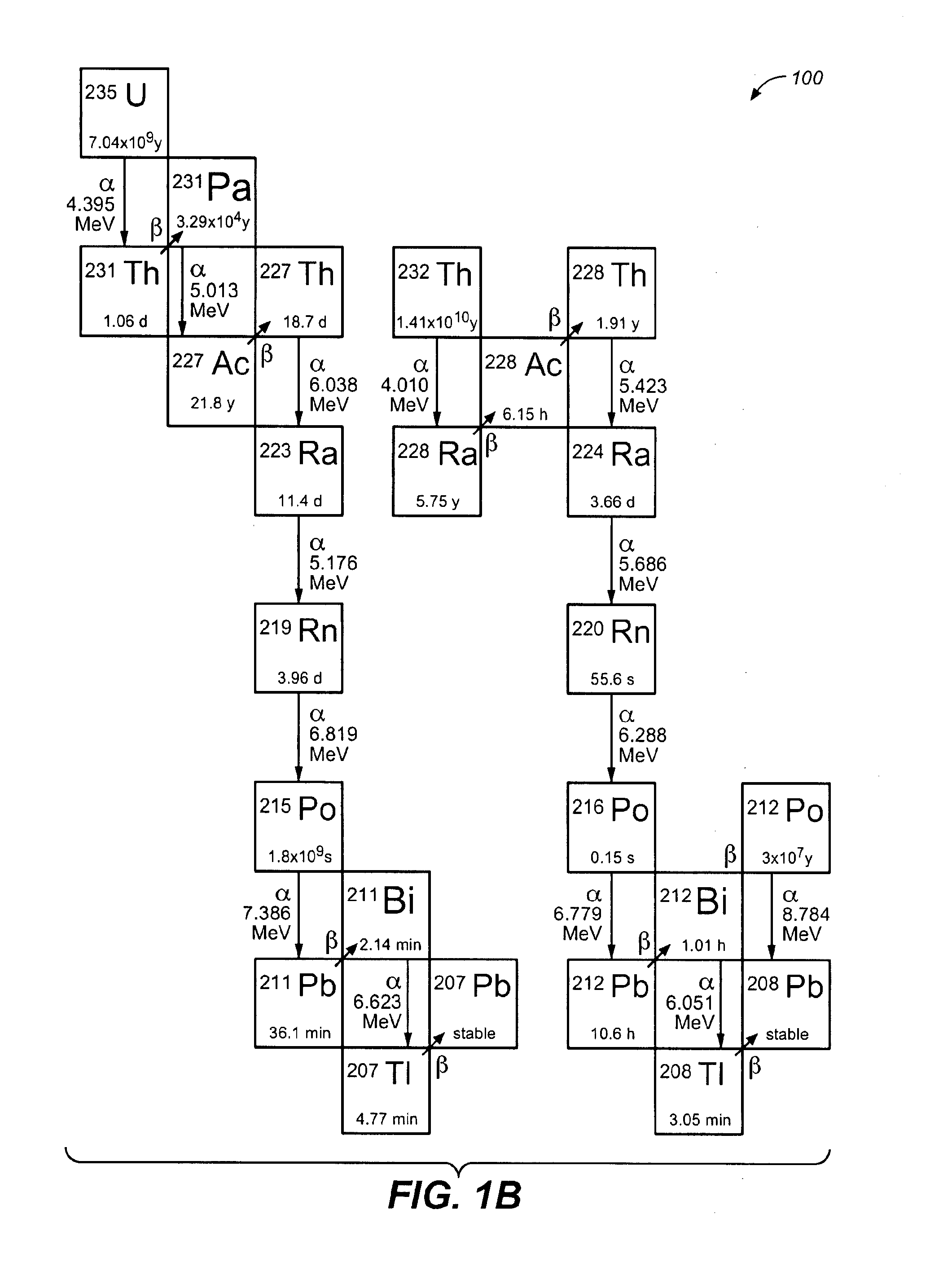

Image

Examples

Embodiment Construction

[0020]The chemical separation process summarily described above is now set out fully for monazite. A similar approach works for bastnaesite and other thorium-containing ores. The monazite sand is first conventionally concentrated. This is accomplished by separating the uniform particle size grains based on physical properties, specific gravity, magnetic susceptibility, electrical conductivity, and surface properties. The monazite-containing sand is processed and conductive ilmenite and conductive rutile constituents are removed. Non-conducting monazite, which is heavy and moderately magnetic, is isolated from non-magnetic components and other materials remaining in the feed material. The resulting concentrate having been processed by magnetic and electrical means is generally more than 90% monazite. This concentrated monazite sand is finely ground and is ready for digestion by the inventive process described herein.

[0021]Monazite is a phosphate ore. It occurs in three varieties: (Ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Molar density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com