Expanded vermiculite cement board capable of releasing negative ions and preparation method thereof

A technology of expanded vermiculite and cement board, which is applied in the field of building materials, can solve the problems of human health, ineffective air purification, insufficient negative ion concentration, and endangering human health, so as to improve human immunity and resistance, promote body metabolism, The effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of expanded vermiculite cement board capable of releasing negative ions;

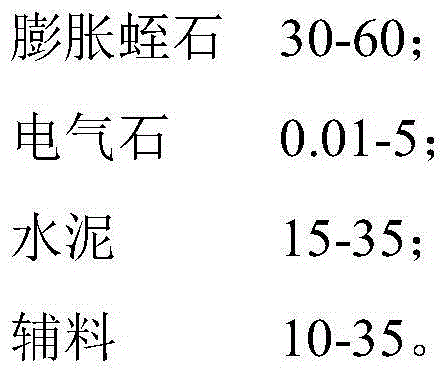

[0048] (1) Prepare raw materials by the following parts by volume content components:

[0049]

[0050] The expanded vermiculite is formed by placing the vermiculite raw material in an extruding furnace at 600° C. for 10 seconds.

[0051] The particle diameter of described expanded vermiculite is 0.5mm, and the particle diameter of described tourmaline is 6000 orders;

[0052] (2) Mixing material: the above raw materials are mixed and stirred evenly by a stirrer, the stirring speed is 300rpm, and the stirring time is 10min;

[0053] (3) Forming: The evenly stirred slurry is transported to the felt of the running felt support slurry conveying drum through the headbox, and the material layer is formed through natural dehydration and vacuum dehydration, and is wound on the forming cylinder for rolling and forming; adjust the felt support The conveying speed of the slurry co...

Embodiment 2

[0057] A preparation method of expanded vermiculite cement board capable of releasing negative ions;

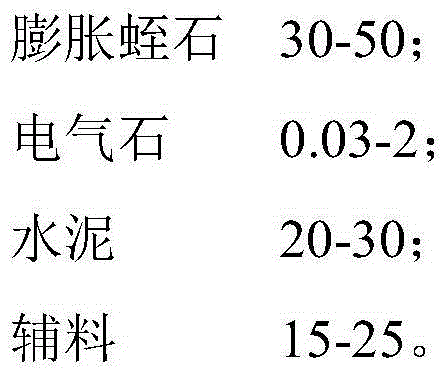

[0058] (1) Prepare raw materials by the following parts by volume content components:

[0059]

[0060] The expanded vermiculite is formed by placing the vermiculite raw material in an extruding furnace at 800° C. for 20 seconds.

[0061] The particle diameter of described expanded vermiculite is 4mm, and the particle diameter of described tourmaline is 1000 orders;

[0062] (2) Mixing material: the above-mentioned raw materials are mixed and stirred evenly by a stirrer, the stirring speed is 500rpm, and the stirring time is 5min;

[0063] (3) Forming: The evenly stirred slurry is transported to the felt of the running felt support slurry conveying drum through the headbox, and the material layer is formed through natural dehydration and vacuum dehydration, and is wound on the forming cylinder for rolling and forming; adjust the felt support The conveying speed of the sl...

Embodiment 3

[0067] A preparation method of expanded vermiculite cement board capable of releasing negative ions;

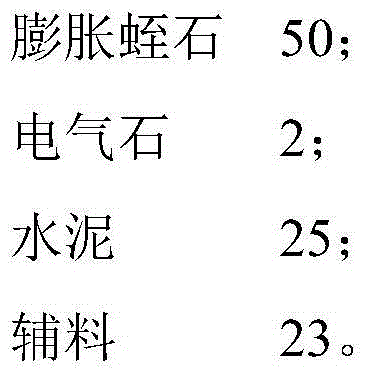

[0068] (1) Prepare raw materials by the following parts by volume content components:

[0069]

[0070] The expanded vermiculite is obtained by placing the vermiculite raw material in an extruding furnace at 900° C. and expanding it for 25 seconds.

[0071] The particle diameter of described expanded vermiculite is 0.5mm, and the particle diameter of described tourmaline is 200 orders;

[0072] (2) Mixing material: the above-mentioned raw materials are mixed and stirred evenly by a stirrer, the stirring speed is 400rpm, and the stirring time is 8min;

[0073] (3) Forming: The evenly stirred slurry is transported to the felt of the running felt support slurry conveying drum through the headbox, and the material layer is formed through natural dehydration and vacuum dehydration, and is wound on the forming cylinder for rolling and forming; adjust the felt support The conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com