Patents

Literature

94results about How to "With flash effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

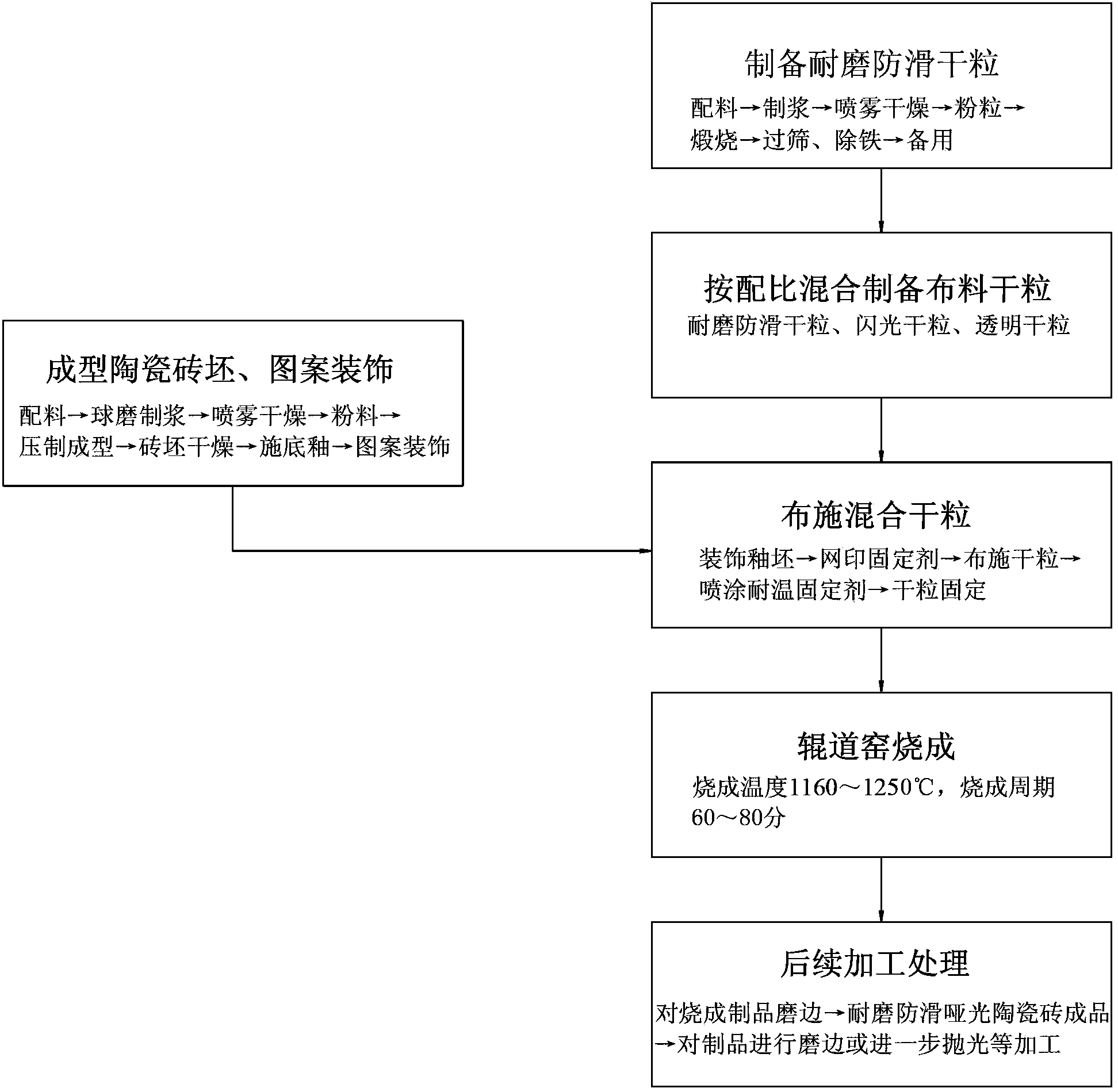

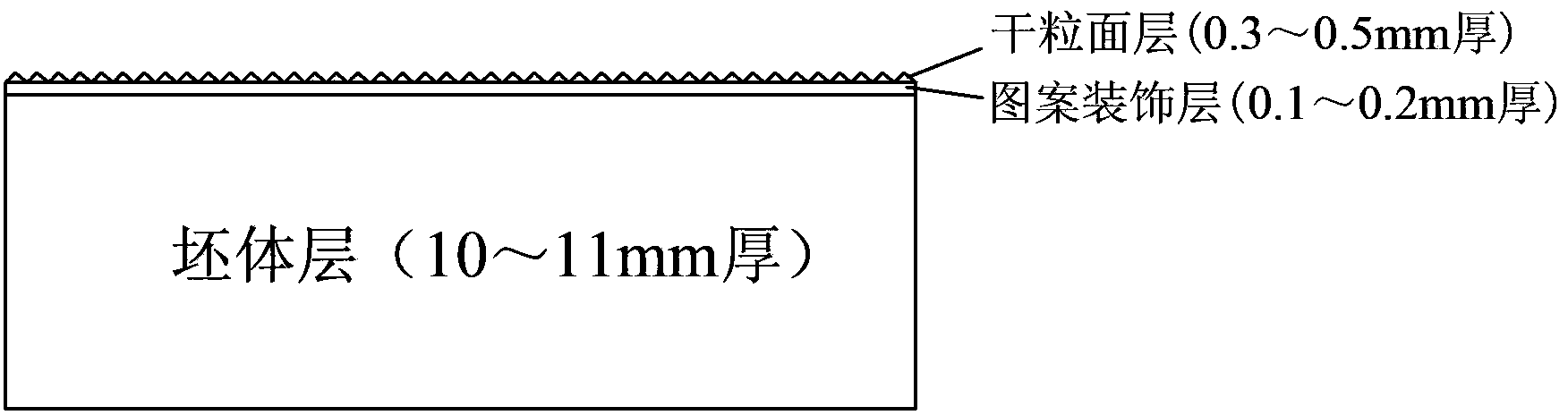

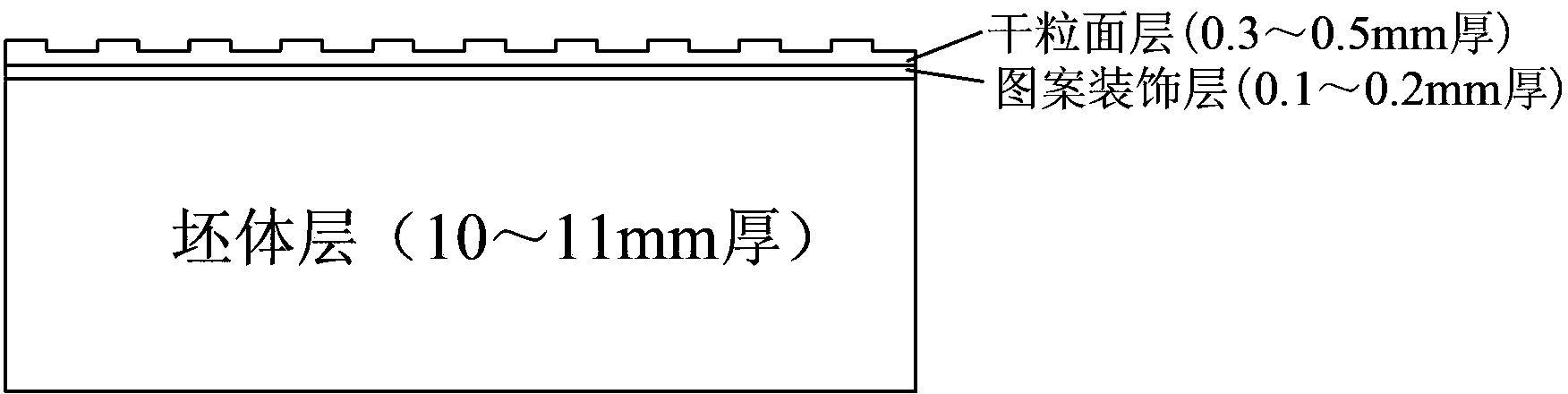

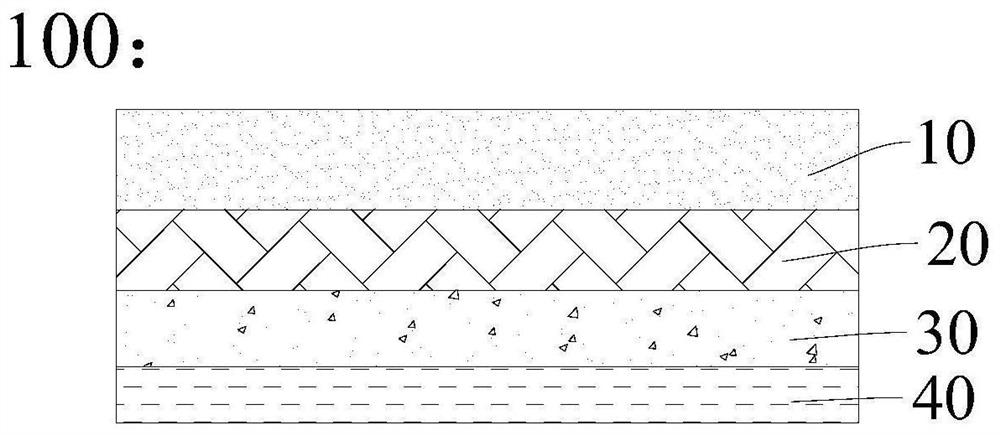

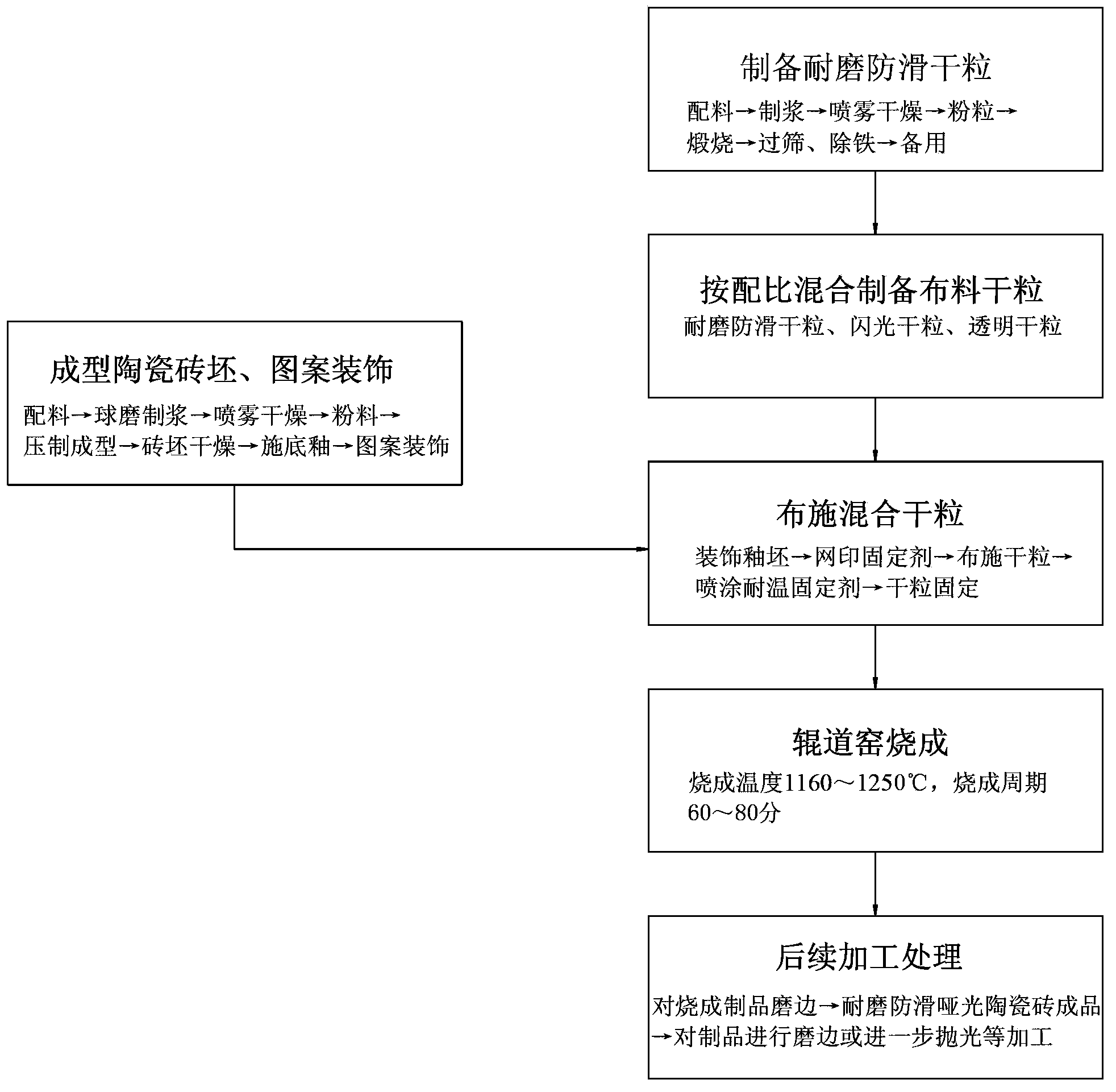

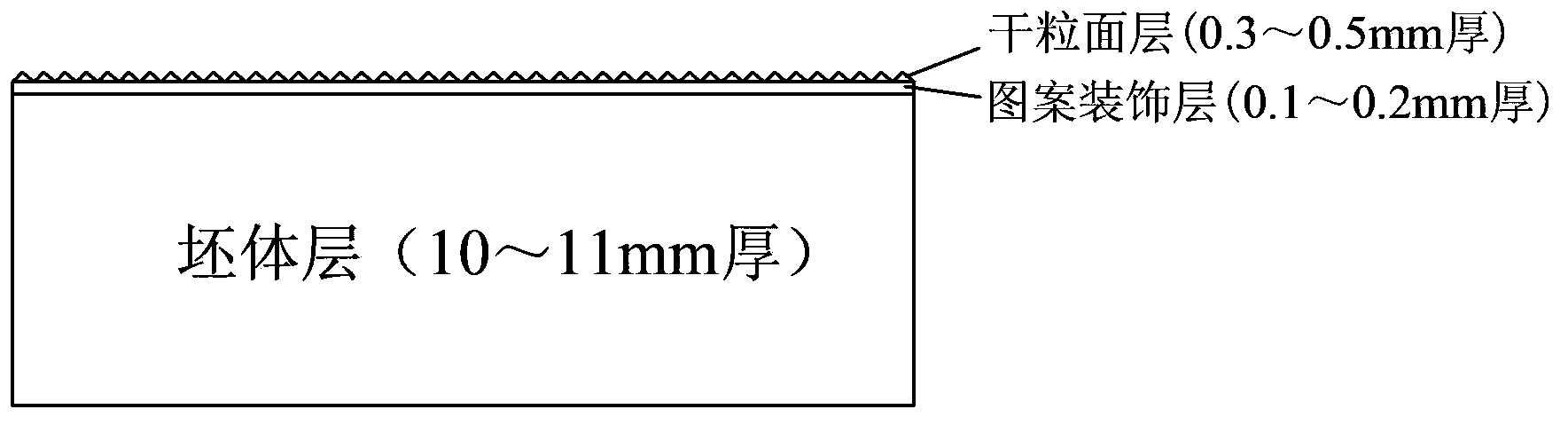

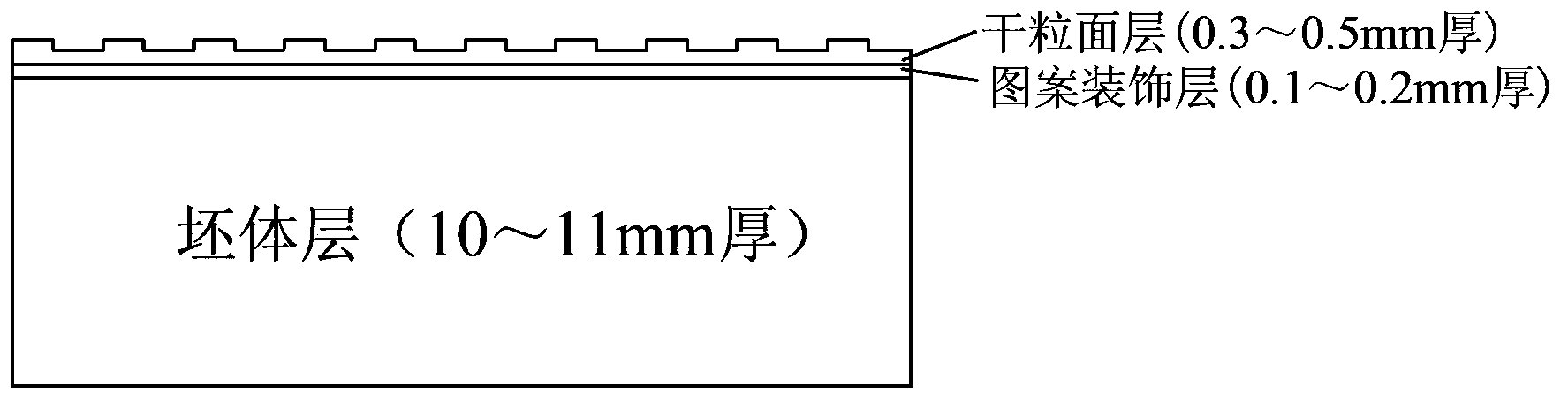

Method for manufacturing wear-resistant antiskid dry-particle ceramic tile

The invention relates to a method for manufacturing a wear-resistant antiskid dry-particle ceramic tile, which comprises the following steps: (1) forming a ceramic tile plane matrix and carrying out pattern decoration; (2) preparing dry particles with wear-resistant and antiskid properties; (3) mixing the wear-resistant antiskid dry particles, flashing dry particles and transparent dry particles according to a certain proportion for distribution; (4) applying the mixed dry particles to the surface of a decorative glazed body and spraying a temperature-resistant fixing agent; (5) conveying the obtained product to a roller kiln for firing and preparing the finished product of the ceramic tile through subsequent processes. According to the method for manufacturing the wear-resistant antiskid dry particle ceramic tile, the dry particles with good wear resistance are mixed with the transparent dry particles and the flashing dry particles, a dry powder distribution mode is adopted and the wear-resistant antiskid dry particles are bulged due to different melting performance of various dry particles in the firing process, so that the problems of wear resistance of the surface and thickness of a wear-resistant layer are solved; by distributing the transparent dry particles, a decorative pattern has a stereoscopic decorating effect under the covering of a glass layer, so that unification of wear-resistant and antiskid properties and decoration of the ceramic tile is achieved.

Owner:JIANGXI HEMEI CERAMICS

Bicolor elastic corded velveteen made from multi-fiber

A multifiber elastic double- color corduroy include weft velvet, warp and ground and weft, among which, raw material of the weft velvet is cotton fiber yarn, that for warp is terylene long silk fiber yarn or cotton yarn or core-spun yarn of long silk with spandex or core spun yarn of spandex with cotton fiber, and raw material of ground weft is terylene long silk fiber yarn or core-spun yarn of terylone long silk with spandex or that of spandex with cotton fiber.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Double-color burnt-out sofa fabric technology

InactiveCN106120136AFluff erectGood brightnessLiquid/gas/vapor treatment of propelled fabricsWarp knittingBurning outDyeing

The invention discloses a double-color burnt-out sofa fabric technology, and specific steps comprise: preparing raw materials, warping, putting on a machine, weaving, checking, shaping at high temperature, napping, performing pre-lustring treatment, performing pre-shaping treatment, performing burnt-out treatment, performing water processing, performing dyeing treatment, performing dewatering treatment, shaping and drying, shearing, performing post-lustring treatment, shaping a finished product, combining, and rolling and packaging. Fluff of a sofa fabric produced by the technology is upright, and is good in brightness. The fabric is smooth and soft in hand feeling, good in strength, and is durable.

Owner:ZHEJIANG FAMOUS TEXTILE CO LTD

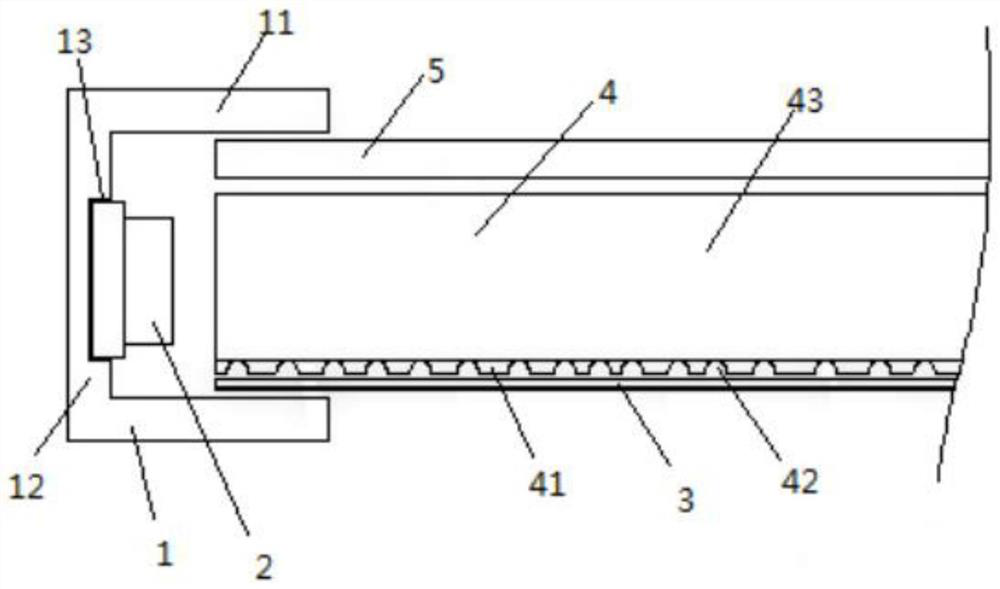

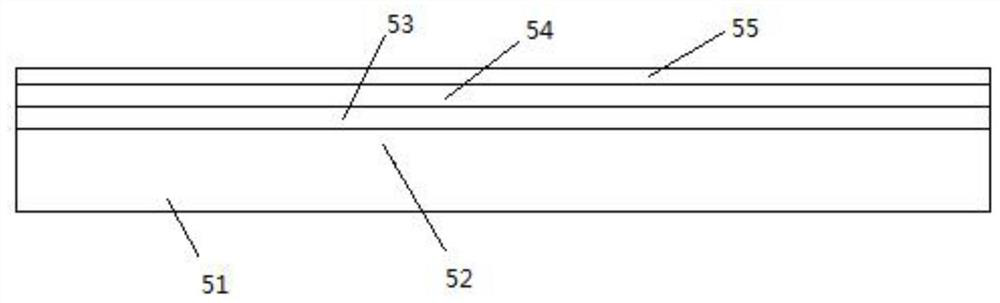

Glass shell assembly, manufacturing method thereof and electronic equipment

ActiveCN111756896AWith flash effectReduce manufacturing costTelephone set constructionsMechanical engineeringElectronic equipment

The invention provides a glass shell assembly, a manufacturing method thereof and electronic equipment. The glass shell assembly comprises a glass body; a diaphragm arranged on one surface of the glass body; a UV frosting texture layer arranged on the surface, far away from the glass body, of the diaphragm, wherein frosting textures on the surface of the UV frosting texture layer are arranged faraway from the glass body; and a reflective coating layer arranged on the surface, far away from the glass body, of the UV frosting texture layer. Therefore, the glass shell assembly has a flashing appearance effect under illumination, has a relatively good flashing sand effect, realizes a flashing effect, and can also realize anti-glare and anti-fingerprint effects; moreover, frosting treatment does not need to be carried out on the glass body, so that dependence on specially-made flashing sand liquid medicine during frosting treatment can be avoided; moreover, the glass body does not need tobe treated, so that the strength of the glass body cannot be reduced, and the overall strength and reliability of the glass shell assembly are improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Preparation method of fibroin nanofibers

InactiveCN104233496ASmall diameterImprove spinnabilityMonocomponent protein artificial filamentFilament/thread formingFiberLithium bromide

The invention discloses a preparation method of fibroin nanofibers. The preparation method comprises the following steps: (1) degumming silk by an alkaline process to remove sericin on the surface of the silk, washing the silk with deionized water, drying the silk, dissolving the dried silk in a CaCl2\C2H5OH\H2O ternary solution or a lithium bromide solution to obtain a fibroin and inorganic salt mixed solution, and dialyzing by a dialysis bag to obtain a fibroin solution; (2) mixing the fibroin solution with a spinning solvent in a volume ratio, and stirring for 30-60 minutes for mixing uniformly; and (3) transferring an obtained spinning solution into a cylinder with a nozzle with triangular cross section, and spraying the spinning solution out of the nozzle under the action of a high voltage electric field to form the nanofibers. The preparation method is simple and convenient to operate, the obtained fibroin nanofibers are good in spinnability, the specifications of the fibers can be adjusted by adjusting spinning parameters, and the fibers have the characteristics of small diameter, excellent performance, stable structure and glittering effect.

Owner:SUZHOU INSILK CO LTD

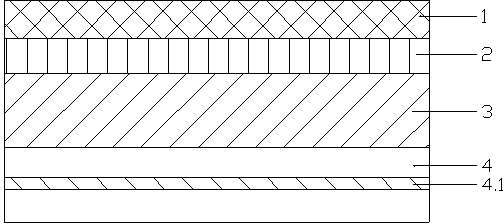

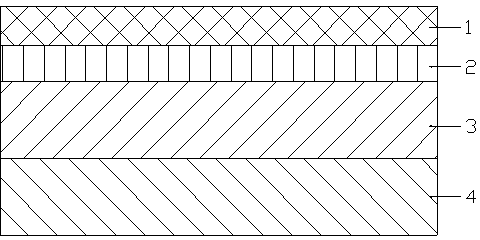

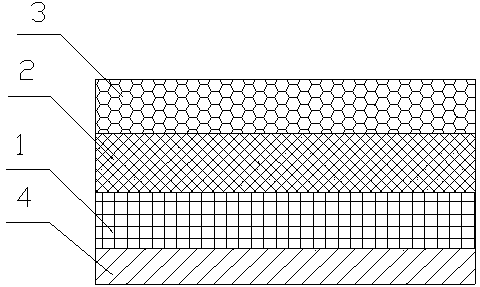

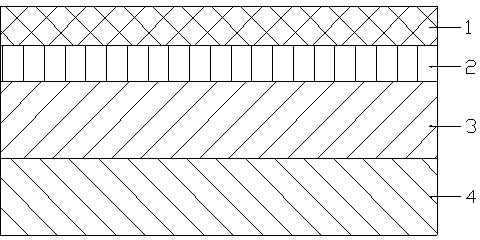

Artificial leather with ultraviolet resistance, colorful effect and flash effect

InactiveCN104342988AWith UV protection functionRich textureTextile decorationMetal layered productsSurface layerUltraviolet

The invention relates to an artificial leather with ultraviolet resistance, colorful effect and flash effect. The artificial leather comprises a surface layer (3) and a base layer (4) which are bonded to each other, a silver colloid coating (4.1) with an ultraviolet resistance function is embedded in the base layer (4), a pearl essence layer (2) is bonded to the surface layer (3), a transparent film (1) is bonded to the pearl essence layer (2), the base layer (4) is made of a fabric, the fabric comprises a netted layer, the netted layer is provided with a plurality of laser reflectors, the laser reflectors are rhombic, and the laser reflectors are arranged in a rhombic array manner with one of the rhombic laser reflectors as a base. The artificial leather has an ultraviolet resistance function. The fabric adopted in the invention has the advantages of abundant texture, layered sensation and flash effect.

Owner:JIANGYIN CHUANGJIA ELECTRICAL APPLIANCE

Method for manufacturing wear-resistant antiskid dry-particle ceramic tile

The invention relates to a method for manufacturing a wear-resistant antiskid dry-particle ceramic tile, which comprises the following steps: (1) forming a ceramic tile plane matrix and carrying out pattern decoration; (2) preparing dry particles with wear-resistant and antiskid properties; (3) mixing the wear-resistant antiskid dry particles, flashing dry particles and transparent dry particles according to a certain proportion for distribution; (4) applying the mixed dry particles to the surface of a decorative glazed body and spraying a temperature-resistant fixing agent; (5) conveying the obtained product to a roller kiln for firing and preparing the finished product of the ceramic tile through subsequent processes. According to the method for manufacturing the wear-resistant antiskid dry particle ceramic tile, the dry particles with good wear resistance are mixed with the transparent dry particles and the flashing dry particles, a dry powder distribution mode is adopted and the wear-resistant antiskid dry particles are bulged due to different melting performance of various dry particles in the firing process, so that the problems of wear resistance of the surface and thickness of a wear-resistant layer are solved; by distributing the transparent dry particles, a decorative pattern has a stereoscopic decorating effect under the covering of a glass layer, so that unification of wear-resistant and antiskid properties and decoration of the ceramic tile is achieved.

Owner:JIANGXI HEMEI CERAMICS

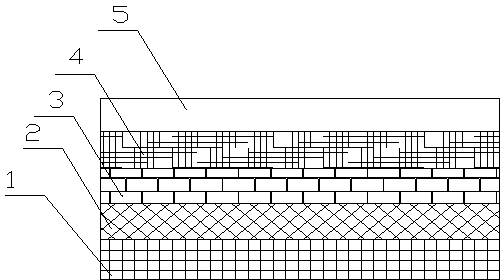

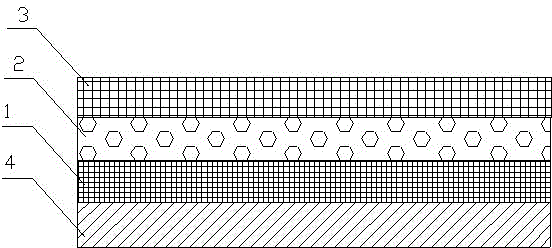

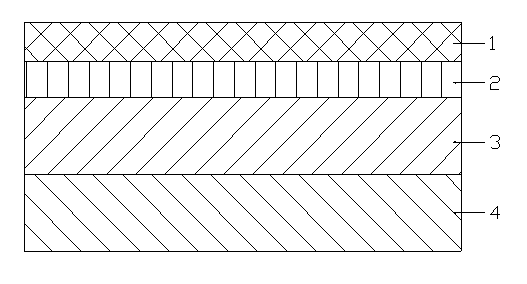

Waterproof antibacterial heat-insulating fabric with stereoscopic impression

InactiveCN104385736AGood warmth retentionGuaranteed warmthSynthetic resin layered productsWoven fabricsFiberEngineering

The invention relates to a waterproof antibacterial heat-insulating fabric with a stereoscopic impression. The waterproof antibacterial heat-insulating fabric comprises a base layer (1), an inner layer (2), a fabric layer (3) and an outer layer (4) from inside to outside in sequence, wherein the base layer (1) is made by connecting warps and wefts mutually; the warps and the wefts are woven from nano silver fiber; the inner layer (2) is a heat-insulating layer; the outer layer (4) and the fabric layer (3) are laminated; the outer layer (4) is a windproof waterproof breathable membrane; the fabric layer (3) is a textile. The textile comprises a weaving layer comprising a front side and a back side; a plurality of sequins are arranged on the front side of the weaving layer, and are circular; holes are formed in the centers of the sequins; the sequins are horizontally arranged on the weaving layer, and form a crisscrossed grid matrix on the weaving layer. The antibacterial efficiency can be improved. The fabric is rich in texture, has the stereoscopic impression and layering, and has a flashing effect.

Owner:JIANGYIN BETTER TEXTILE

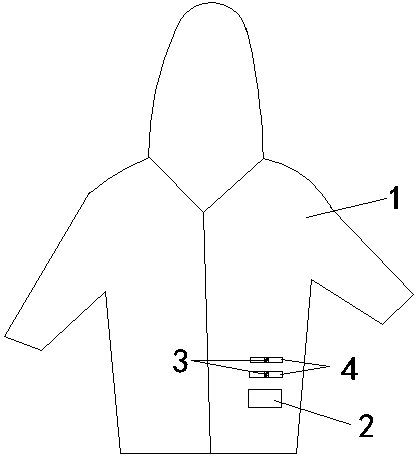

Layering clothes capable of carrying water bottle

InactiveCN104223395AEasy to carryAchieve the effect of fixing the water bottleGarmentsLight reflectionEngineering

The invention relates to layering clothes capable of carrying a water bottle. The clothes comprise a clothes body (1). An elastic bag (2) is arranged on the front body waist of the clothes body (1), two belts (4) with belt buckles (3) are arranged above the bag (2), and the belts (4) are sewn on the front body. The clothes body (1) is made of fabric, the fabric comprises a reticular layer, the reticular layer contains laser reflection light, the laser reflection light at least forms a series of straight lines equally spaced on the reticular layer, a light reflection piece is further arranged on the front of the reticular layer, the light reflection piece is made of a transparent material and is piece-shaped, the light reflection piece is round, a hole is formed in the center of the light reflection piece, and the laser reflection layer is arranged on the surface of the light reflection piece. The clothes can achieve the effect of fixing the water bottle, so that the water bottle can be carried conveniently. The adopted fabric is rich in texture, achieves the layering sense and achieves the flickering effect.

Owner:JIANGSU YUNFU FASHION CO LTD

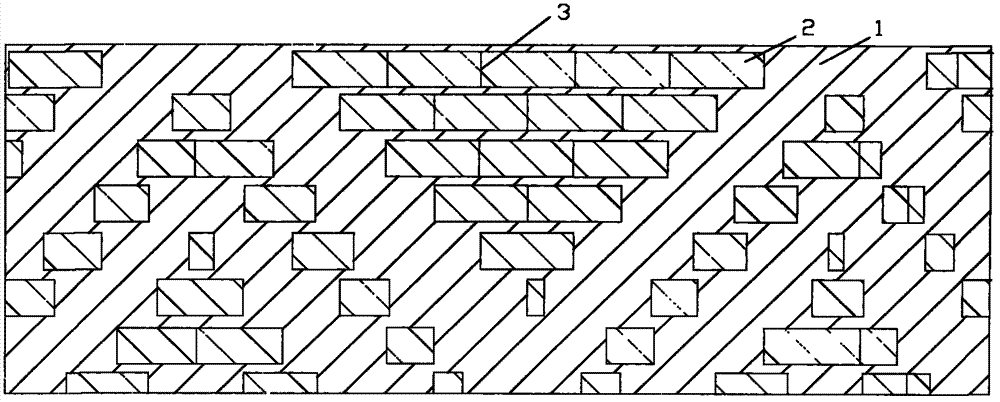

Artificial leather with magical color and glittering effects

InactiveCN104294659AMeet actual needsRich textureLayered productsTextile decorationColor effectSurface layer

The invention relates to an artificial leather with magical color and glittering effects. The artificial leather comprises a surface layer (3) and a base layer (4) that are bonded to each other. A pearl powder layer (2) is bonded to the surface layer (3), and a transparent film (1) is bonded to the pearl powder layer (2). The base layer (4) is made of a fabric, which comprises a reticular layer. The reticular layer is provided with a plurality of rhombic laser reflective sheets, which are arranged in the mode that: one rhombic laser reflective sheet is adopted as the basis to make arrangement formed by rhombic arrays. People can feel a magical color effect when they see the artificial leather, thus meeting people's needs. The fabric adopted by the base layer involved in the invention has a glittering effect.

Owner:JIANGYIN YONGLONG PLASTICS

Antistatic, antibacterial and anti-radiation stereoscopic fabric

The invention relates to an antistatic, antibacterial and anti-radiation stereoscopic fabric. The fabric comprises a bottom layer (4), wherein a base layer (1) is compounded on the surface of the bottom layer and is formed by connecting warps with wefts; the warps and the wefts are formed by spinning nano-silver fibers; an aluminium alloy film (2) is bonded on the upper surface of the base layer via adhesives; an antistatic layer (3) is arranged on the aluminium alloy film and is formed by interweaving warps and wefts; the warps are formed by cotton yarns; the wefts are formed by conductive fibers; the base layer is made from a fabric; the fabric comprises a woven layer; the woven layer has a front side and a reverse side; a plurality of sequins are arranged at the front side of the woven layer and are circular; a hole is formed in the center of each sequin; the sequins are horizontally arranged on the woven layer. The adopted fabric is abundant in texture, is stereoscopic, has a sense of layering, and has a glittering effect.

Owner:JIANGYIN SHANGFENG TEXTILE

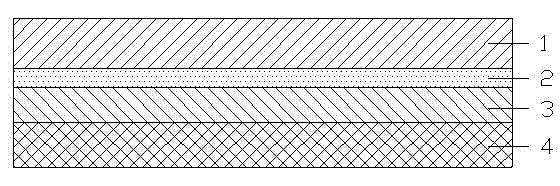

Antibacterial and anti-mite shell fabric with layered feeling

InactiveCN104290378AEliminate static electricityGood breathability and durabilitySynthetic resin layered productsClothingsAcarusOptoelectronics

The invention relates to an antibacterial and anti-mite shell fabric with layered feeling. The shell fabric sequentially comprises a surface layer (1), a moisture-permeable bonding layer (2), an anti-mite film layer (3) and a base layer (4) from outside to inside; the base layer comprises a reticular layer, the reticular layer contains laser reflecting threads, at least a series of equidistant straight lines are formed on the reticular layer by the laser reflecting threads, light-reflective sheets are further arranged on the front face of the reticular layer, are sheets made from a transparent material and are circular, a hole is formed in the center of each light-reflective sheet, and a laser reflecting layer is further arranged on the surface of each light-reflective sheet. The shell fabric not only has an anti-mite function, but also has a very good antibacterial property. The shell fabric has layered feeling.

Owner:JIANGYIN YUEDA DYEING & PRINTING

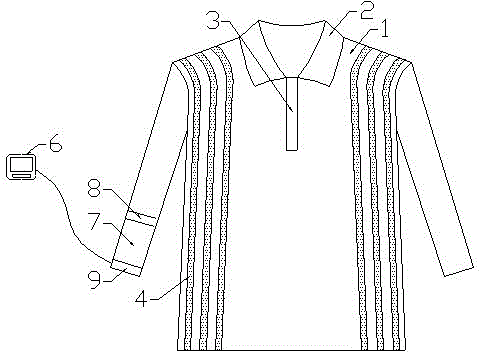

Stereoscopic sweat-absorption clothes with reminding function by color changes

InactiveCN105581387AAchieve internal and external ventilationEasy dischargeProtective garmentSpecial outerwear garmentsStereoscopic acuityDisplay device

The invention relates to stereoscopic sweat-absorption clothes with a reminding function by color changes. The stereoscopic sweat-absorption clothes comprise a clothes body (1), a setting device (6), a reminding display device and a reminding control device (9). Two sides of a front piece of the clothes body (1) are provided with multiple stripped grooves (4) in a longitudinal direction. Holes (5) are densely arranged in the grooves (4). The clothes body is made by fabric comprising a braiding layer having a right side and a back side. The right side of the braiding layer is provided with multiple flashy pieces in the circular shapes. A hole is arranged in the center of each flashy piece. The flashy pieces are arranged on the braiding layer and form a criss-cross grid matrix on the braiding layer. Cross points are formed by longitudinal grids and transverse grids and take two forms including direct criss-cross points and star-shaped criss-cross points. The stereoscopic sweat-absorption clothes with the reminding function by color changes is capable of reminding seriousness of events according to color changes of a color-changing display and is stereoscopic.

Owner:周忠平

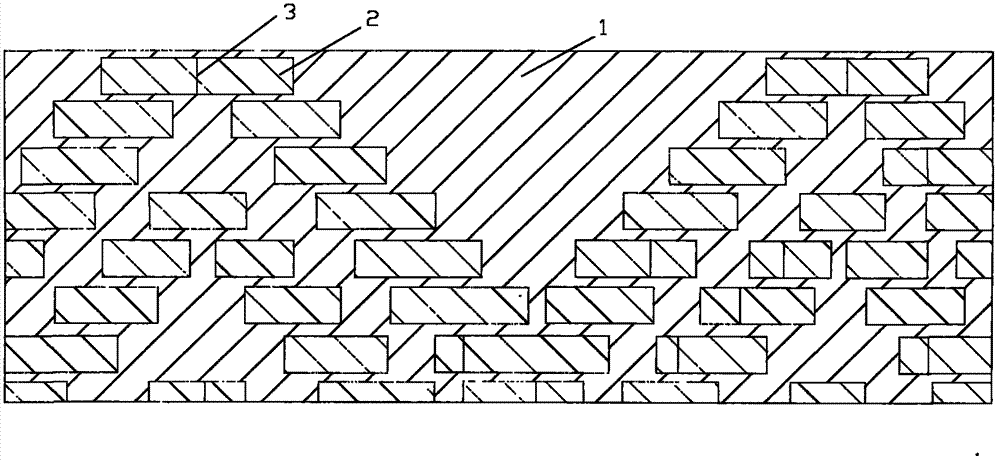

Artificial leather with multicolor effect and hierarchy sense

InactiveCN104328673ASuit one's needsRich textureLayered productsTextiles and paperSurface layerOptoelectronics

The invention relates to artificial leather with multicolor effect and hierarchy sense. The artificial leather comprises a surface layer (3) and a base layer (4) which are bonded with each other; the surface layer (3) is bonded with a pearl powder layer (2), and the pearl powder layer (2) is bonded with a transparent film (1); and the base layer (4) is prepared from fabric, the fabric comprises a net-like layer, the net-like layer comprises laser reflective lines which form at least a series of straight lines in equal intervals on the net-like layer, the observe side of the net-like layer is provided with circular reflective sheets prepared from a transparent material, the center of each reflective sheet is provided with a hole, and the surface of the reflective sheet is provided with a laser reflective layer. The multicolor effect is generated when people see the artificial leather, and people demands are satisfied. The employed fabric is abundant in texture, and has hierarchy sense and flash effect.

Owner:JIANGYIN SHENGDA BUILDING MATERIALS

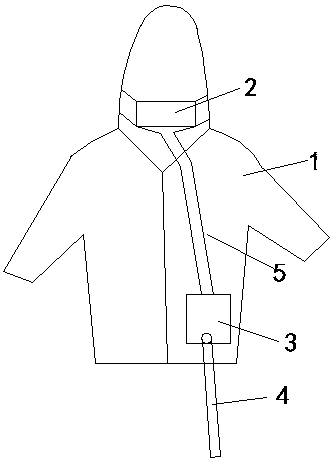

Layering clothing enabling people to breath in fire

InactiveCN104288929AReduce sootRich textureChemical protectionHeat protectionActive carbonRespirator

The invention relates to layering clothing enabling people to breath in fire. The layering clothing comprises a clothing body (1), wherein a mask (2) is arranged on a collar of the clothing body (1); a filter box (3) is arranged in a pocket of the clothing body (1), and is filled with active carbon particles; the bottom of the filter box is connected with a long guide pipe (4); the mask (2) and the filter box (3) are connected through a flexible pipe (5); the clothing body (1) is made of a fabric; the fabric comprises a netty layer; the netty layer comprises laser reflecting rays; the laser reflecting rays at least form a series of straight lines with equal distances on the netty layer; a reflecting chip is additionally arranged on the frontal surface of the netty layer, is a sheet made of a transparent material, and is circular; a hole is formed in the center of the reflecting chip; and a laser reflecting layer is arranged on the surface of the reflecting chip. The layering clothing can provide a certain guarantee for people to escape in fire. The fabric adopted by the layering clothing is rich in texture, and has the layering sense and the flashing effect.

Owner:JIANGYIN HANXIN TEXTILE

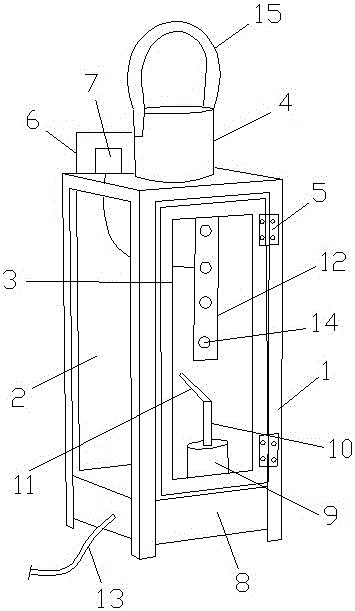

Intelligent lamp

InactiveCN106604445AEasy to operateEasy to carryElectrical apparatusElectroluminescent light sourcesEngineeringOrganic glass

The invention discloses an intelligent lamp, and the lamp comprises a frame, an organic glass plate, a window frame, and a battery module. The organic glass plate is disposed at an outer side of the frame, and the window frame is disposed at one side of the frame. The window frame is provided with a hinge, and is connected with the fame through the hinge. The battery module is fixed on the frame, and the frame is also provided with a control module. The control module is provided with a WIFI module, and the bottom of the frame is provided with a pedestal. The interior of the pedestal is provided with a motor, and the top of the motor is provided with a rotating shaft. The rotating shaft is provided with a reflecting plate, and the reflecting plate and the horizontal line form a 45-degree angle. The interior of the frame is provided with a lamp strip, and the battery module, the control module and the lamp strip are connected sequentially. The intelligent lamp is convenient to operate, has a flashing effect, and is portable.

Owner:CHENGDU GERUISI CULTURAL COMM

Waterproof fireproof antibacterial fabric with stereoscopic impression

InactiveCN104385709AGood fire and flame retardant propertiesPrevent flames from burning clothesSynthetic resin layered productsClothingsMesh gridEngineering

Owner:JIANGYIN HAIYING WOOLEN GOODS

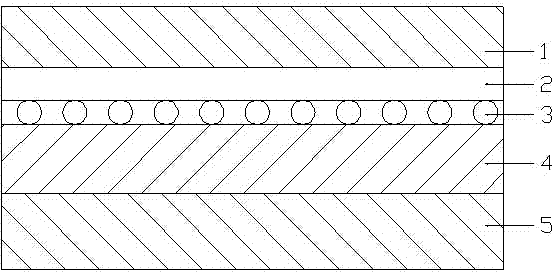

Mosquito repellent antifouling fabric with glittering effect

InactiveCN104260510ASuperamphiphobicWaterproofSynthetic resin layered productsCoatingsEngineeringPolytetrafluoroethylene

The invention relates to a mosquito repellent antifouling fabric with a glittering effect. The fabric comprises a first antifouling coating (1), a mosquito resistant protective layer (2), a small fish scale knitted layer (3), a first base fabric layer (4) and a second antifouling coating (5) from outside to inside, wherein the first base fabric layer (4) is formed by arranging warps containing nano antifoulants and wefts containing nano antifoulants in a cross manner; the first antifouling coating (1) and the second antifouling coating (5) are polytetrafluoroethylene layers; a second base fabric layer is compounded on the back of the second antifouling coating and comprises a reticular layer; a plurality of laser reflectors are arranged on the reticular layer, are diamond-shaped and are arranged to form a diamond-shaped array based on one diamond-shaped laser reflector. The fabric is effectively antifouling. The mosquito repellent function of the fabric prevents people from being perplexed by mosquitoes in summer. The fabric has a glittering effect.

Owner:JIANGSU BAILIDA

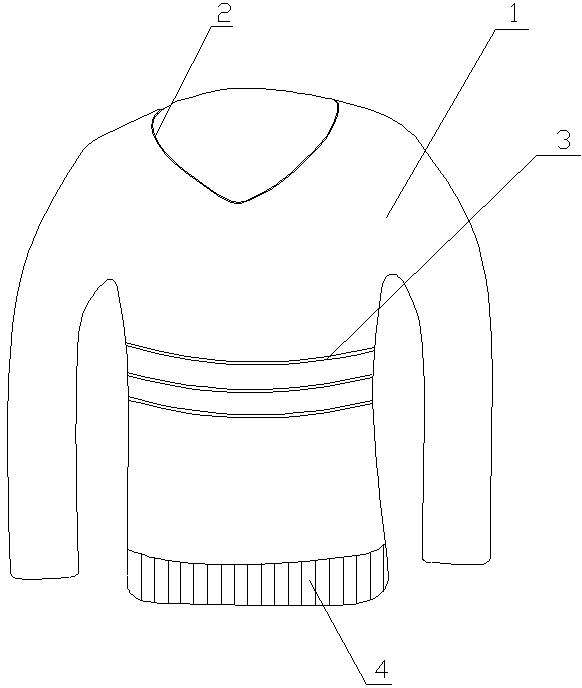

Women's cashmere sweater with good toughness and layering

InactiveCN104336858AImprove toughnessImprove the ability to resist pullingProtective garmentSpecial outerwear garmentsLaser lightEngineering

The invention relates to a women's cashmere sweater good in toughness and layering. The sweater comprises a sweater body (1). The front body of the sweater body is made of cashmere, sleeves are made of fabric, a first reinforcing strip (2) is arranged at the neckline of the sweater body (1), a plurality of second reinforcing strips (3) are arranged at the waist position of the sweater body (1), and strip protrusions are arranged vertically on the lower hem (4) of the sweater body (1). The fabric comprises a net layer. The net layer comprises laser light reflection lines at least forming a series of equidistant straight lines on the net layer. Light reflection pieces are further arranged on the front of the net layer, the light reflection pieces are in the shape of sheets made of a transparent material, the light reflection pieces are round, a hole is formed in the center of each light reflection piece, and a laser light reflection layer is arranged on the surface of each light reflection piece. The cashmere sweater is long in service life. The adopted fabric is rich in texture, stereoscopic impression and layering and has the flashing effect.

Owner:JIANGYIN BEIYE TEXTILE

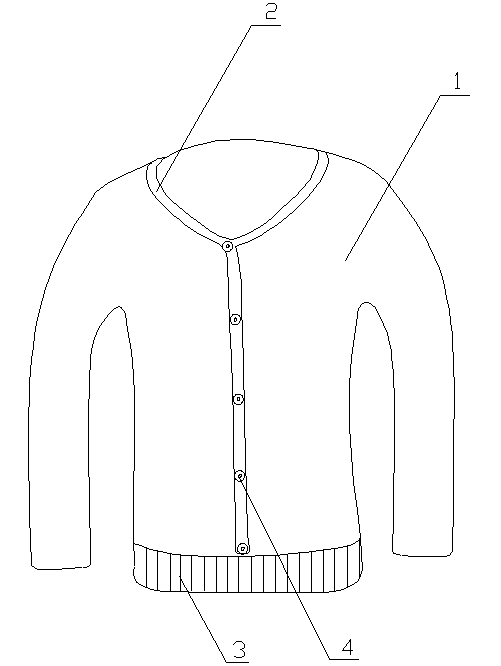

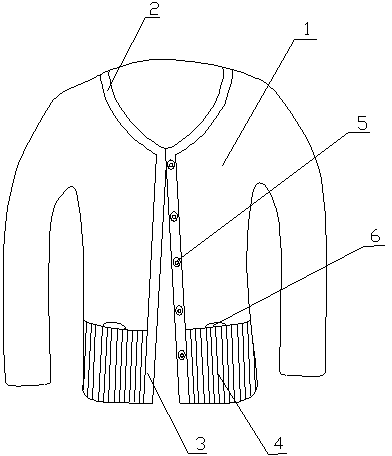

Women's cashmere sweater attractive in appearance, with pocket and with flashing effect

The invention relates to a women's cashmere sweater attractive in appearance, with a pocket and with a flashing effect. The sweater comprises a sweater body (1). The front body of the sweater body is made of cashmere, sleeves are made of fabric, a thickening strip is vertically arranged in the middle of the front of the sweater body (1), a decorative button (4) is arranged on the thickening strip, the pocket (5) is arranged on the sweater body (1), a thickening strip is arranged on the neckline (2) of the sweater body (1), an annular thickening strip is arranged at the position of each cuff of the sweater body (1), and strip protrusions are arranged on the lower hem (3) of the sweater body (1) vertically. The fabric comprises a net layer, a plurality of laser light reflection pieces are arranged on the net layer, the laser light reflection pieces are rhombus and arranged in the way that a rhombus array is formed with one rhombus laser light reflection piece as the basis. The sweater is attractive in appearance. The adopted fabric is rich in texture, has layering and has the flashing effect.

Owner:JIANGYIN BEIYE TEXTILE

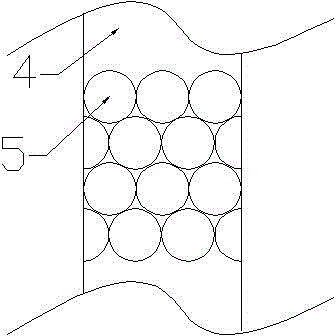

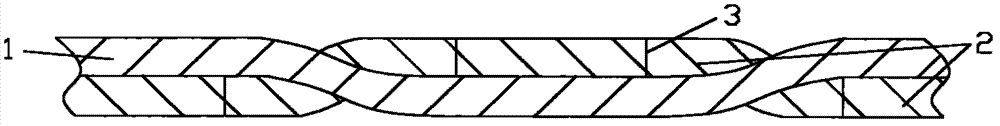

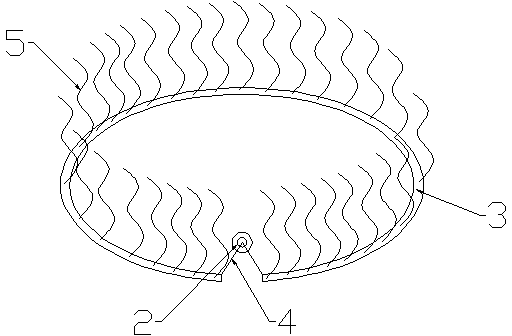

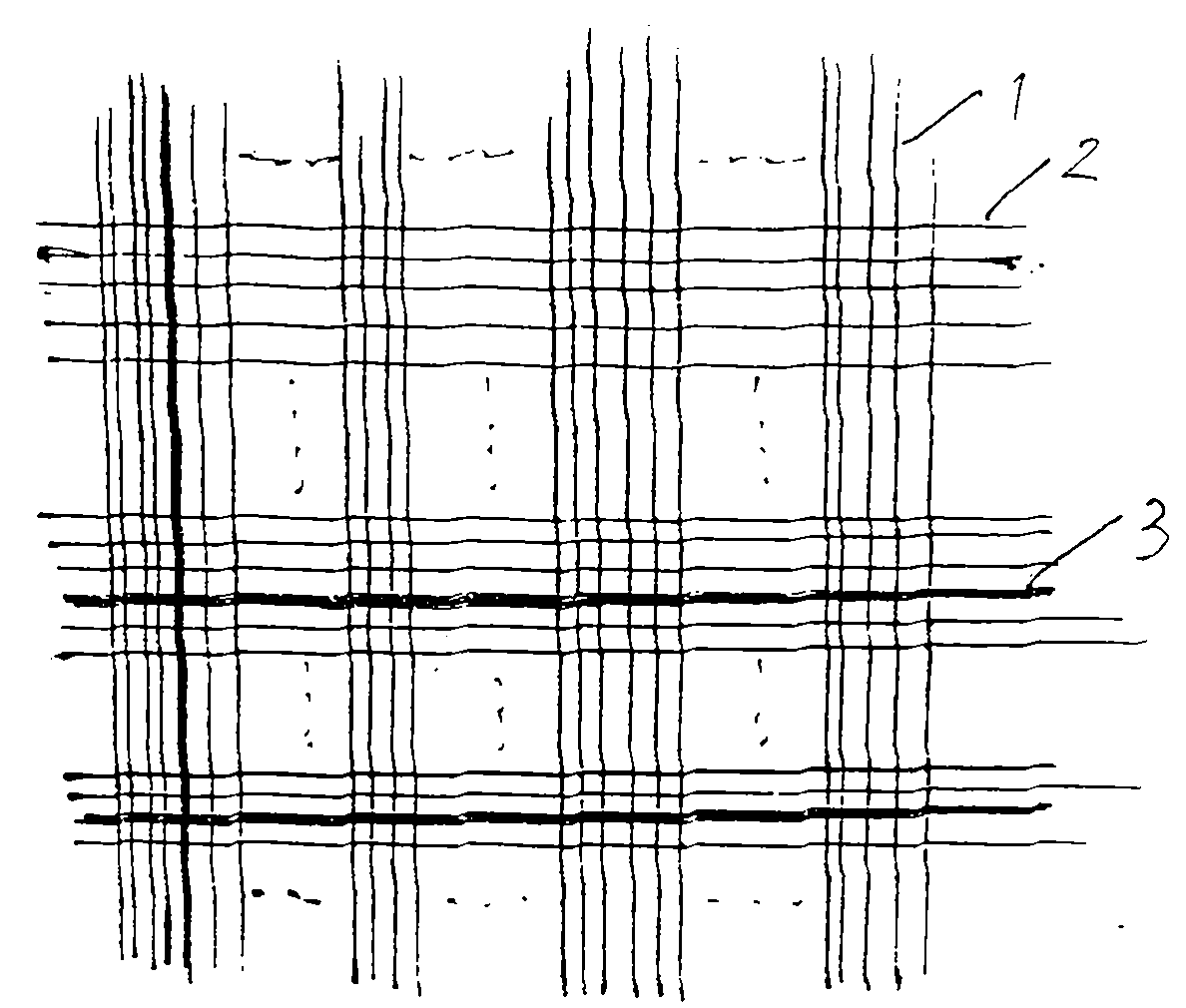

Flash slub woolen cloth

The invention relates to flash slub woolen cloth, which is widely used in the production of high-end clothing, and belongs to the field of textile fabrics. The slub woolen cloth includes a woolen cloth body (1), and is characterized in that: the woolen cloth body (1) is woolen cloth, the woolen cloth body (1) is provided with a plurality of slubs (2), and the slubs penetrates through the woolen cloth body (1) up and down, are arranged in parallel and fixed on the woolen cloth body (1) with threads (3). The rough slub and exquisite woolen cloth are combined, so the slub woolen cloth is rich in layering sense. The front surface of the woolen cloth body is provided with a plurality of flash sheets which are round shape. The center of each flash sheet is provided with a hole. The surface of the woolen cloth has a flash effect.

Owner:吴栋标

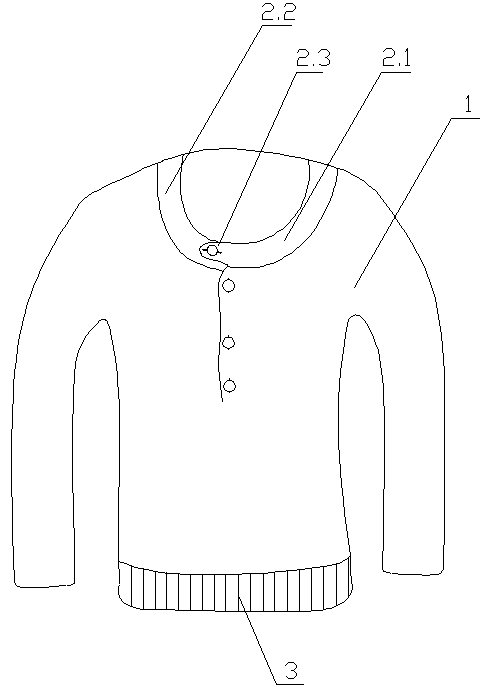

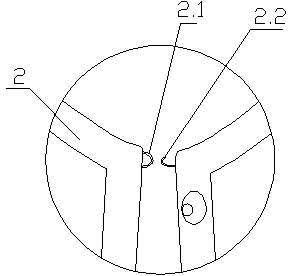

Warm-keeping and attractive man cashmere sweater with flickering effect

InactiveCN104287148AAdd dimensionAesthetically pleasingGarment special featuresProtective garmentMedicineLaser light

The invention relates to a warm-keeping and attractive man cashmere sweater with the flickering effect. The warm-keeping and attractive man cashmere sweater comprises a cashmere sweater body (1); a main body of the cashmere sweater body (1) is made of cashmere; sleeves are made of shell fabric; a neckline of the cashmere sweater body (1) comprises a left neckline body (2.1) and a right neckline body (2.2); a warm-keeping piece (2.3) is arranged at the end, close to the neckline body (2.2), of the left neckline body (2.1) in an extending mode and is arranged above the right neckline body (2.2); a button hole is formed in the warm-keeping piece (2.3); a button matched with the button hole is arranged on the neckline body (2.2); the shell fabric comprises a net-shaped layer; a plurality of laser light reflecting sheets are arranged on the net-shaped layer; the laser light reflecting sheets are rhombic; and the arrangement mode of the laser light reflecting sheets is that the rhombic laser light reflecting sheets are arranged in a rhombic array with one rhombic laser light reflecting sheet serving as a basis and. After being worn, the warm-keeping and attractive man cashmere sweater can have the good warm keeping effect on the throat portion. The shell fabric adopted by the warm-keeping and attractive man cashmere sweater has the flickering effect.

Owner:JIANGYIN GUORUN TEXTILE RAW MATERIALS SALES

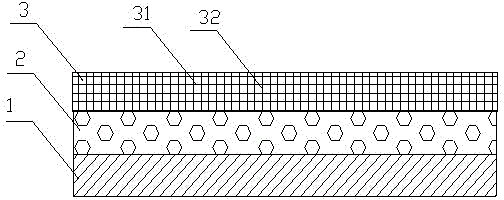

Anti-static radiation-proof three-dimensional fabric

InactiveCN104369467AImprove securityImprove performanceTextile decorationMetal layered productsFiberAlloy thin film

The invention relates to an anti-static radiation-proof three-dimensional fabric, which comprises a base layer (1). An aluminum alloy thin film layer (2) is adhered to the upper surface of the base layer (1); an antistatic layer (3) is arranged on the aluminum alloy film, and the anti-static layer (3) is composed of mutually woven warp yarns (31) and weft yarns (32); the warp yarn (31) is made of cotton yarn, and the weft yarn (32) is made of a striped conductive fiber conductive fiber with spacing of 5-10 mm. The base layer is made of fabric; the fabric comprises a braiding layer; the braiding layer has a right side and a back side; the right side of the braiding layer is provided with a plurality of flash chips, the chips are round and have a hole in the center, and the flash chips are spread on the braiding layer to form vertically and horizontally staggered grid matrix. The fabric provided by the invention has good antistatic performance and radiation-proof performance. The fabric used in the invention has rich texture, rich three-dimensional sense and layering sense, but also has the flash effect.

Owner:JIANGYIN YASHUN GARMENT

Anti-static stereoscopic clothes

InactiveCN105581394AEliminate static electricityAvoid damageProtective garmentSpecial outerwear garmentsPerspirationMoisture absorption

The invention relates to anti-static stereoscopic clothes. The anti-static stereoscopic clothes comprise a clothes body (1) and static electricity conductive wires (5) arranged in the clothes body (1). The bottom side of the clothes body (1) is provided with an electric conduction arm (3). The lower ends of the static electricity conductive wires (5) are connected with the electric conduction arm (3) which is connected with metal fasteners (2) via two electric conduction connecting strips (4). The clothes body (1) comprises an outer layer (1.1), a middle layer (1.2) and an inner layer (1.3). The back surface of the clothes body is compounded with a layer of fabric having a right side and a back side. The right side of a braiding layer is provided with multiple flashy pieces in circular shapes. Centers of the flashy pieces are provided with holes. The flashy pieces are horizontally arranged on the braiding layer. A criss-cross grid matrix is formed by the flashy pieces on the braiding layer. The anti-static stereoscopic clothes have good moisture-absorption and perspiration effects and can eliminate static electricity in time and are stereoscopic.

Owner:吴孟涛

Wool/polyester flashing bright cloth

The invention discloses a wool / polyester flashing bright cloth. The cloth is characterized in that the cloth comprises a wool / polyester blend fiber cloth body; the wool / polyester blend fiber cloth body comprises warp and weft fibers; and flashing fibers are arranged between the warp or weft fibers at intervals. The cloth has reasonable structure and flashing effect and can play a role of warning in the specific environment.

Owner:瞿新

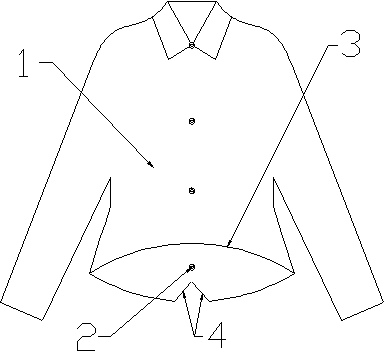

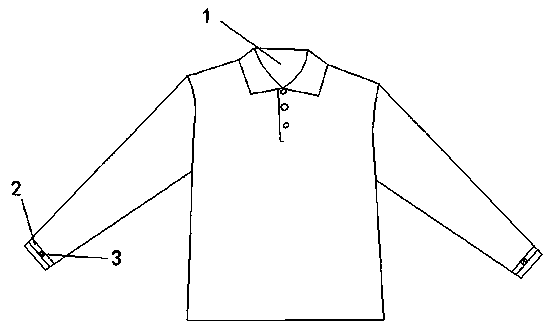

Flashy clothes with sleeves convenient to roll up

InactiveCN104287129AAchieve the effect of fixing the sleevesRich textureTextiles and paperProtective garmentEngineeringLaser

The invention relates to flashy clothes with sleeves convenient to roll up. The flashy clothes comprise a clothes body (1), elastic strips (2) are arranged on linings of sleeve openings of the clothes body (1), buckles (3) are arranged at the two ends of each strip (2), the clothes body (1) is made of fabric which comprises a meshed layer, a plurality of diamond laser reflectors are arranged on the meshed layer, and the diamond laser reflectors are arranged in the mode that based on one diamond laser reflector, other diamond laser reflectors are distributed in a diamond array. The sleeves can not fall down, and the fabric of the flashy clothes is rich in texture, has a layered sense, and has a flashy effect.

Owner:JIANGYIN HANXIN TEXTILE

A color-changing luminescent panel light

ActiveCN108916715BAesthetically pleasingImprove aestheticsMechanical apparatusLight guides detailsLight guideEngineering

The invention discloses a color-changing light-emitting panel lamp, which comprises a frame, a light source, reflective paper, a light guide plate, and a diffusion plate; the shape of the frame is U-shaped, and the frame includes a rib and a light source installation edge, and the two ribs pass through the light source installation edge connection; the sidewall is perpendicular to the light source installation side; the side of the light source installation side on the opening side of the frame is provided with a light source groove, and the light source groove is a rectangular groove; The upper surface is provided with a glitter layer, and the upper surface of the glitter layer is provided with a UV varnish layer; the mixed light and color-changing layer is made of 2-4 parts by weight of phosphor powder, 1-2 parts by weight of color changing powder, and 4-6 parts by weight of UV varnish . The invention has the characteristics of good heat dissipation, narrow frame, thin thickness, beautiful appearance, discoloration and long service life.

Owner:合肥泰沃达智能装备有限公司

Cashmere sweater with advantages of being convenient to wear and good in layered effect

InactiveCN104287150AAdd dimensionQuick wearProtective garmentSpecial outerwear garmentsLaser lightEngineering

The invention relates to a cashmere sweater with the advantages of being convenient to wear and good in layered effect. The cashmere sweater comprises a sweater body (1), wherein sleeves of the sweater body are made of a fabric; a left collar body and a right collar body which form a collar (2) of the sweater body (1) are connected through a buckle; the sweater body (1) is further provided with pockets (6); thickening strips are arranged at the collar (2) and top flies (3) of the sweater body (1); strip-type protrusions are vertically arranged on a lower hem (4) of the sweater body (1); decorative buttons (5) are arranged on one top fly (3) of the sweater body (1); the fabric comprises a netted layer, the netted layer comprises laser light reflecting threads, and the laser light reflecting threads at least form a series of equidistant straight lines on the netted layer; the obverse side of the netted layer is further provided with a light reflecting piece, the light reflecting piece is made of transparent materials and is of a round sheet shape, a hole is formed in the center of the light reflecting piece, and the surface of the light reflecting piece is provided with a laser light reflecting layer. The cashmere sweater has the advantage of being convenient to wear. The fabric adopted for the cashmere sweater has a layered effect.

Owner:JIANGYIN GUORUN TEXTILE RAW MATERIALS SALES

Artificial leather with rich three-dimensional sense and color intrigue effect

InactiveCN104294644ASuit one's needsRich textureSynthetic resin layered productsTextiles and paperSurface layerMaterials science

The invention relates to artificial leather with a rich three-dimensional sense and a color intrigue effect. The artificial leather comprises a surface layer (3) and a base layer (4), wherein the surface layer (3) and the base layer (4) are adhered to each other; a pearl powder layer (2) is bonded on the surface layer (3), and a transparent film (1) is bonded on the pearl powder layer (2); the base layer (4) is made of a fabric; the fabric comprises a braided layer, the braided layer is provided with a front surface and a back surface, a plurality of sequins are arranged on the front surface of the braided layer and are circular, one hole is formed in the center of each sequin, the sequins are horizontally arranged on the braided layer, the sequins form a criss-cross grid matrix on the braided layer, intersection points are formed by a longitudinal grid and a transverse grid, and the intersection points comprise two structural forms of direct cross intersection points and starlike cross intersection points. When people see the artificial leather, the color intrigue effect is shown, and the needs of the people are met. The adopted fabric is rich in texture, three-dimensional sense and layering effect, and moreover, has a flashing effect.

Owner:JIANGYIN HENGLI EDUCATION ARTICLES

A kind of production technology of wear-resistant pa6 bulky yarn

ActiveCN104153077BImprove wear resistanceReduce manufacturing costArtificial thread manufacturing machinesFilament/thread formingWinding machineMolten state

The invention discloses a production process of abrasion-resisting PA6 bulked yarns. The production process of the abrasion-resisting PA6 bulked yarns is characterized by comprising the following steps of 1 extruding and melting solid PA6 slices with the relative viscosity ranging from 2.60 to 2.90 in a screw extruder at the temperature of 250-280 DEG C to form molten-state spinning melts and then conveying the spinning melts into a spinning box body; 2 forming high pressure in a spinning module, spraying the melts through a spinneret plate to form continuous filaments and cooling the filaments through lateral air blowing; 3 cooling cured filaments and putting the filaments into an oiling device to be oiled, wherein the oiling rate is controlled to be 0.4-0.6%; 4 feeding the oiled filaments into a drafting area to be draught, wherein the drafting rate is 1.6-2.2; 5 feeding draught filaments into a bulking box to be subjected to bulking treatment, wherein technological parameters of the bulking box are that the temperature of the bulking box for bulking the filaments is 150-200 DEG C, compressed air for feeding is 7.0-9.0 bar, and the suction air negative pressure for fixing and piling up the filaments in the bulking box to enable the filaments to be bulked is 50-80 mbar; 6 conveying the filaments into a cooling drum to be cooled, wherein the rotating speed of the cooling drum is 50-80 turns / min, and the suction air negative pressure for cooling of the cooling drum is 15-35 mbar; 7 feeding the filaments having passed through a first set of filament guiding discs into a main network system, and feeding the filaments having passed through the main network system into a winding machine to be cylindrical filament drums through winding.

Owner:TAICANG UNIVERSAL FIBERS COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com