Method for manufacturing wear-resistant antiskid dry-particle ceramic tile

A manufacturing method and technology for ceramic tiles, which are applied in the field of manufacture of wear-resistant and anti-skid dry-grain ceramic tiles, can solve the problems of being difficult to withstand long-term wear, limited screen printing thickness, affecting the effect of pattern decoration, etc. Surface anti-skid performance, high decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

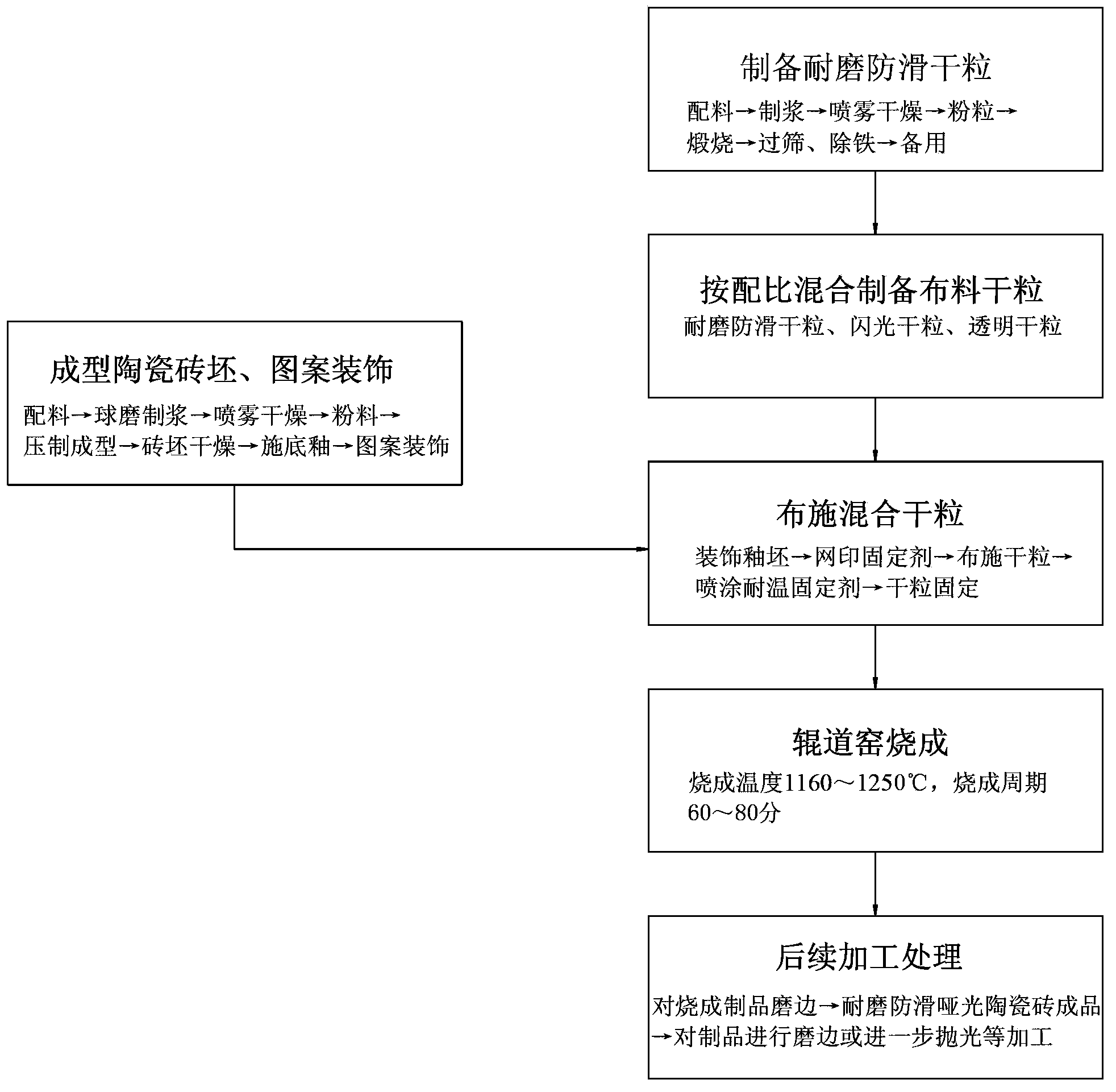

[0046] Please refer to the attached figure 1 Shown, in the present embodiment, the manufacture method of described wear-resisting non-slip dry grain ceramic tile, comprises the following steps:

[0047] ⑴Molding the ceramic tile plane substrate for pattern decoration;

[0048] (2) Preparation of dry granules with wear-resistant and anti-skid properties;

[0049] (2.1) According to the formula of wear-resistant and non-slip dry granules, put the ingredients into a ball mill, add water and wet grind, spray and dry the slurry to make powder particles, with a particle size between 0.12mm and 0.40mm;

[0050] (2.2) Pack the powder particles in a sagger and send them into a kiln for calcination, the firing temperature is 900°C-1100°C, and the cycle is 120 minutes;

[0051] (2.3) Sieve the cooked powder particles to prepare particles with a particle size of 0.13 mm to 0.35 mm for subsequent use;

[0052] (3) Mix wear-resistant and non-slip dry granules, flashing dry granules, and ...

Embodiment 2

[0083] See attached figure 1 Shown, in the present embodiment, the manufacture method of described wear-resisting non-slip dry grain ceramic tile, comprises the following steps:

[0084] ⑴Molding the ceramic tile plane substrate for pattern decoration;

[0085] (2) Preparation of dry granules with wear-resistant and anti-skid properties;

[0086] (2.1) According to the formula of wear-resistant and non-slip dry granules, put the ingredients into a ball mill, add water and wet grind, spray and dry the slurry to make powder particles, with a particle size between 0.12mm and 0.40mm;

[0087] (2.2) Pack the powder particles in a sagger and send them into a kiln for calcination, the firing temperature is 900°C-1100°C, and the cycle is 120 minutes;

[0088] (2.3) Sieve the powder particles into particles with a particle size between 0.13mm and 0.35mm for later use

[0089] (3) Mix wear-resistant and non-slip dry granules, flashing dry granules, and transparent dry granules accord...

Embodiment 3

[0118] See attached figure 1 shown in this example, see the attached figure 1 Shown, in the present embodiment, the manufacture method of described wear-resisting non-slip dry grain ceramic tile, comprises the following steps:

[0119] ⑴Molding the ceramic tile plane substrate for pattern decoration;

[0120] (2) Preparation of dry granules with wear-resistant and anti-skid properties;

[0121] (2.1) According to the formula of wear-resistant and non-slip dry granules, put the ingredients into a ball mill, add water and wet grind, spray and dry the slurry to make powder particles, with a particle size between 0.12mm and 0.40mm;

[0122] (2.2) Pack the powder particles in a sagger and send them into a kiln for calcination, the firing temperature is 900°C-1100°C, and the cycle is 120 minutes;

[0123] (2.3) Sieve the powder particles into particles with a particle size between 0.13mm and 0.35mm for later use

[0124] (3) Mix wear-resistant and non-slip dry granules, flashing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com