Method for preparing high-purity mullite powder through modified fly ash at high yield

A technology of mullite powder and fly ash, which is applied in the field of high-yield preparation of high-purity mullite powder by aluminum sol modified fly ash, and the field of high-purity mullite prepared by fly ash, which can solve the complex process and raw material cost High, low actual utilization rate of fly ash and other problems, to achieve high yield and increase the effect of mullite content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

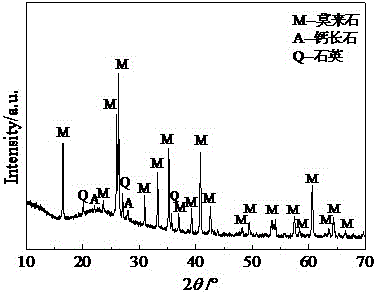

[0028] Take 50g of fly ash passed through a 120-mesh sieve, add 15 g of 20% aluminum sol aqueous solution, ball mill and mix for 1 hour to modify the surface of fly ash, dry in a drying oven at 110°C for 2 hours after ball milling, and pass through 120 mesh screen, and the obtained powder is modified fly ash. The modified fly ash was calcined in a muffle furnace at 1100 °C for 2 h, then crushed with a ceramic mortar, and prepared into a suspension with a solid content of 20%, adding ZrO 2 Grinding balls, ball milling for 4 hours, washing with distilled water, suction filtration, and drying to obtain calcined fly ash powder. Utilize X-ray powder diffractometer to test XRD spectrogram, as attached figure 1 As shown, it can be seen that in addition to the mullite phase, the calcined fly ash also contains a glass phase and a quartz phase. Use Jade 6.0 software to fit the full spectrum of the XRD pattern, and analyze the relative content of mullite, which accounts for about 62% ...

Embodiment 2

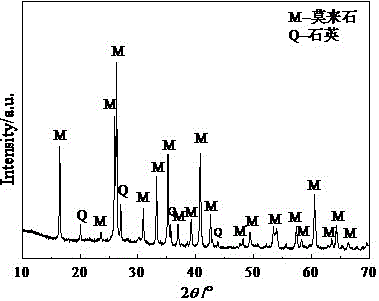

[0030] Take 30 g of calcined fly ash in Example 1, add 270 ml of NaOH aqueous solution with a concentration of 2 mol / L, ultrasonically disperse it, put it into a hydrothermal reaction kettle with a capacity of 500 ml, keep the temperature at 120 ° C for 1 hour, and then use the concentration Wash with 1 mol / L HCl aqueous solution, and obtain mullite powder after drying. Use an X-ray diffractometer to test the powder XRD spectrum, as attached figure 2 As shown, it can be seen that the glass phase in the mullite powder is completely eliminated, and the powder is composed of a mullite phase and a small amount of quartz phase. Use Jade6.0 software to fit the full spectrum of the XRD spectrum, and analyze the relative content of mullite in the powder, which accounts for about 82% of the powder mass.

Embodiment 3

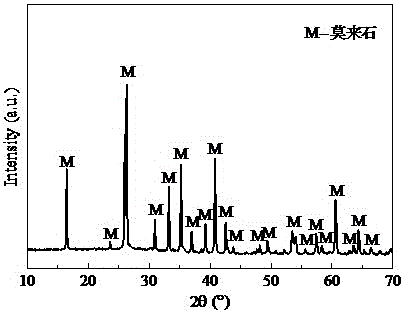

[0032] Take 10 g of mullite powder in Example 2, add 100 ml of distilled water, use NaOH to adjust the pH value to 11, after mechanical stirring for 10 min, according to the concentration of flotation agent 1 × 10 -3 mol / L, add flotation agent sodium dodecylsulfonate, stir for 2 minutes, flotation and scrape foam for 6 minutes, after the flotation is completed, the foam product and the product in the tank are cleaned, filtered, and dried to obtain the quartz separated by flotation. High-purity mullite powder. Utilize X-ray diffractometer to test powder XRD spectrogram, as attached image 3 As shown, it shows that basically only the mullite phase remains in the powder. Use Jade 6.0 software to fit the full spectrum of the XRD pattern, and analyze the relative content of mullite in the powder, which accounts for about 98.2% of the powder mass. The morphology of the high-purity mullite powder is observed by scanning electron microscopy, as shown in attached Figure 4 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com