Method for preparing mullite refractory material from aluminum plant sludge and pyrophyllite

A technology of aluminum factory sludge and refractory materials, which is applied in the field of refractory materials, can solve the problems of performance impact, large body shrinkage, etc., and achieve the effects of excellent performance, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Take the dry sludge provided by Nanping Aluminum Plant in Fujian Province and pyrophyllite from Minhou, Fuzhou as examples. Al in aluminum plant sludge 2 o 3 Content is 6116%, SiO 2 The content is 2.34%, the loss on ignition is 34.26%, and the Al in pyrophyllite 2 o 3 Content is 16.93%, SiO 2 The content is 78.41%, the main mineral composition is pyrophyllite and a small amount of quartz and kaolinite.

[0037] 2. Send the aluminum plant sludge and pyrophyllite to the ball mill for dry grinding. The input particle size of aluminum plant sludge is controlled within 1 mm, and the output particle size is controlled within 3 μm; the input particle size of pyrophyllite is controlled within 10 mm, and the output particle size is controlled within 5 μm.

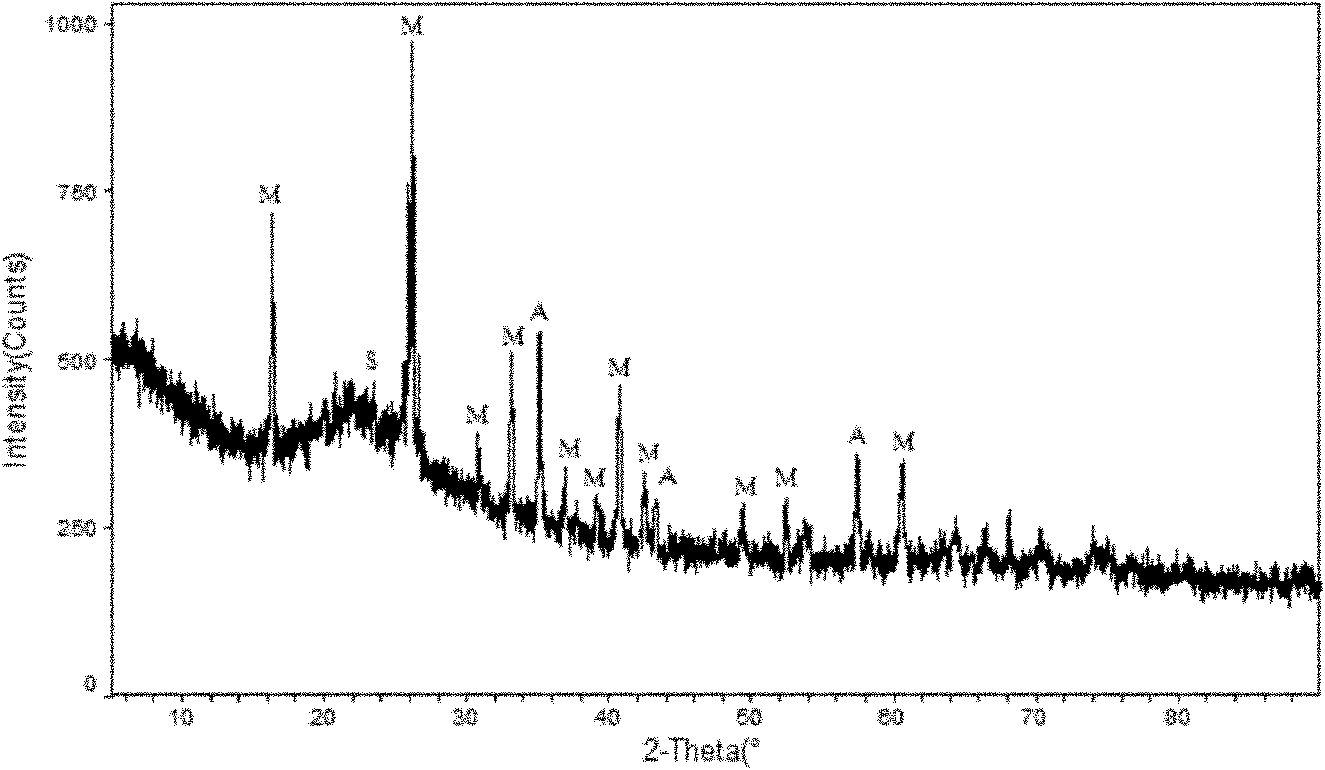

[0038] 3. Send the dry-milled aluminum plant sludge and pyrophyllite into a ball mill, add water for wet grinding, and obtain aluminum plant sludge-pyrophyllite mixed slurry. According to the mass ratio, aluminum pl...

Embodiment 2

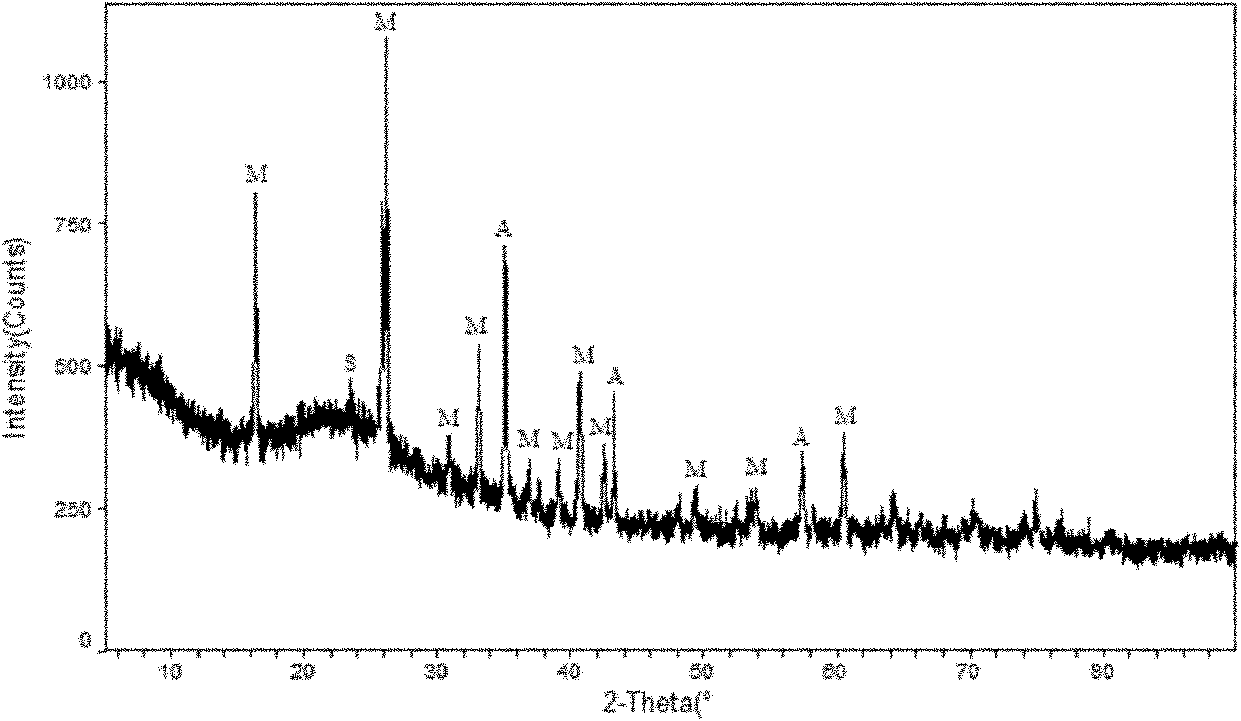

[0045] Raw material and technological process are with embodiment 1. Aluminum plant sludge: pyrophyllite is 3:1, at this time Al 2 o 3 with SiO 2 The ratio of the mass percent content is 2.35. The size of the pressed green body is 5mm×4mm×50mm, and the molding pressure is 135MPa; the pressurization speed is controlled as: 5MPa / s when 0-50MPa; 10MPa / s when 50-100MPa; 5MPa / s when 100-135MPa s; holding time is 10s. The sintering temperature is 1550°C; the heating rate of the sintering process is controlled as follows: from room temperature to 900°C, 10°C / min; from 900 to 1200°C, 5°C / min; from 1200 to 1550°C, 3°C / min; the sintering time is 4h. The obtained sample forms three crystal phases, which are mullite, Al 2 o 3 , SiO 2 . Among them, the content of mullite is 93.3%, Al 2 o 3 content of 6.1%, SiO 2 The content is 0.6%. The flexural strength of the sample is 22.17MPa, the primary thermal shock retention rate is 77.9%, the refractoriness is 1650°C, and the bulk den...

Embodiment 3

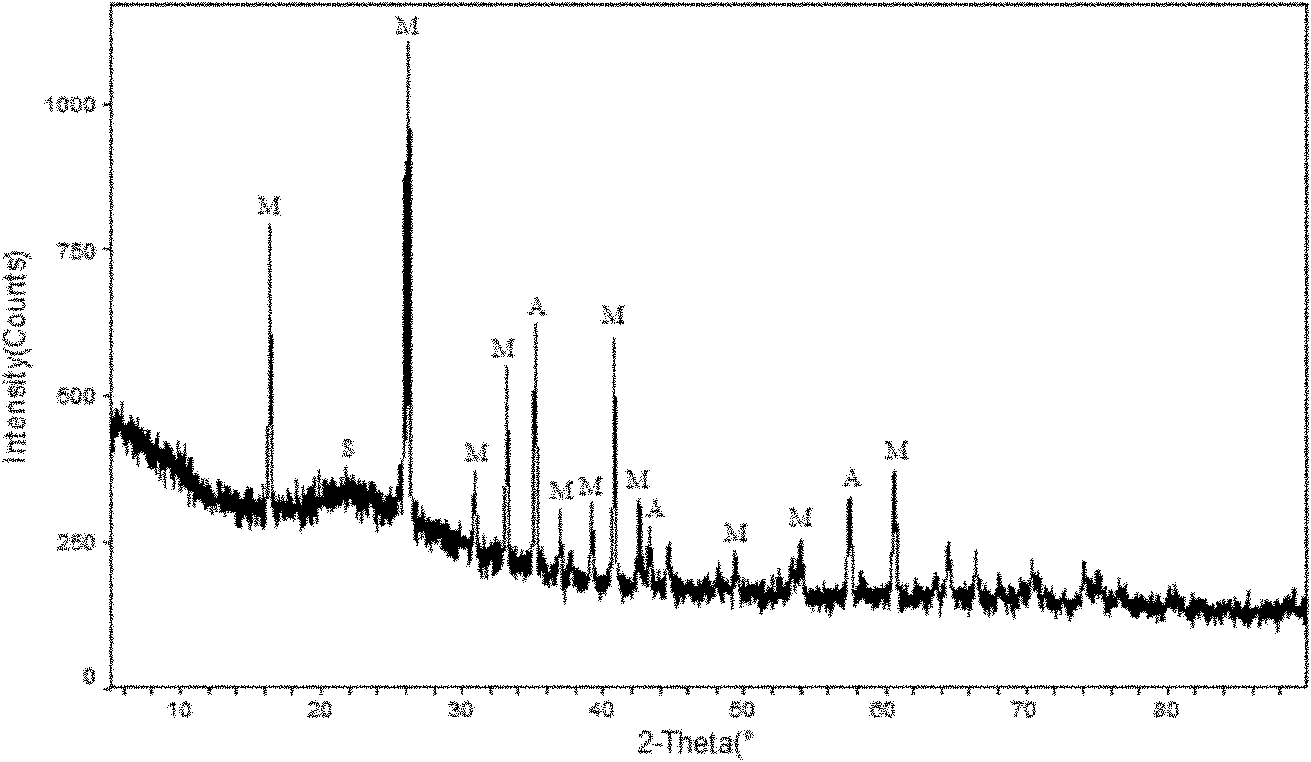

[0047] Raw material and technological process are with embodiment 1. Aluminum plant sludge: pyrophyllite is 3.55:1, at this time Al 2 o 3 with SiO 2 The ratio of the mass percent content is 2.70. The size of the pressed green body is 300mm×300mm×30mm, and the molding pressure is 150MPa; the pressurization speed is controlled as: 3MPa / s when 0-50MPa; 5MPa / s when 50-100MPa; 3MPa / s when 100-150MPa s; holding time is 45s. The sintering temperature is 1500°C; the heating rate of the sintering process is controlled as follows: from room temperature to 900°C, 10°C / min; from 900 to 1200°C, 5°C / min; from 1200 to 1500°C, 3°C / min; the sintering time is 6h. The obtained sample forms three crystal phases, which are mullite, Al 2 o 3 , SiO 2 . Among them, the content of mullite is 94.2%, Al 2 o 3 Content is 5.2%, SiO 2 The content is 0.6%. The flexural strength of the sample is 21.53MPa, the primary thermal shock retention rate is 82.6%, the refractoriness is 1600°C, and the bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com