A kind of petroleum fracturing proppant prepared by utilizing oil shale ash residue and preparation method thereof

A technology of fracturing proppant and oil shale ash, which is applied in the direction of chemical instruments and methods, earthwork drilling, and drilling compositions, etc., which can solve the health hazards of surrounding residents, serious pollution of land, water sources, and oil shale Problems such as large accumulation of ash and slag can be achieved to improve the use value, solve the effects of large volume density and apparent density, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

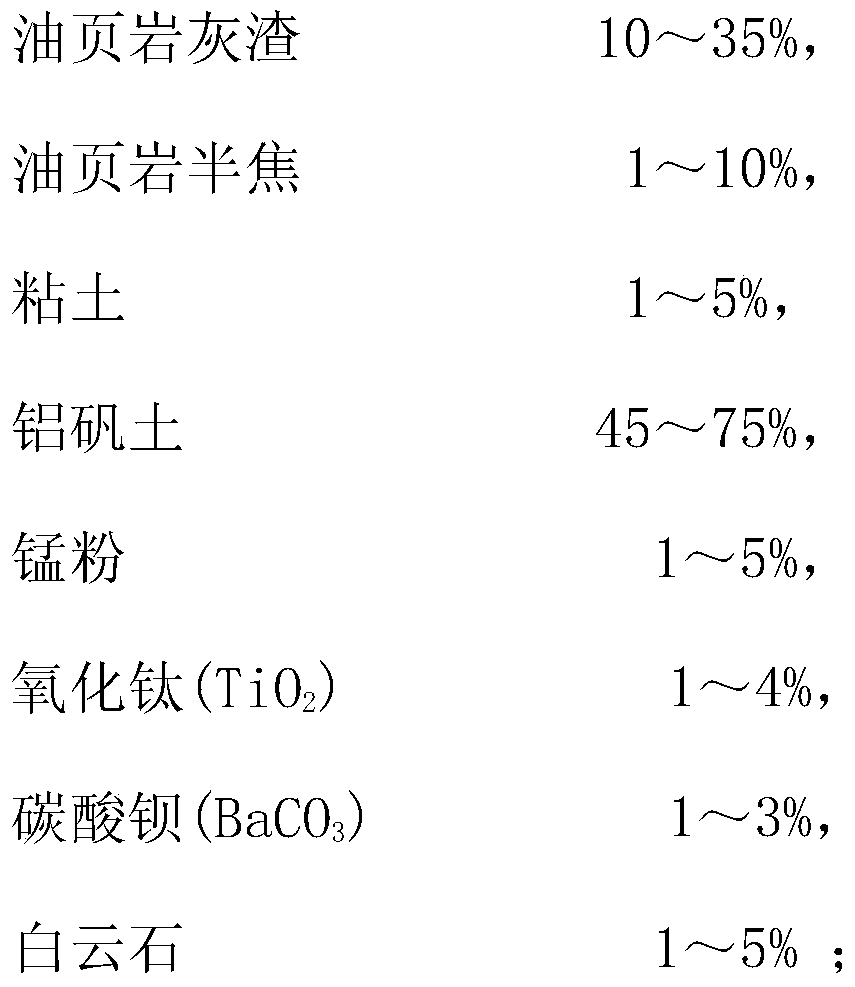

[0021] A petroleum fracturing proppant prepared by using oil shale ash, which is composed of the following mass percentages of material raw materials:

[0022]

[0023] The preparation method of the petroleum fracturing proppant includes the following steps:

[0024] 1) Raw material pretreatment: Crushed oil shale ash, oil shale semi-coke and bauxite;

[0025] 2) Mixing: Mix the crushed oil shale ash, oil shale semi-coke, bauxite with clay, manganese powder, titanium oxide, barium carbonate and dolomite, and use a ball mill to grind the mixture to a size of 400 mesh screen;

[0026] 3) Pellets: use a pan granulator to pelletize, and then mix and subdivide the mixture into pellets of 0.45 to 0.9 mm, and the water content of the pellets is 40% to 55%;

[0027] 4) Drying: Dry the pellets at 200°C for 1 hour to dry;

[0028] 5) Calcining: The dried pellets are sent to the rotary kiln for sintering, the sintering temperature is 1100℃, and the sintering time is 2h;

[0029] 6) Cooling: Air coo...

Embodiment 2

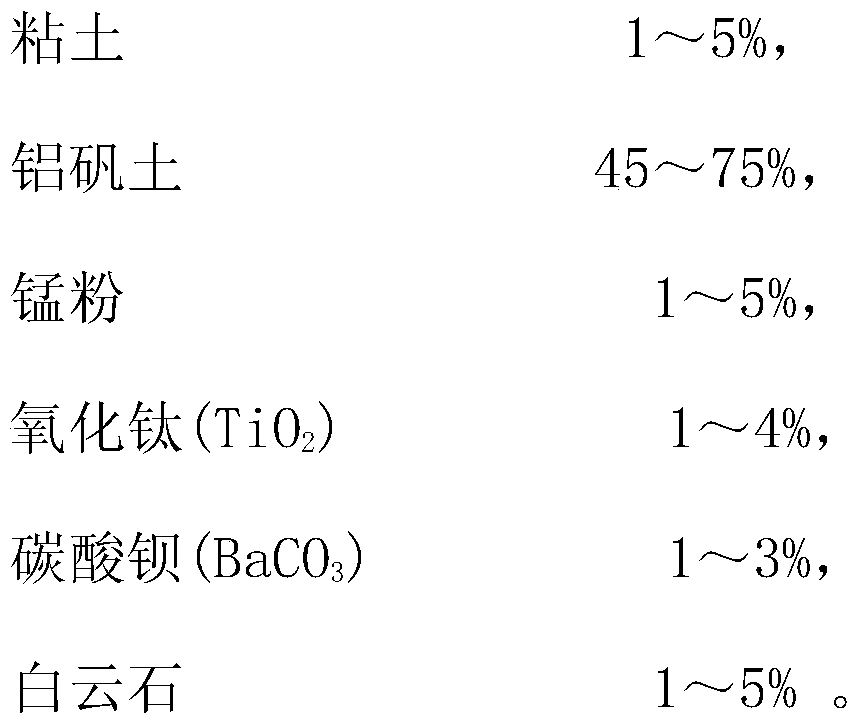

[0032] A petroleum fracturing proppant prepared by using oil shale ash, which is composed of the following mass percentages of material raw materials:

[0033]

[0034] The preparation method of the petroleum fracturing proppant includes the following steps:

[0035] 1) Raw material pretreatment: Crushed oil shale ash, oil shale semi-coke and bauxite;

[0036] 2) Mixing: Mix the crushed oil shale ash, oil shale semi-coke, bauxite with clay, manganese powder, titanium oxide, barium carbonate and dolomite, and use a ball mill to grind the mixture into fine particles, and pass 400 mesh screen;

[0037] 3) Pellets: use a pan granulator to pelletize, and then mix and subdivide the mixture into pellets of 0.45 to 0.9 mm, and the water content of the pellets is 40% to 55%;

[0038] 4) Drying: Dry the pellets at 200°C for 1 hour to dry;

[0039] 5) Calcining: The dried pellets are sent to the rotary kiln for sintering, the sintering temperature is 1200℃, and the sintering time is 2h;

[0040] 6)...

Embodiment 3

[0043] A petroleum fracturing proppant prepared by using oil shale ash, which is composed of the following material components by mass percentage:

[0044]

[0045]

[0046] The preparation method of the petroleum fracturing proppant includes the following steps:

[0047] 1) Raw material pretreatment: crushing oil shale ash, oil shale semi-coke and bauxite;

[0048] 2) Mixing: Mix the crushed oil shale ash, oil shale semi-coke, bauxite with clay, manganese powder, titanium oxide, barium carbonate and dolomite, and grind the mixture into fine particles with a ball mill and pass through a 400 mesh sieve ;

[0049] 3) Pellets: use a pan granulator to pelletize, and then mix and subdivide the mixture into pellets of 0.45 to 0.9 mm, and the water content of the pellets is 40% to 55%;

[0050] 4) Drying: Dry the pellets at 200°C for 1 hour to dry;

[0051] 5) Calcining: send the dried pellets to the rotary kiln for sintering, the sintering temperature is 1250℃, and the sintering time is 2.5h;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com