Antibacterial and anti-mite shell fabric with layered feeling

A layering and fabric technology, applied in the field of fabrics and textile fabrics, can solve the problems of not being able to prevent mites, few types of bacteria that can be resisted, and not having a sense of layering, so as to achieve good air permeability and durability, ensure good health, layered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

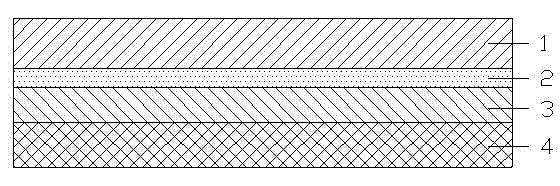

[0018] see figure 1 , the present invention relates to a layered antibacterial and anti-mite fabric, which sequentially includes a surface layer 1, a moisture-permeable adhesive layer 2, an anti-mite film layer 3 and a base layer 4 from outside to inside, and the surface layer 1 is PU mixed with an antibacterial agent The antibacterial agent is a silver ion mixed liquid antibacterial agent, and the antibacterial agent is uniformly fused in the PU film, and the thickness of the surface layer 1 is 12-13 μm.

[0019] The anti-mite film layer 3 has micropores for air molecules to freely penetrate and can isolate water molecules and mites. The size of the micropores is between the diameter of water molecules and the diameter of air molecules. The weight of the base layer 4 is 30~600g / m 2 , the anti-mite film layer 3 can be one or any combination of TPU film layer, PVC film layer, PE film layer or foamed PVC film layer, and its weight is 10 ~ 300g / m 2 .

[0020] The surface layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com