Low-zirconium white glaze for sanitary ceramic and preparation process of low-zirconium white glaze

A technology of sanitary ceramics and preparation technology, which is applied in the field of ceramic glazes, can solve the problems of unsatisfied processing performance, product performance and environmental protection, and does not take into account the internal composition and matching of ceramic glazes, etc., to achieve high gloss, Effect of high ceramic whiteness and low fluidity at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preparation process of low-zirconium white glaze, comprising the following steps:

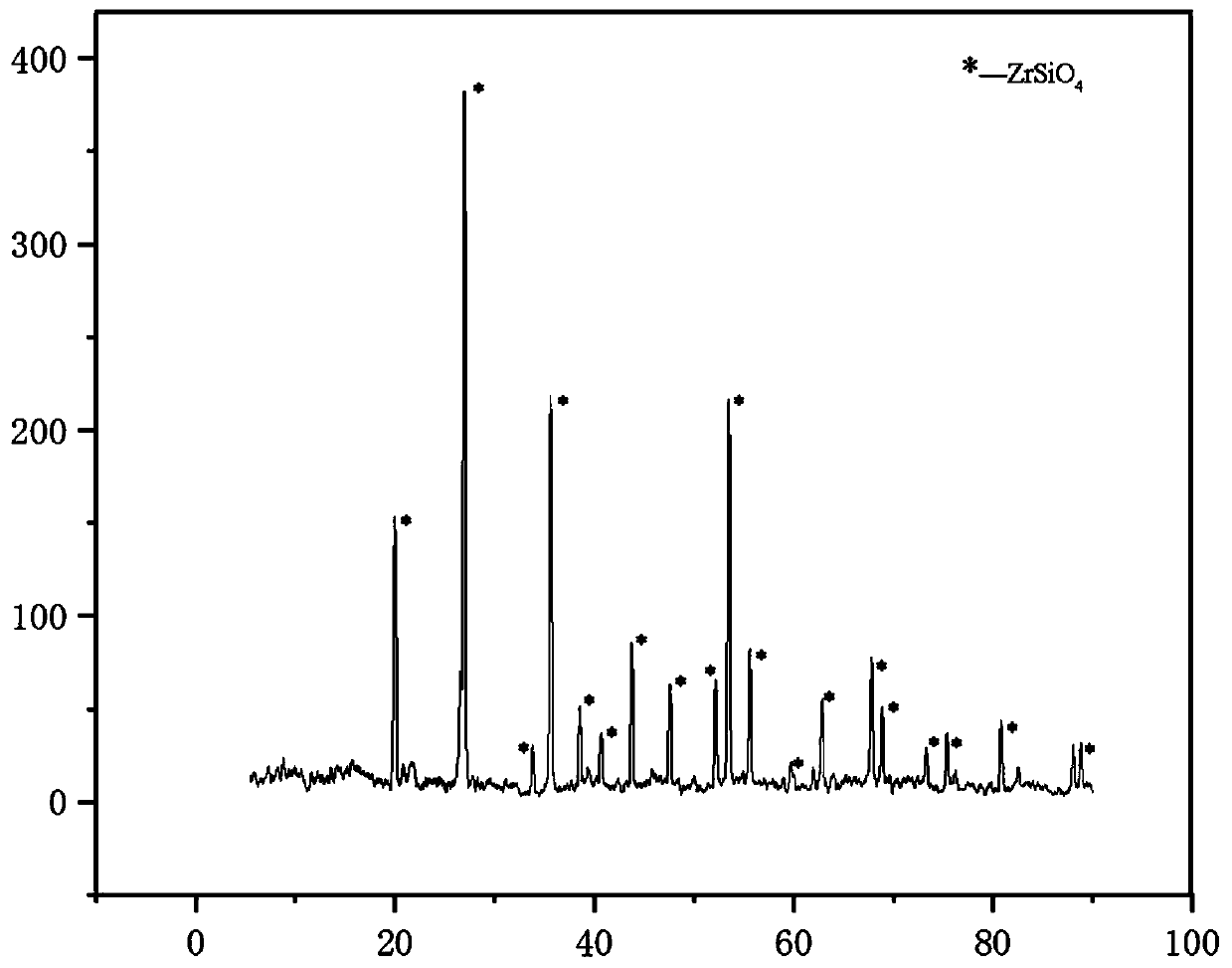

[0036] (1) Mix raw materials including zirconium silicate, wollastonite, dolomite, frit and calcined talc, and ball mill until the content of particle size below 10 μm accounts for 70-74%, that is, the whitening agent is prepared;

[0037] (2) Mix the raw materials including quartz, kaolin, alumina, potassium feldspar, albite, calcite and zinc oxide, into balls, and add step (1) when the ball mill particle size is less than 10 μm and the content accounts for 45-65%. whitening agent; and continue ball milling to mix evenly to obtain coarse white glaze;

[0038] (3) Sieve the coarse white glaze to remove iron to obtain a low-zirconium white glaze.

[0039] To further illustrate, in the step (2), after adding the whitening agent, ball mill until the glaze slurry has a particle size of less than 10 μ and the content is 56-60%, and passes through a 325-mesh sieve, and the balance is ≤0.1%....

Embodiment A

[0057] A preparation process of low-zirconium white glaze, comprising the following steps:

[0058] (1) Mix the raw materials including zirconium silicate, wollastonite, dolomite, frit and burnt talc, and ball mill until the content of the particle size is less than 10 μm accounts for 72%, that is, the whitening agent is prepared;

[0059] (2) Mix the raw materials including quartz, kaolin, alumina, potassium feldspar, albite, calcite and zinc oxide, and put them into balls, and add the additive of step (1) when the ball mill particle size is less than 10 μm and the content accounts for 55%. White agent; ball milled until the content of the glaze slurry with a particle size of less than 10μ is 60%, and passed through a 325-mesh sieve, with a balance of ≤0.1%, to obtain a coarse and clean white glaze;

[0060] (3) Mix the coarse white glaze iron remover and the magnetic rod to remove iron, pass through a 180-mesh sieve to obtain a low zirconium white glaze; repeat 2 times.

[...

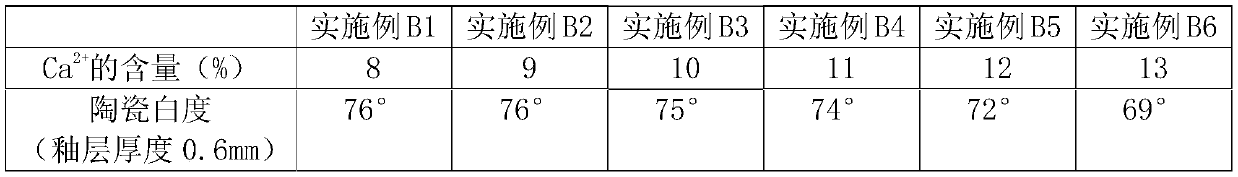

Embodiment B

[0074] A preparation process of low-zirconium white glaze, comprising the following steps:

[0075] (1) Mix the raw materials including zirconium silicate, wollastonite, dolomite, frit and burnt talc, and ball mill until the content of the particle size is less than 10 μm accounts for 72%, that is, the whitening agent is prepared;

[0076] (2) Mix the raw materials including quartz, kaolin, alumina, potassium feldspar, albite, calcite and zinc oxide, and put them into balls, and add the additive of step (1) when the ball mill particle size is less than 10 μm and the content accounts for 55%. White agent; ball milled until the content of the glaze slurry with a particle size of less than 10μ is 60%, and passed through a 325-mesh sieve, with a balance of ≤0.1%, to obtain a coarse and clean white glaze;

[0077] (3) Mix the coarse white glaze iron remover and the magnetic rod to remove iron, pass through a 180-mesh sieve to obtain a low zirconium white glaze; repeat 2 times.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com