Intelligent controlling wall coating material and preparation method thereof

A coating material and intelligent coating technology, applied in coatings, polyether coatings, etc., can solve problems such as difficult large-scale on-site construction, inability to visually determine the photocatalytic effect, and product characteristics of a single composition structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

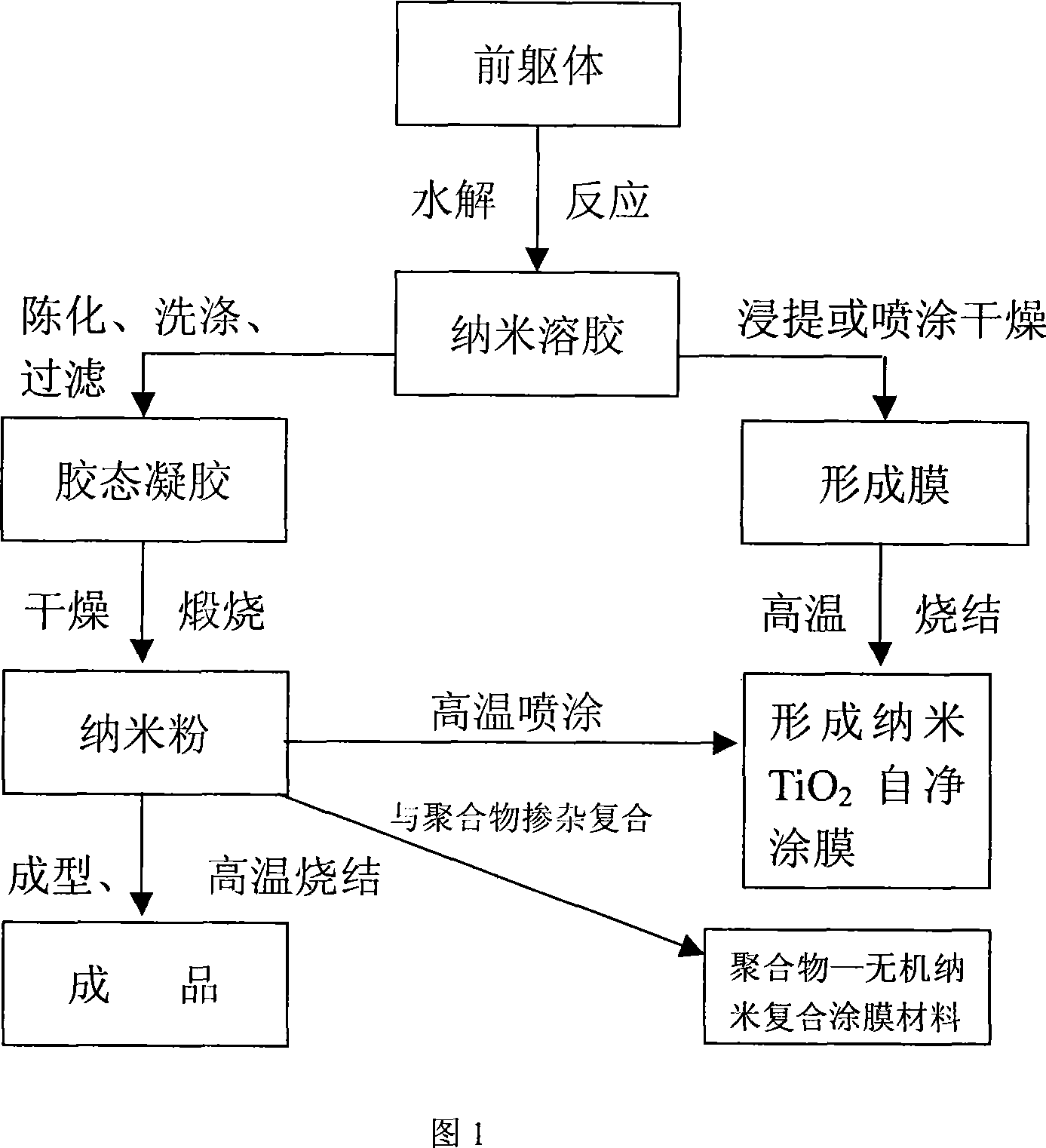

Method used

Image

Examples

Embodiment 1

[0087] Embodiment 1 1. Preparation of intelligent coating materials suitable for interior walls:

[0088]

[0089] Steps:

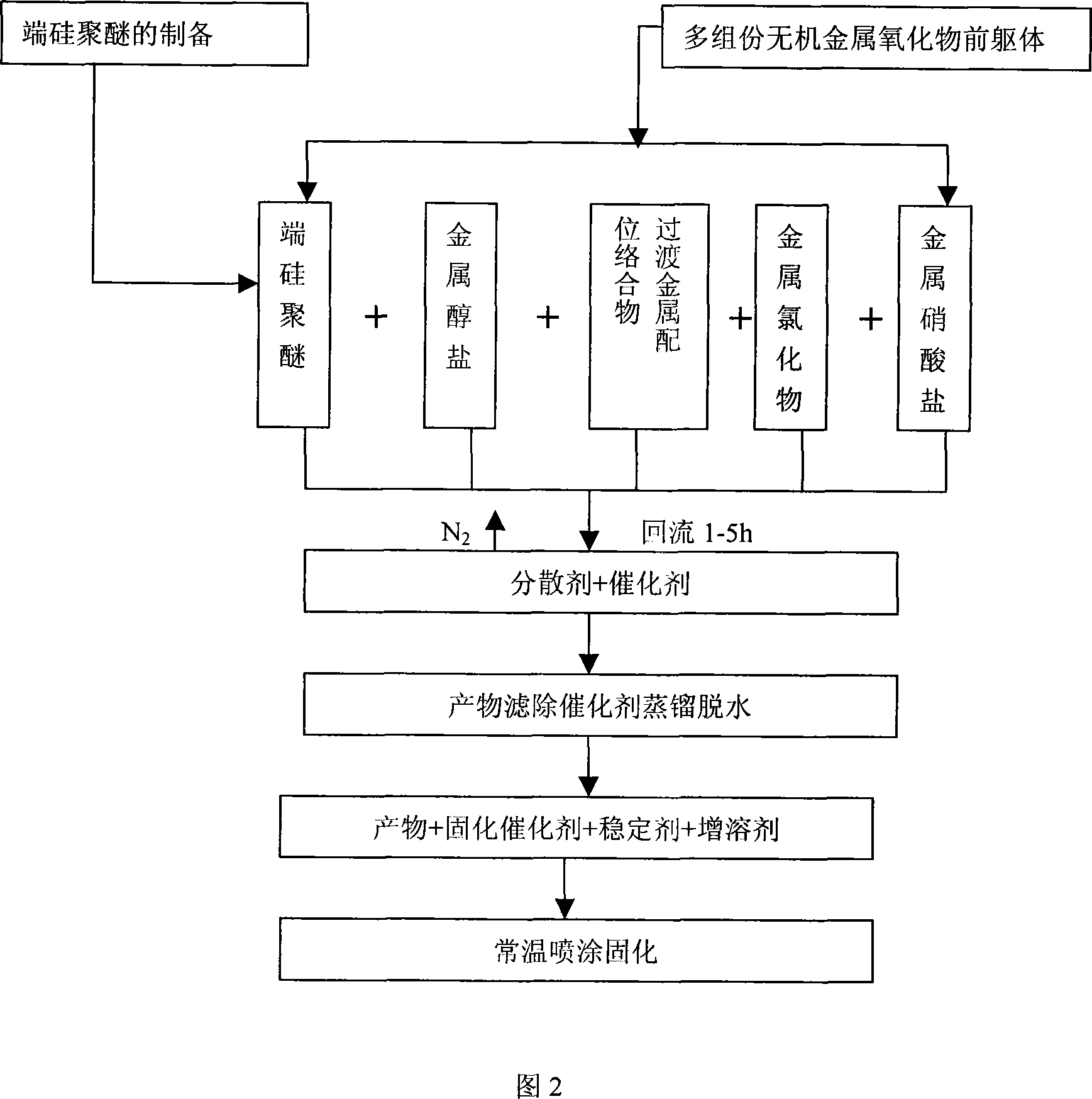

[0090] 1. A. Dissolve the transition metal alkoxide in absolute ethanol, and then add AcAc according to the metered amount to make a complex solution. B. Nitrates are soluble in ethanol or water. C. Aluminum isopropoxide (or aluminum acetylacetonate) is dissolved in absolute ethanol. D. Add ethyl orthosilicate [Si(OEt) 4 ], Mn ‾ = 400 - 15000 Components such as silicon-terminated polyether with 2-3 functional groups are refluxed for 1-5h under nitrogen.

[0091] 2. After hydrolysis and condensation, the catalyst is filtered out, the filtrate is evaporated to remove solvent and water, and 1-5% stabilizer, 1-5% solubilizer, tin-titanium composite curing catalyst (Sn / Ti=1-1.5), 0.1 -3%

[0092] Note: To prevent NOx from escaping during the reaction, use urea to absorb t...

Embodiment 2

[0093] Embodiment 2, the preparation example that is suitable for the intelligent coating material of exterior wall

[0094]

[0095]

[0096] All the other ingredients consumption and operation method are identical with example 1.

Embodiment 3

[0097] Embodiment 3, the preparation example that is suitable for the intelligent coating material of interior wall

[0098]

[0099] The remaining ingredients and operating steps are the same as Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com