Novel plastic raw material

A raw material and plastic technology, applied in the field of plastics, can solve the problems of poor anti-ultraviolet and anti-aging, light leakage, loss of light source, etc., and achieve the effect of strong anti-ultraviolet performance, good comprehensive performance, and meeting market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with specific embodiment:

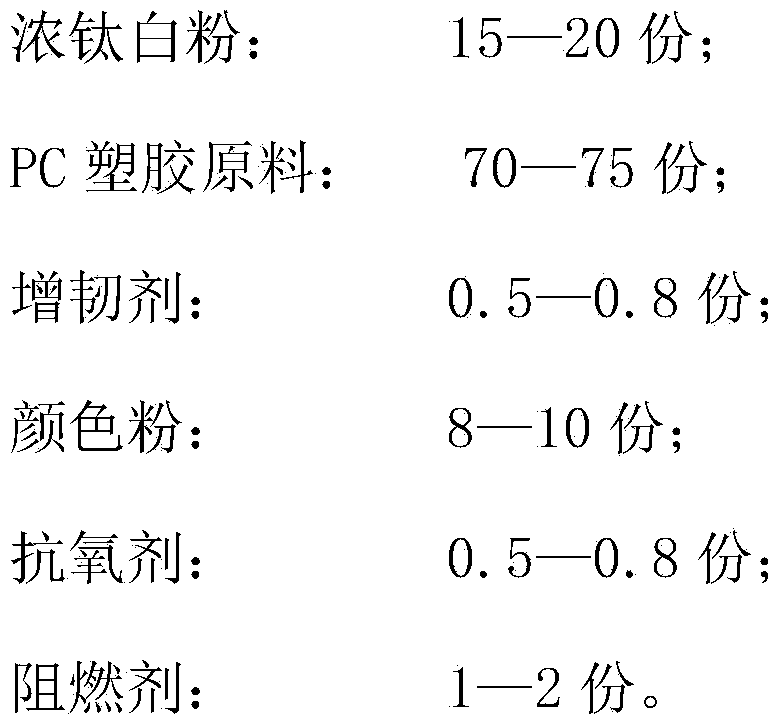

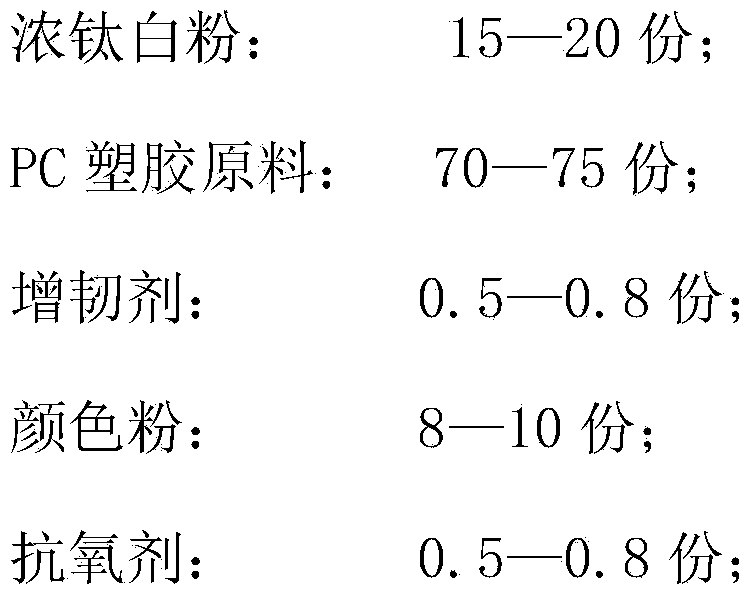

[0014] A novel plastic raw material is prepared from the following raw materials in parts by weight:

[0015]

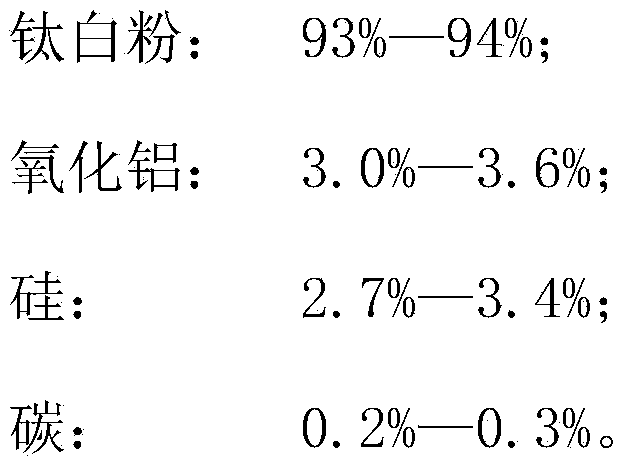

[0016] The proportioning (percentage by weight) of the above-mentioned concentrated titanium dioxide is:

[0017]

[0018] The above-mentioned toughening agent is: phthalate or aliphatic dibasic acid ester or phosphoric acid ester or chlorinated paraffin.

[0019] Among them: the toughening agent can increase the flexibility of the adhesive film.

[0020] Antioxidants can inhibit or delay the deterioration of the appearance and intrinsic properties of plastics and products caused by factors such as heat, light, mechanical stress, electric field, radiation and heavy metal ions contained in additives during the manufacture, processing, application and storage of plastics effect. Such as: phenols, amines, phosphorus-containing compounds, sulfur-containing compounds and orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com