Superfine wool yarn and manufacturing method thereof

A wool yarn and production method technology, applied in yarn, spinning machine, textile and papermaking, etc., can solve the problems affecting product quality and production rate, poor cohesion of mercerized wool fibers, scarce natural resources, etc., to achieve high quality Excellent, soft to the touch, comfortable to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below with embodiment.

[0013] A, Spinning raw material, choose ultra-fine mercerized shrink-proof merino wool, the average fiber length is 76.78mm, the average fineness is 16.31μm, the dispersion coefficient is 21.53%, and the short hair rate below 30mm is 2.21%.

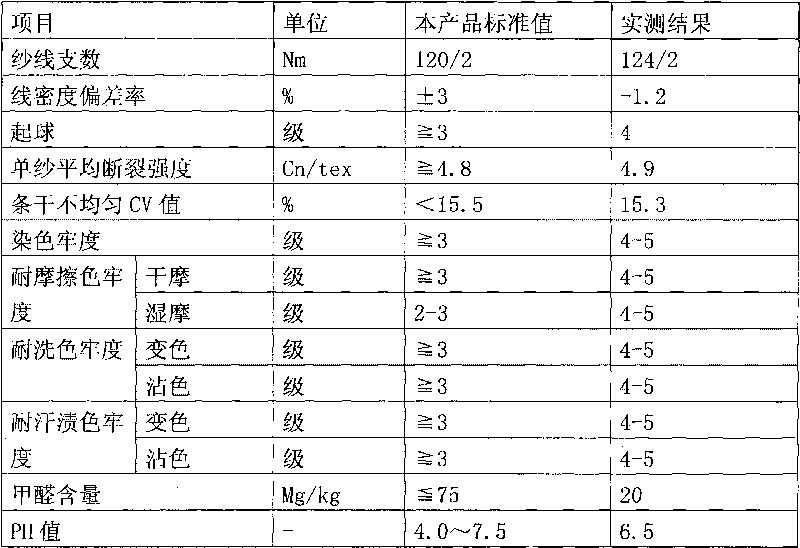

[0014] B, spinning, spinning into twist is 1186t / m, the spun yarn of Z twist direction, then ply into twist is 518t / m, the ply yarn of S twist direction, and yarn count is 120Nm / 2.

[0015] The spinning process steps are:

[0016] ①, Raw material pretreatment, mercerized anti-shrink treatment.

[0017] ②, Combing the wool top again, and the combed wool top is nourished in the humidification room for 48 hours.

[0018] ③, one-time mixing, use B412 mixing machine, feed wool to 8 pieces, control the weight of the sliver at 21g / m (±0.6), mix the sliver with oil and water to ensure that the moisture regain of the fiber off the machine is 17% to 18%; Board model:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Torsion | aaaaa | aaaaa |

| Torsion | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com