Method for producing high-efficiency thermal protection high hygroscopic perspiration-discharging weaving terylene face fabric

A production method and high moisture absorption technology, applied in knitting, dyeing, weft knitting, etc., can solve the problems of not very obvious capillary effect, can not further meet the wearing requirements, fabric functional limitations, etc., to achieve fluffy fibers, High static electricity and lower specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

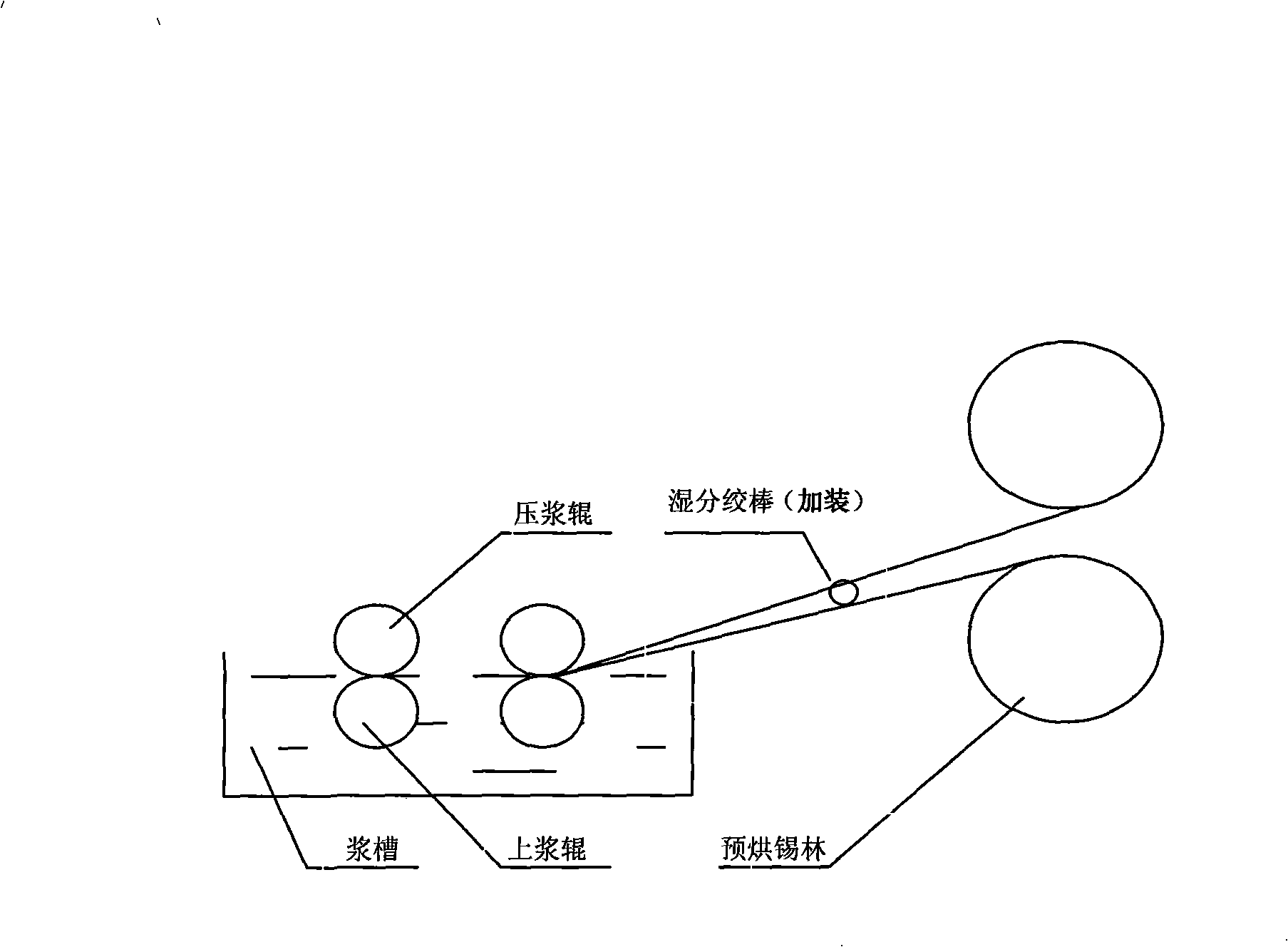

[0015] The production method of high-efficiency warmth, high moisture wicking woven polyester fabric includes the following steps in sequence: 1. spinning, 2. weaving, 3. finishing after printing and dyeing.

[0016] 1. Spinning: The polyester staple fiber with honeycomb in both longitudinal and cross-section is relatively fluffy, and the cohesion between the fibers is poor. During the spinning process, the fiber is easy to be damaged, easy to roll, easy to wind, and easy to block the bell mouth.

[0017] 1) Clean flowers; pre-treatment spray appropriate amount of antistatic agent, cotton roll basis weight 350g / m.

[0018] 2) Carding; choose suitable flat card clothing, use slow speed (16-18rpm), light weight (16.5g / 5m-17.5g / 5m), the 5-point distance between cylinder and flat plate is too large, respectively It is 0.36mm, 0.33mm, 0.30mm, 0.30mm, 0.33mm. Control the temperature and humidity of the workshop: 23±2℃ in winter, 30±2℃ in summer, and 65-68% relative humidity for carding....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com