Method for producing high-efficiency thermal protection high hygroscopic perspiration-discharging weaving terylene face fabric

A production method and high moisture absorption technology, applied in knitting, dyeing, weft knitting, etc., to achieve the effect of improving the process, large specific surface area, and reducing fiber damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

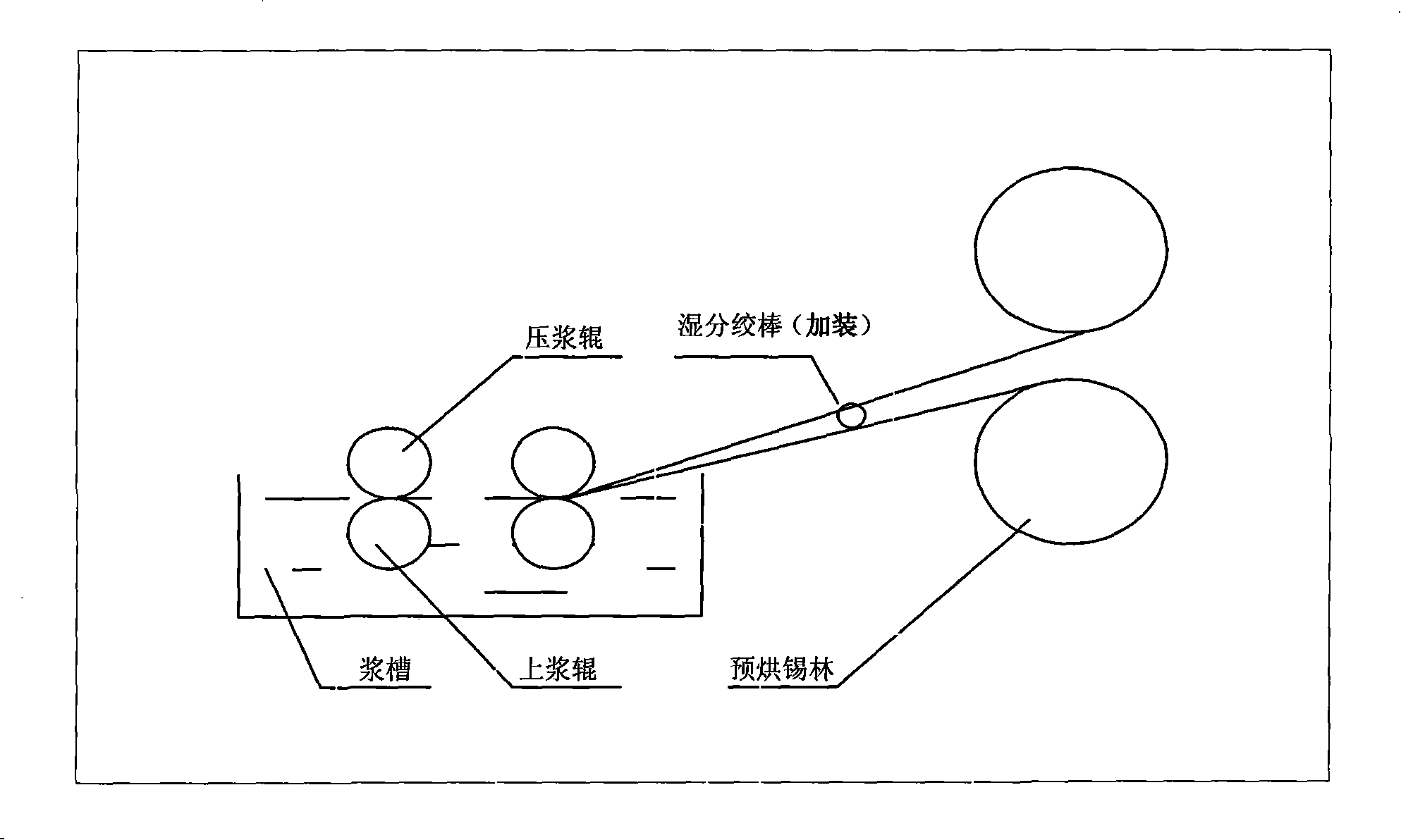

[0017] The production method of the high-efficiency warm-keeping, high moisture-absorbing and sweat-wicking woven polyester fabric comprises the following steps in sequence: 1. spinning, 2. weaving, 3. finishing after printing and dyeing.

[0018] 1. Spinning: Polyester staple fibers with honeycomb-shaped longitudinal and cross-sections are relatively fluffy, and the cohesion between fibers is poor. During the spinning process, the fibers are easy to be damaged, rolled, wound, and blocked.

[0019] 1) Cleaning; Spray an appropriate amount of antistatic agent for pretreatment, and the basis weight of the cotton lap is 350g / m.

[0020] 2) Carding: choose suitable flat card clothing, use slow speed (16-18rpm), light weight (16.5g / 5m-17.5g / 5m), grasp the 5-point distance between the cylinder and the flat too large, respectively 0.36mm, 0.33mm, 0.30mm, 0.30mm, 0.33mm, control workshop temperature and humidity: 23±2°C in winter, 30±2°C in summer, relative humidity 65-68% for carding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com