Branched chain type degradable hydrophilic polyester master batch and preparation method thereof

A technology of polyester masterbatch and branched chain type, which is applied in the field of branched chain degradable hydrophilic polyester masterbatch and its preparation, which can solve the problems of insufficient mechanical strength, poor thermal and mechanical properties of prepared products, and large addition amount , achieve good hydrophilic performance and degradable performance, improve degradable performance, and improve hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

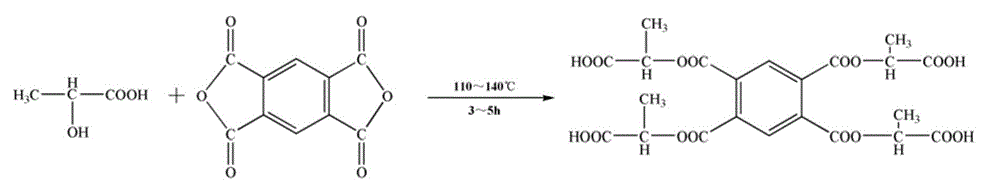

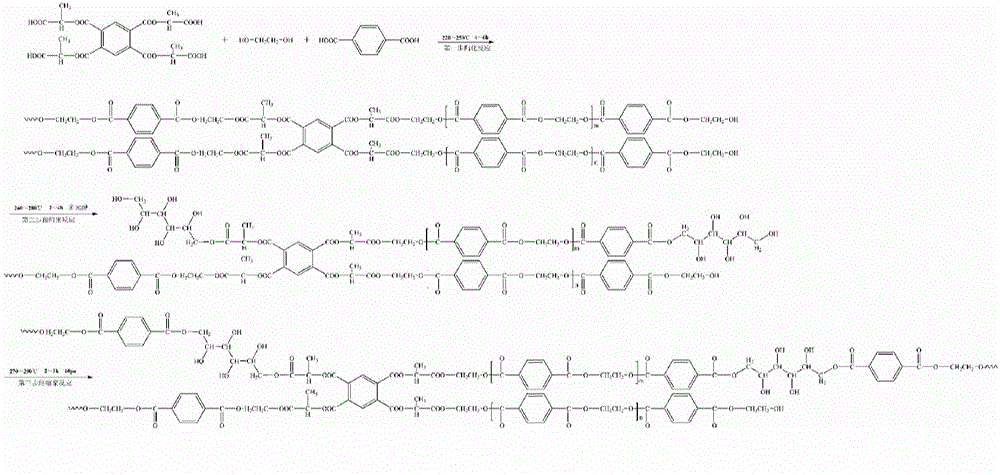

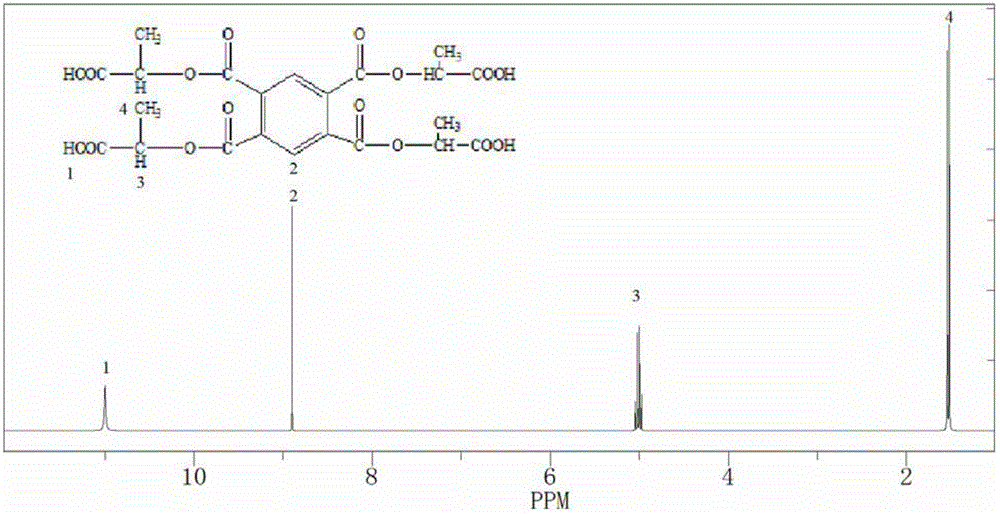

Method used

Image

Examples

Embodiment 1

[0024] Under the protection of nitrogen, the molar ratio of pyromellitic anhydride and lactic acid is 1:4, the reaction temperature is controlled at 110°C, and the reaction is stirred for 5 hours to prepare a branched functional monomer; then under the protection of nitrogen, according to The molar ratio of the polybasic acid and ethylene glycol formed by the branched functional monomer of the raw material and terephthalic acid is 1: 1.25, and the molar ratio of the branched functional monomer and terephthalic acid is 1: 0.05, and then Add terephthalic acid and ethylene glycol raw materials, control the system pressure at 0.3MPa, and the reaction temperature at 220°C, and react for 4 hours to carry out esterification reaction between polybasic acid and ethylene glycol; The molar ratio of alcohol is 1:0.002 for feeding, the raw material of polyol is sorbitol, and the second step of precondensation reaction is carried out, the reaction temperature of the system is controlled at 2...

Embodiment 2

[0026] Under the protection of nitrogen, feeding is carried out according to the molar ratio of pyromellitic anhydride and lactic acid as 1:4, the reaction temperature is controlled at 140 ° C, and the reaction is stirred for 3 hours to prepare branched functional monomers; then under the protection of nitrogen, according to The molar ratio of the polyacid and ethylene glycol formed by the branched chain type functional monomer and terephthalic acid is 1: 1.75, and the molar ratio of the branched chain type functional monomer and terephthalic acid is 1: 0.30, and then Add terephthalic acid and ethylene glycol raw materials, control the system pressure at 0.4MPa, and the reaction temperature at 250°C, and react for 4 hours to carry out esterification reaction between polybasic acid and ethylene glycol; The molar ratio of alcohol is 1:0.008 for feeding, the polyol raw material is pentaerythritol, and the second step of precondensation reaction is carried out. The reaction tempera...

Embodiment 3

[0028] Under the protection of nitrogen, the molar ratio of pyromellitic anhydride and lactic acid is 1:4, the reaction temperature is controlled at 130°C, and the reaction is stirred for 5 hours to prepare a branched functional monomer; then under the protection of nitrogen, according to The molar ratio of the polyacid and ethylene glycol formed by the raw material branched functional monomer and terephthalic acid is 1: 1.65, and the molar ratio of the branched functional monomer and terephthalic acid is 1: 0.25, and then Add terephthalic acid and ethylene glycol raw materials, control the system pressure at 0.3MPa, and the reaction temperature at 250°C, react for 5h for esterification reaction between polybasic acid and ethylene glycol; The molar ratio of alcohol is 1:0.005 for feeding, the raw material of polyol is sorbitol, and the second step of precondensation reaction is carried out, the reaction temperature of the system is controlled at 280° C., and the reaction is kep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com