Mono-carboxyl chitosan/alkannin composite nanometer particles and preparation method thereof

A technology of composite nanoparticles and chitosan, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems of long preparation cycle of nanoparticles, poor stability of nanoparticles, and cytotoxicity. And side effects and other problems, to achieve the effect of increasing accessibility and reactivity, reducing the regularity of molecular arrangement, and improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Stir and disperse monocarboxychitosan powder with a viscosity average molecular weight of 4 to 360,000, a degree of deacetylation ≥ 88.6%, and a C6 carboxyl degree of 19.41% to 56.25% in absolute ethanol, with a working frequency of 19 Ultrasonic cell pulverizer with ~25kHz and ultrasonic power of 50~300W performs ultrasonic cavity treatment on the dispersion liquid for 5~20min, so that the monocarboxychitosan precipitate is crushed into submicron particles, and then dried to obtain monocarboxychitosan submicron particles.

[0036] (2) stirring and dissolving the dried monocarboxychitosan submicron particles in ultrapure water (deionized water filtered 2 to 3 times with a 0.22 to 0.45 μm filter membrane) to prepare a solution with a mass concentration of 0.1 to 1.0%, Then add emulsifier and shikonin, and fully emulsify by magnetic stirring for 1-3 hours to obtain a stable emulsion system. The emulsifier is polysorbate-80, polyvinylpyrrolidone, fatty alcohol polyoxy...

Embodiment 2

[0041] (1) Stir and disperse monocarboxychitosan powder with a viscosity-average molecular weight of 80,000, a deacetylation degree of 90%, and a C6 carboxyl degree of 26.74% in absolute ethanol, with a working frequency of 20kHz and an ultrasonic power of 100W Ultrasonic cell pulverizer is used to ultrasonically treat the dispersion liquid for 10 minutes, so that the monocarboxychitosan precipitate is crushed into submicron particles, and then dried to obtain monocarboxychitosan submicron particles.

[0042] (2) Stir and dissolve the dried monocarboxyl chitosan submicron particles in ultrapure water (deionized water filtered through a 0.22 μm filter membrane 3 times) to prepare a solution with a mass concentration of 0.4%, add emulsifier fatty alcohol polyoxygen Vinyl ether and shikonin were fully emulsified by magnetic stirring for 2 hours to obtain a stable emulsion system. The mass ratio of the emulsifier fatty alcohol polyoxyethylene ether to monocarboxy chitosan is 1:1; ...

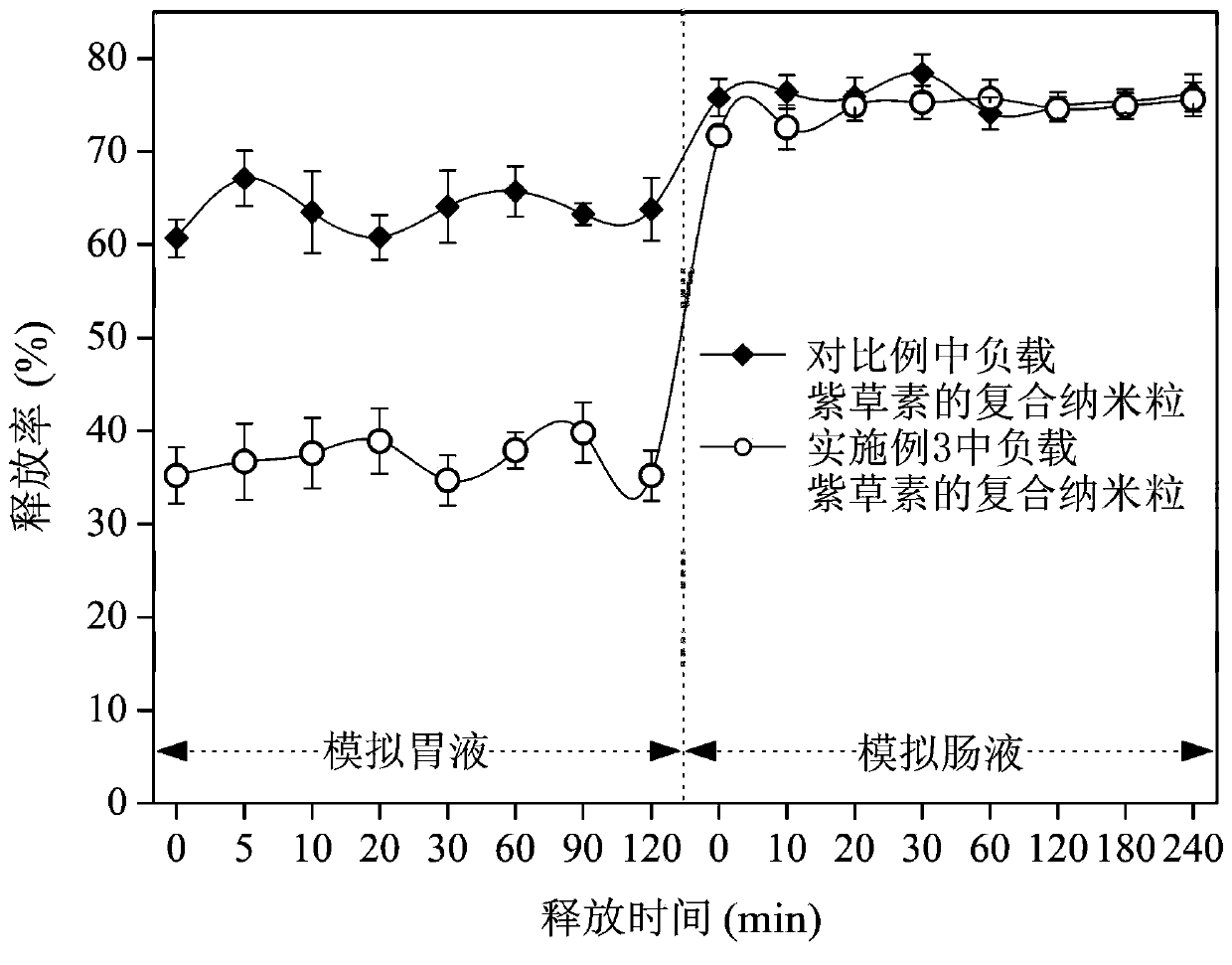

Embodiment 3

[0047] (1) Stir and disperse monocarboxychitosan powder with a viscosity-average molecular weight of 80,000, a deacetylation degree of 90%, and a C6 carboxyl degree of 43.61% in absolute ethanol, with a working frequency of 20kHz and an ultrasonic power of 100W Ultrasonic cell pulverizer is used to ultrasonically treat the dispersion liquid for 15 minutes, so that the monocarboxychitosan precipitate is crushed into submicron particles, and then dried to obtain monocarboxychitosan submicron particles.

[0048] (2) the monocarboxyl chitosan submicron particle after drying is stirred and dissolved in ultrapure water (0.22 μm filter membrane filter 3 times of deionized water) and is formulated with a mass concentration of 0.4% solution, adding emulsifying agent polyvinylpyrrolidone and Shikonin was fully emulsified by magnetic stirring for 2 hours to obtain a stable emulsion system. The mass ratio of emulsifier polyvinylpyrrolidone and monocarboxychitosan is 2:1; the purity of shi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com