Patents

Literature

119 results about "Air voids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

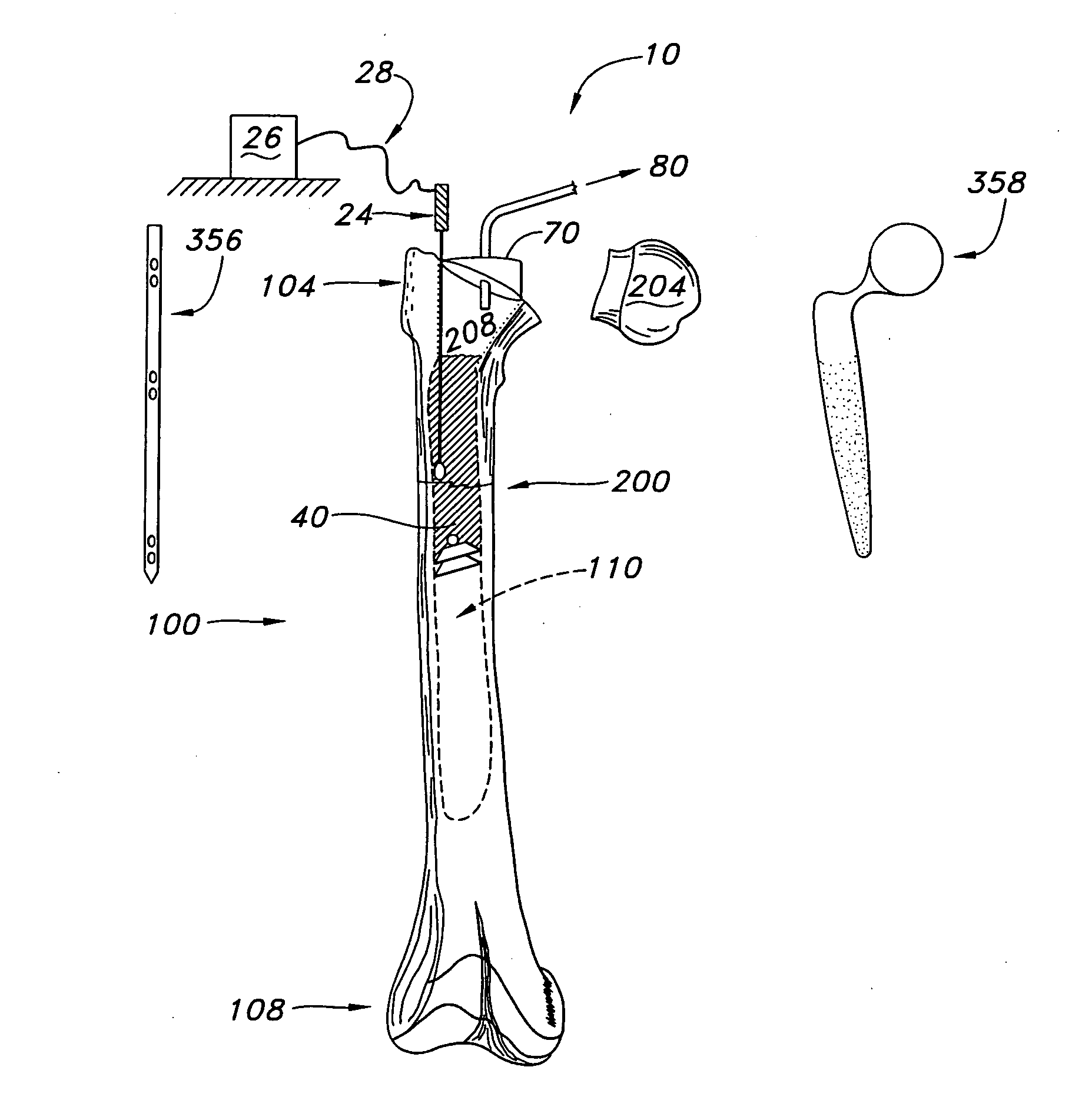

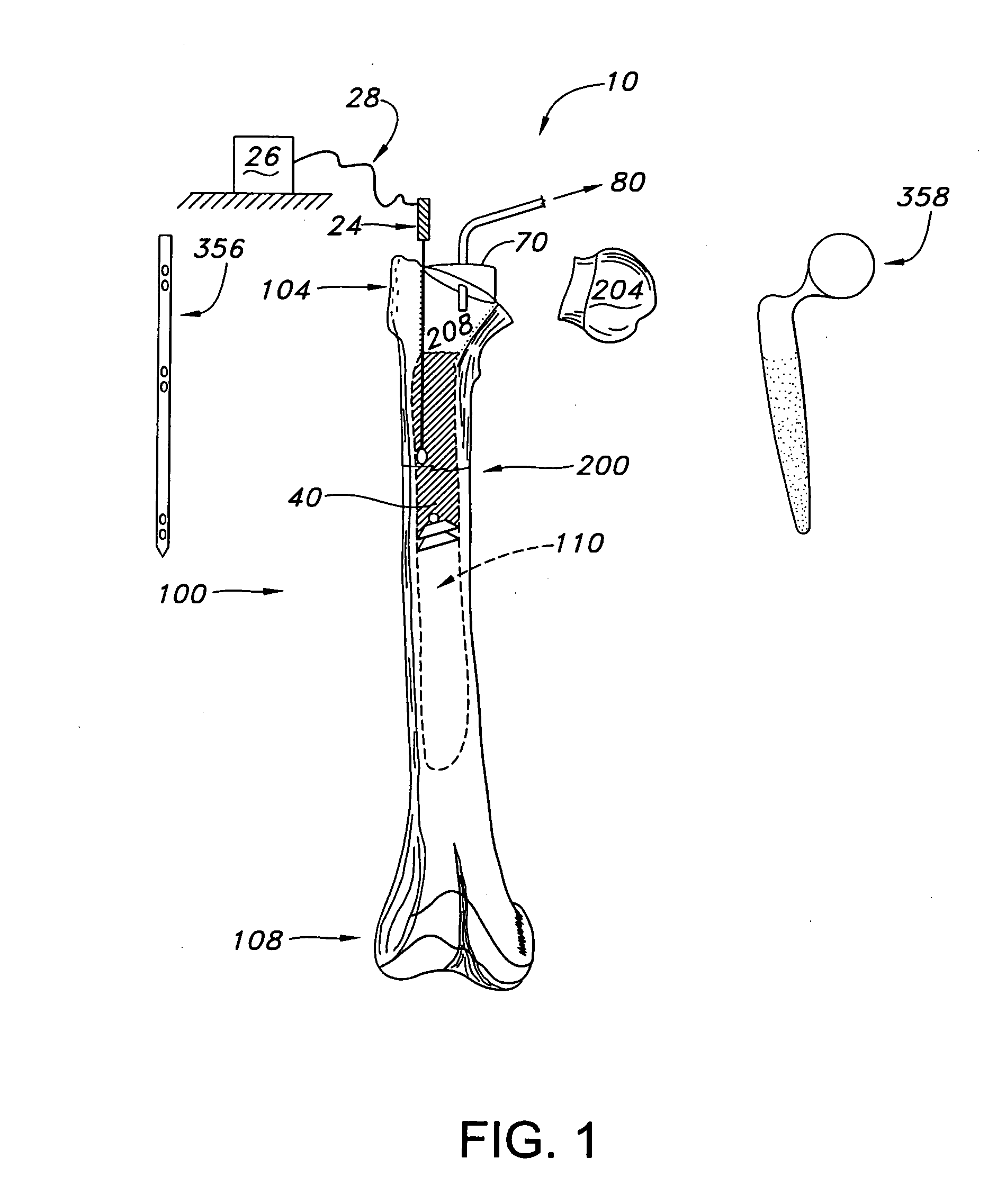

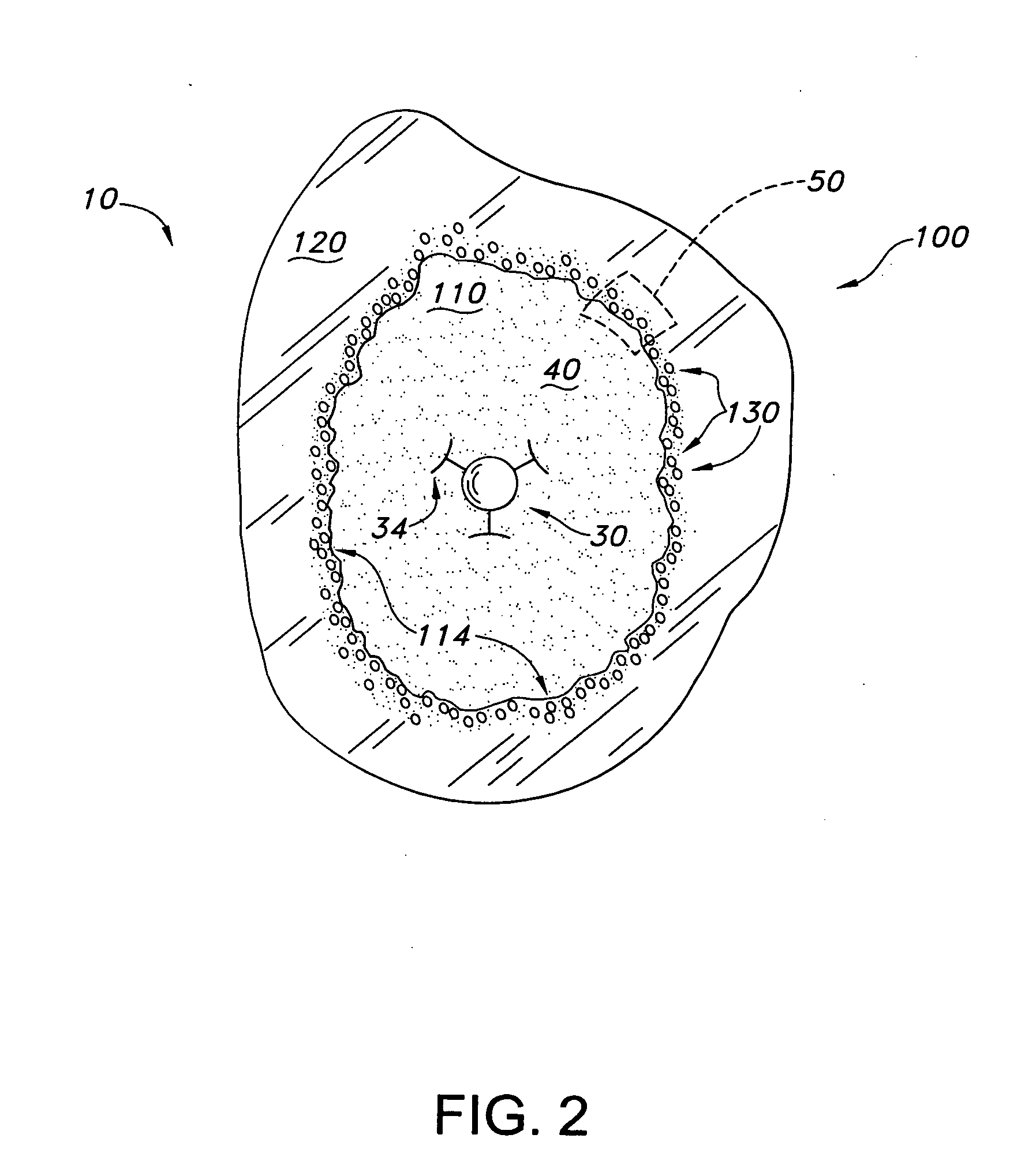

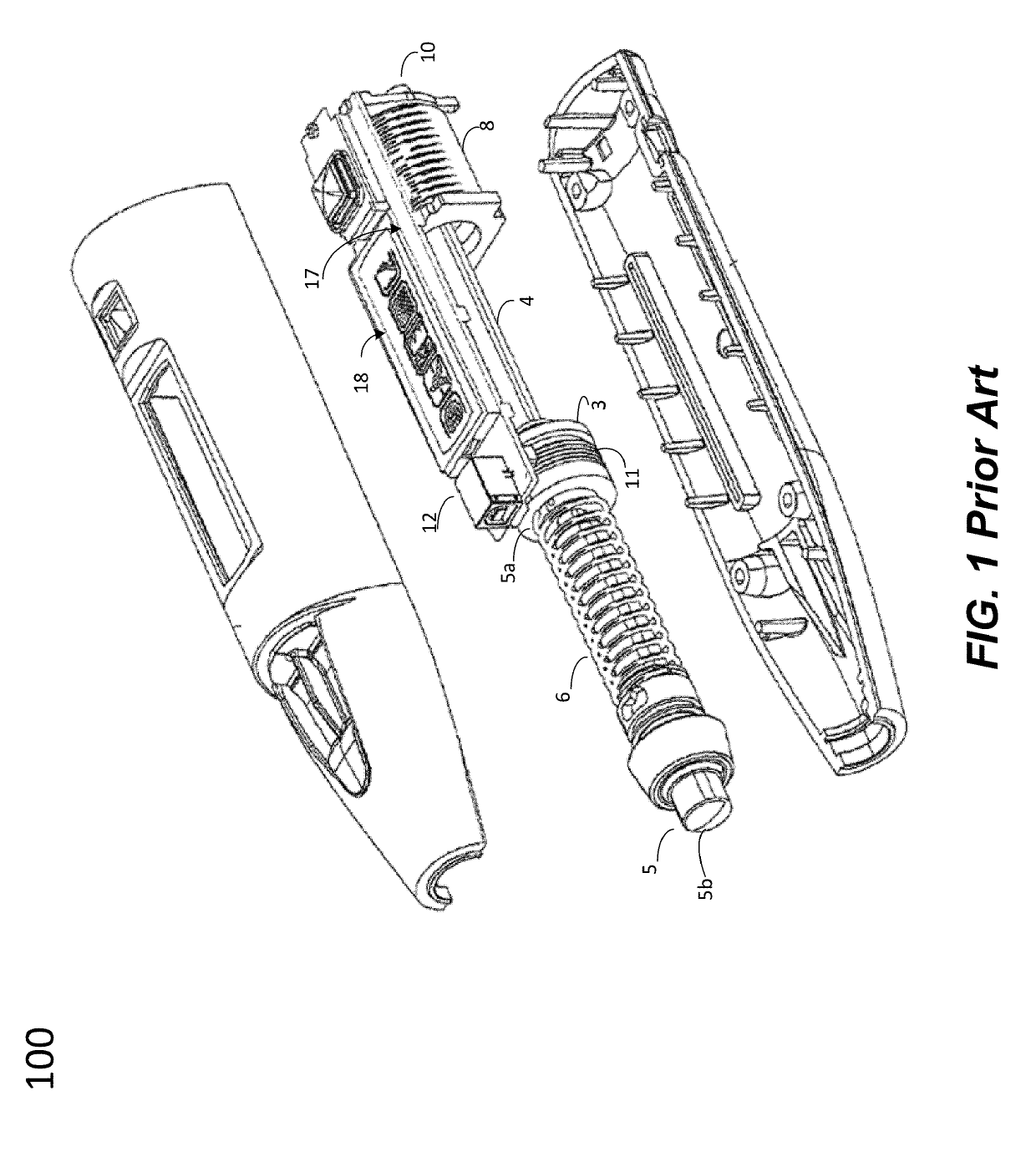

Method and apparatus for strengthening the biomechanical properties of implants

InactiveUS20050010231A1Add depthImproves Structural IntegrityInternal osteosythesisJoint implantsBiomechanicsSubject matter

A method for agitating a surgical fluid using a vibrating probe is disclosed. The agitation method drives entrapped air voids out of the surgical fluid and forces the fluid into a plurality of pores of various sizes in the adjacent bone. The vibrating apparatus in one embodiment includes a probe tip disposed upon a graspable elongate shaft and a series of fins extending into the fluid. The apparatus in one embodiment may include a set of probe tips of different shapes and sizes. The agitation and interdigitation method may facilitate any procedure involving any type of surgical fluid, with or without a prosthetic device such as an intramedullary nail or femoral prosthesis. This Abstract is provided to quickly inform a reader about the subject matter, and not for use interpreting the scope or meaning of the claims.

Owner:MYERS SURGICAL SOLUTIONS LLC

Low dust gypsum wallboard

ActiveUS20070048490A1High strengthReduce weightConstruction materialCovering/liningsDust controlSlurry

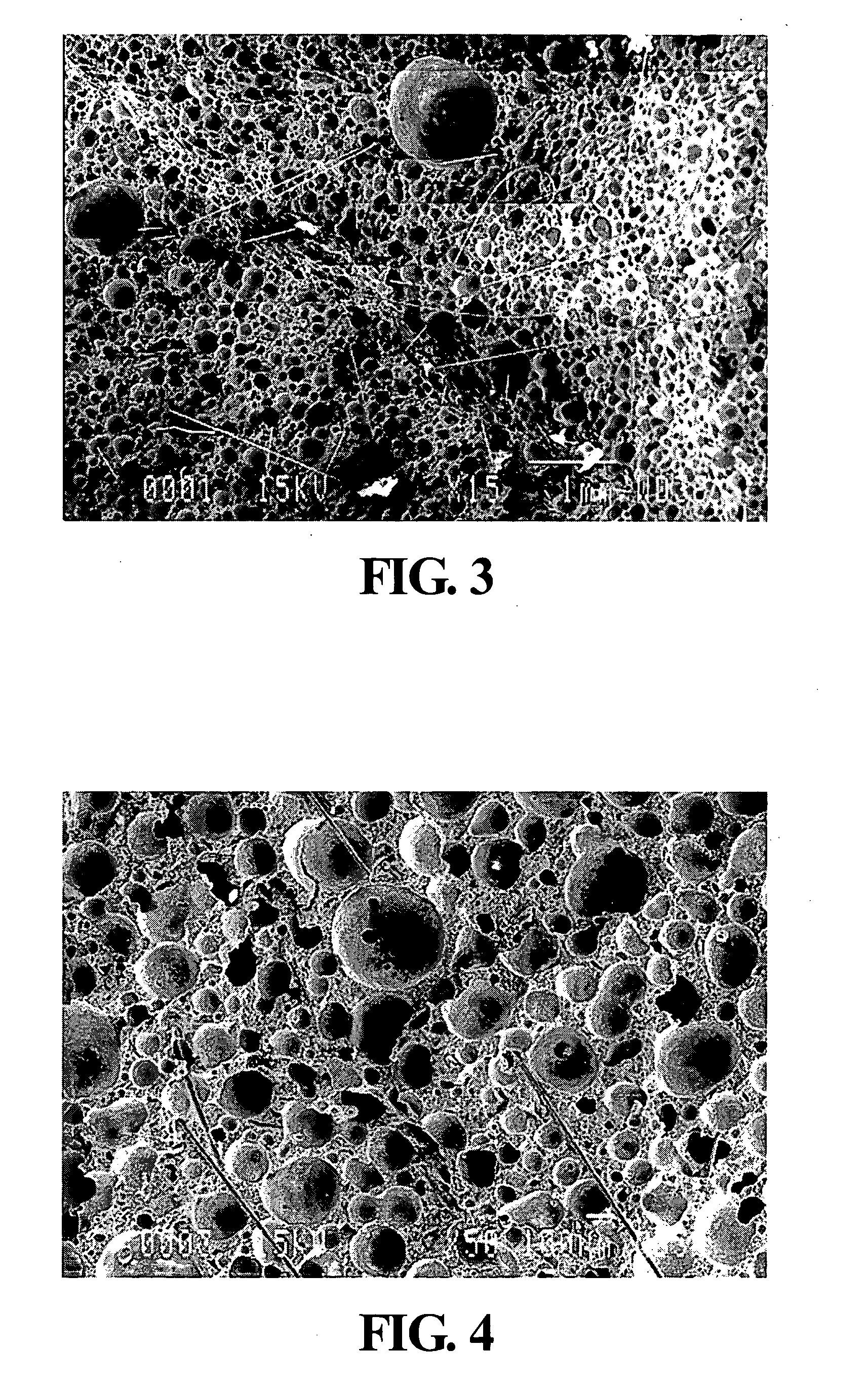

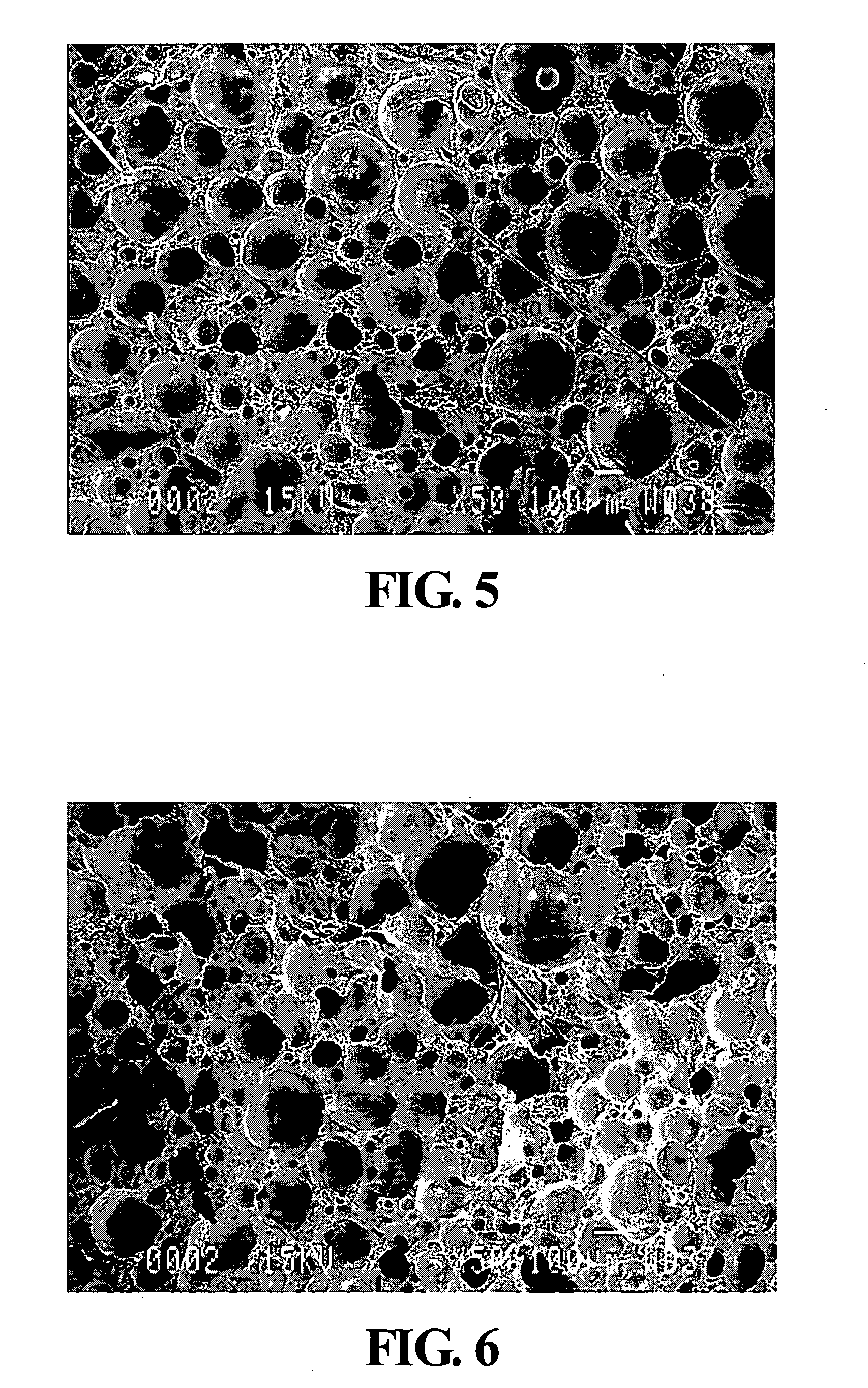

This invention provides low dust low density gypsum wallboard products having high total core void volumes, corresponding to low densities in the range of about 10 to 30 pcf. The wallboards have a set gypsum core formed between two substantially parallel cover sheets, the set gypsum core preferably having a total void volume from about 80% to about 92%, and made from a slurry including stucco, pregelatinized starch, and a naphthalenesulfonate dispersant. The combination of the pregelatinized starch and the naphthalenesulfonate dispersant also provides a glue-like effect in binding the set gypsum crystals together. The wallboard formulation, along with small air bubble voids (and water voids) provides dust control during cutting, sawing, routing, snapping, nailing or screwing down, or drilling of the gypsum-containing products. This invention also provides a method of making the low dust low density gypsum products including the introduction of soap foam in an amount sufficient to form a total void volume, including air voids, preferably from about 80% to about 92% in the set gypsum core, corresponding to a set gypsum core density from about 10 pcf to about 30 pcf. The wallboards produced by the method generate significantly less dust during working.

Owner:UNITED STATES GYPSUM CO

Enhancement of LED light extraction with in-situ surface roughening

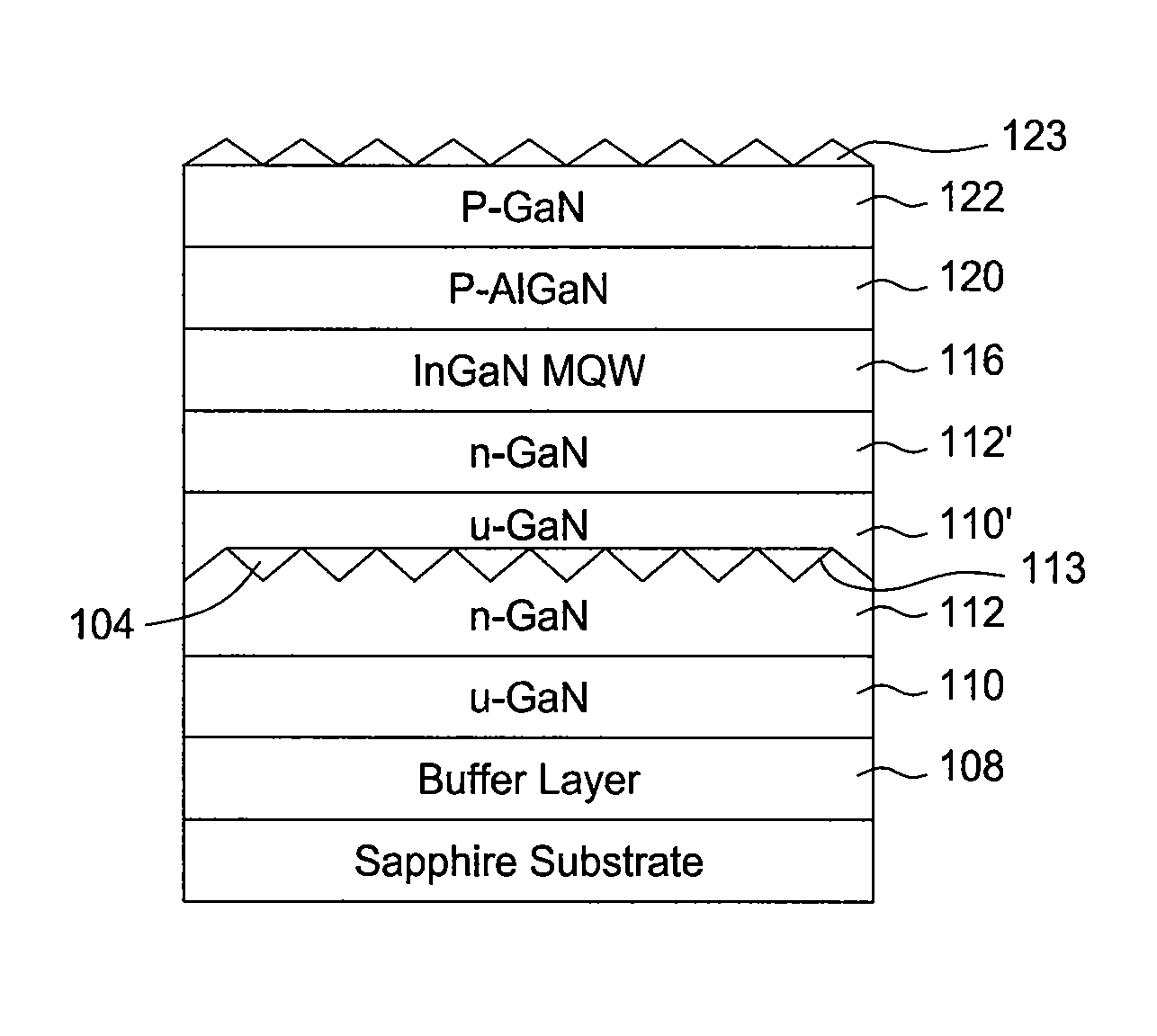

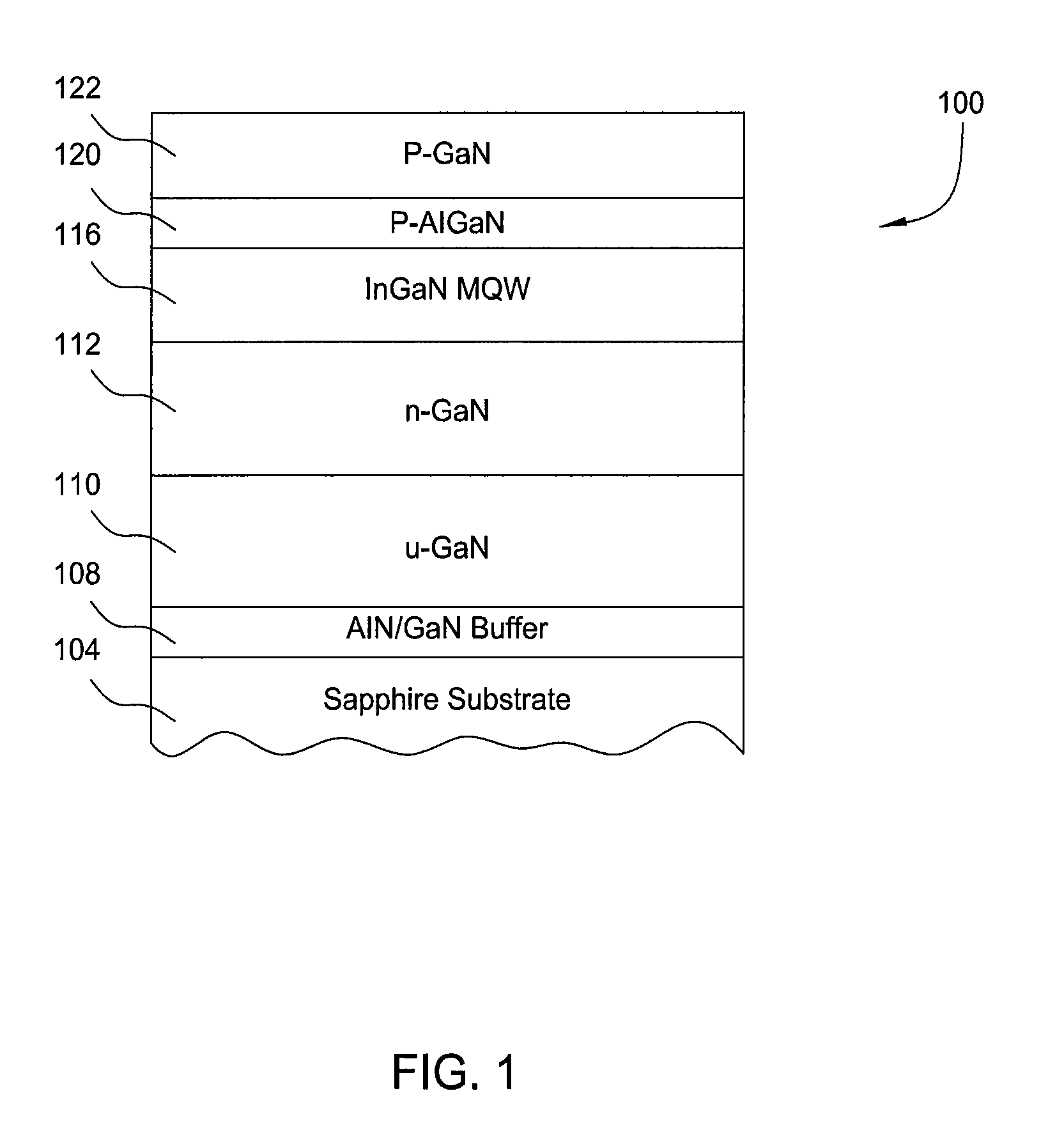

ActiveUS20110227037A1Improve external quantum efficiencyImprove light extractionCellsPolycrystalline material growthQuantum efficiencyActive layer

The embodiments of the present invention generally relates to methods for enhancing the light extraction by surface roughening of the bottom n-GaN layer and / or top p-GaN layer so that the internal light from the active region is scattered outwardly to result in a higher external quantum efficiency. In one embodiment, a surface roughening process is performed on the n-GaN layer to form etching pits in a top surface of the n-GaN layer. Once the etching pits are formed, growth of the n-GaN material may be resumed on the roughened n-GaN layer to partially fill the etching pits, thereby forming air voids at the interface of the n-GaN layer and the subsequent, re-growth n-GaN layer. These air voids provide one or more localized regions with indices of reflection different from that of the n-GaN layer, such that the internal light generated by the active layers (e.g., the InGaN MQW layer), when passing through the n-GaN layer, is scattered by voids or bubbles. The surface roughening process may be further performed on a top surface of a p-GaN layer to scatter the light emitted from the active layers outwardly rather than being reflected back to the active layers.

Owner:APPLIED MATERIALS INC

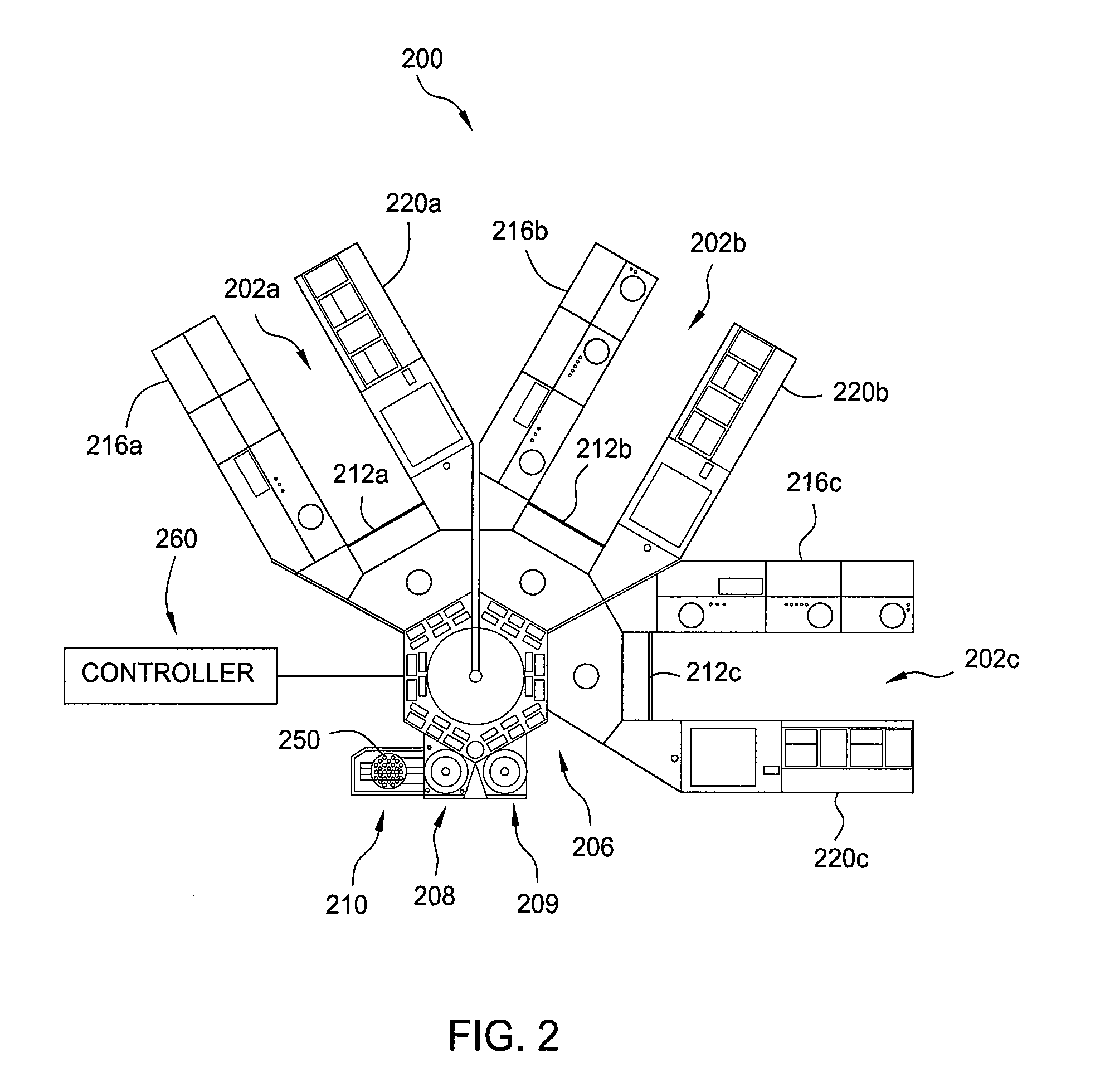

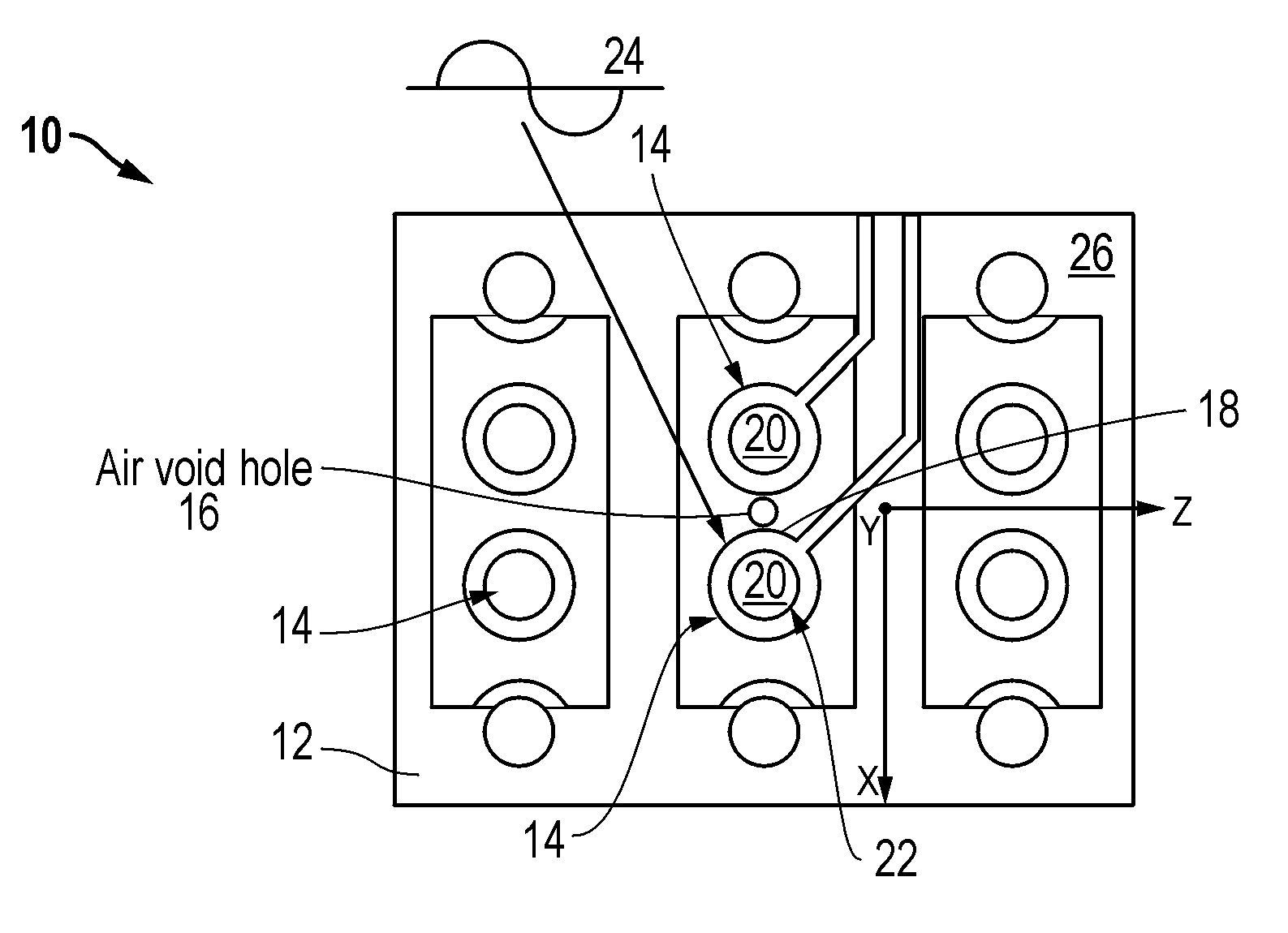

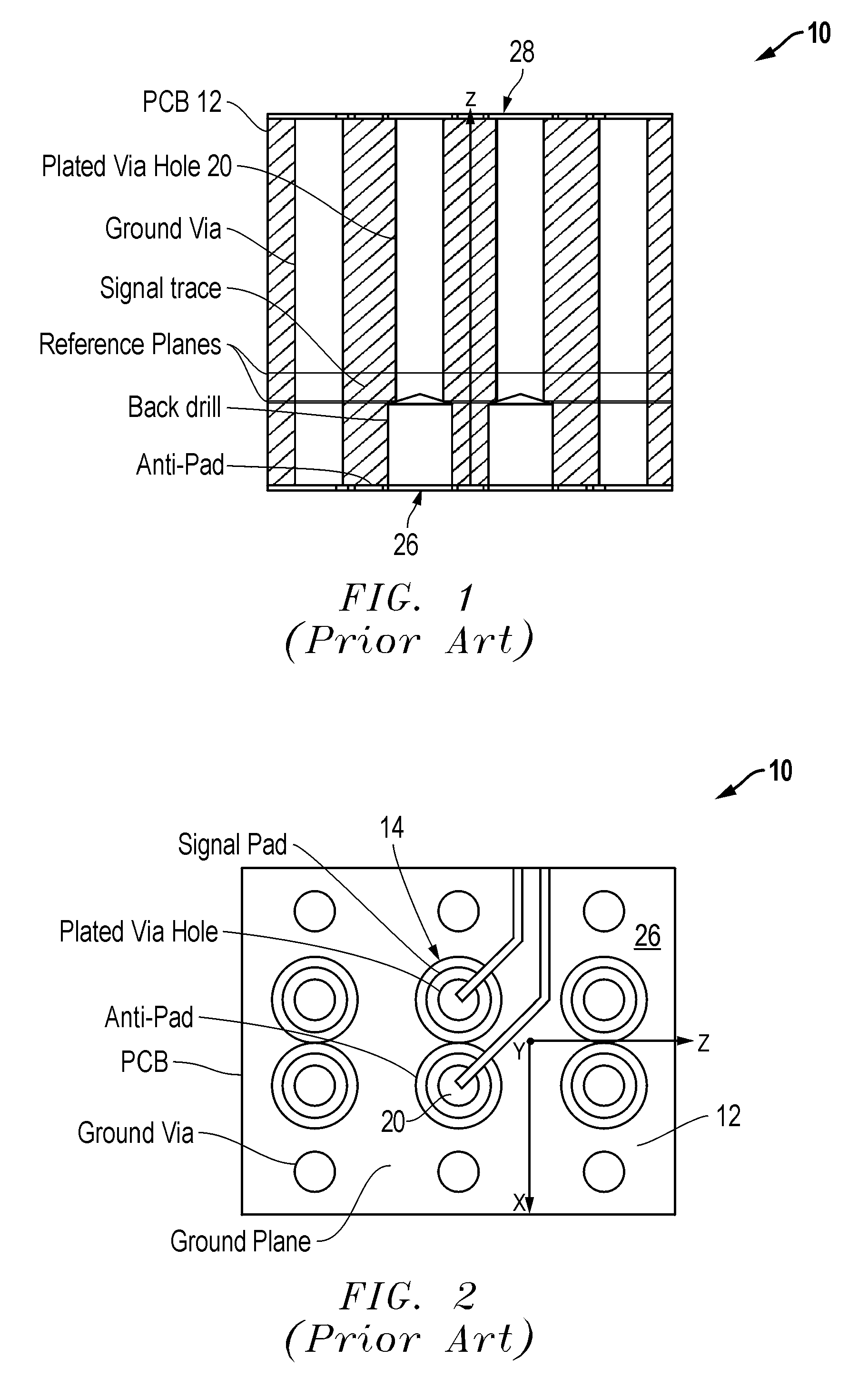

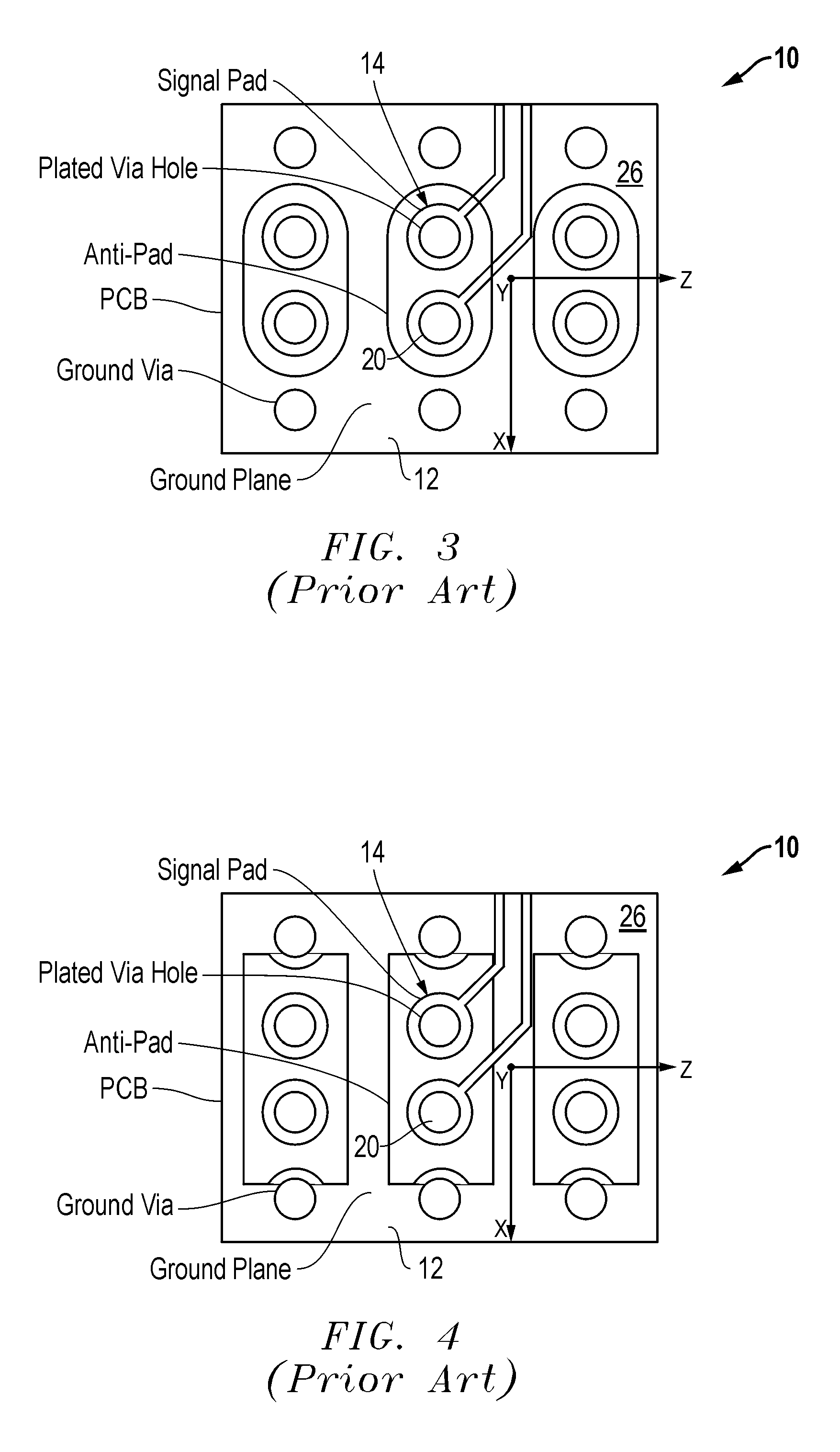

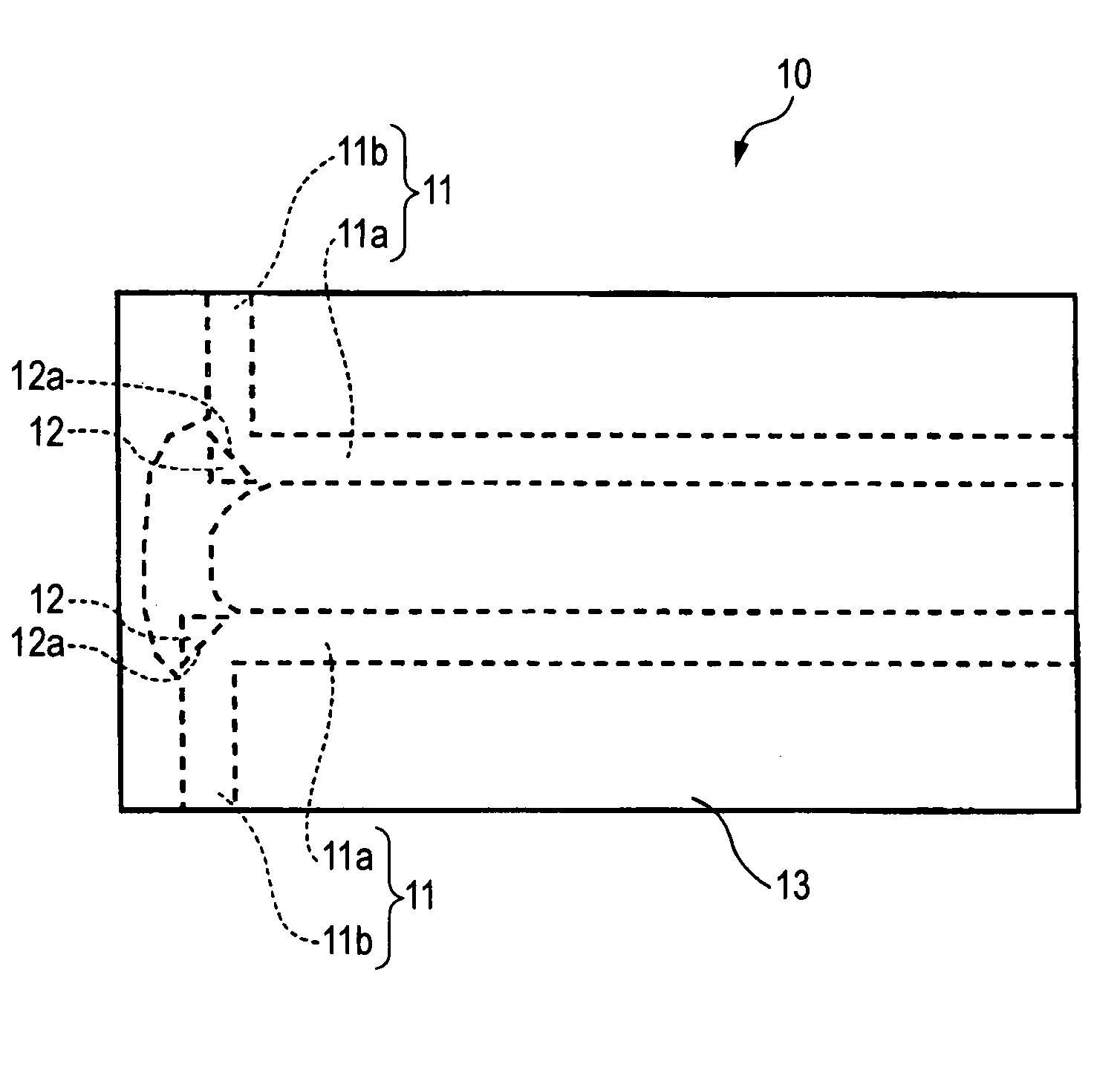

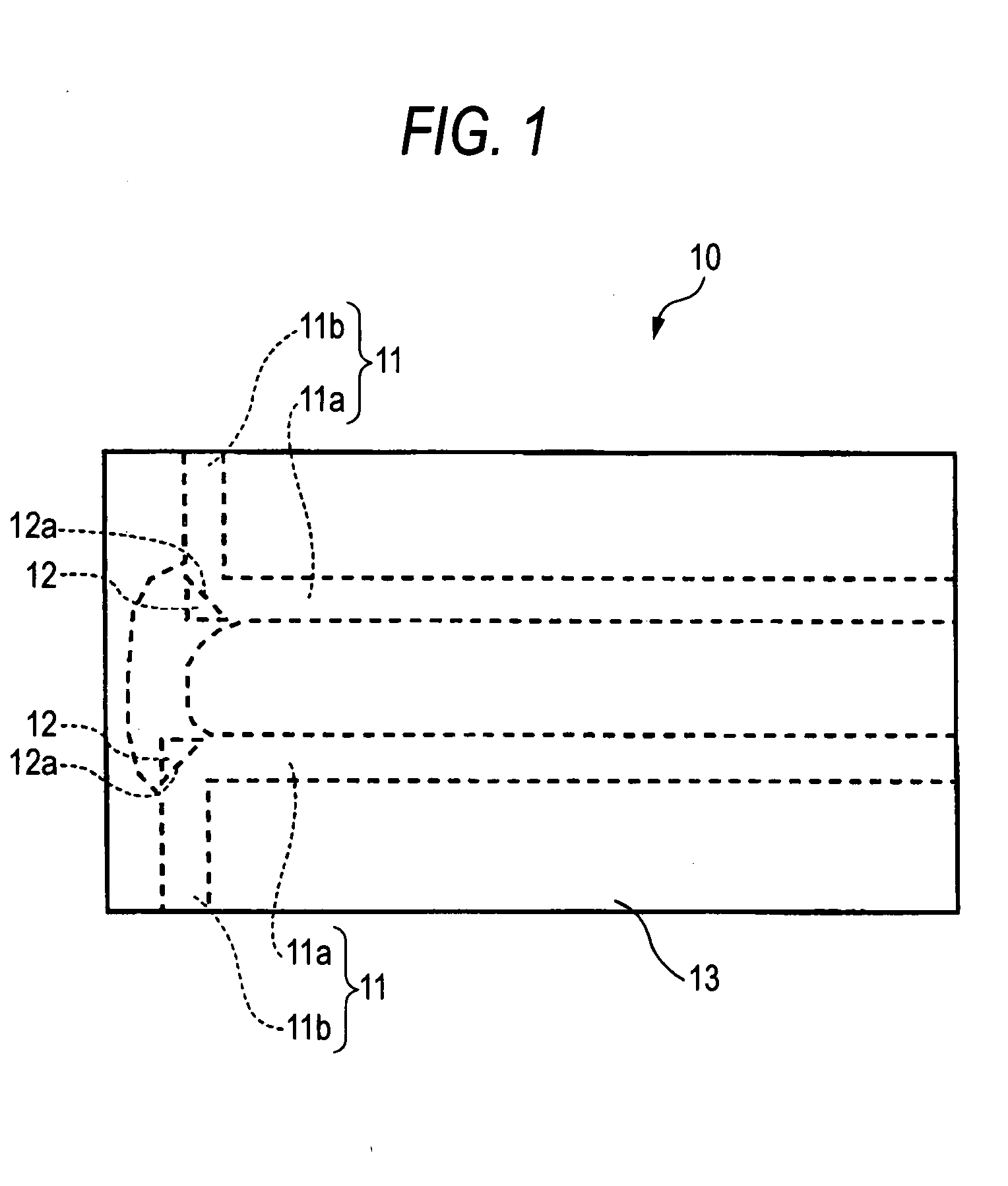

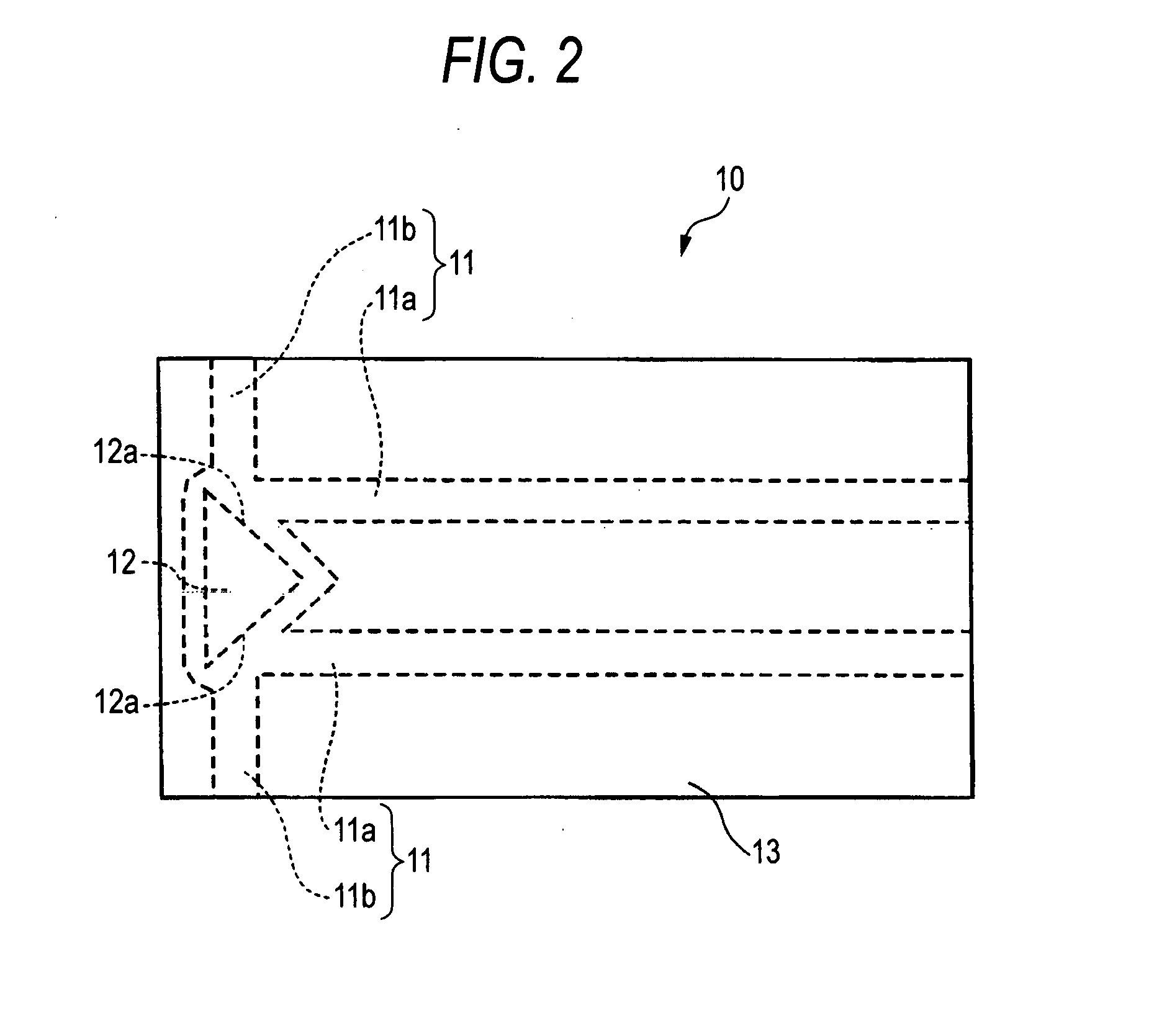

Air void via tuning

InactiveUS20060185890A1Improves main contributory factorImproves the main contributory factorsCross-talk/noise/interference reductionPrinted circuit aspectsElectromagnetic couplingEngineering

A wiring board (10) having reduced electromagnetic coupling between electronic devices includes a base board (12) that is adaptable to receive at least one electronic component (14) mounted on the base board (12). At least one hole or void (16) is formed in the base board (12). The hole (16) is separated from the selected electronic component (14) to be isolated against undesired electromagnetic radiation by a portion (18) of the base board (12).

Owner:SIMCLAR INTERCONNECT TECH

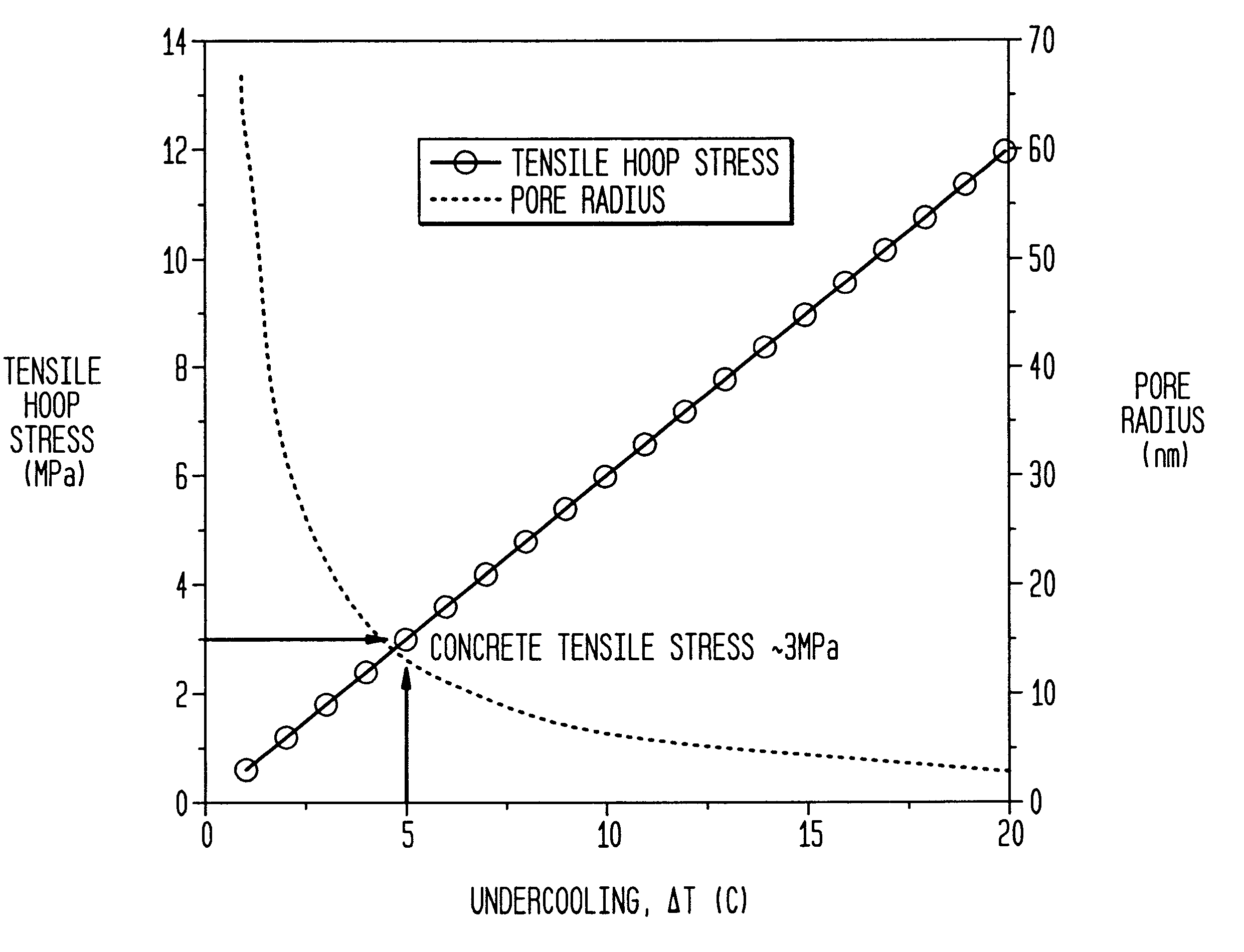

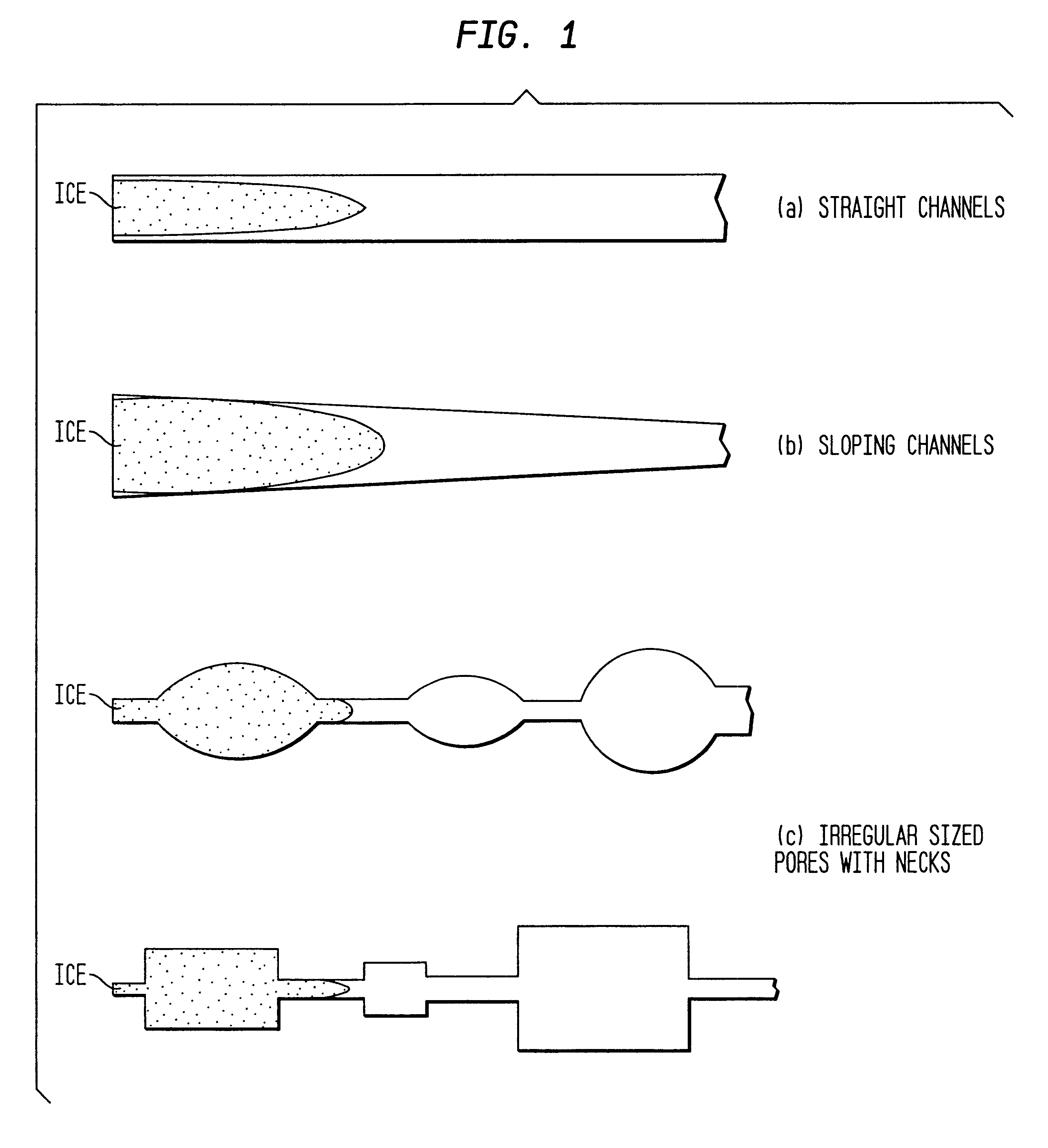

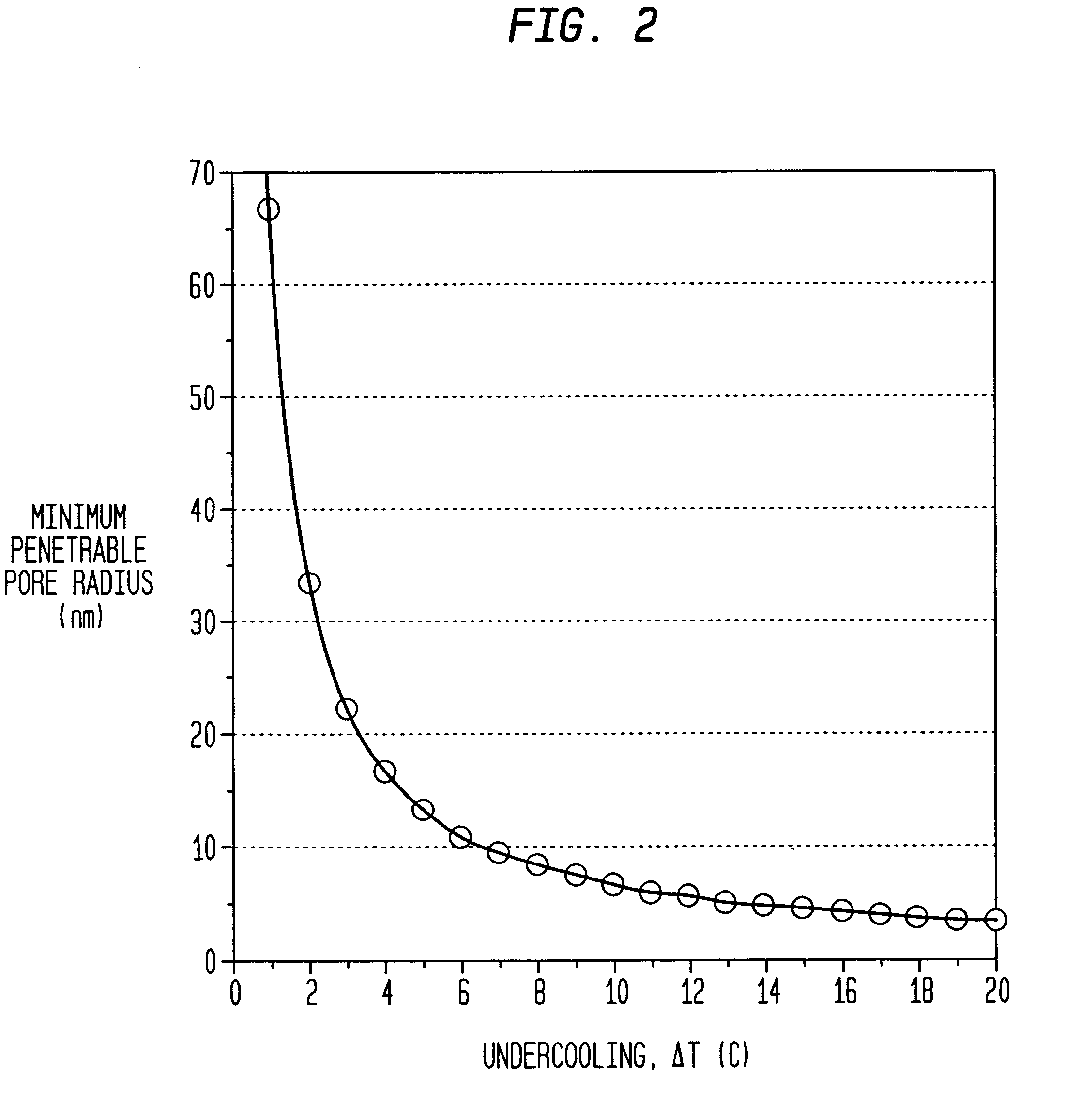

Methods of protecting concrete from freeze damage

A method of protecting a cementitious mixture from freeze damage is provided. The method consists of incorporating an entrainment air composition into the cementitious mixture to form air voids in the concrete, and further adding an effective agent for nucleating ice, preferably, in the air voids, such that upon the freezing of concrete formed from the cementitious mixture, ice is nucleated in the air voids. In one embodiment, the air entrainment composition includes ceramic shells, which could be impregnated with an agent for nucleating ice such as metaldehyde.

Owner:THE TRUSTEES FOR PRINCETON UNIV

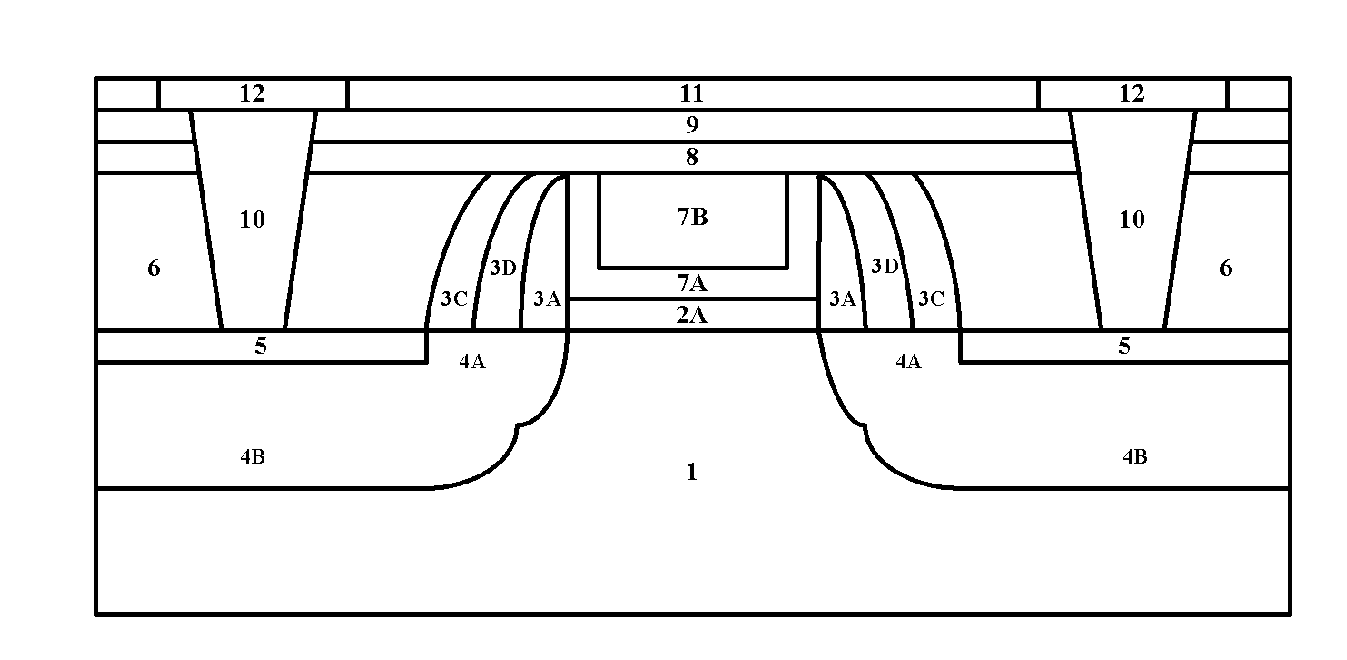

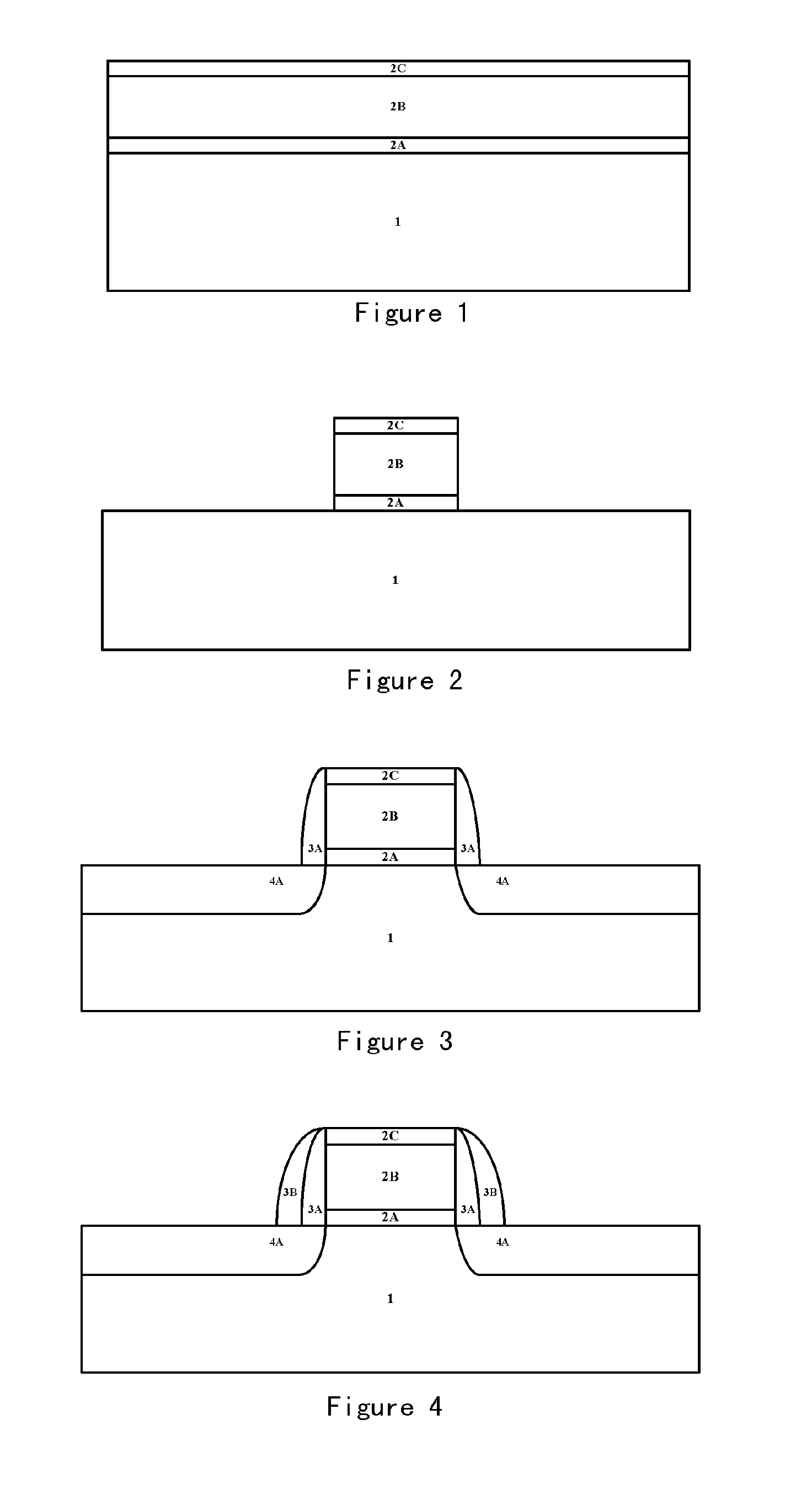

Semiconductor device and method for manufacturing the same

InactiveUS20130299920A1Reduce parasitic capacitanceImprove device performanceSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceParasitic capacitance

The present invention discloses a semiconductor device, comprising a substrate, a gate stack structure on the substrate, a gate spacer structure at both sides of the gate stack structure, source / drain regions in the substrate and at opposite sides of the gate stack structure and the gate spacer structure, characterized in that the gate spacer structure comprises at least one gate spacer void filled with air. In accordance with the semiconductor device and the method for manufacturing the same of the present invention, carbon-based materials are used to form a sacrificial spacer, and at least one air void is formed after removing the sacrificial spacer, the overall dielectric constant of the spacer is effectively reduced. Thus, the gate parasitic capacitance is reduced and the device performance is enhanced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

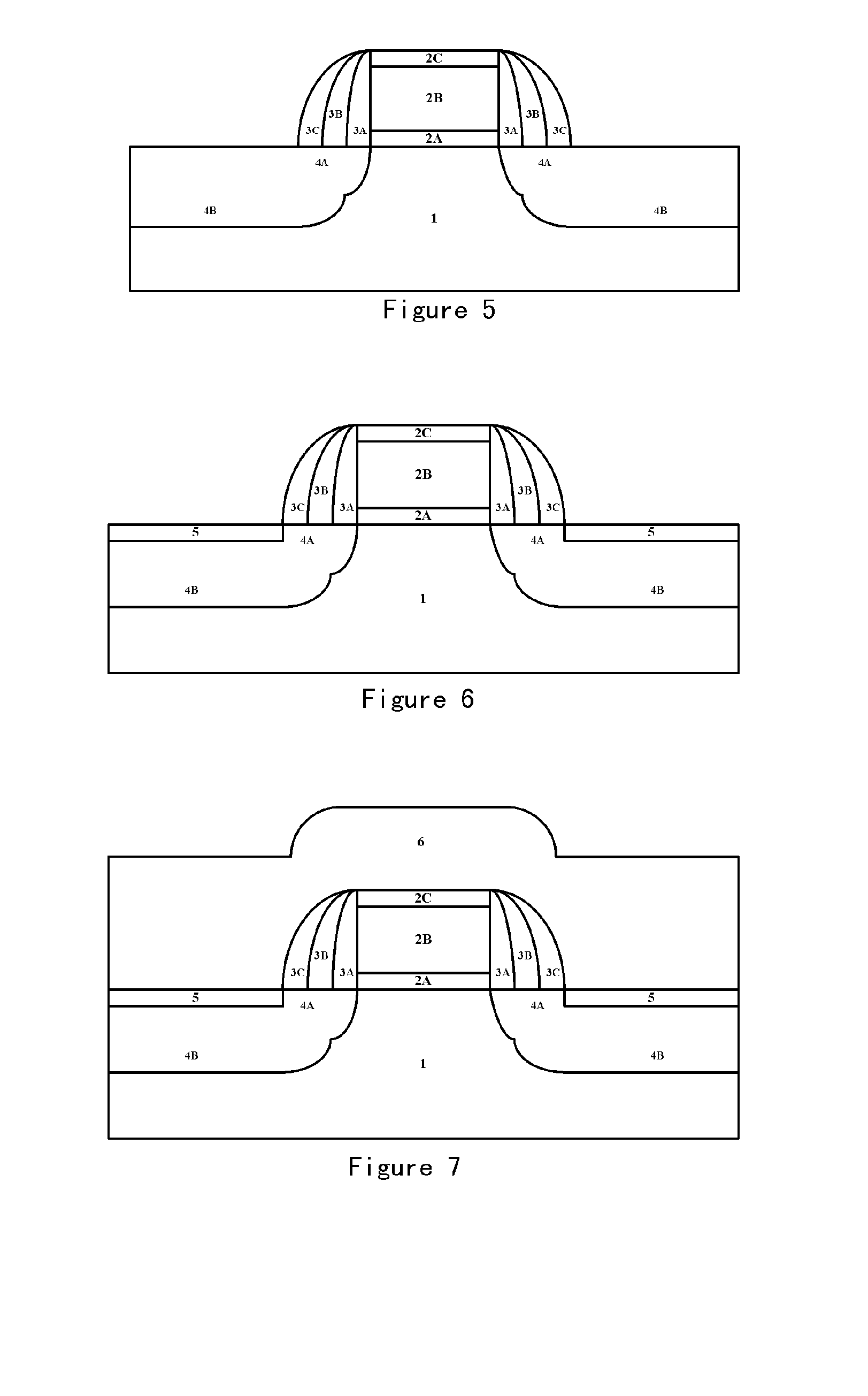

Integrated circuit chip utilizing dielectric layer having oriented cylindrical voids formed from carbon nanotubes

InactiveUS7229909B2Low dielectric constantSemiconductor/solid-state device detailsNanoinformaticsCarbon nanotubeDielectric structure

A dielectric in an integrated circuit is formed by creating oriented cylindrical voids in a conventional dielectric material. Preferably, voids are formed by first forming multiple relatively long, thin carbon nanotubes perpendicular to a surface of an integrated circuit wafer, by depositing a conventional dielectric on the surface to fill the area between the carbon nanotubes, and by then removing the carbon nanotubes to produce voids in place of the carbon nanotubes. A layer of dielectric and voids thus formed can be patterned or otherwise processed using any of various conventional processes. The use of a conventional dielectric material having numerous air voids substantially reduces the dielectric constant, leaving a dielectric structure which is both structurally strong and can be constructed compatibly with conventional processes and materials.

Owner:GLOBALFOUNDRIES INC

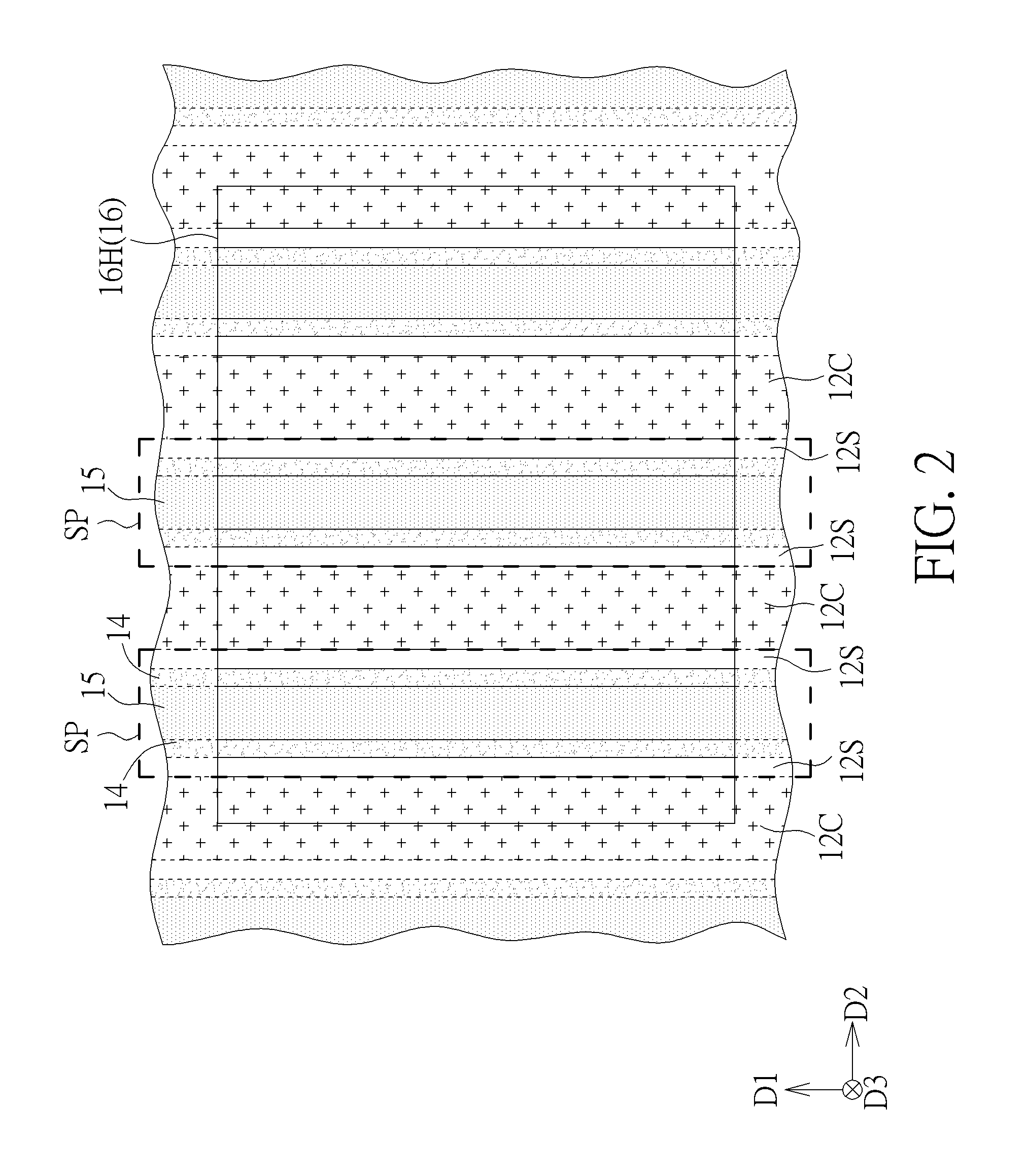

Flexible optical waveguide film, optical transceiver module, multi-channel optical transceiver module, and method of manufacturing flexible optical waveguide film

A flexible optical waveguide film comprises: two waveguide cores; and a clad surrounding the two waveguide core, wherein a light entrance / exit part is disposed at one end of each of the two waveguide cores, the waveguide film having an optical path converting part comprising an air void located inside the waveguide film, and a light entrance / exit end face of the light entrance / exit part is a plane surface facing an optical path converting surface of the optical path converting part, the optical path converting surface being an interface defining the air void.

Owner:FUJIFILM BUSINESS INNOVATION CORP

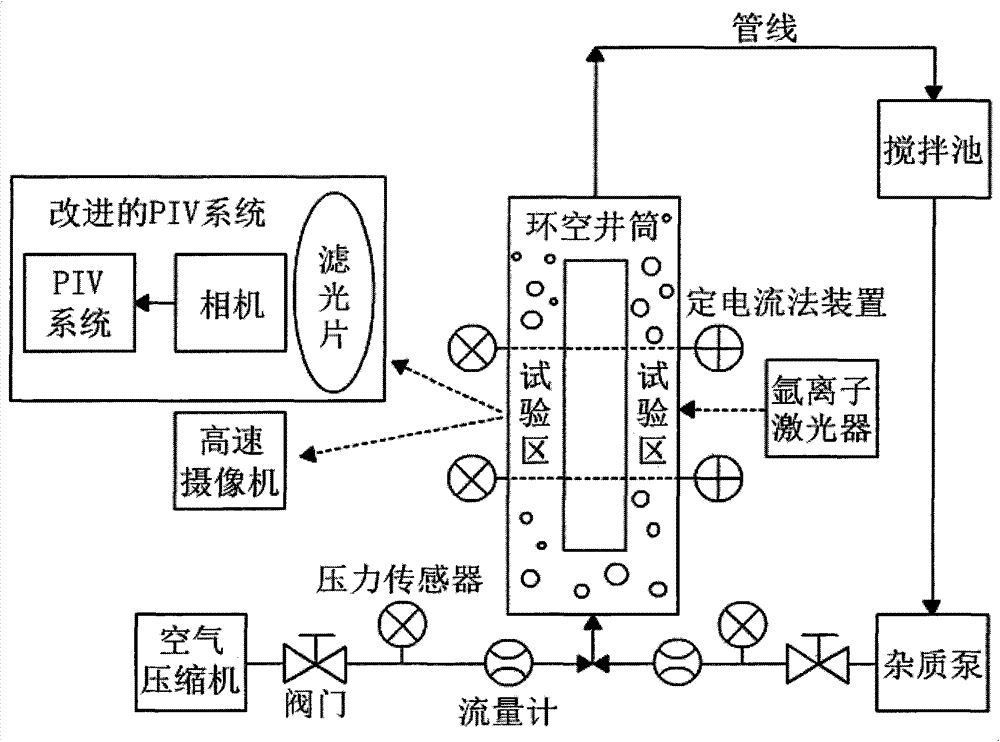

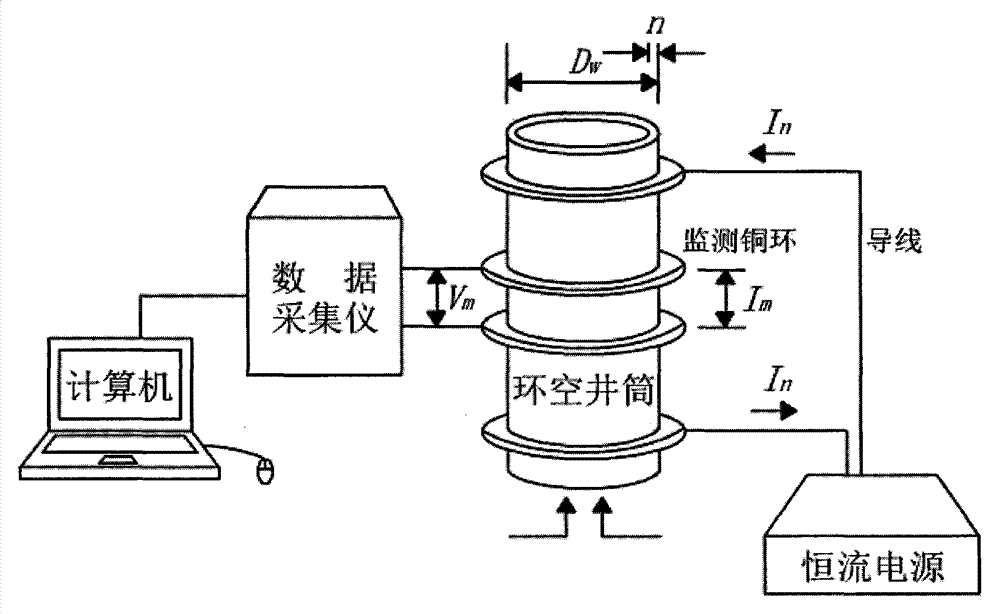

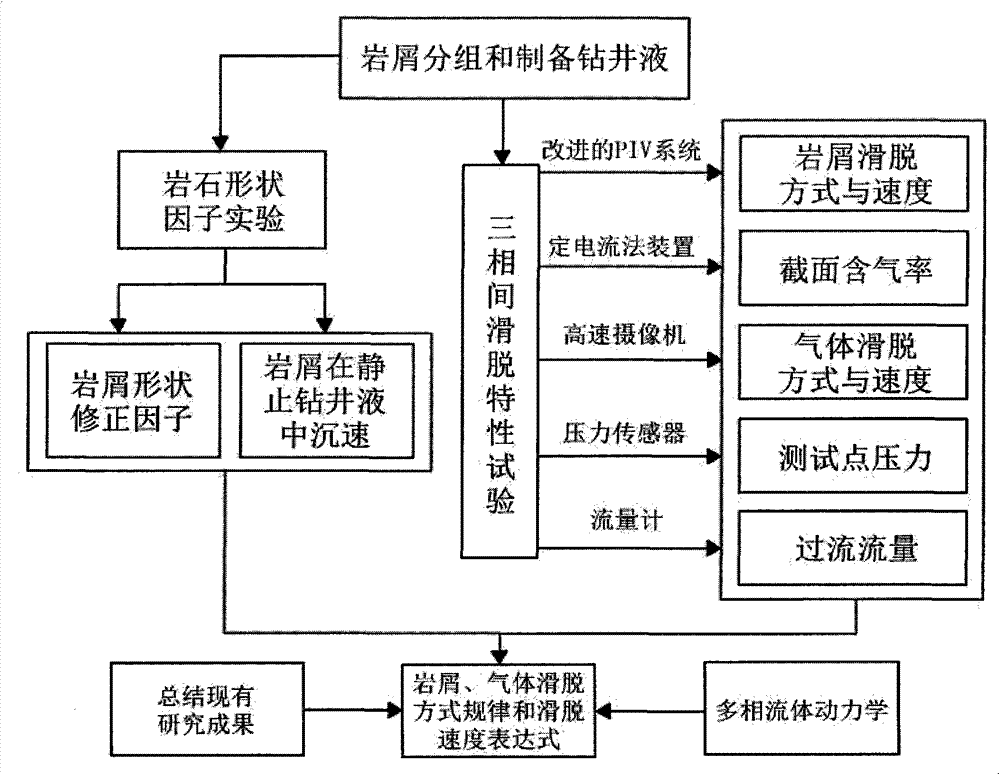

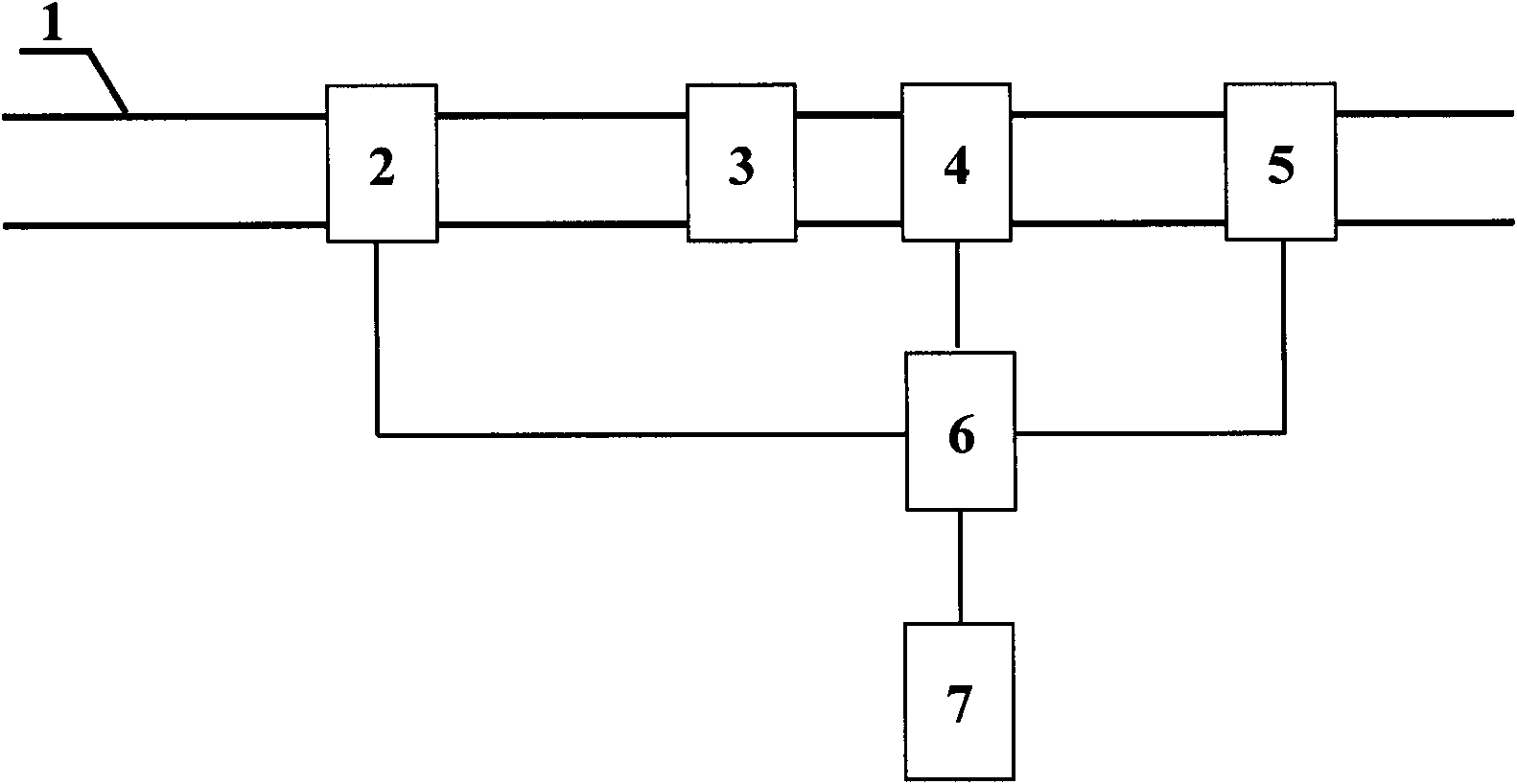

Device and method for measuring slippage among gas phase, liquid phase and solid phase in shaft annulus

The invention provides a device and method for measuring slippage among a gas phase, a liquid phase and a solid phase in a shaft annulus. The device is composed of an annulus shaft, an improved PIV system, a constant-current method device, a high-speed camera, a stirring pool, an impurity pump, an air compressor, a pressure sensor, a flow meter, a pipeline and a valve. The PIV system, the laser induction technology, the refraction index matching technology, the constant-current method and the high-speed camera recording technology are combined for the first time, and the slippage characteristics in flowing of the air phase, the liquid phase and the solid phase in the shaft annulus are systemically studied through transparent drilling fluid and transparent rock debris. According to the device and the method, the specific expressions of the laws and the slippage speeds of slipping modes when debris and gas flow in the gas phase, the liquid phase and the solid phase in the shaft annulus are obtained through tests for studying the stickness of different types of drilling fluid, drilling fluid flow, debris concentration and the section air voids factors, and effective technology support is provided for process design and well control safety of well drilling.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Design technique for selecting a bituminous mixture for use in a hot in-place recycling process

ActiveUS7503202B1Improve performanceIn situ pavingsPaving detailsSurface grindingUltimate tensile strength

Owner:ARRMAZ PROD INC

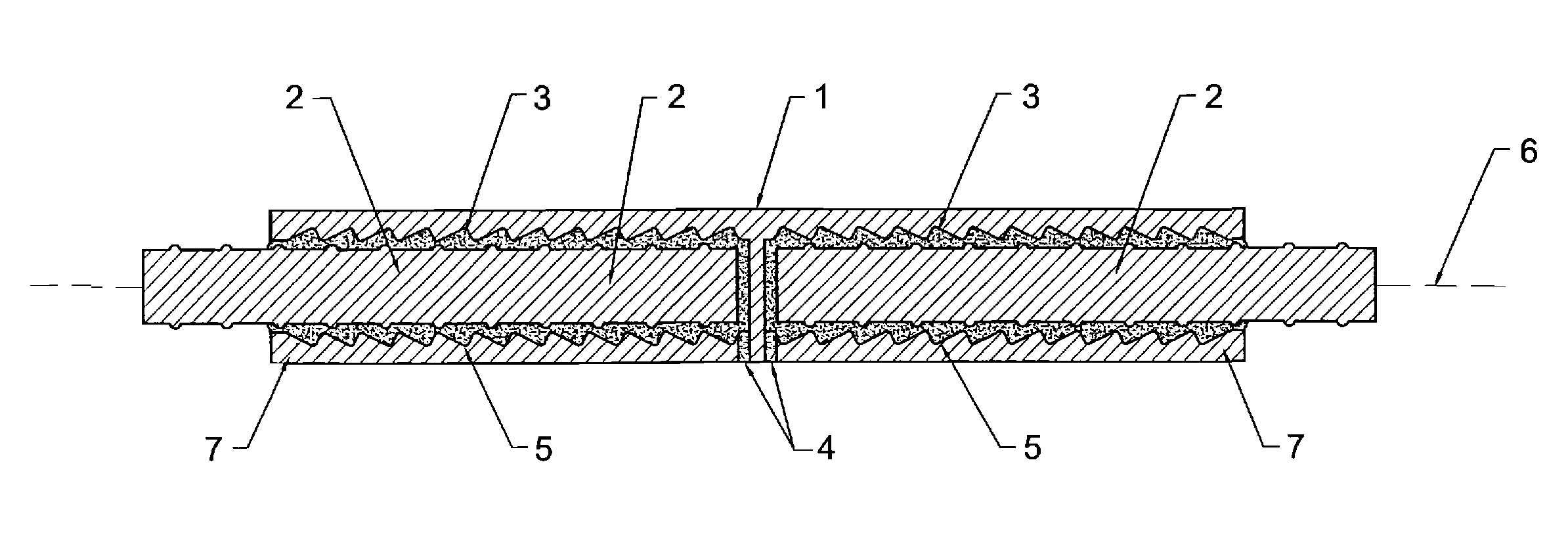

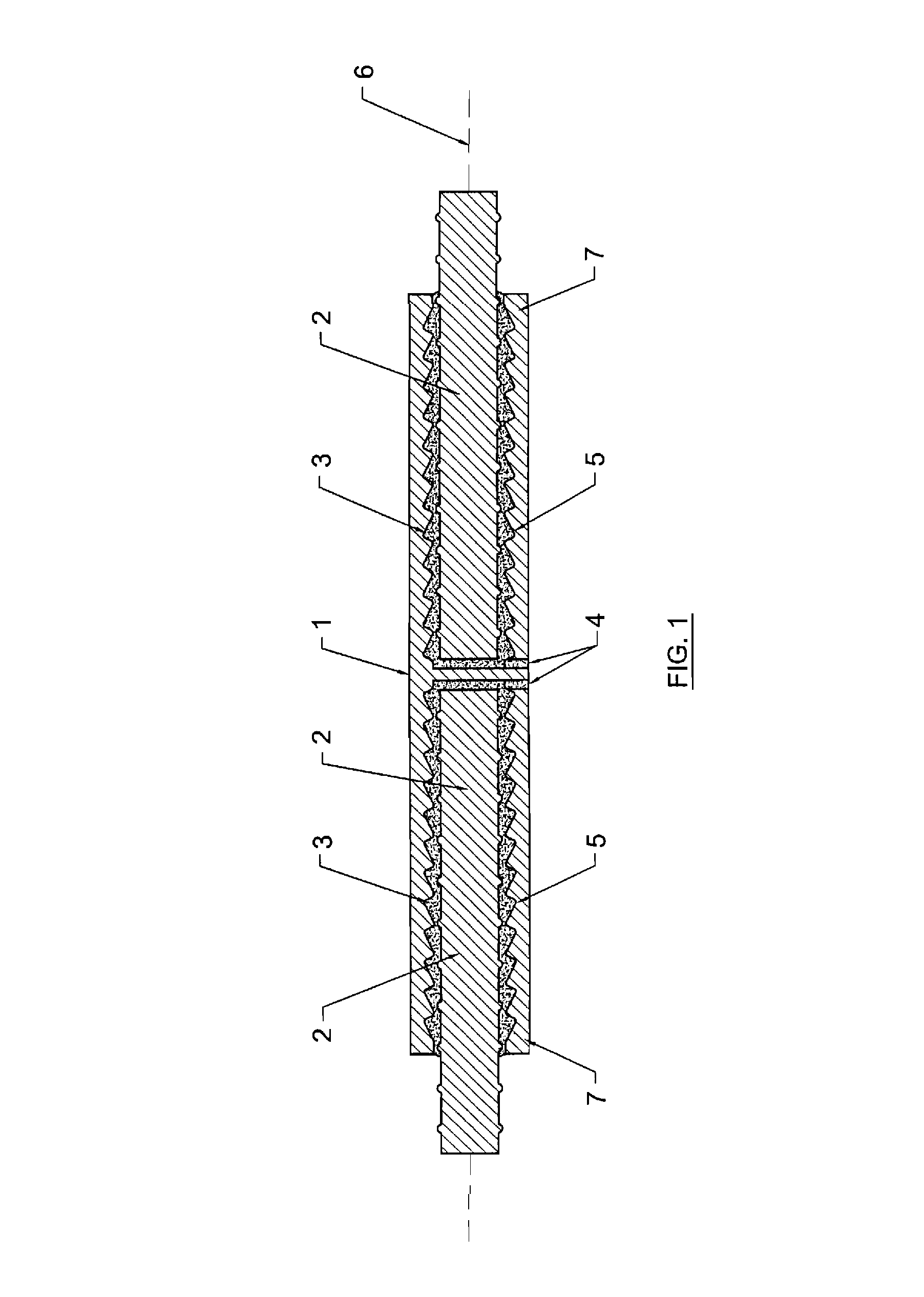

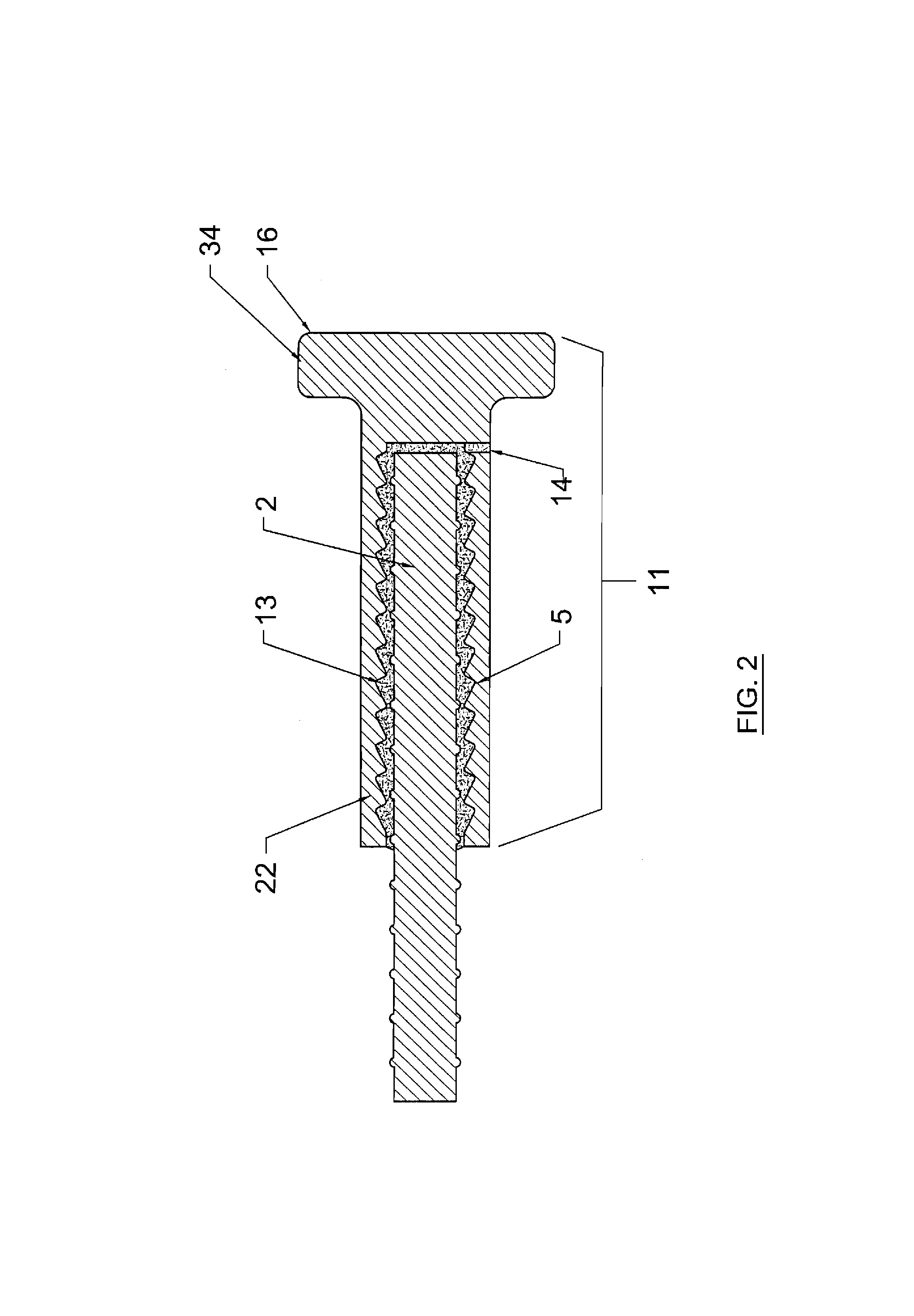

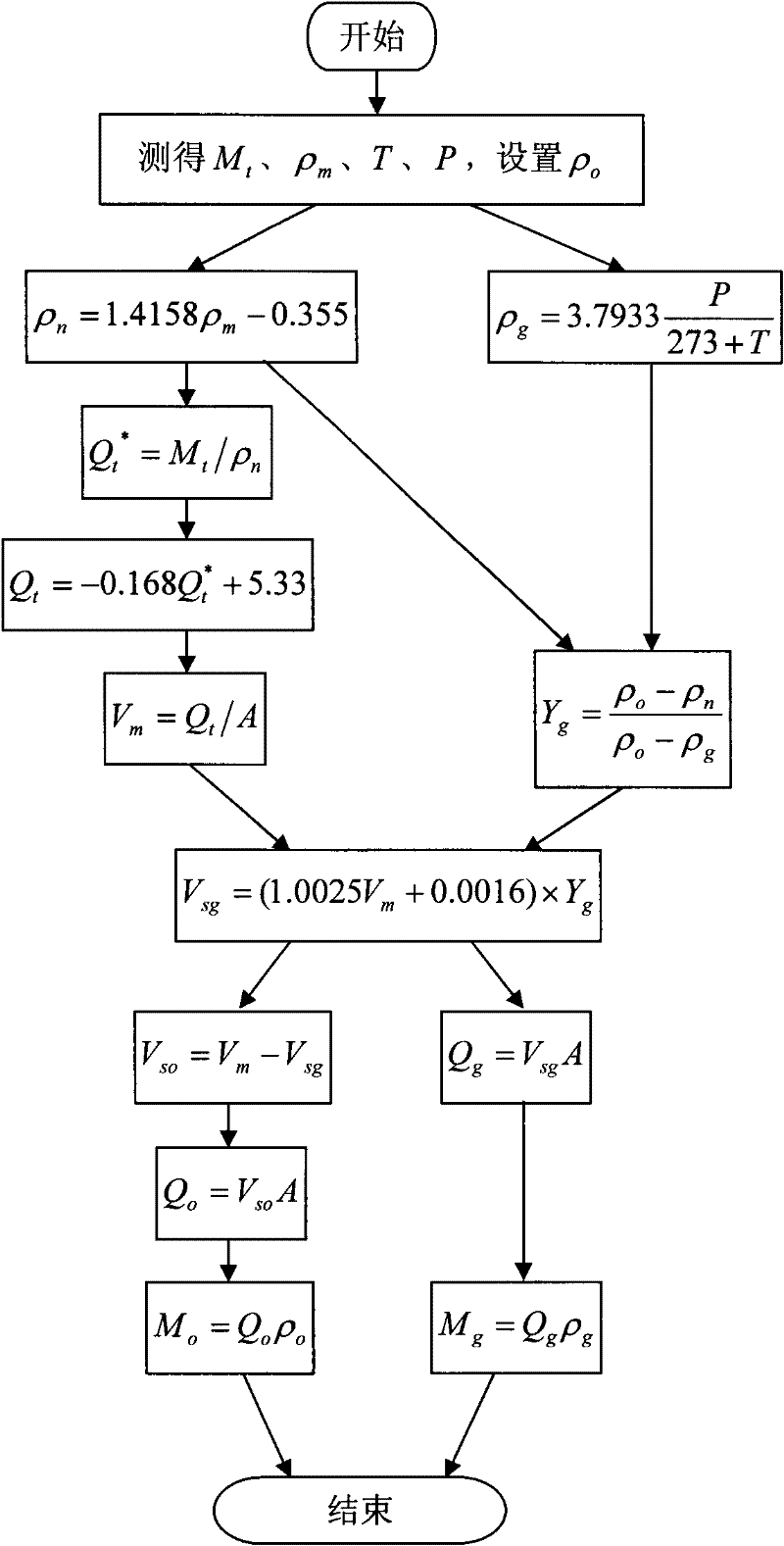

Bar coupling apparatus and methods

ActiveUS7878730B2Increase surface areaMore bondingRopes and cables for vehicles/pulleyRod connectionsAdhesiveEngineering

Particular embodiments of the inventive technology relate to a device for connecting the ends of two concrete reinforcing bars in which a metal sleeve has chambers at each end to accommodate the end of one reinforcing bar. Forces may be transferred from one bar to the other through, the use of, inter alia, an adhesive established within the space between the outside of the reinforcing bars and the deformed inner surface of the sleeve. The chambers are, preferably, separated by a fluid impervious barrier. One port associated with each chamber may be established to allow fluid such as air to escape, preventing air voids in the adhesive. Another configuration of the inventive device would be intended for the retention (under load, of course) of only one reinforcing bar, with an enlarged flange for anchoring the end of one reinforcing bar, perhaps at and outer surface of, e.g., a concrete slab.

Owner:WEAVER INNOVATIONS

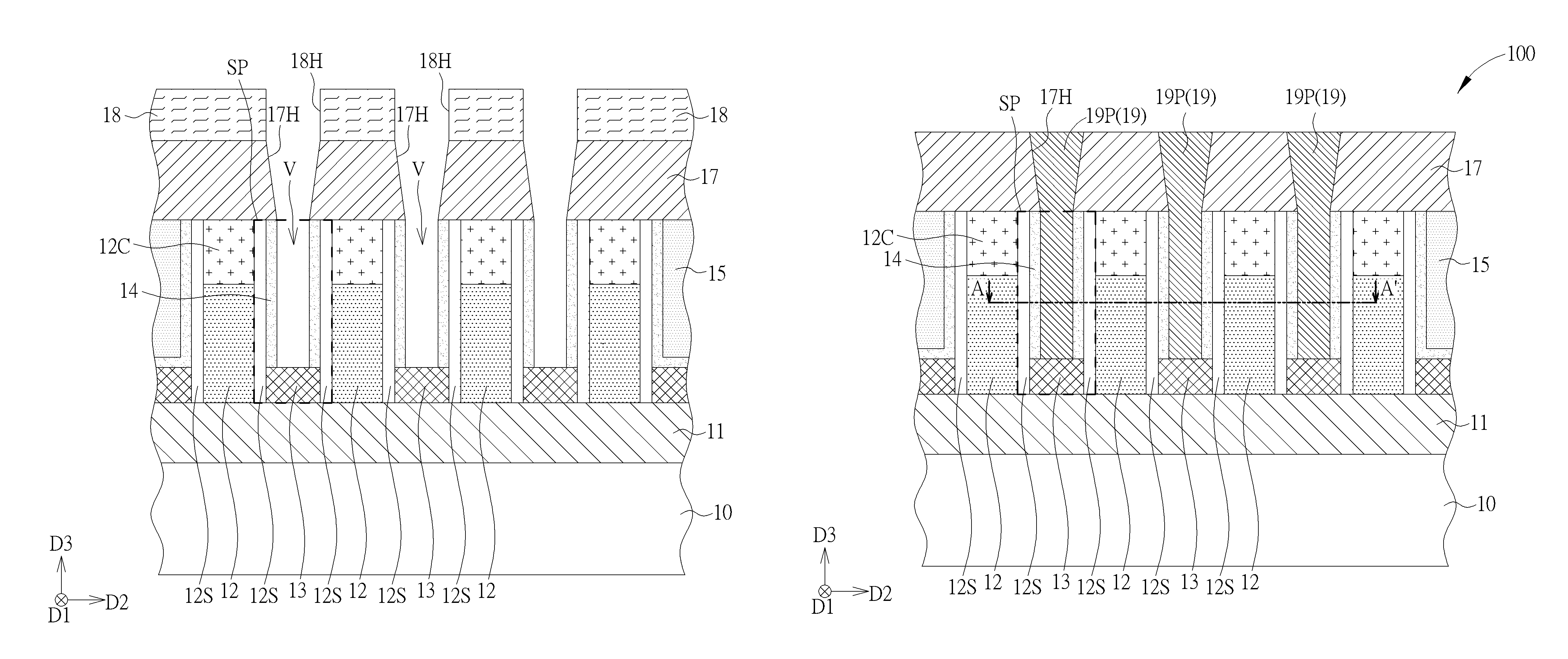

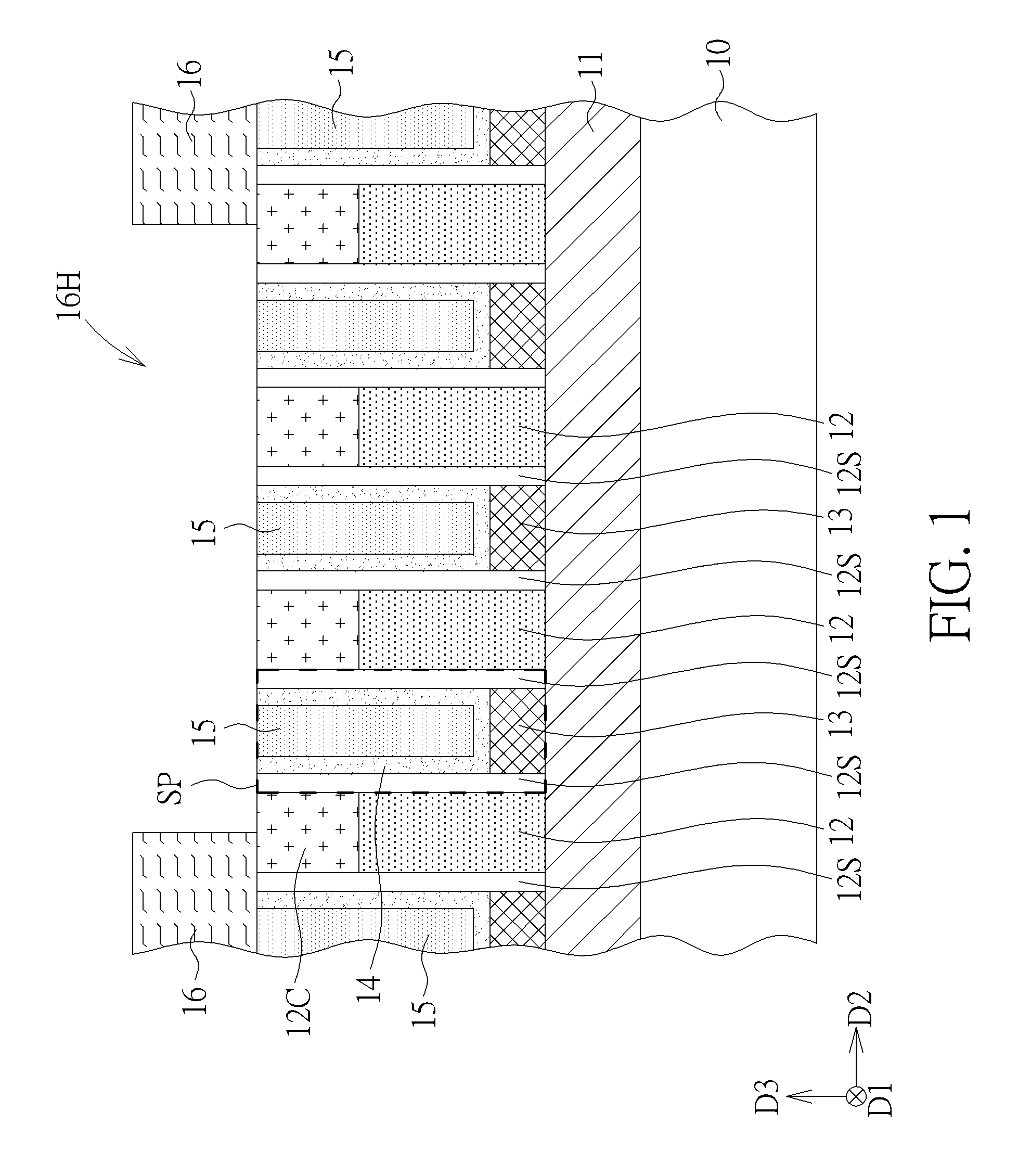

Semiconductor device and manufacturing method of conductive structure in semiconductor device

ActiveUS9397008B1Increased process windowHigh yieldTransistorSemiconductor/solid-state device detailsSemiconductor structureEngineering

A manufacturing method of a conductive structure in a semiconductor device includes the following steps. A plurality of gate structures are formed on a semiconductor structure, and a first dielectric layer is formed in space between the gate structures. A first process is then performed to remove at least a part of the first dielectric layer in the space between the gate structures. A second dielectric layer is then formed and covers the gate structures so as to form at least one air void in the space between the gate structures. A second process is performed to form at least one opening penetrating the second dielectric layer and exposing the air void. The air void exposed by the opening is then filled with at least one conductive material for forming a conductive structure between the gate structures.

Owner:MARLIN SEMICON LTD

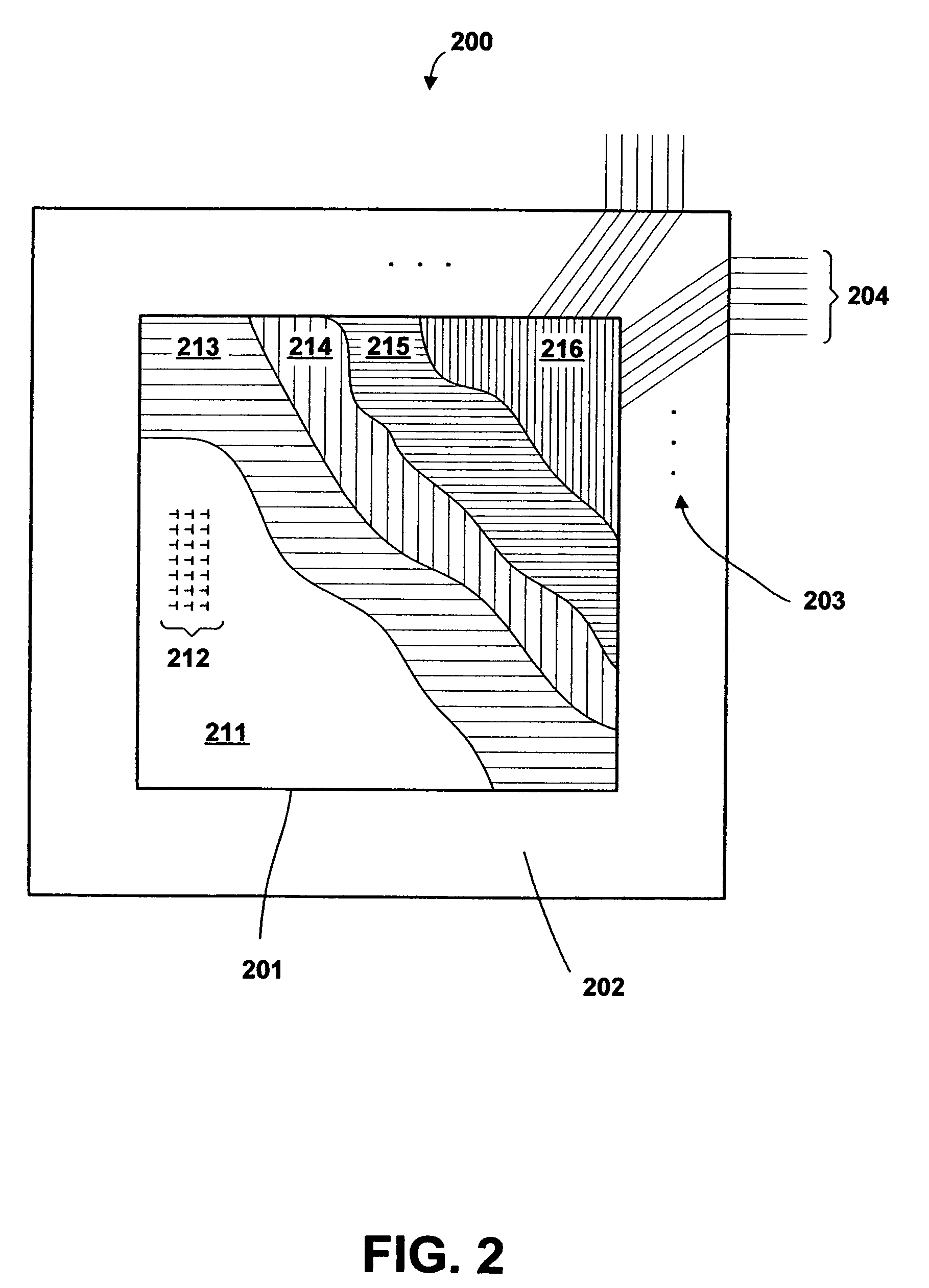

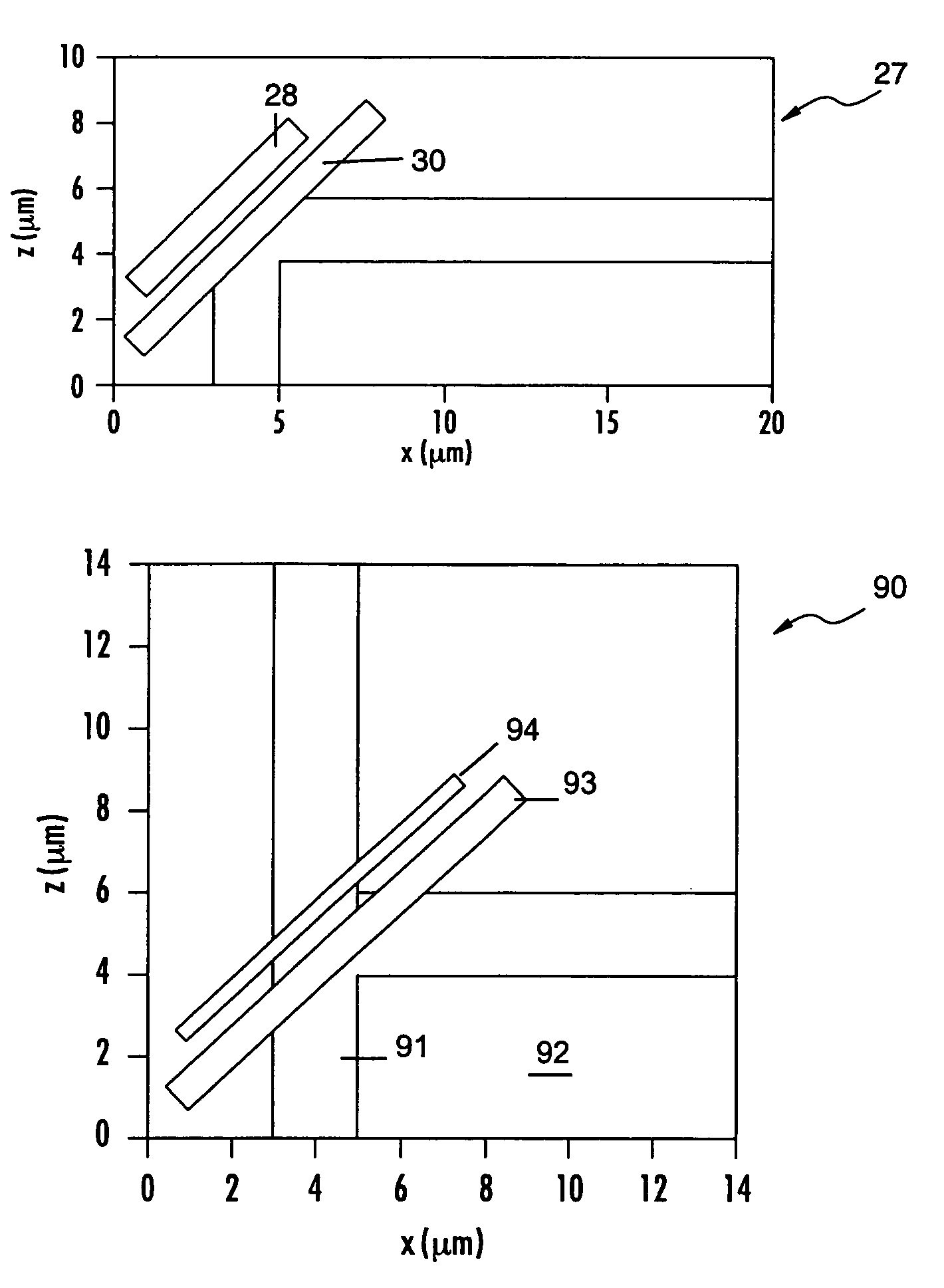

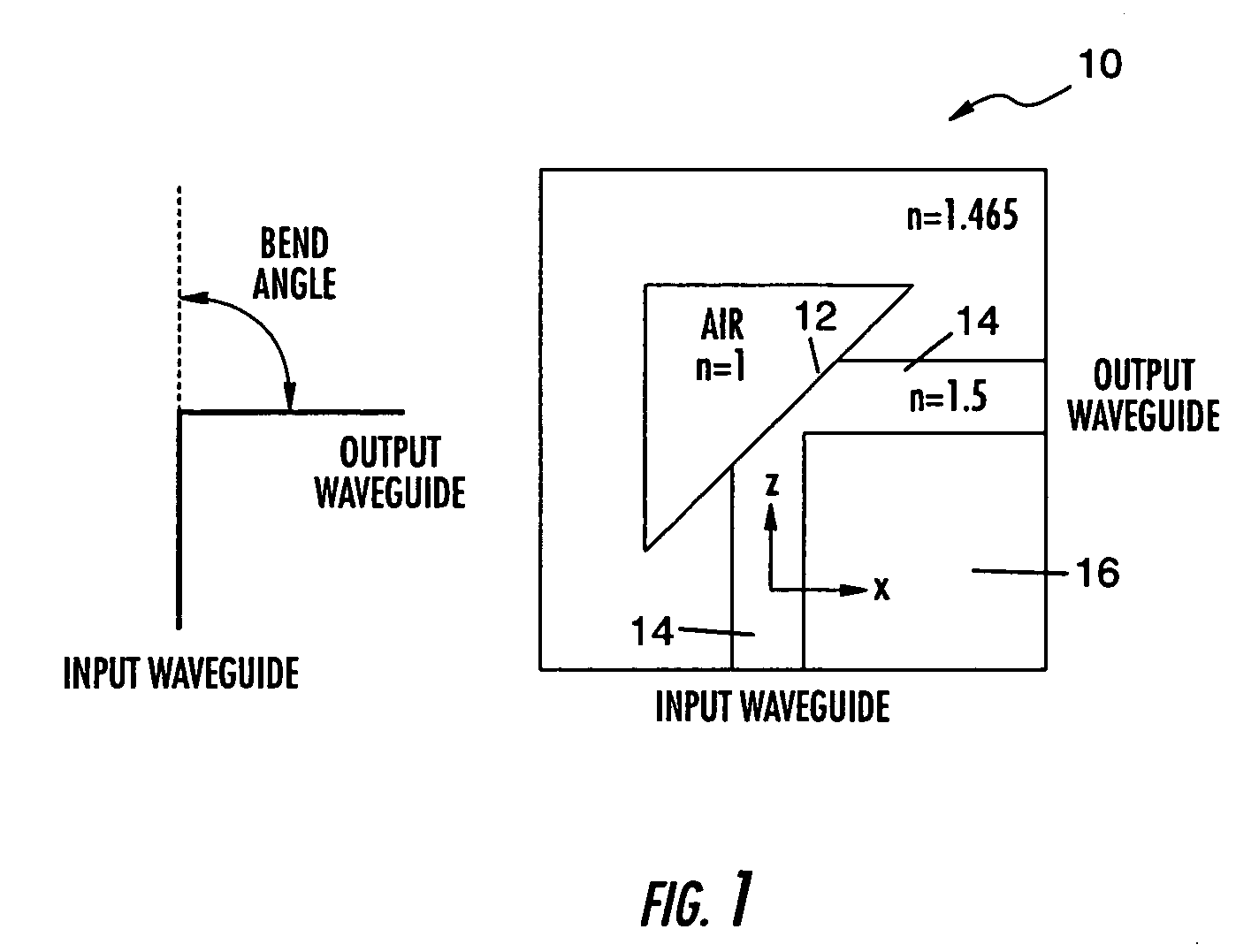

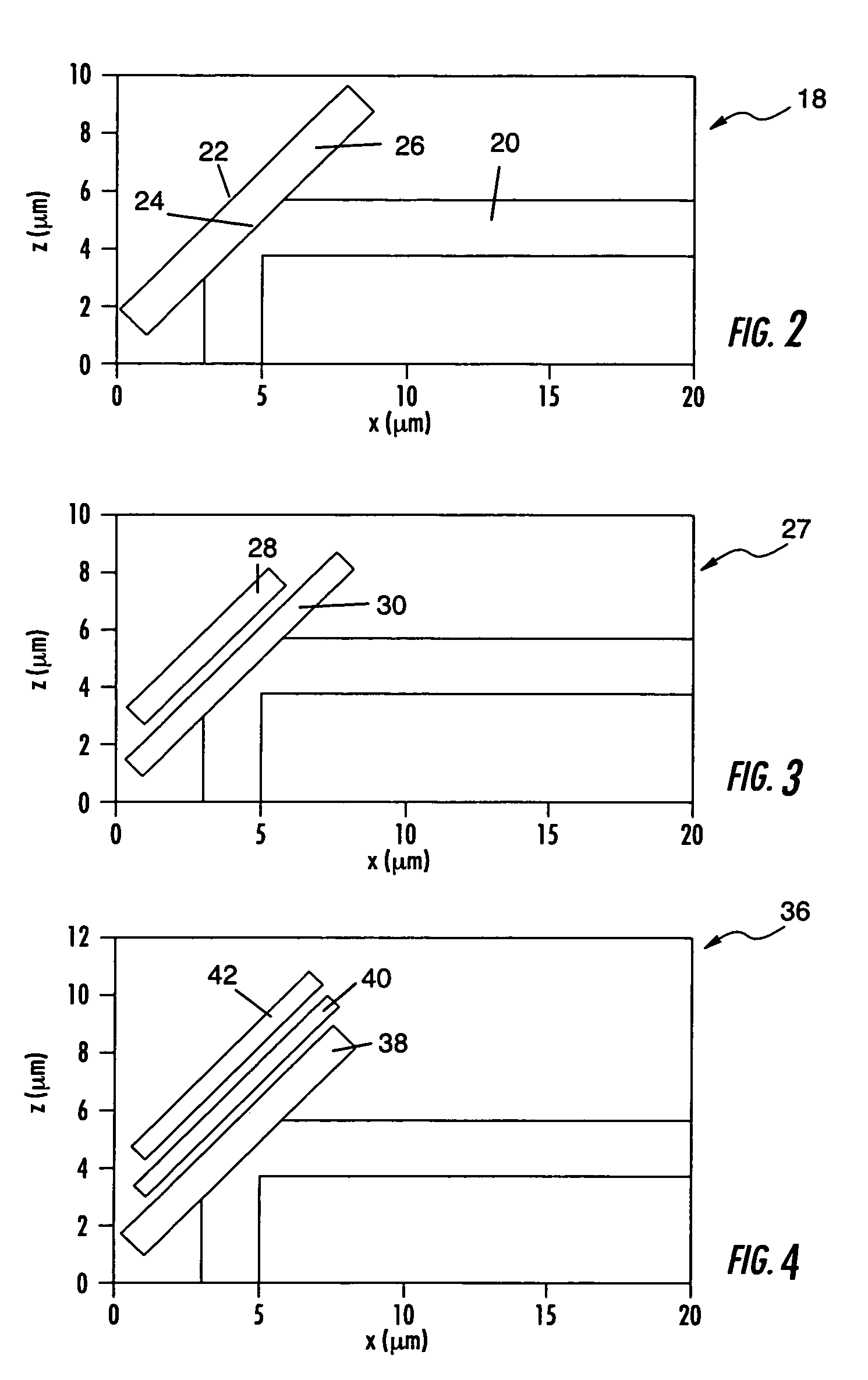

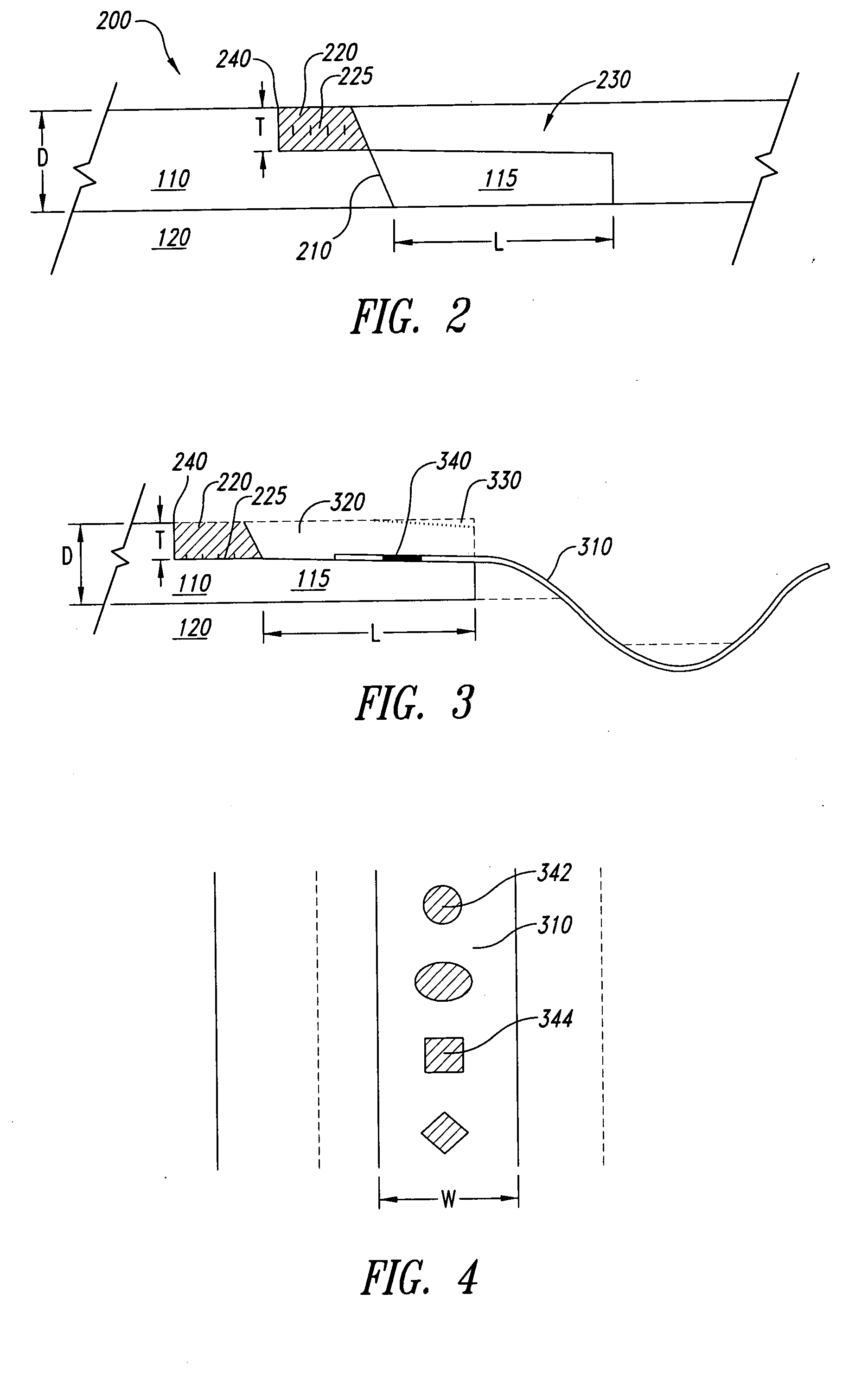

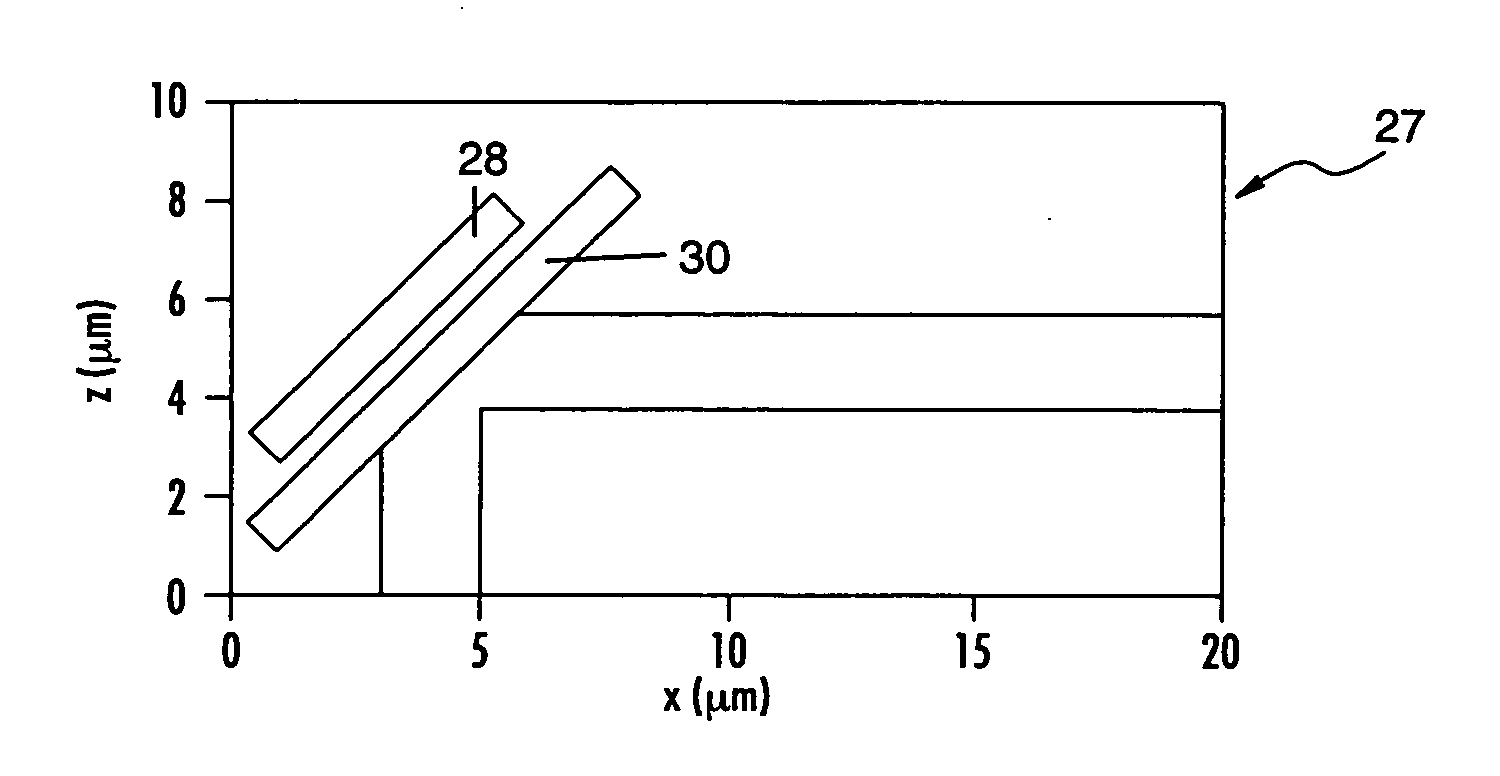

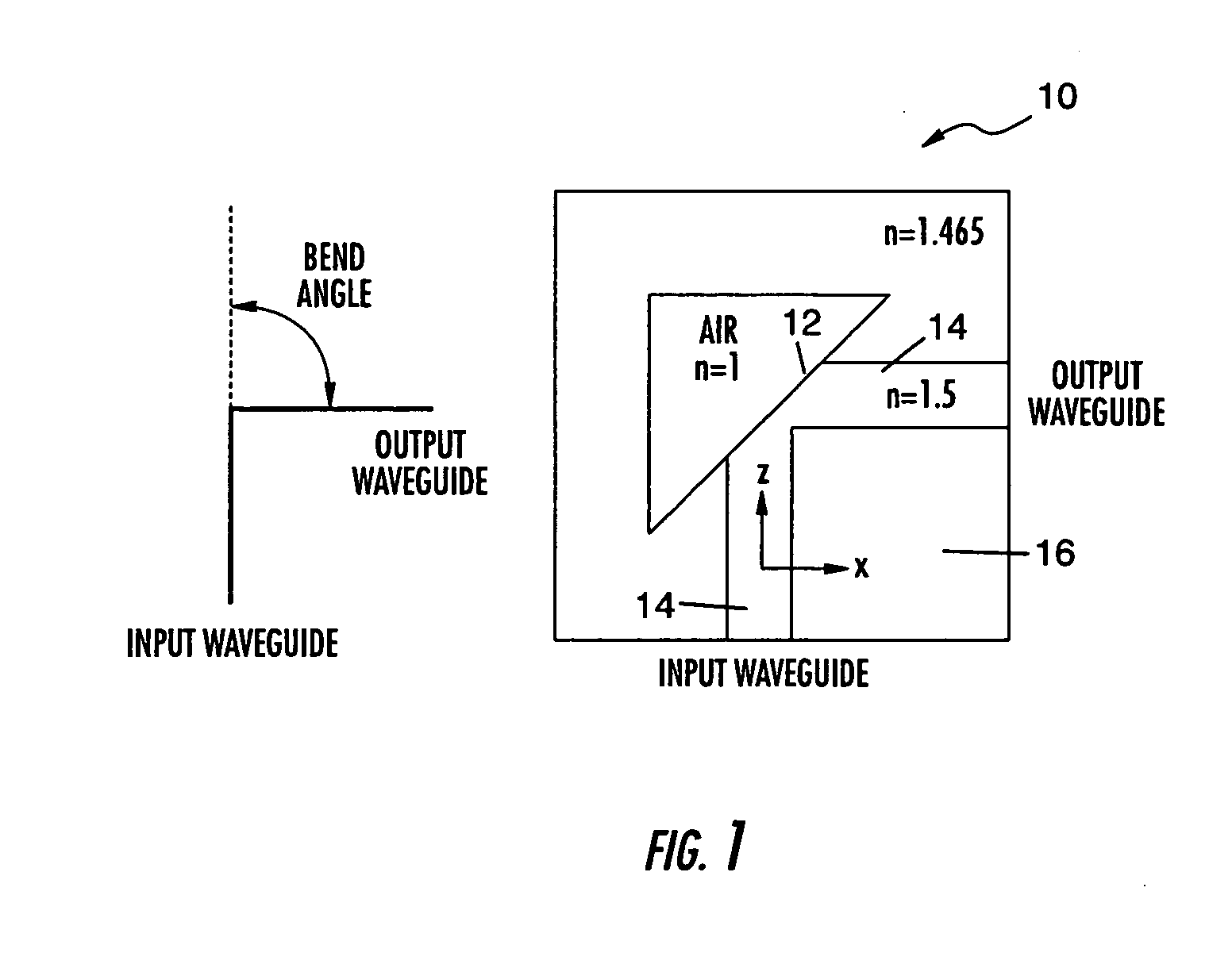

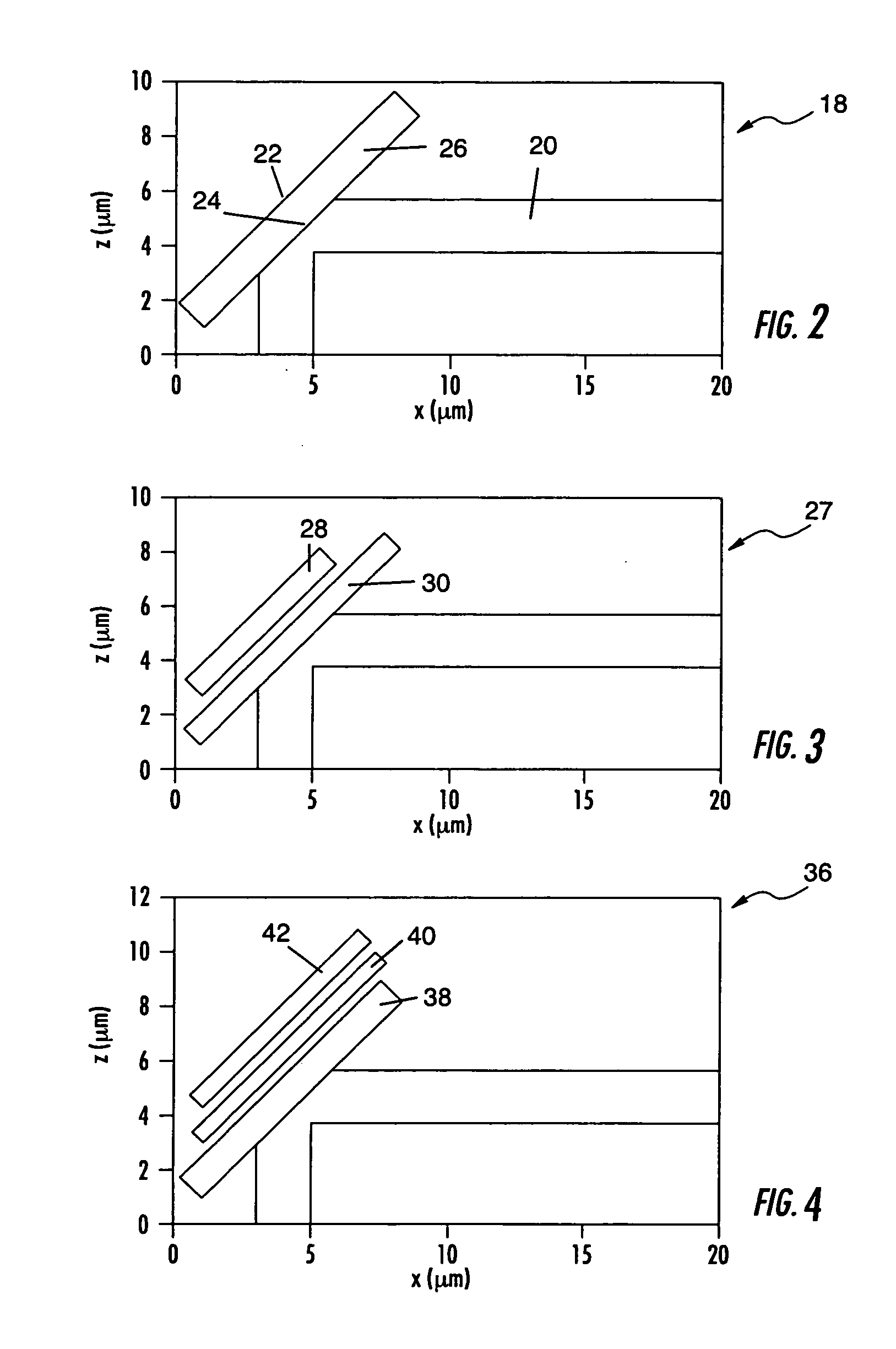

Planar lightwave circuit waveguide bends and beamsplitters

InactiveUS7206470B2Coupling light guidesOptical waveguide light guideAngle of incidenceRefractive index

A planar lightwave circuit has a waveguide having a bend and plurality of multiple trenches with parallel front and back interfaces. The trench and waveguide refractive indexes are different such that a refractive interface is defined between the waveguide and the trench. The trench may include a material of higher refractive index than the waveguide, such as silicon, or alternatively a material having a lower refractive index than the waveguide, such as an air void. The trench is disposed on the waveguide bend such that the front and back planar interfaces have an angle of incidence to a direction of the lightwave propagation from the waveguide. The invention also includes beamsplitters that include trenches that reflect a portion of a lightwave in a first direction and a portion of a lightwave in a second direction.

Owner:UNIVERSITY OF ALABAMA

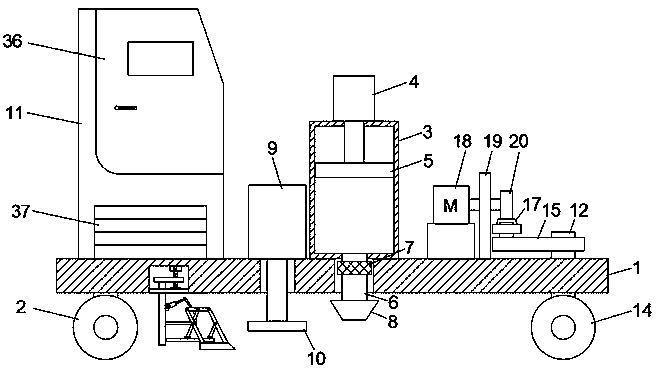

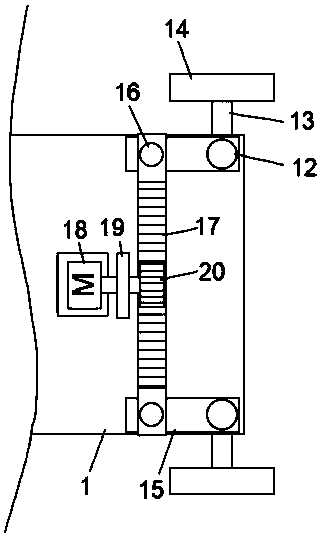

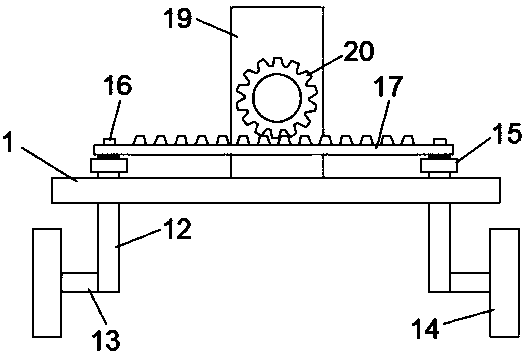

Residential area asphalt pavement paver capable of swinging from side to side

The invention discloses a residential area asphalt pavement paver capable of swinging from side to side. The residential area asphalt pavement paver capable of swinging from side to side comprises a mounting platform; a driving rear wheel is mounted at the bottom of the rear end of the mounting platform; a swinging mechanism is mounted at the front end of the mounting platform; an asphalt storagebox is fixedly mounted above the mounting platform; a cylinder is fixedly mounted at the upper end of the asphalt storage box; a driving rod of the cylinder penetrates through the asphalt storage boxand is fixedly connected with a piston block; a pipeline is fixedly connected to the bottom of the asphalt storage box; a valve is mounted on the pipeline; one end, far away from the asphalt storage box, of the pipeline penetrates through the mounting platform; a discharging hopper is fixedly mounted at the end, far away from the asphalt storage box, of the pipeline; a first hydraulic cylinder isalso fixedly mounted at the upper end of the mounting platform; and a driving rod of the first hydraulic cylinder penetrates through the mounting platform, and a compaction block is welded on the driving rod of the first hydraulic cylinder. According to the residential area asphalt pavement paver capable of swinging from side to side, the paving in pot holes in a residential area asphalt pavementis much compacter to prevent air voids; the paving effect is better; more filled asphalt during paving can be cleaned so that the laid asphalt is kept flat with the original pavement; and the construction quality is better.

Owner:吉林省荣达建设工程有限公司

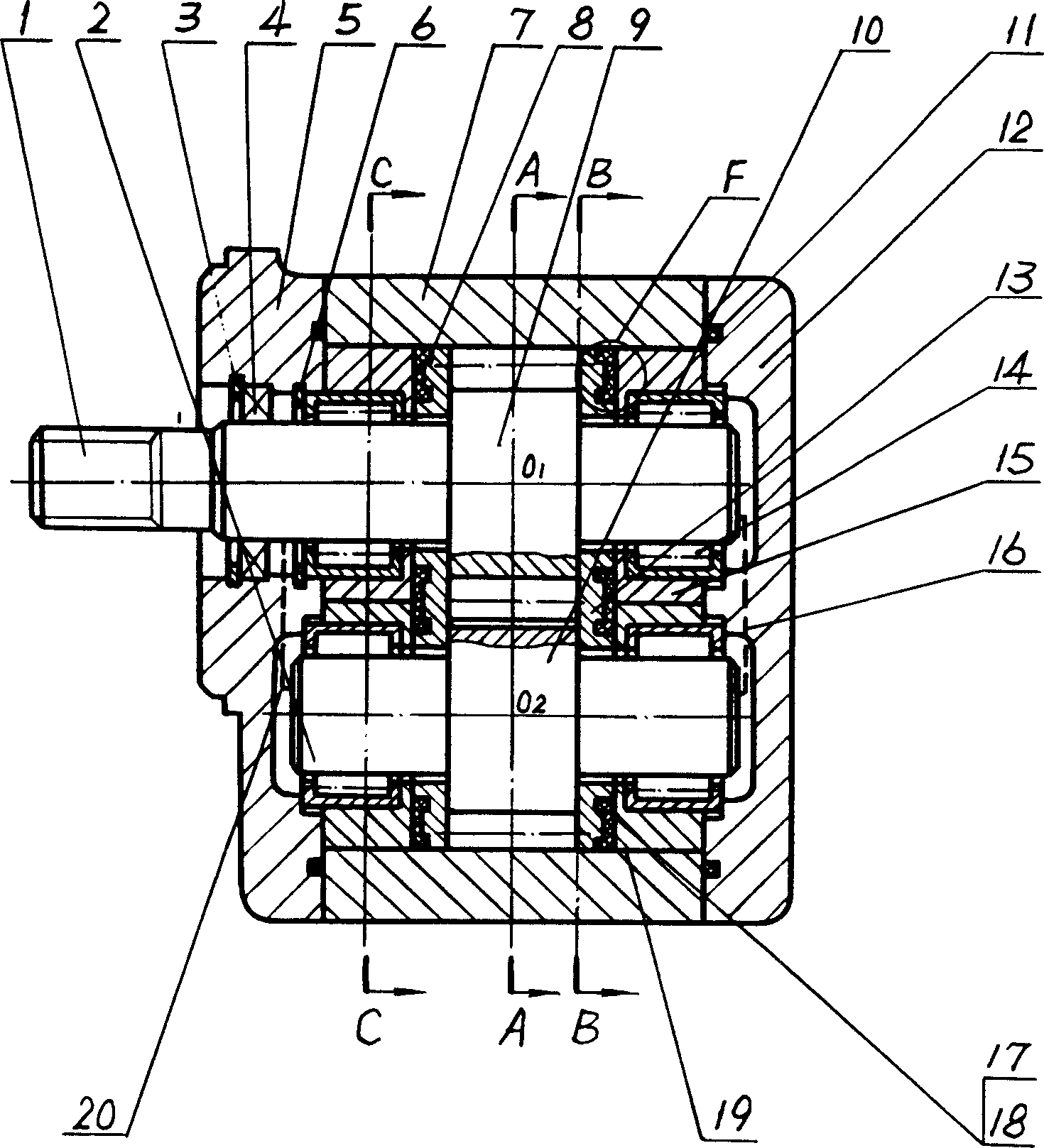

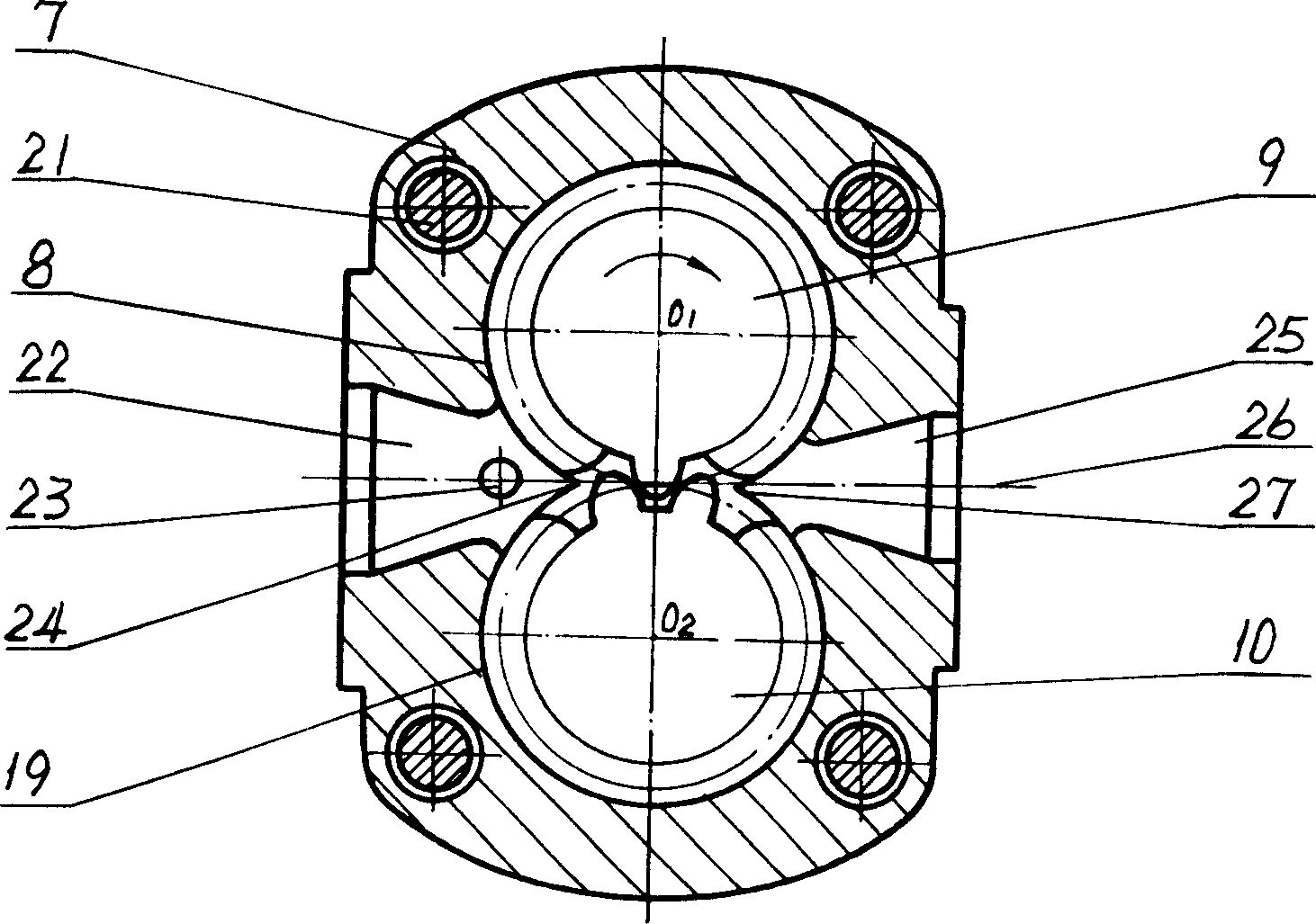

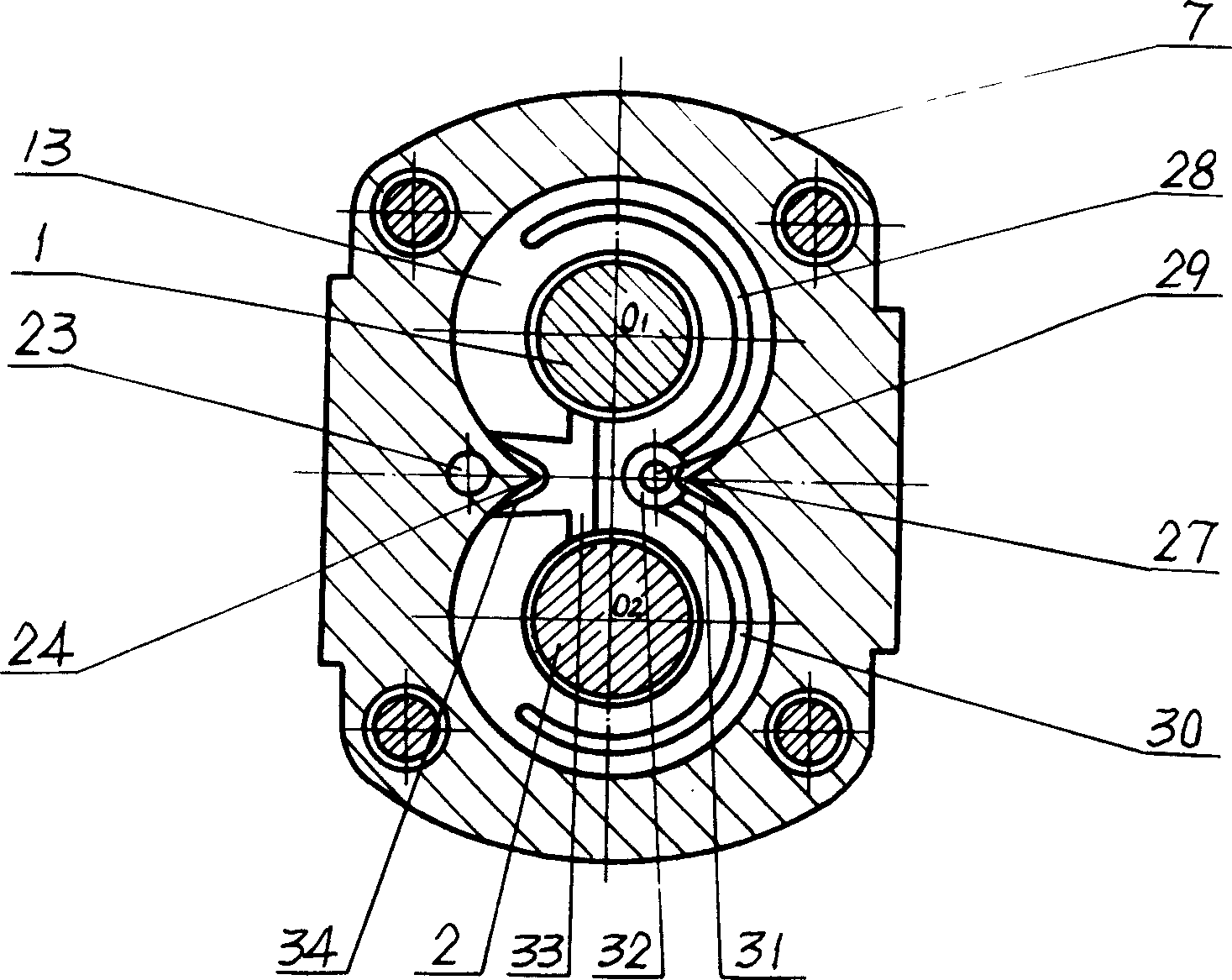

Axial housing type gear pump mounted with rolling bearing and gear motor

InactiveCN1755114AAvoid deformationAvoid noiseRotary piston pumpsRotary piston liquid enginesGear pumpGear wheel

The invention discloses a bearing gear pump and gear motor with rolling bearing, which is characterized by the following: fixing a couple of gear pairs with lateral plate on each side in the '8' keyhole-shaped case inner wall; setting four axle sleeves with bearing on the outer side of lateral plate; setting high pressure oil axial sealing oil system; the appearance of two interapplying axle sleeves is the same as cave keyhole-shaped, which is inserted in the zero air void matching cave with rolling bearing in the axle sleeve. The axle sleeve doesn't bear liquid pressure action any longer because of zero air void matching between axle sleeve and cave, which avoids the deformation and noise of axle sleeve and provides large displacement gear pump and gear motor for engineering machinery and mining machinery under terrible working condition.

Owner:程安强

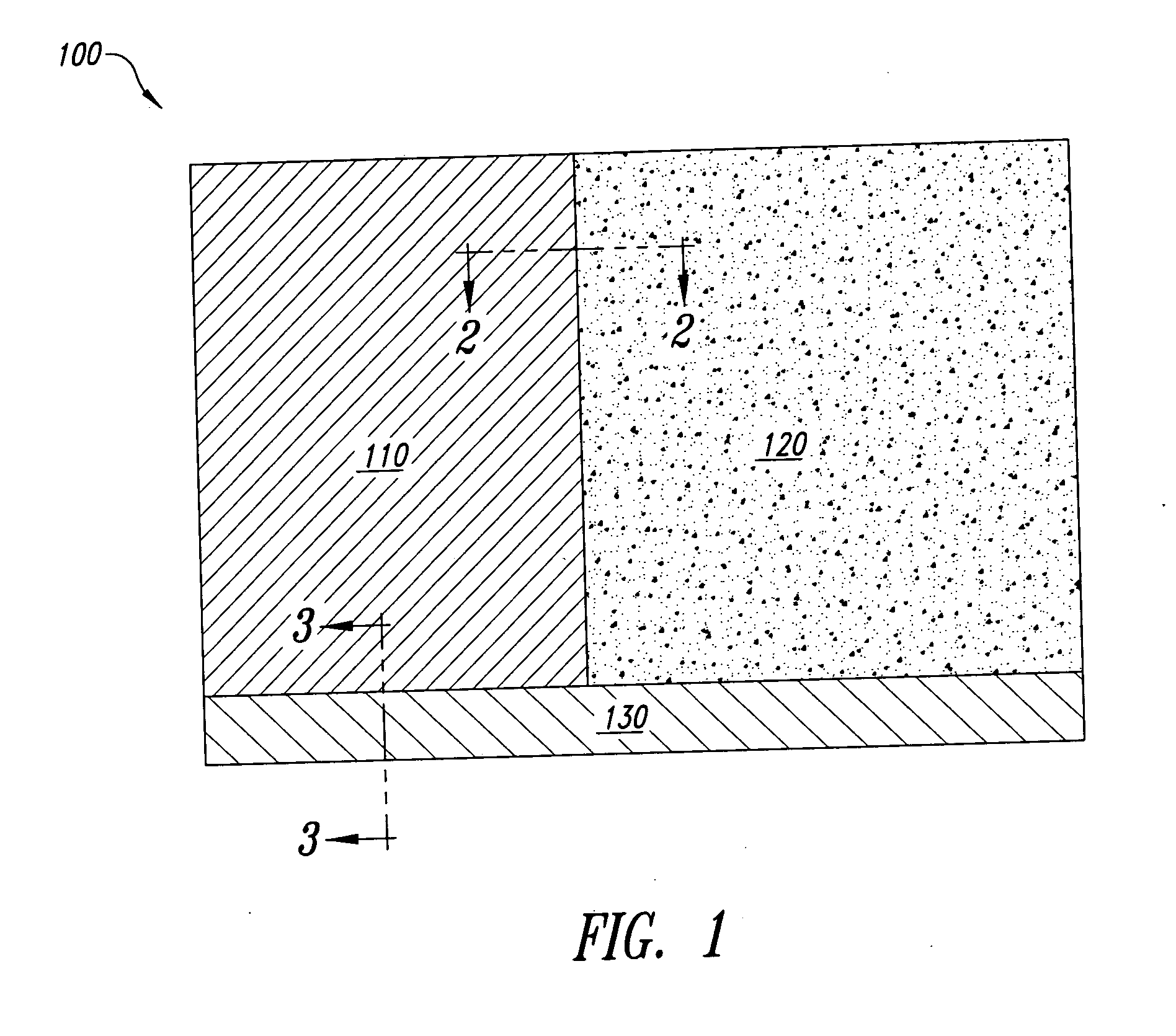

Crack resistant coating and method of applying crack resistant coating

InactiveUS20110038668A1Increase to horizontal movementIncrease horizontal resistanceIn situ pavingsPaving detailsAir voidsMaterials science

The present invention relates to a method for applying a crack resistant coating on a surface, where the crack resistant coating increases resistance to high vertical and horizontal movements and high shear stresses on the surface. The method comprises the steps of applying a binding material to the surface and applying an aggregate mixture within 15 seconds of applying the binding material to the surface, where the aggregate mixture comprises aggregate particles and an asphalt solution and where the aggregate mixture has a plurality of air voids, and where the binding material fills at least 15% of the air voids in the aggregate mixture (AVFA).

Owner:ARR MAZ PRODS

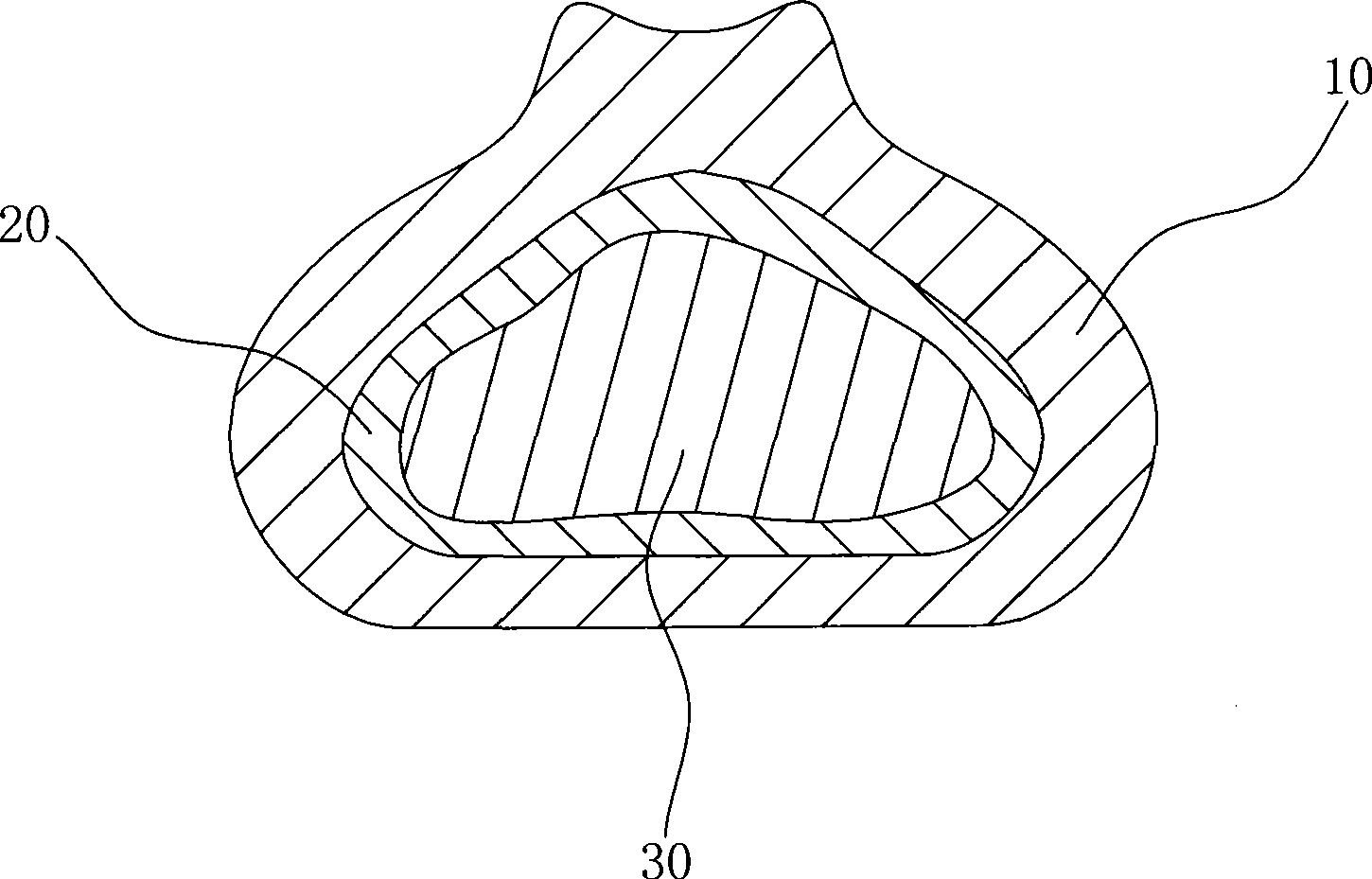

Steamed stuffed bun and production method thereof

InactiveCN101422221AAvoid breakingFor long-term storageBakery productsFood preparationDermatologyAir voids

The invention pertains to the technical field of foods, in particular relates to a steamed stuffed-bun and a preparation method thereof. The skin of the steamed stuffed-bun is divided into an external skin and an internal skin, which are mutually jointed, wherein, the external skin is a fermented wrapper and the external skin is a dull wrapper; and stuffing is wrapped in the internal skin. When the steamed stuffed-bun is prepared, the internal skin is put on the external skin at first; then the stuffing is put on the internal skin; the internal skin is intervolved to wrap the stuffing; and finally, the external skin is intervolved to lead the internal skin to be jointed with the external skin and closed. The dull wrapper is also called a fixed wrapper and made by mixing unfermented flour with water. As the dull wrapper has good flexibility and tenacity and great adhesive force and is not easy to be destroyed, spoon meat does not flow out during cooking the steamed stuffed-bun; as the interior of the dull wrapper has no air void and weak adsorption performance, the spoon meat in the stuffing can be well kept in the internal skin and is not be absorbed by the fermented wrapper of the external skin after cooking; therefore, the taste of the steamed stuffed-bun is not affected by long-term storage.

Owner:安徽省高记餐饮管理有限公司

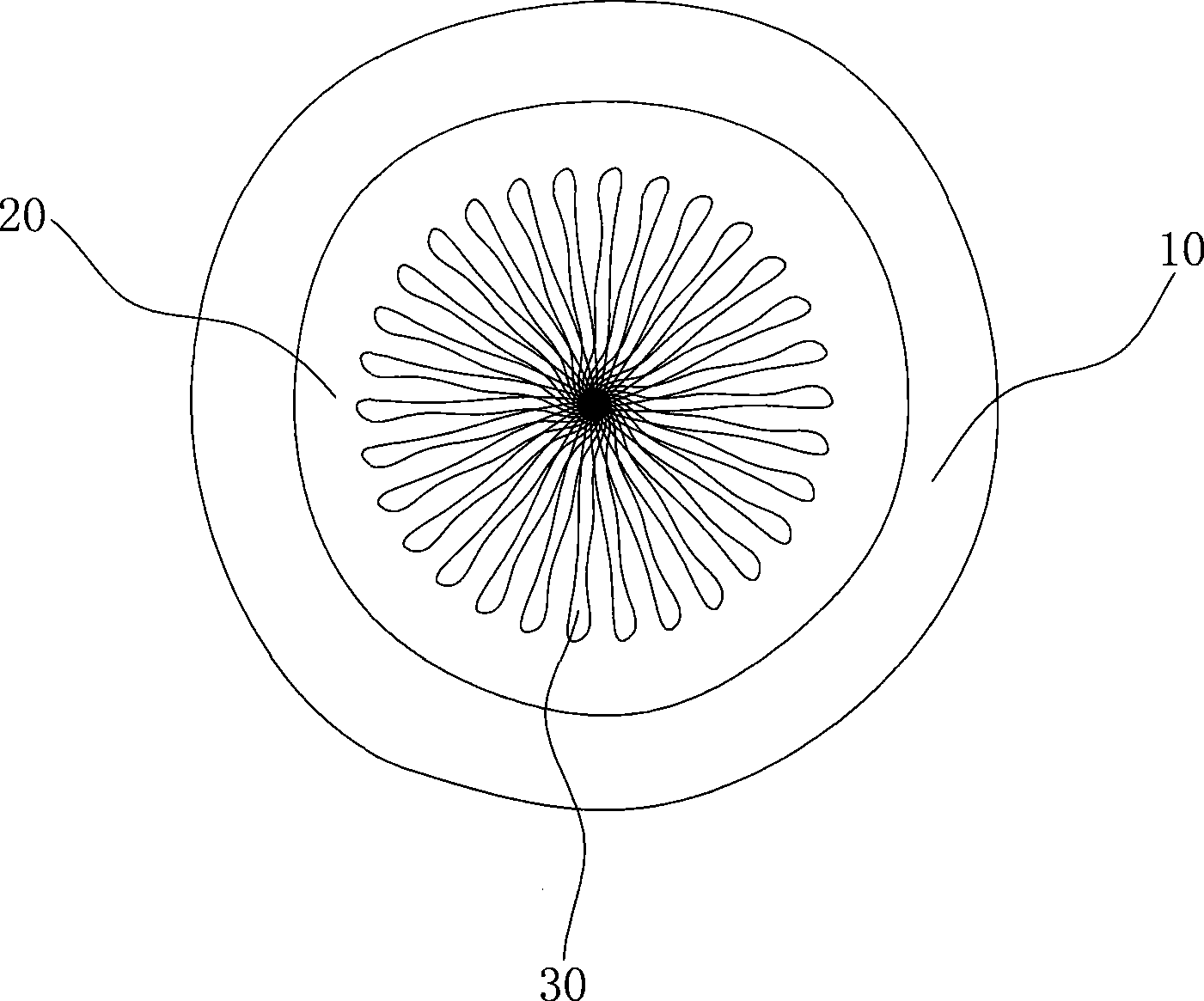

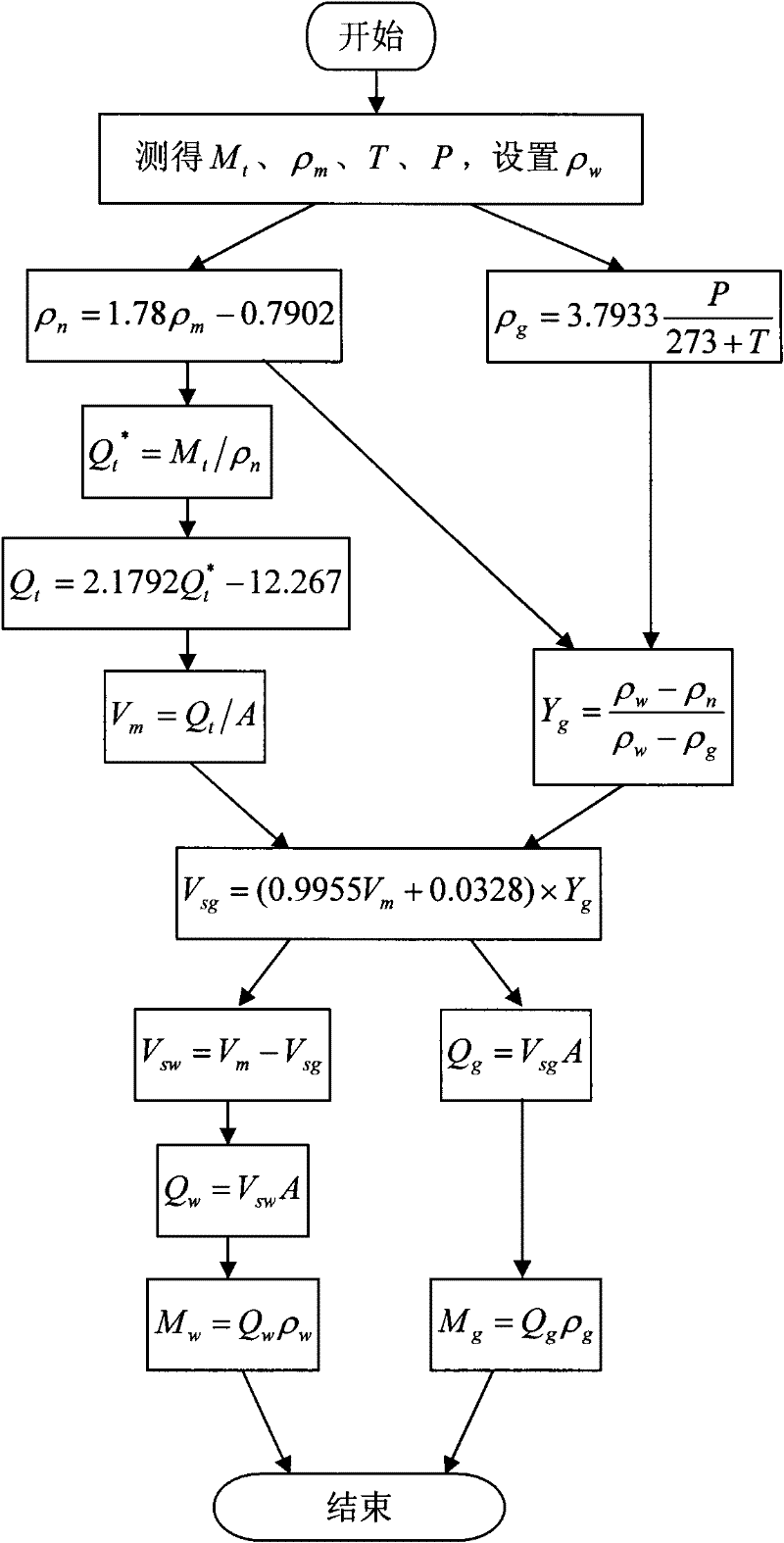

Device and method for measuring crude oil with low air void

InactiveCN101666770AImprove detection accuracySolve the problem of poor separation effectMaterial capacitanceDirect mass flowmetersOil fieldEngineering

The invention discloses a device and a method for measuring crude oil with low air void, belonging to the technical field of fluid measurement. The device for measuring crude oil with low air void comprises a measurement pipeline, a capacitance transducer at the front end of the measurement pipeline, a flow mixer at the middle of the measurement pipeline, a Coriolis mass-flow meter and a pressuretransducer at the rear end of the measurement pipeline, an A / D switch card and a computer. The capacitance transducer, the Coriolis mass-flow meter and the pressure transducer are connected with the computer via the A / D switch card. The invention also provides a measurement method adopted by the device. The invention has the advantages of small volume, simple structure, convenient installation, more obtained measurement parameters, high detection precision of the parameters, good real time measurement, high reliability, easy implementation and the like, and is suitable for measuring crude oilwith low air void in oil field.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

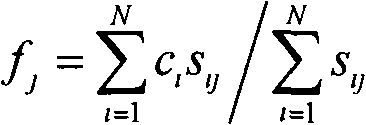

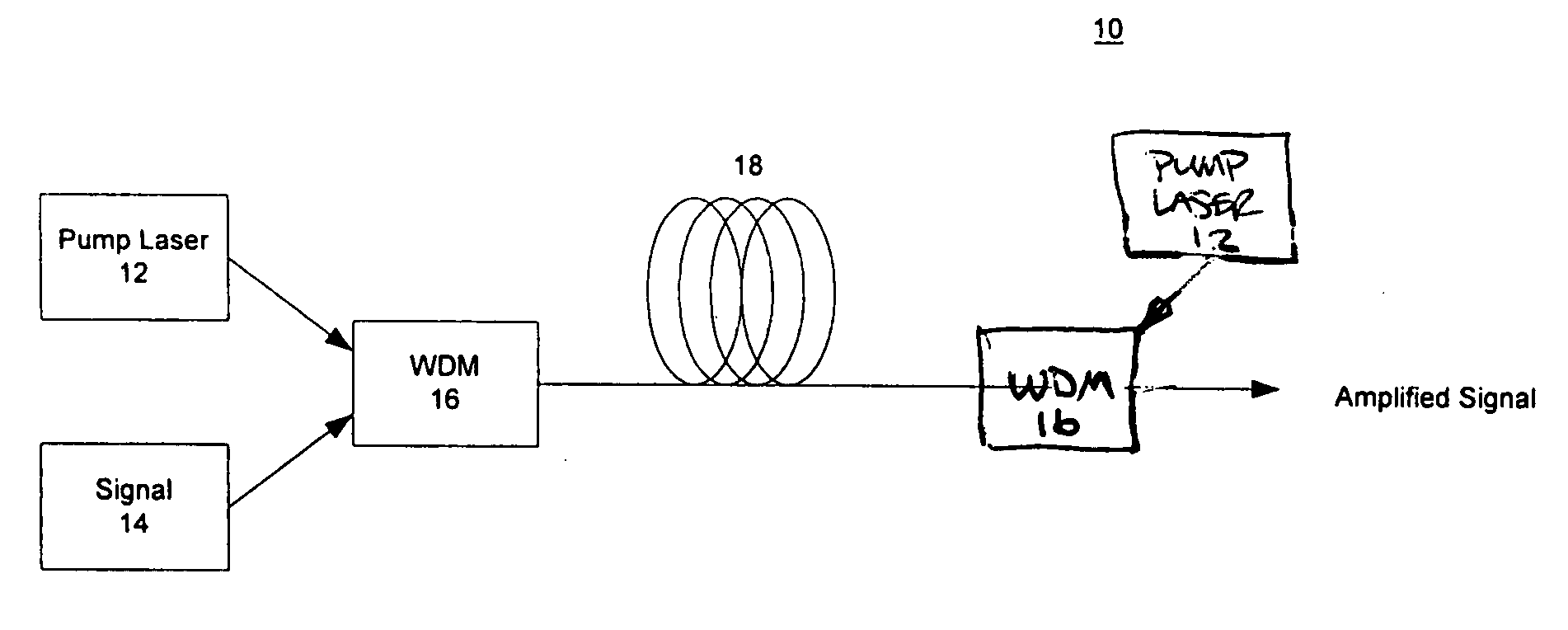

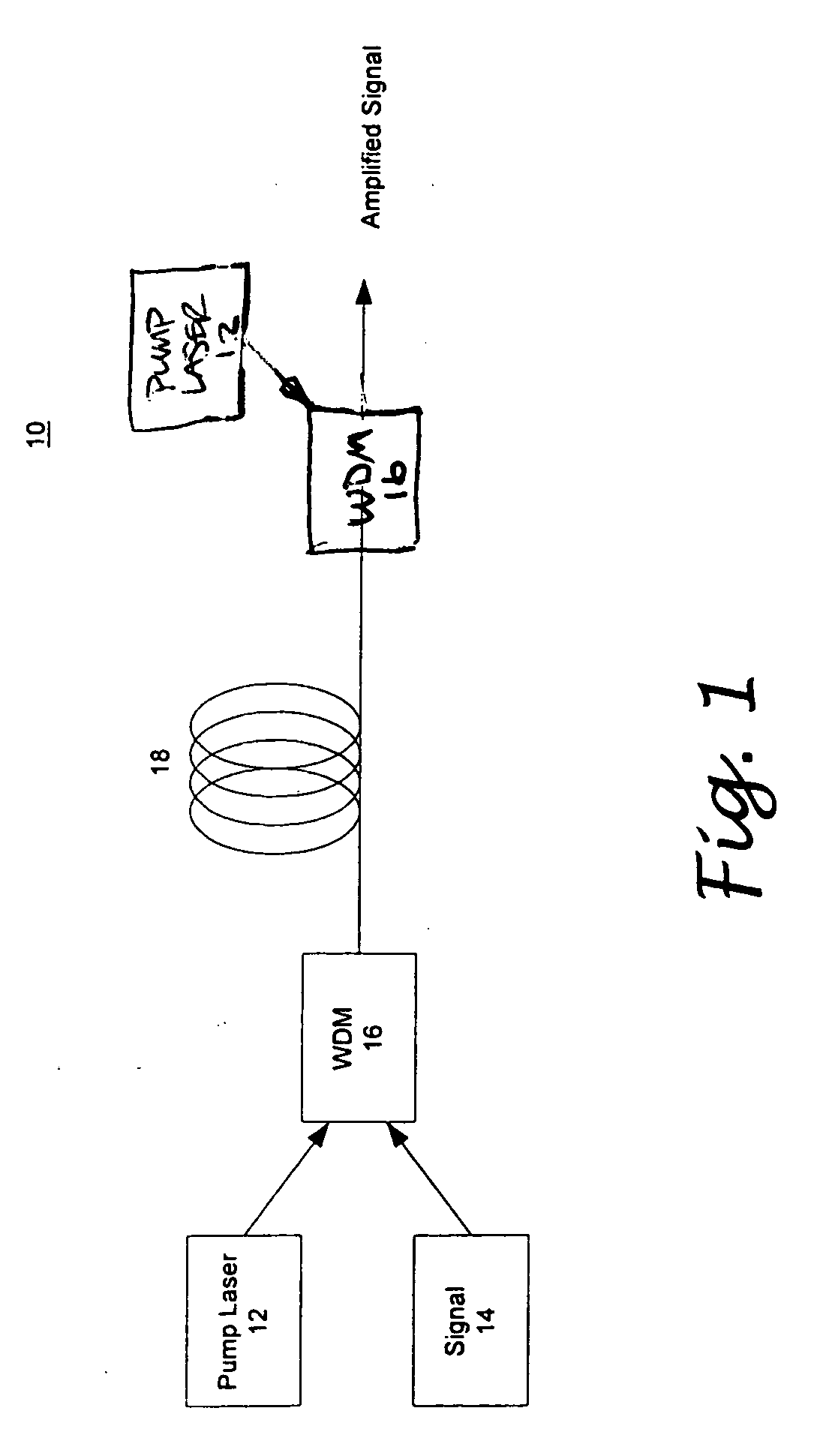

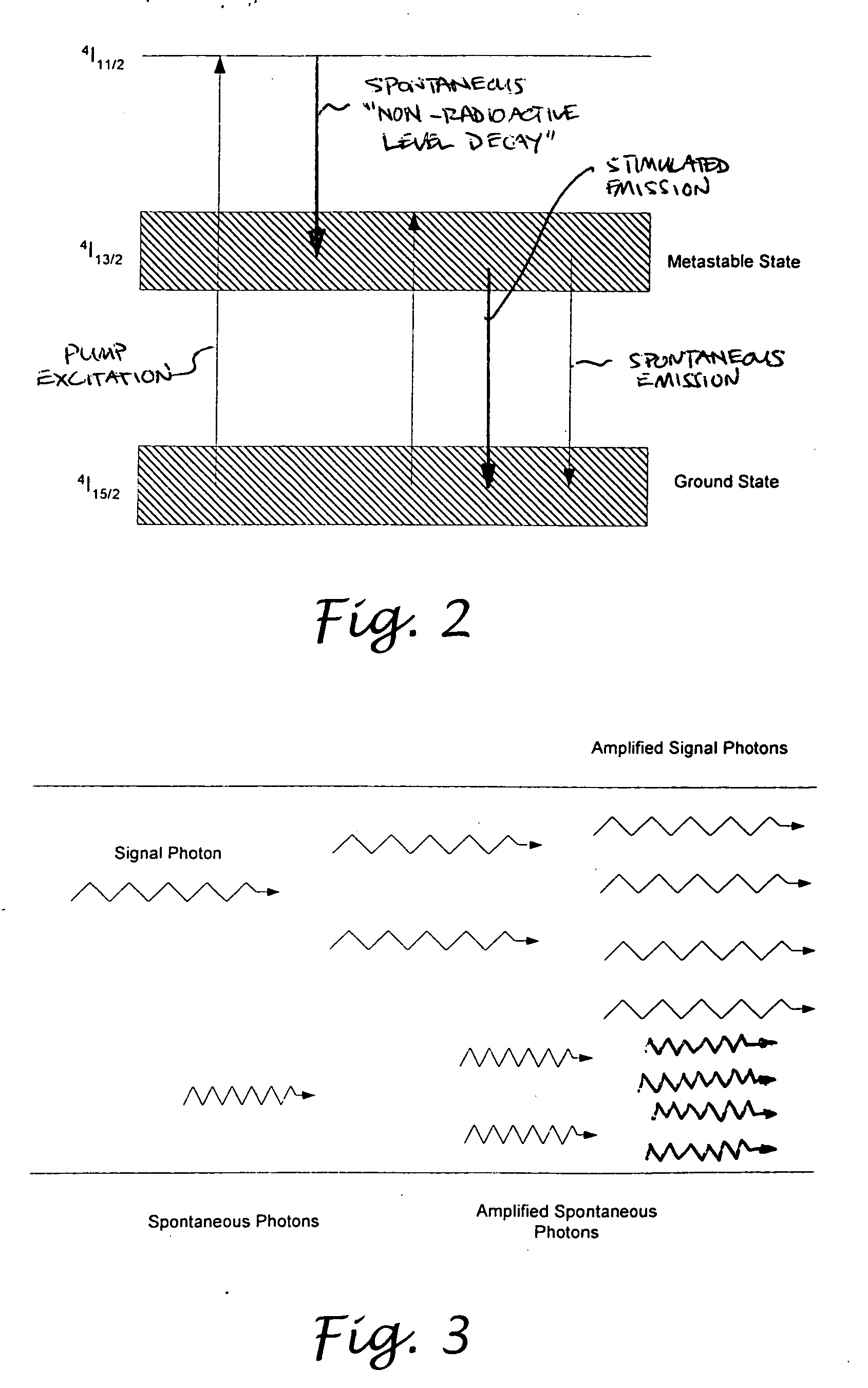

High-efficiency, high-reliability fiber amplifier using engineered passband of photonic bandgap optical fiber

InactiveUS20080130100A1Low costSmall sizeExcitation process/apparatusFibre transmissionPhotonic bandgapRefractive index

A fiber amplifier is configured such that its spontaneous emissions are filtered out at the instant of creation. The fiber optic amplifier combines the gain medium of the fiber optical amplifier with a continuous filter to filter out the spontaneous emissions to prevent spontaneously emitted photons from stealing gain from signal photons. The photonic crystal fiber has a central core doped with a gain medium such as erbium, ytterbium or thulium ions. The central core of the photonic crystal fiber is surrounded by a cladding region having an array of holes or air voids that may be filled with materials with refractive index different from that of the central core. The array of holes are configured to restrict the wavelength range within which light can propagate inside the central core thereby providing continuous filtering functionality. The fiber amplifier has a pump operative to generate pump energy that is coupled to the photonic crystal fiber simultaneously with the signal. The wavelength of the pump energy is within the absorption band of the gain medium to facilitate amplification of the signal.

Owner:NORTHROP GRUMAN CORP

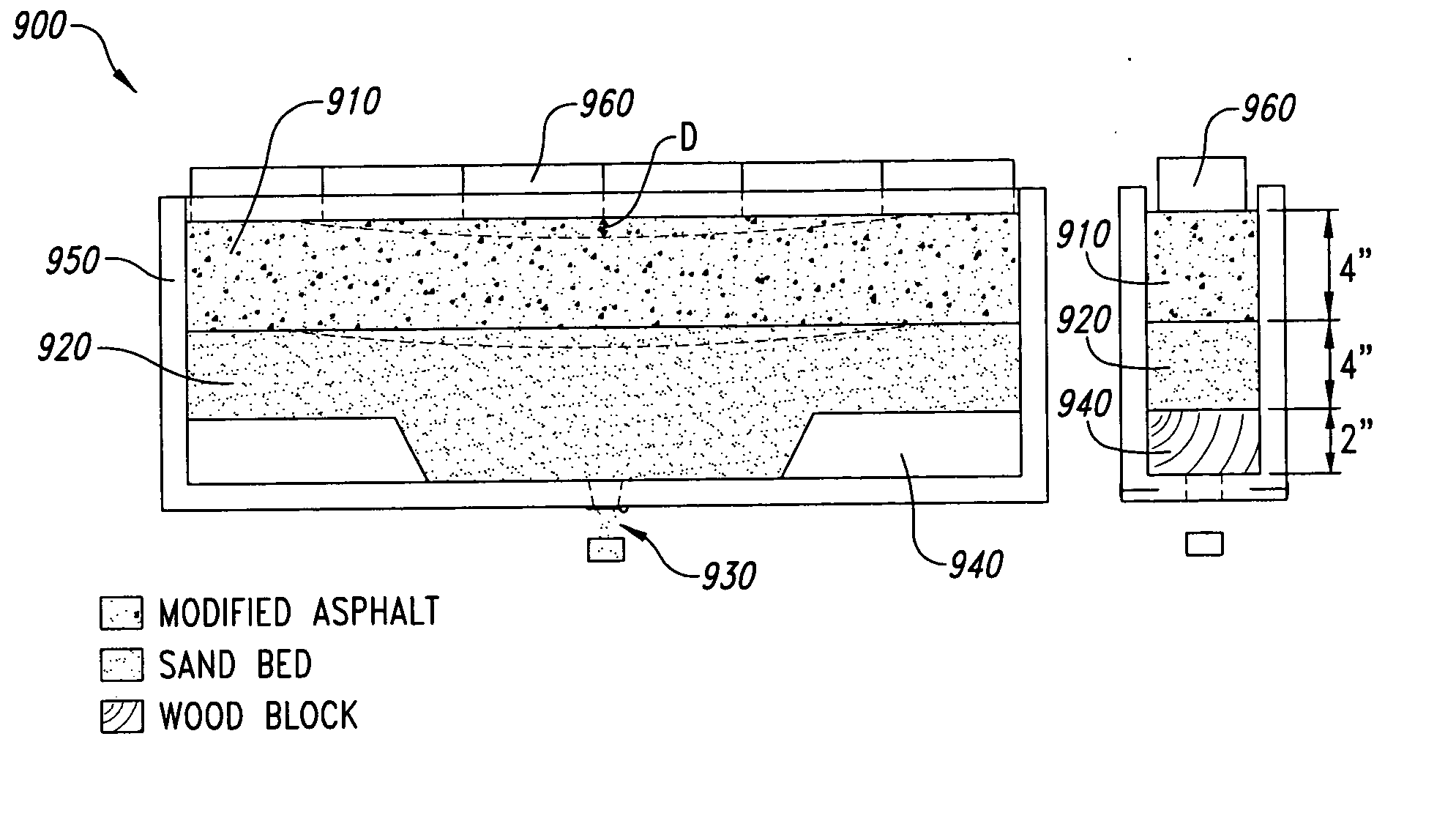

Method and system for containment, such as a containment cap for solid waste constructed of modified asphalt

InactiveUS20050191132A1Longevity easeEasy maintenanceSolid waste disposalLandfill technologiesSuperfund siteSuperfund

The present invention is directed to a waste or environmental containment system that includes modified asphalt specifically designed for containment, and a system of installation that provides a seamless cap over the area to be contained. The modified asphalt of the present invention has a permeability less than 1×10−8 cm / sec and an air void content less than 3 percent. The system of installation includes joint designs that meet the same parameters as the modified asphalt mat to provide a seamless containment cap or liner to contain hazardous wastes at RCRA, Superfund sites, waste sites and environmental containment areas.

Owner:MATCON

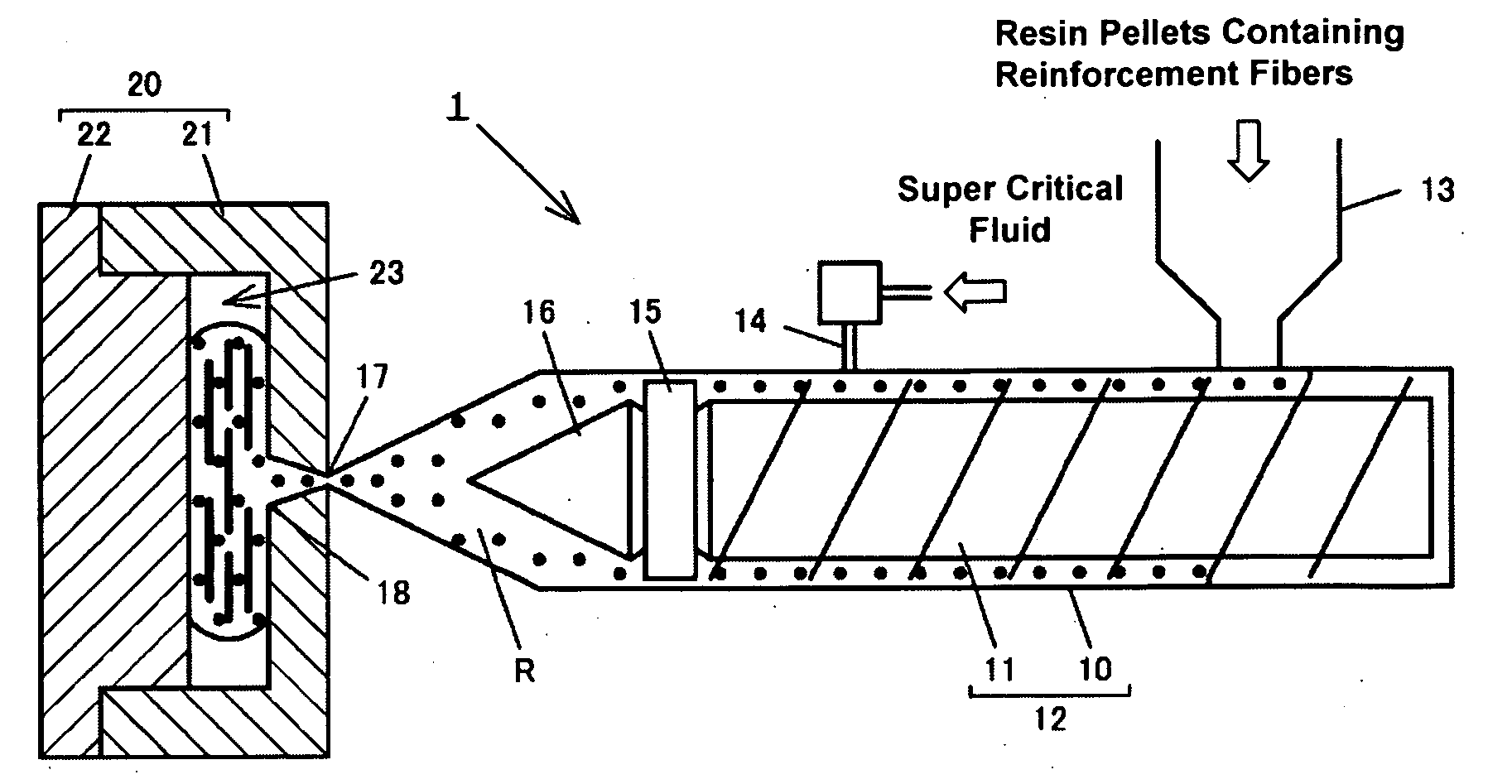

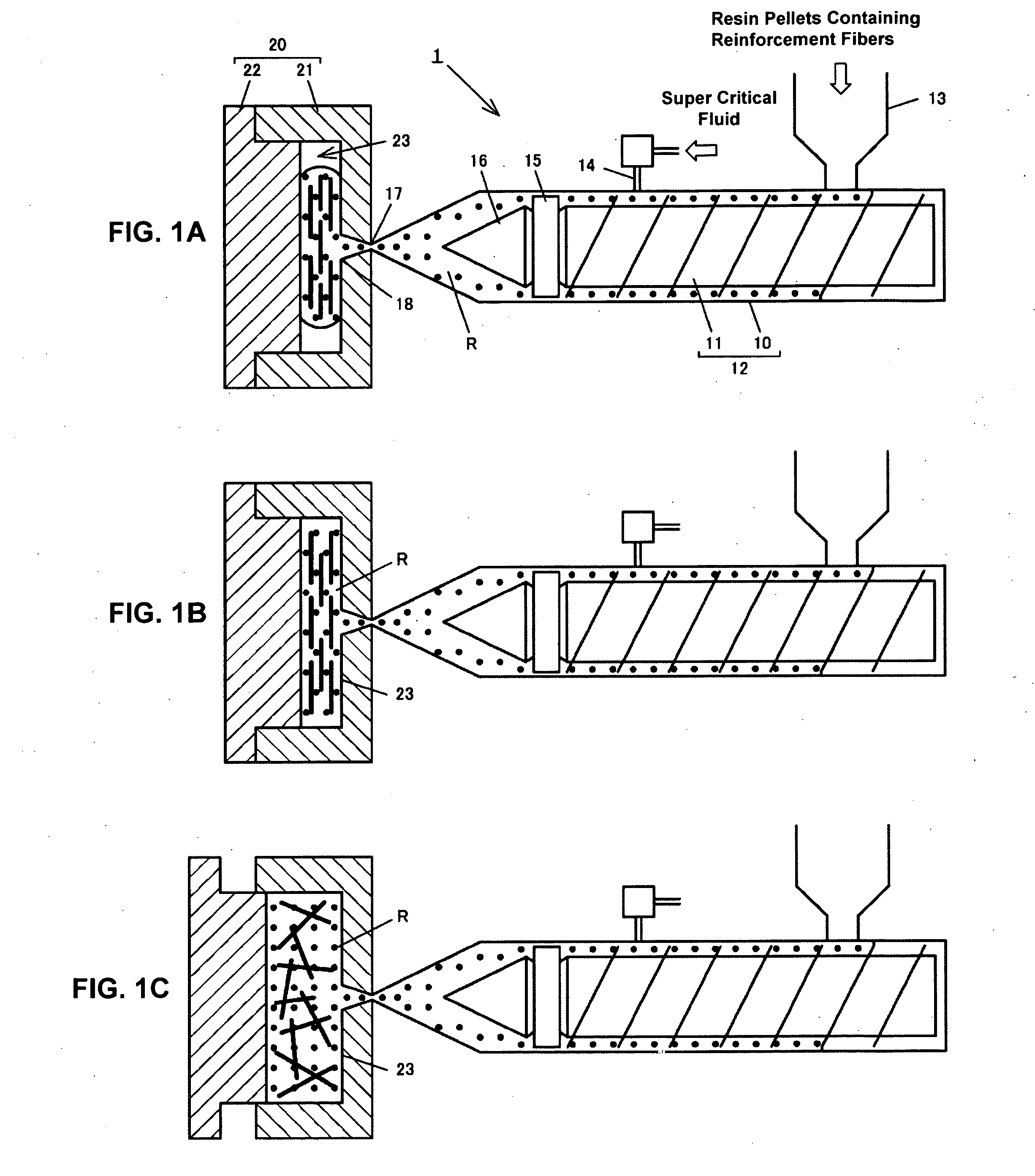

Molding method and apparatus of resin molded article

InactiveUS20070187859A1Sufficient volume expansionSpeed up the flowFood shapingVolume expansionAir voids

A foaming molten resin containing reinforcement fibers and super critical fluid is injected into a cavity with a short shot (a), the foaming molten resin is made self-foam and flow in the cavity (b), and a volume of the cavity is increased by expanding molds so as to expand the foaming molten resin in the cavity (c). During the expansion step (c), the expansion of the foaming molten resin is assisted by gas vent, vacuum suction, partial pressure adding with gas or resin, or a spring back force of the reinforcement fiber in the foaming molten resin. Accordingly, there can be provided a resin foam molded article that has no improperly large air voids therein, a sufficient volume expansion thereof, and a superior transferability function.

Owner:MAZDA MOTOR CORP

Model method for measuring flow rate of air-assisted liquid by Coriolis mass flowmeter (CMF)

InactiveCN102346058AMany detection parametersImprove real-time performanceIndirect mass flowmetersModel methodRelational model

The invention discloses a model method for measuring the flow rate of air-assisted liquid by a Coriolis mass flowmeter (CMF), which comprises the following three basic steps: 1) acquiring data by measurement: acquiring the data such as pressure value, instantaneous mass flow rate, medium density and medium temperature; 2) building models: building the relational model between density and air-assisted liquid flow density which are measured by the CMF, building the response model of the CMF, and building the drift-flux model of the air-assisted liquid; and 3) measuring the flow rate: estimating the flow density, the volume flow rate and the air void of the air-assisted liquid, and applying the drift-flux model to calculate instantaneous volume flow rate and the mass flow rate of gas and liquid. The model method for measuring the flow rate of the air-assisted liquid by the CMF has the advantages that the method is simple in structure, convenient to install, good in real-time performance, reliable, easy to realize and the like. The model method is applicable to measuring the air-assisted liquid. The model method can be used for measuring the flow rate of the air-assisted liquid. When the air void is less than 8%, the maximum relative error of liquid phase flow rate is 5%, and the maximum relative error of gas phase flow rate is 10%.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

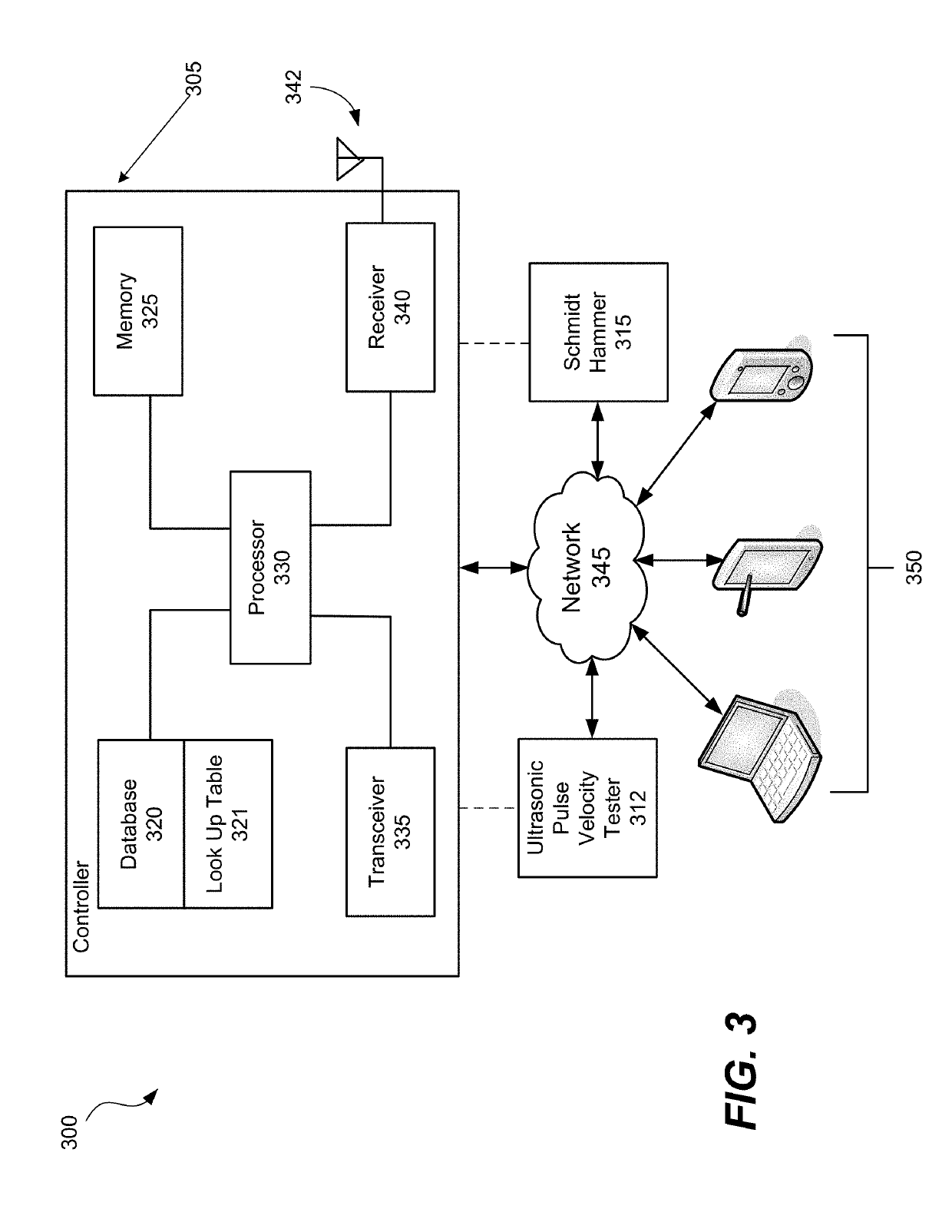

Combined ultrasonic pulse velocity and schmidt hammer rebound test for non-destructive evaluation

ActiveUS20190178765A1Improve accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationPorositySonification

A tester for evaluating pullout load capacity and bond quality of anchor bolts embedded in concrete includes a Schmidt hammer for measuring a rebound number and an ultrasonic pulse velocity tester for measuring the transit time of a pulse transmitted through concrete surrounding an anchor bolt. The rebound number and the transit time are combined and matched against a database record which identifies the pullout load capacity and the bond quality. The transit time is matched to thresholds of transit times associated with porosity, internal cracking, air voids, and water pockets located around the embedded anchor bolt. The Schmidt hammer is further modified by the incorporation of a digital level for measuring the vertical and horizontal angles of inclination of the plunger with the concrete surface, a guide tube for supporting the plunger, and by using a convex plunger tip for improved registration with anchor bolt head.

Owner:IMAM ABDULRAHRNAN BIN FAISAL UNIVERSITY

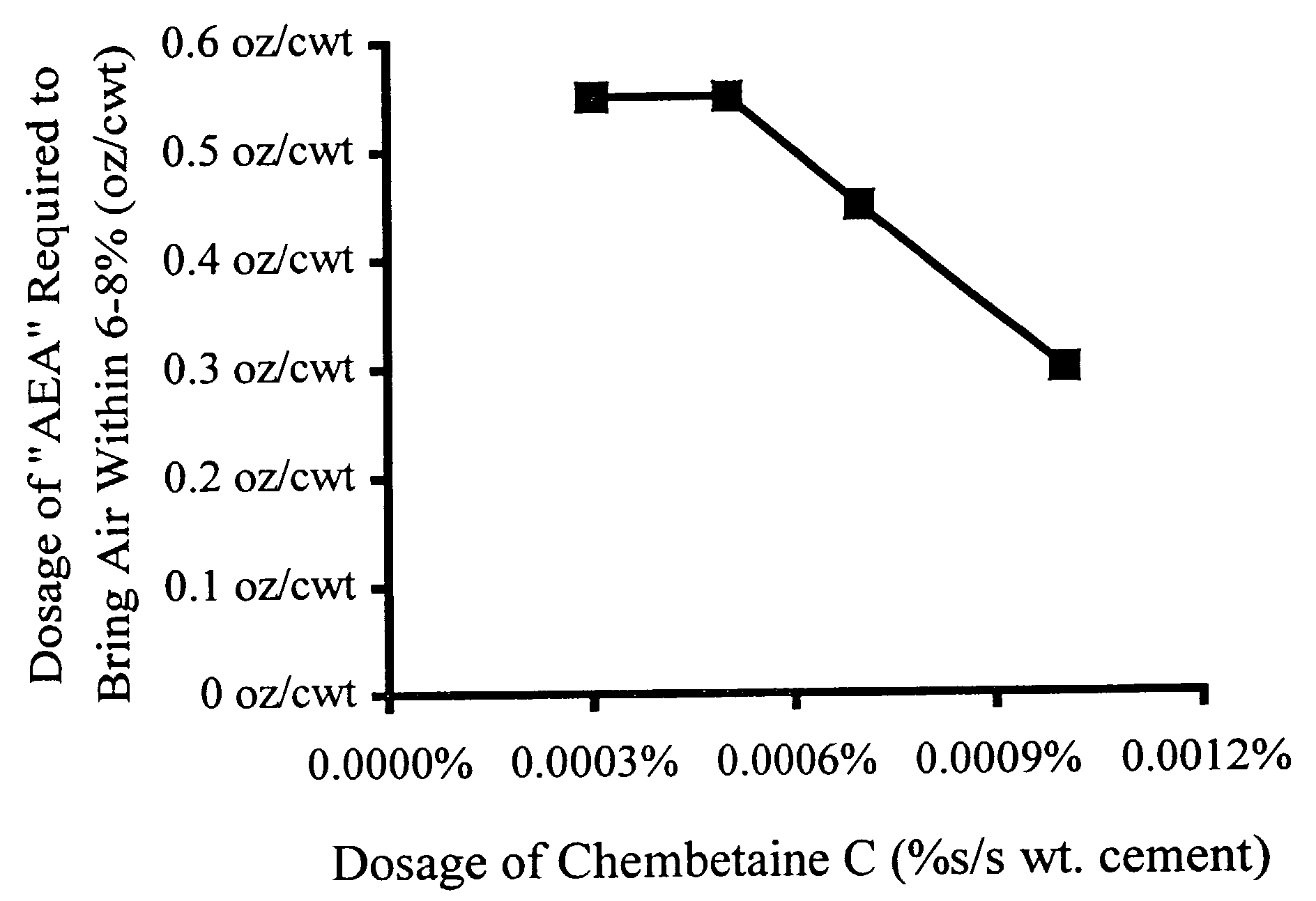

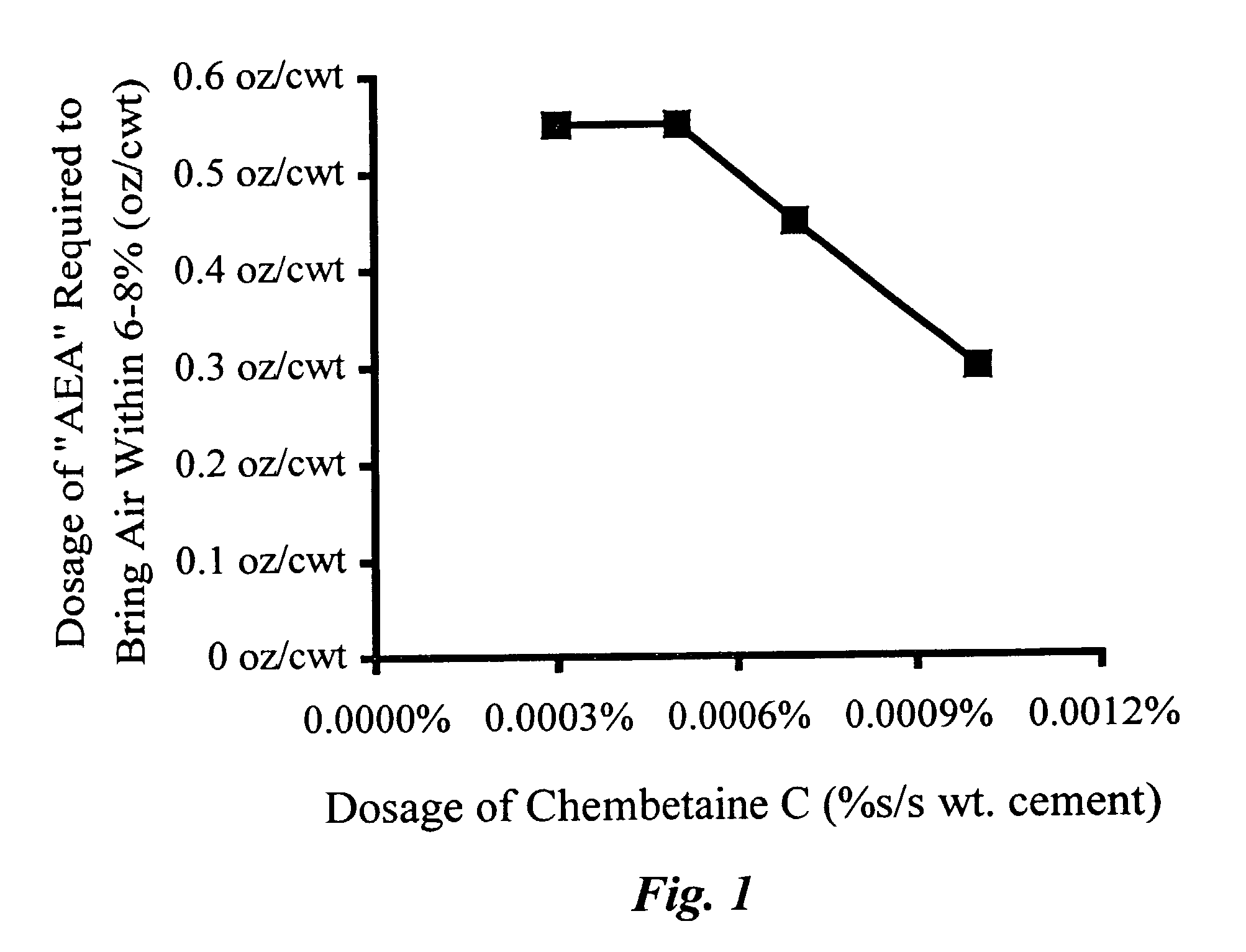

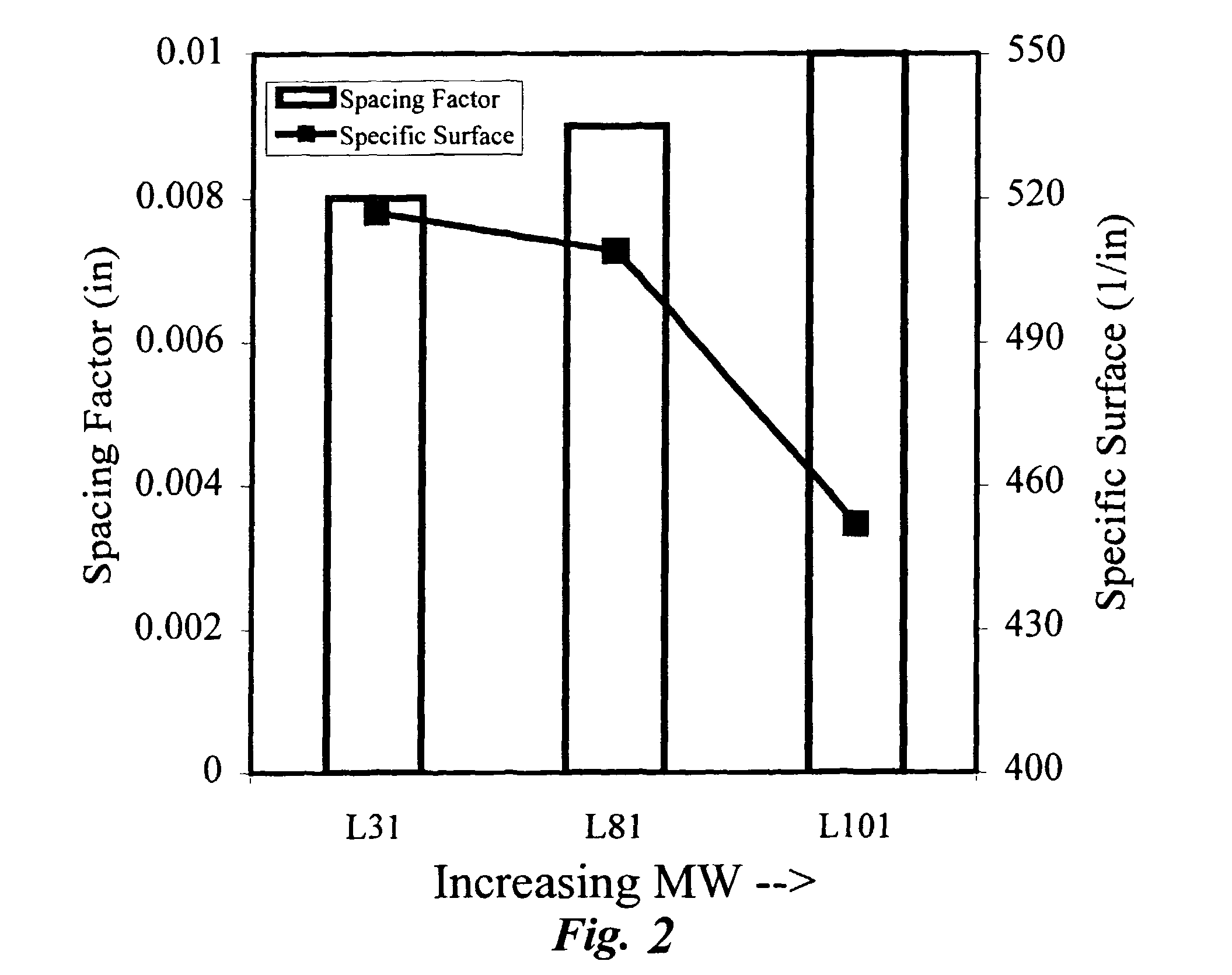

Air management in cementitious mixtures having plasticizer and a clay-activity modifying agent

InactiveUS7972436B2Porosity is easy to controlImprove finenessCeramicwareColloidal chemistry detailsPolymeric surfaceAryl

An exemplary surface active agent admixture composition of the invention comprises (1) a first surface active agent comprising a betaine, an alkyl or aryl or alkylaryl sulfonate, or mixture thereof; and (2) a second surface active agent comprising a nonionic oxyalkylene-containing polymer surfactant. The present invention therefore provides a system for ensuring the presence in a hydratable cementitious composition (when hardened) a sufficient air volume and sufficient air void fineness and consistency. Further exemplary admixture compositions may comprise one or more plasticizers and one or more clay activity-modifying agents. Cementitious compositions and methods for modifying cementitious compositions, which incorporate the above-mentioned surface active agent combination, are also described. The invention provides the ability to adjust and stabilize air void systems in hydratable cementitious compositions, while allowing conventional air entraining agent (AEA) dosage practices to be followed.

Owner:GCP APPL TECH INC

Planar lightwave circuit waveguide bends and beamsplitters

InactiveUS20050152633A1High refractive indexLow refractive indexCoupling light guidesOptical waveguide light guideAngle of incidenceRefractive index

A planar lightwave circuit has a waveguide having a bend and plurality of multiple trenches with parallel front and back interfaces. The trench and waveguide refractive indexes are different such that a refractive interface is defined between the waveguide and the trench. The trench may include a material of higher refractive index than the waveguide, such as silicon, or alternatively a material having a lower refractive index than the waveguide, such as an air void. The trench is disposed on the waveguide bend such that the front and back planar interfaces have an angle of incidence to a direction of the lightwave propagation from the waveguide. The invention also includes beamsplitters that include trenches that reflect a portion of a lightwave in a first direction and a portion of a lightwave in a second direction.

Owner:UNIVERSITY OF ALABAMA

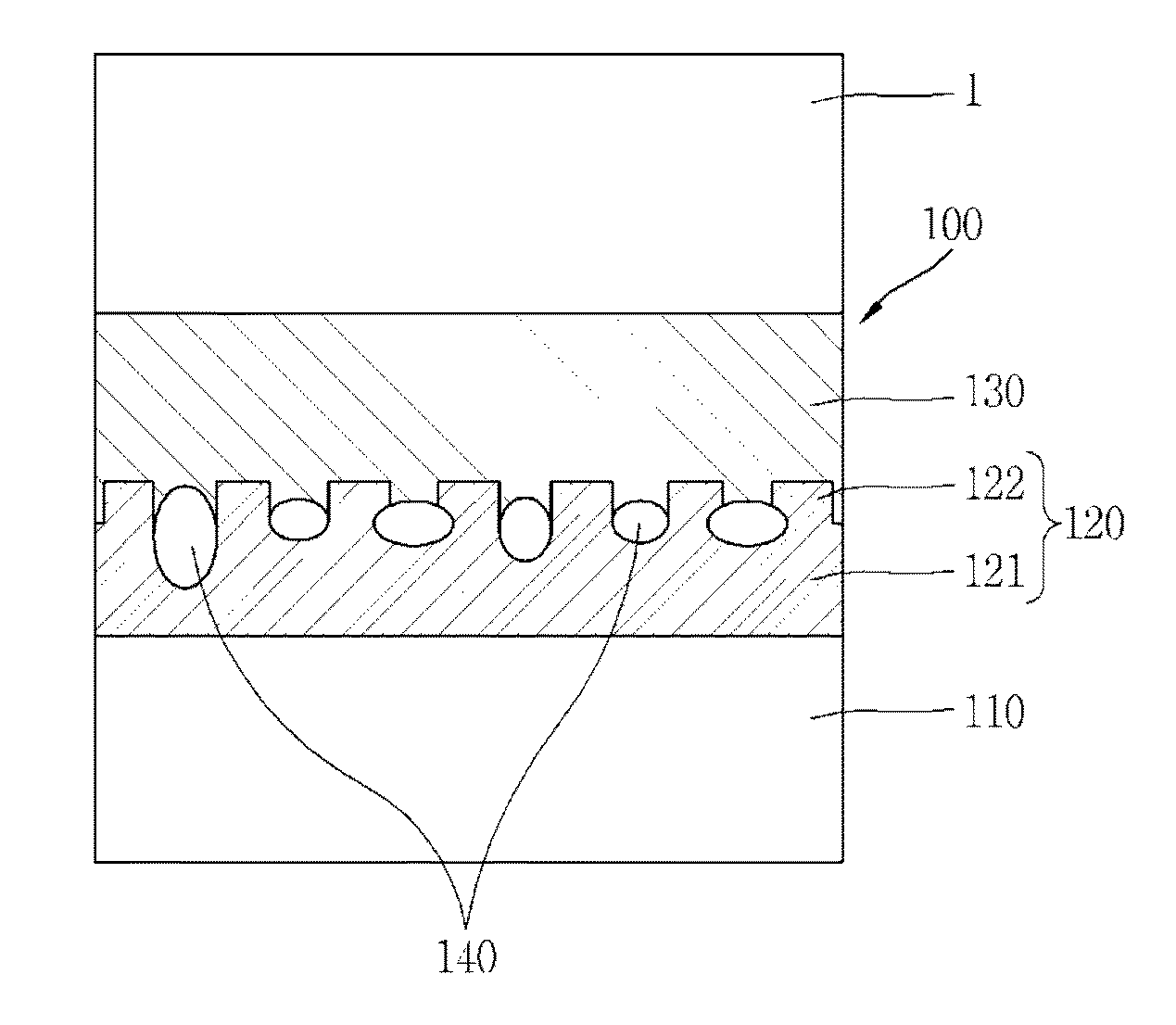

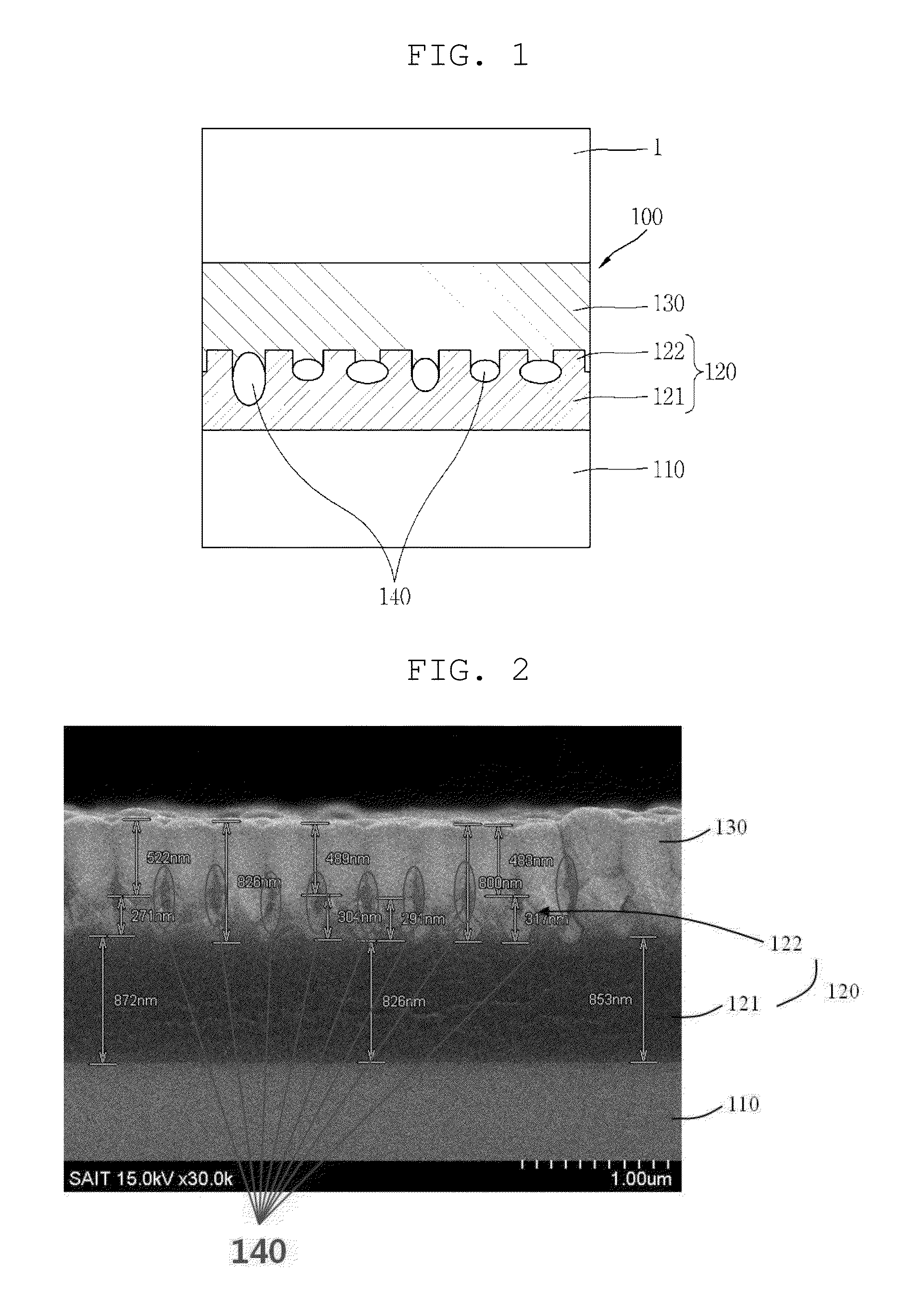

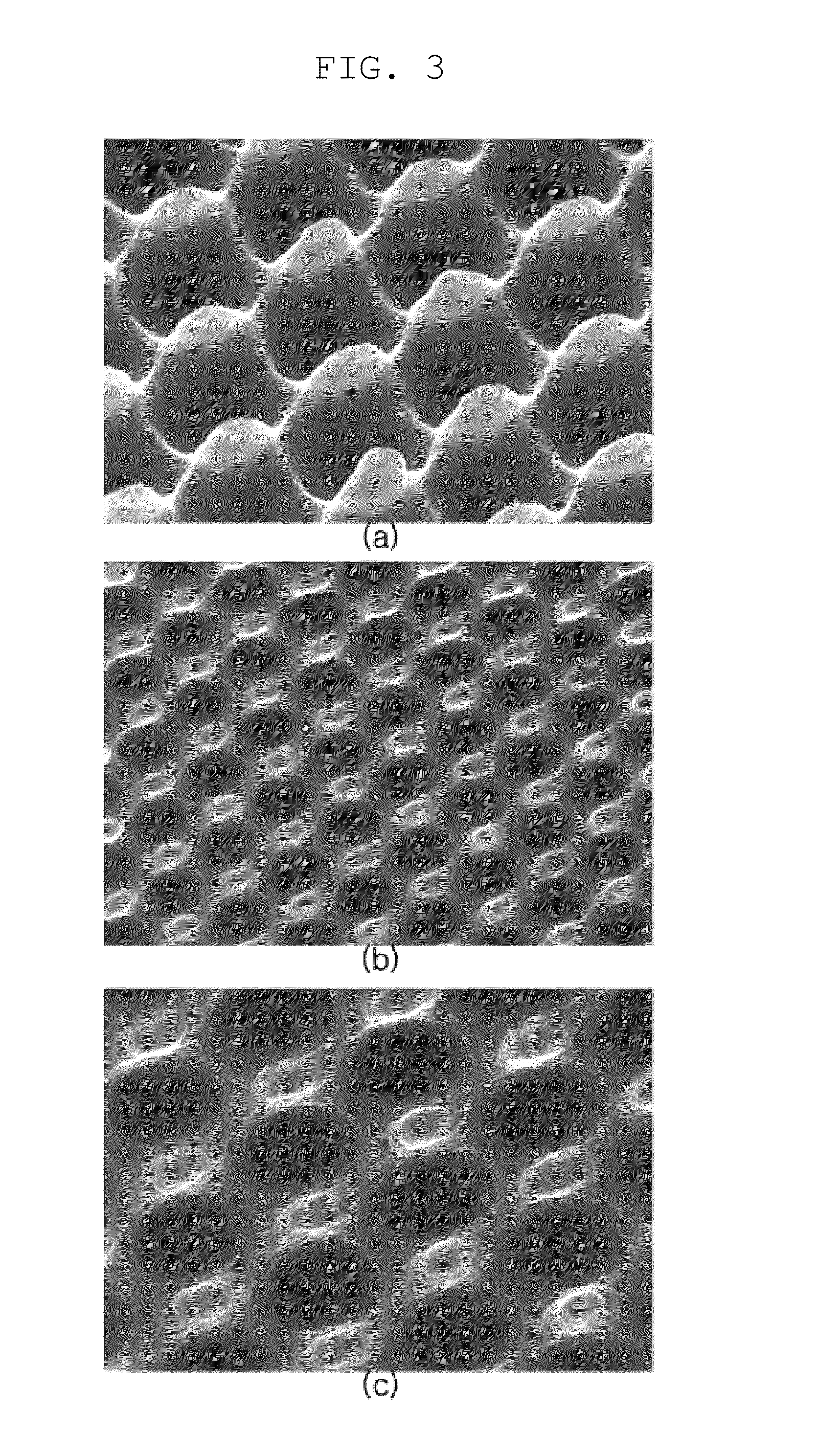

Light extraction substrate for organic light-emitting element, method for manufacturing same and organic light-emitting element including same

ActiveUS20160172632A1Wide wavelength rangeLight extraction efficiency can be improvedFinal product manufactureSolid-state devicesWavelength rangeAir voids

The present invention relates to a light extraction substrate for an organic light-emitting element, a method for manufacturing the same and an organic light-emitting element including the same, which can shed its dependence on light extraction in a specific wavelength range appearing in a light determining pattern of a cyclical form and induce light extraction in a broader wavelength range. To this end, the present invention relates to a light extraction substrate for an organic light-emitting element, a method for manufacturing the same and an organic light-emitting element including the same. The light extraction substrate is disposed on one surface through which light emitted from the organic light-emitting element is outwardly released and comprises: a base substrate; a light determining pattern formed on the base substrate; and a leveling layer formed on the light determining pattern and having a surface contacting the organic light-emitting element, wherein a plurality of air voids having a random shape and size are irregularly distributed on an interface between the light determining pattern and the leveling layer.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

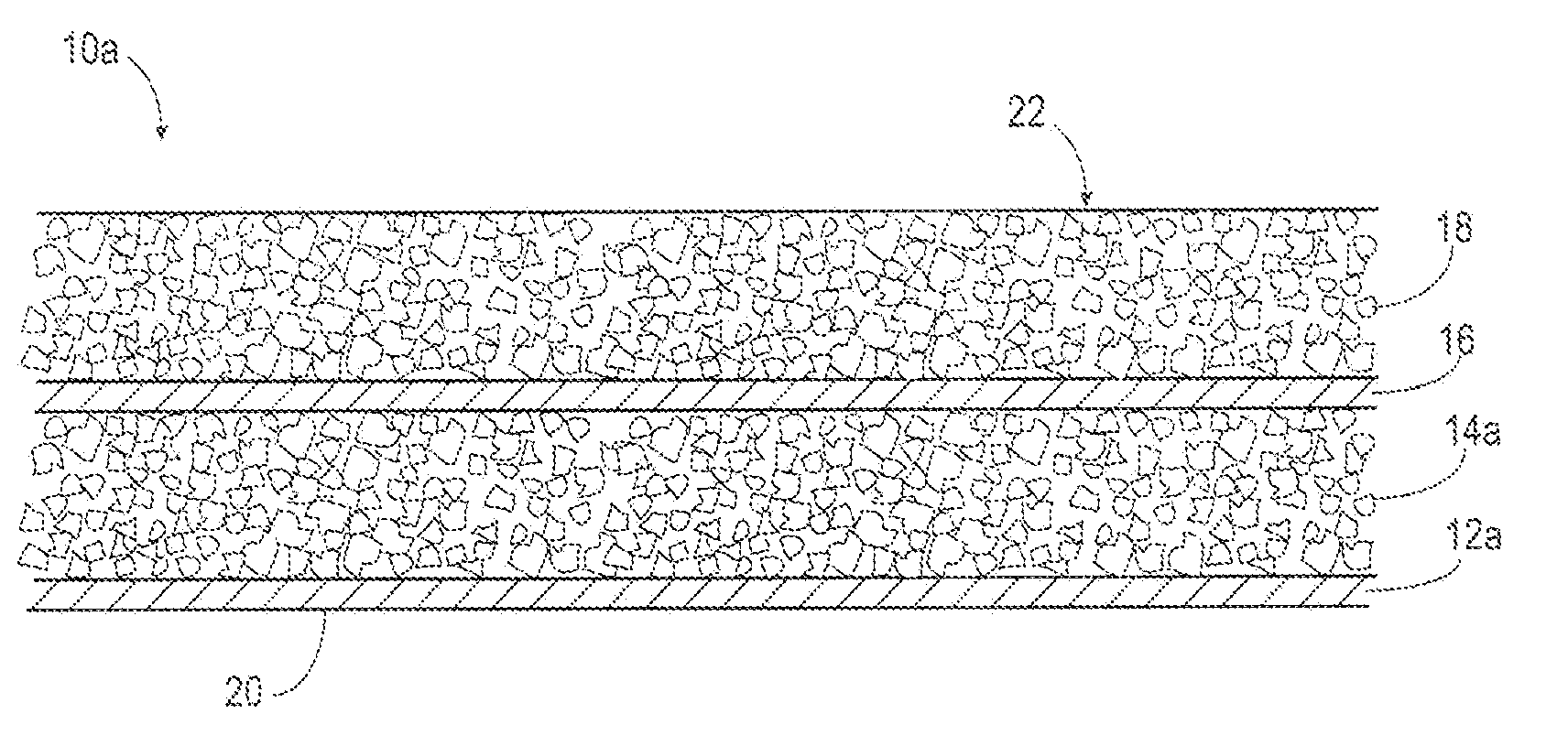

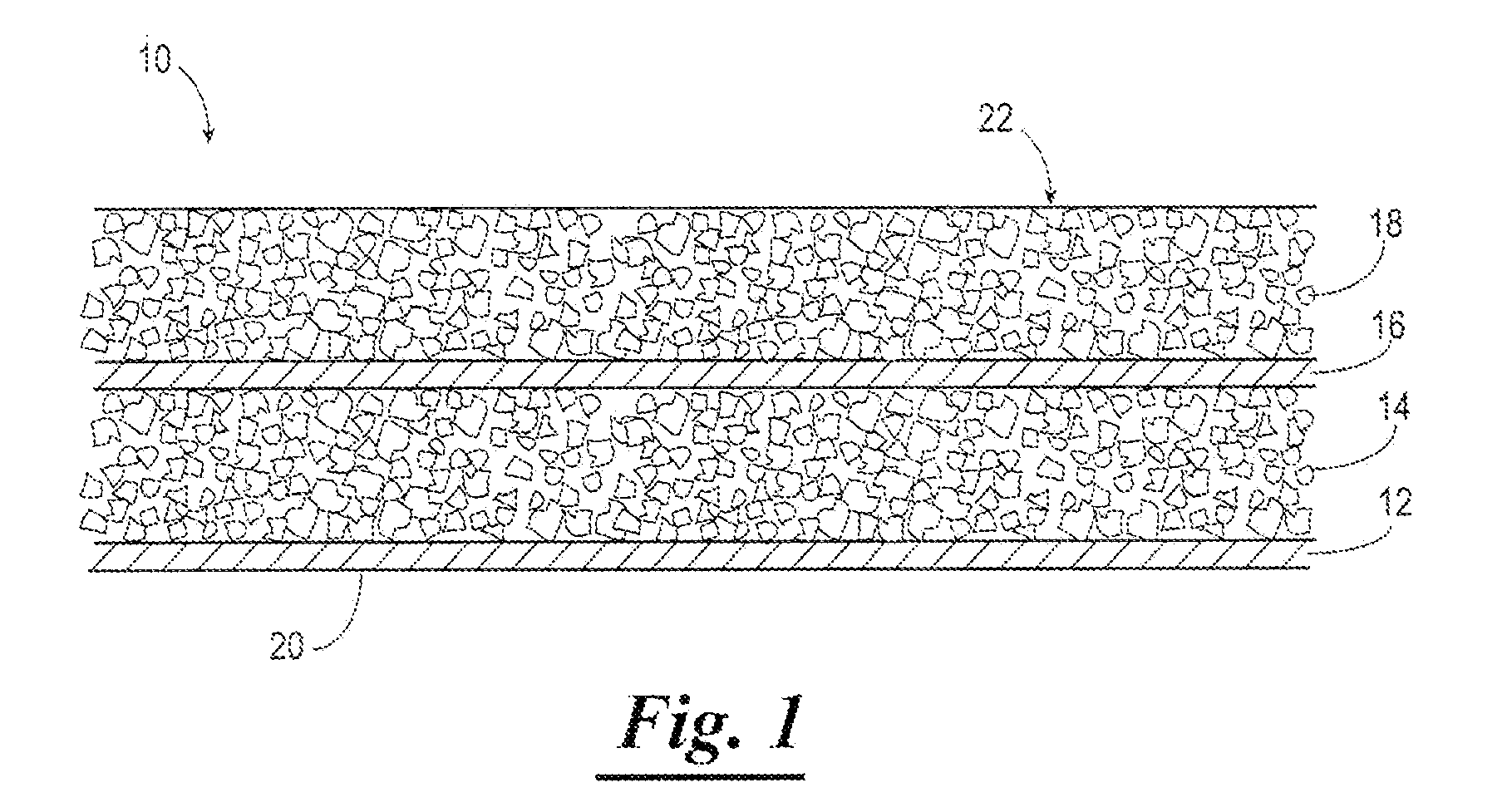

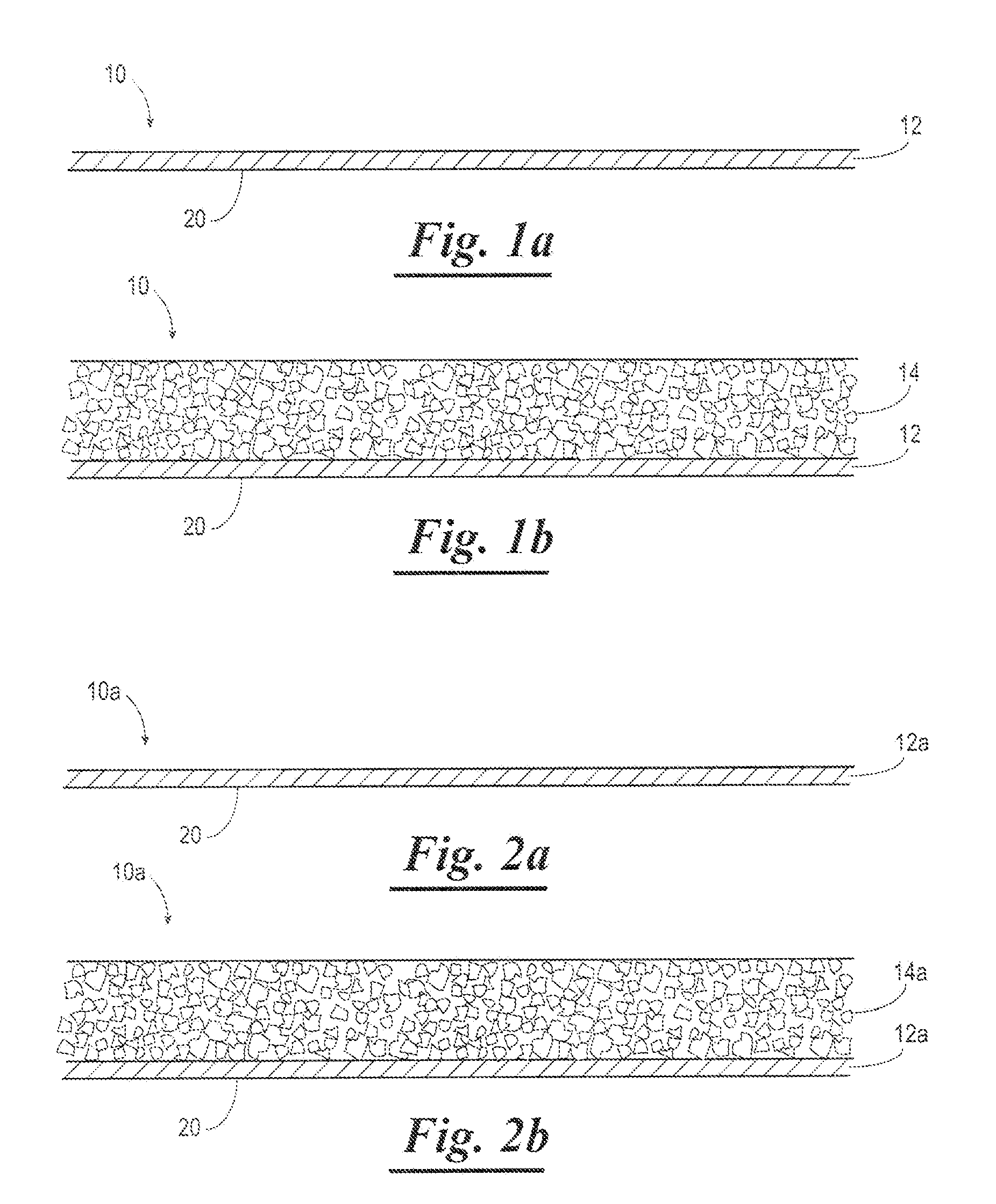

Flexurally rigid composite sheet

InactiveUS20080160272A1Suitable for insertion of nailIncrease stiffnessSynthetic resin layered productsVehicle componentsGlass fiberPolypropylene fiber

Rigid yet lightweight composite sheets contain a core layer formed by thermal consolidation of a needled non-woven mat of glass fibers and polypropylene fibers, optionally with a melt-bonded polypropylene film on at least one side thereof, sandwiched between layers of GMT. The core contains from 20 to 80 volume percent air voids, whereas the GMT outer layers have a very low or zero void content. The composite sheets may be used for structural panels, for fabricating furniture, and for other uses.

Owner:QUADRANT PLASTIC COMPOSITES

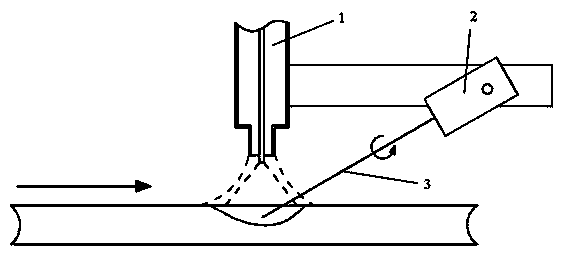

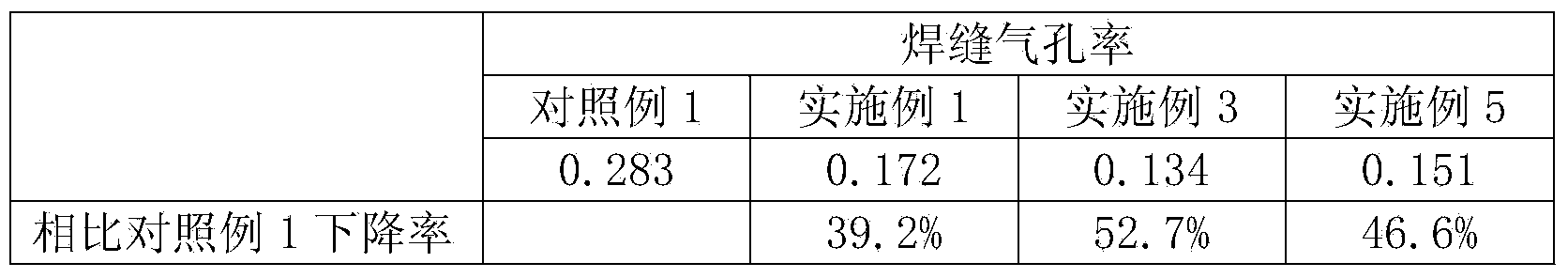

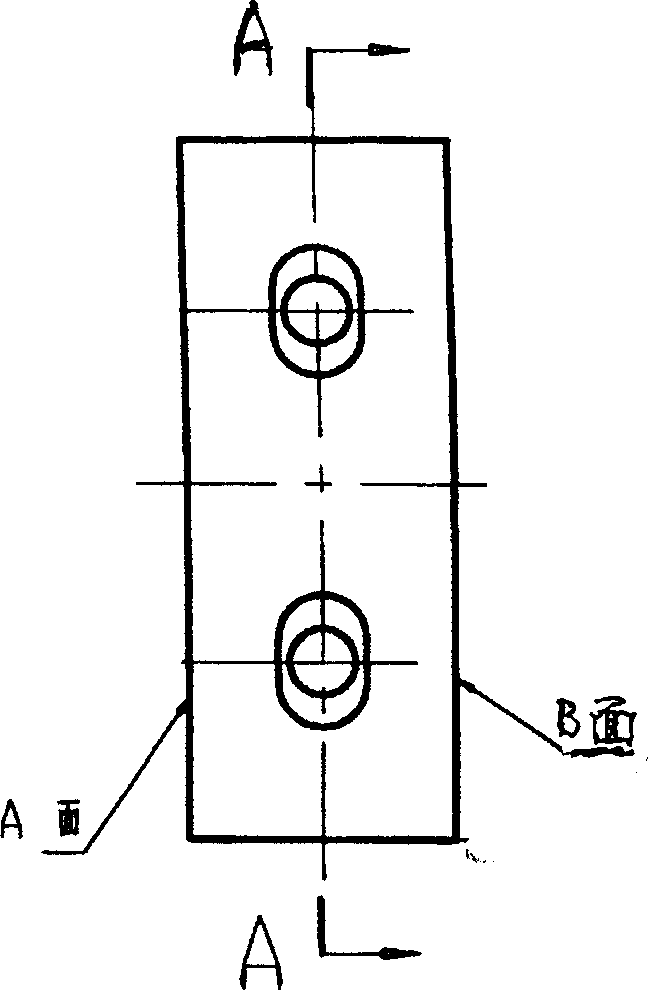

Die-casting piece welding method and welding gun with interventional mechanical disturbance feature

InactiveCN104227195AEffective escapeReduce die casting welding methodsWelding accessoriesDie castingWeld seam

The invention discloses a die-casting piece welding method with an interventional mechanical disturbance feature. During fusion welding of a die-casting piece, a heat-resistant disturbing needle which is vibrating or rotating is inserted into a pool. Compared with the prior art, the disturbing needle used as disturbing medium in the invention can deep into the pool to fully agitate the pool, gas especially at deep positions in the pool can effectively and fully escape and the welding quality is better. A disturbing device applicable to the welding method disclosed by the invention is provided with a micro vibrating or rotating mechanism, the output end of the vibrating or rotating mechanism is connected with the heat-resistant disturbing needle which can be inserted into the welding pool, the disturbing needle synchronously moves with a welding gun during welding, the pool agitating effect of the disturbing needle is better, the content of air voids in welding seams can be greatly reduced and good welded joints can be obtained.

Owner:CHONGQING UNIV

Prepn of particle-reinforced composite material

InactiveCN1383945AEvenly distributedImprove wettabilityFoundry mouldsFoundry coresWear resistantCasting

The particle-reinforced composite material casting process is used in preparing wear-resisting and heat resisting, wear-resistant and anticorrosive and other composite material. The process includes:fabricating formed plastic mold with channel in the part corresponding to the composite material part of casting; filling the channel with reinforcing particle stuffing before adhering different moldpart; painting, stoving and molding; and vacuum casting. Through the disappeared mold and negative casting process, casting with composite material may be prepared easily. The present invention has the advantages of clear reinforcing particle leading to no inclusion and air void defect, optional composite location and homogeneous particle distribution.

Owner:JIANGSU MACHINERY & ELECTRICAL RES INST

Anti-reflective film and production method thereof

The invention discloses an anti-reflective film and a production method thereof. The anti-reflective film comprises film basic materials and a low refractive index layer which is arranged on at least a layer of the film basic materials; the low refractive index layer comprises (a) fluorine-containing organic matters which contain acryloyl group and methylacryloyl and with an refractive index between 1.30 to 1.43, (b) two kinds of inorganic particles with different particle diameters, (c) organic solvent with a boiling point which is higher than 100 DEG C and organic solvent with a boiling point which is lower than 100 DEG C, (d) adhesive resign and coating liquid which is made of (e) silane coupling agent and (f) photoinitiator and at least a surface of the film basic materials is coated by the coating liquid to be solidified to form into the low refractive index layer. The production method of the anti-reflective film is simple in production technology and enabling the air void of the low refractive index layer to be higher and the refractive index to be lower due to dry at different gradient. The anti-reflective film has the advantages of being good in anti-reflective performance and good in scratch resistant performance and satisfying requirements such as the anti-reflective performance and the scratch resistant performance of image displaying device such as liquid crystal displays, plasma displays and electroluminescent displays.

Owner:CHINA LUCKY FILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com