Axial housing type gear pump mounted with rolling bearing and gear motor

A technology of rolling bearing and gear motor, which is applied to rotary piston/swing piston pump components, rotary piston pumps, components of pumping devices for elastic fluid, etc. Sealing, increased displacement, etc., to prevent abnormal noise, large impact load, and prevent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0028] The structure of the present invention is suitable for both gear pumps and gear motors, and will be described separately below as gear pumps or gear motors.

[0029] As the gear pump is detailed below:

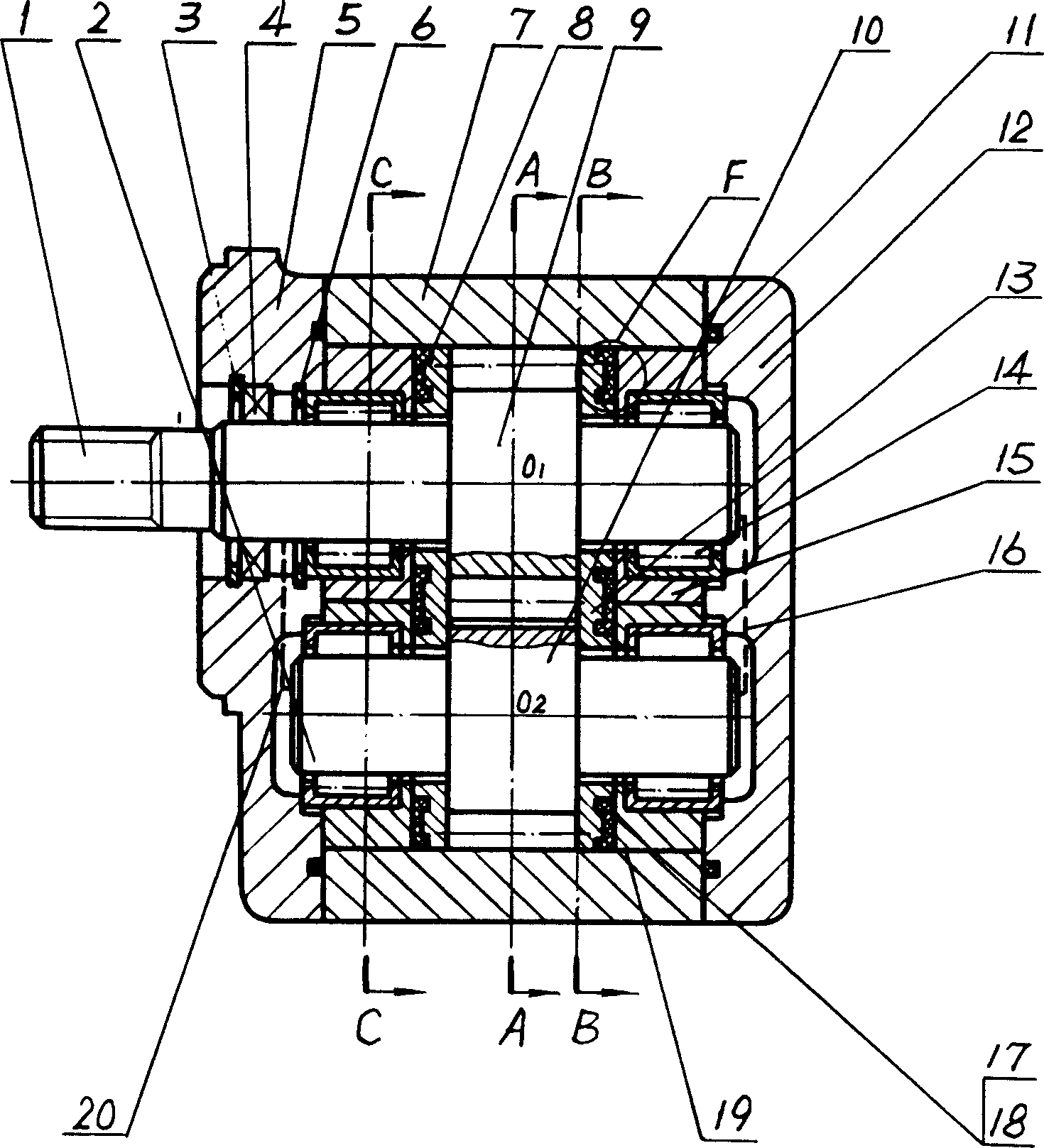

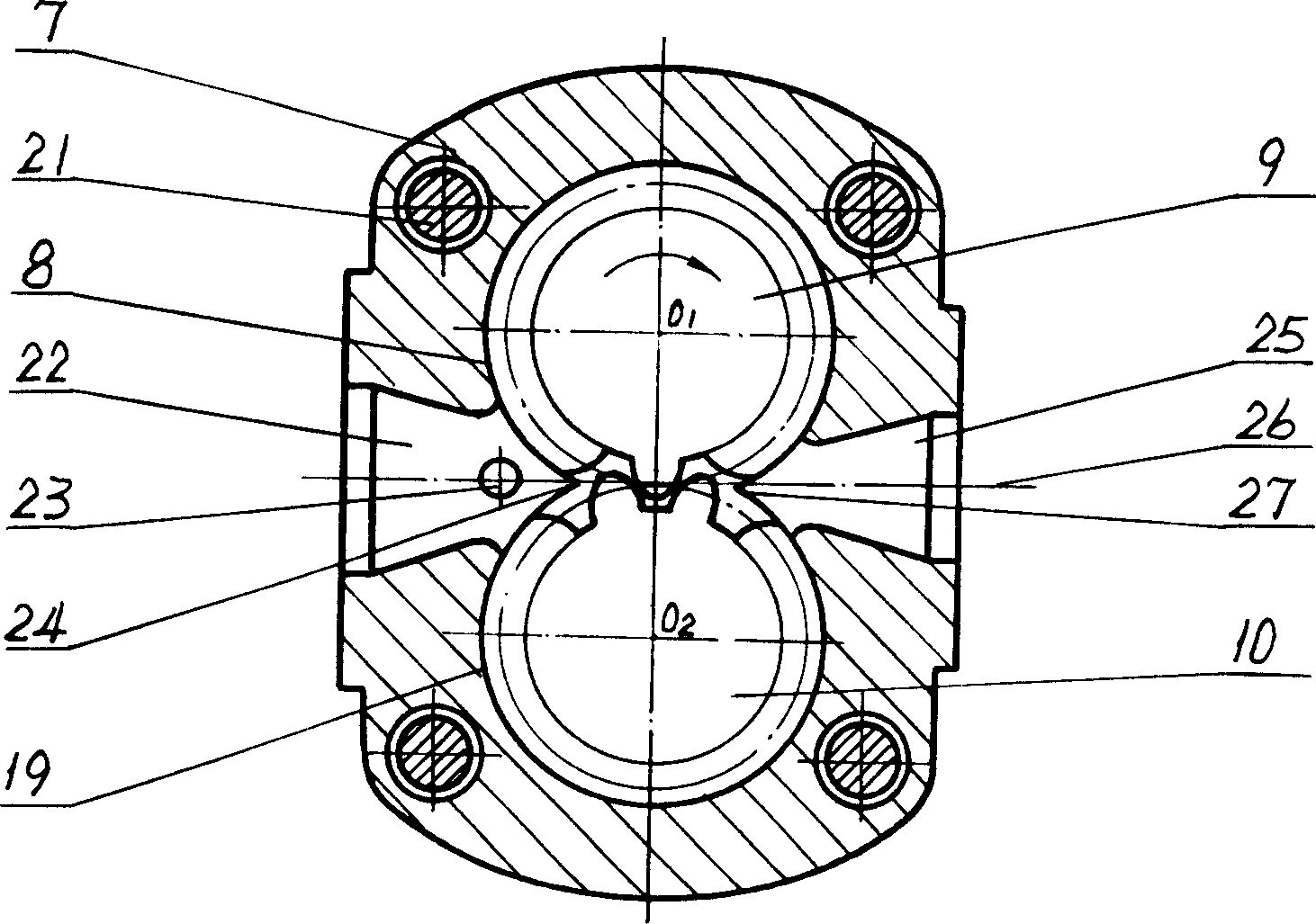

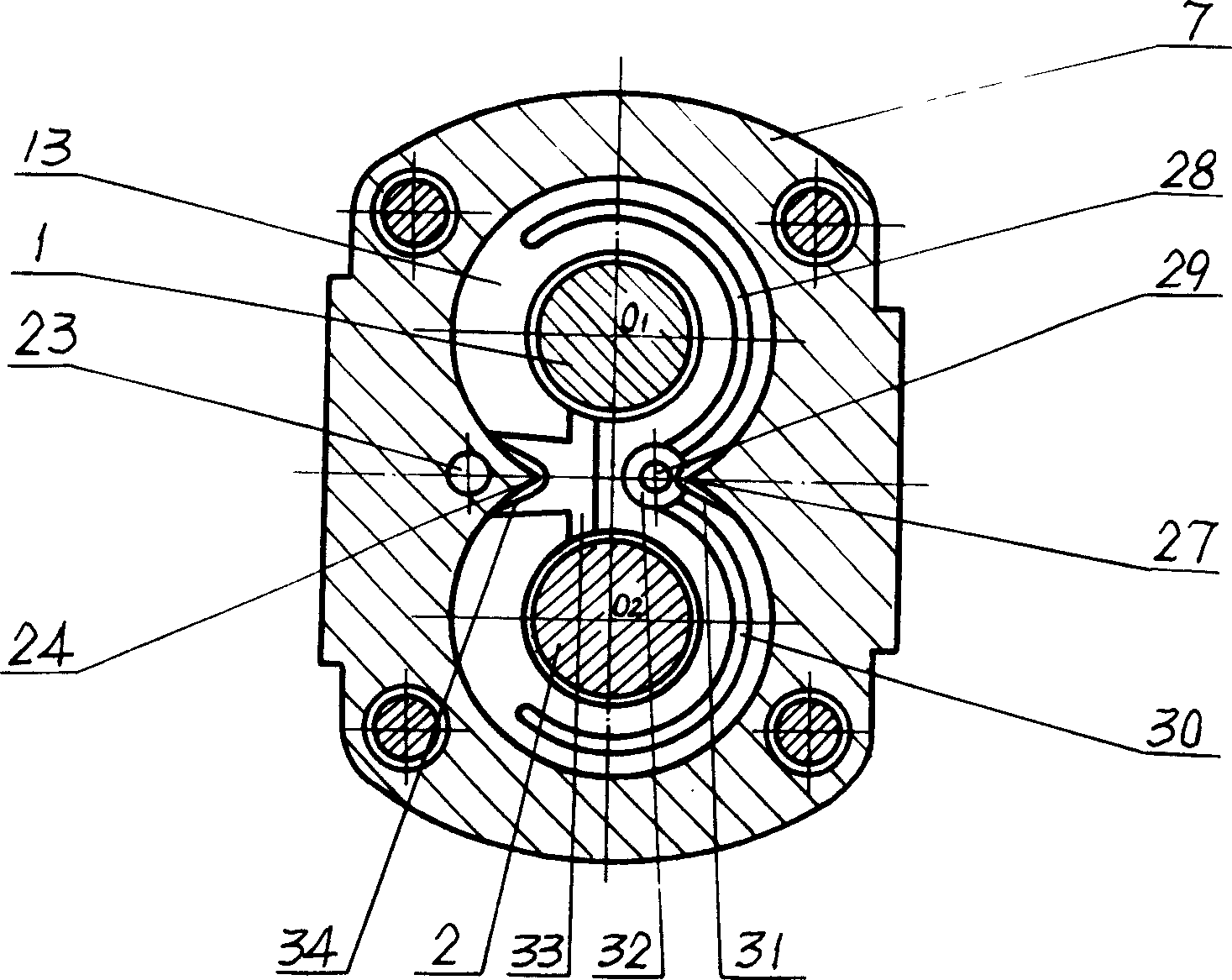

[0030] see Figure 1 to Figure 8 . There are a front cover 5, a housing 7 with an oil inlet and an oil outlet, and a rear cover 12, and they are fastened together with bolts 21, and grooves are respectively opened on the joint surfaces of the front cover and the rear cover with the housing And be equipped with sealing rubber ring 11 in order to prevent oil leakage. On the shell, there are two equal diameters perpendicular to the front cover and the rear cover and at its center O 1 and O 2The "8"-shaped gear holes 8 and 19 intersec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com