Model method for measuring flow rate of air-assisted liquid by Coriolis mass flowmeter (CMF)

A mass flow meter, liquid flow technology, applied in the direction of mass flow measurement devices, indirect mass flow meters, etc., can solve problems such as affecting the response of Coriolis mass flow meters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

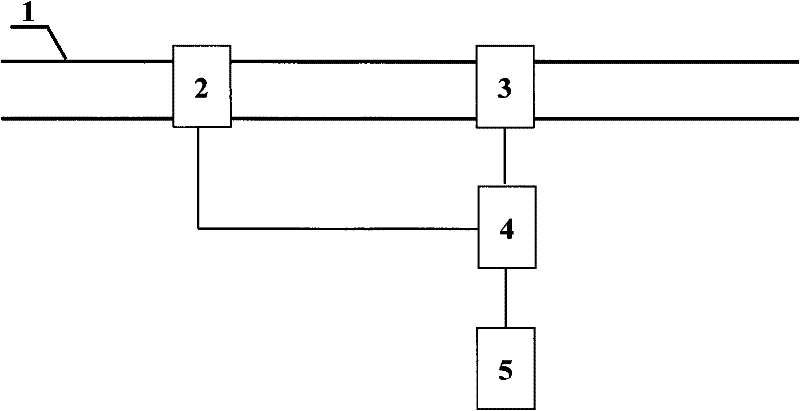

[0028] The air-entrapped liquid flow measurement device based on Coriolis mass flowmeter has a metering pipeline (1), on which a pressure sensor (2), a Coriolis mass flowmeter (3), and an A / D conversion card are sequentially arranged on the metering pipeline (1) (4) is connected with the pressure sensor (2) and the Coriolis mass flow meter (3), and the computer (5) is connected with the A / D conversion card (4).

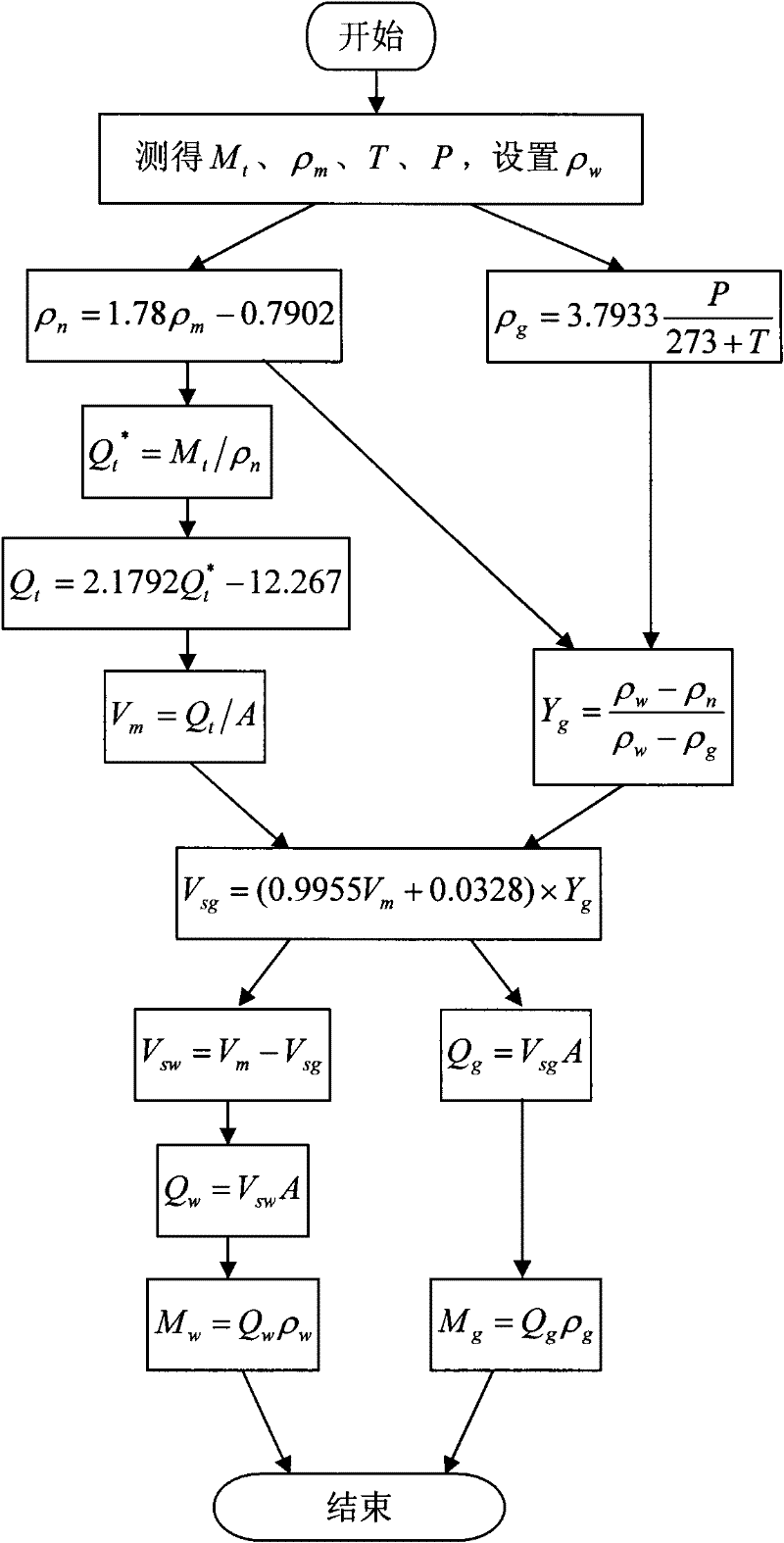

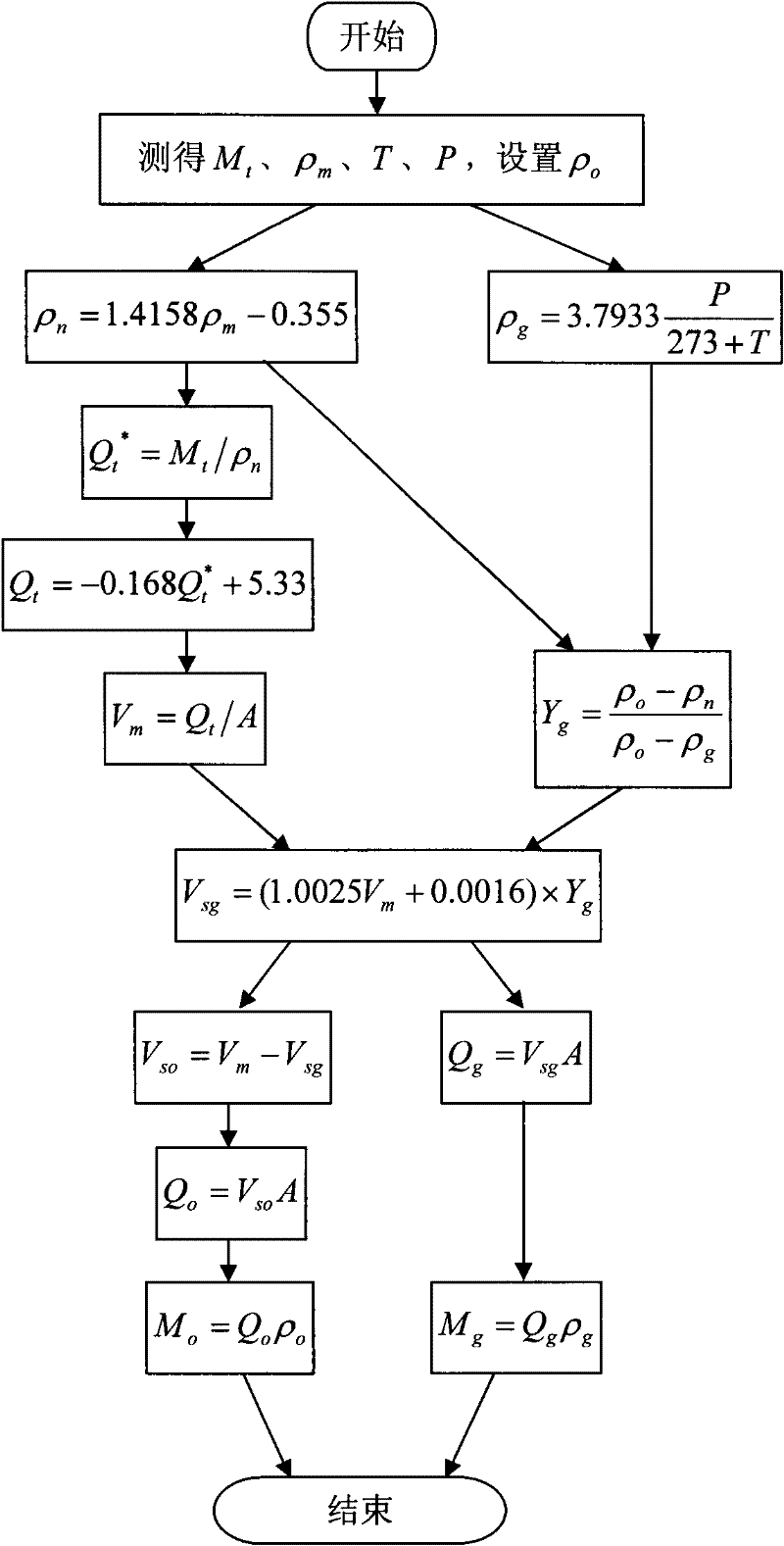

[0029] In this embodiment, the gas volume flow rate is from 0.29m 3 / h to 0.905m 3 / h, and the flow rate of air-entrained liquid with a water mass flow rate of 170Kg / min shall be measured by the model method.

[0030] 1) Measurement data

[0031] The pressure sensor is used to measure the instantaneous pressure P of the pipeline, and the Coriolis mass flowmeter is used to measure the instantaneous mass flow rate M of the gas-entrained liquid t , density ρ m and temperature T.

[0032] 2) Build a model

[0033] Establish the density ρ measured by the Coriolis mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com