Die-casting piece welding method and welding gun with interventional mechanical disturbance feature

A technology of disturbance characteristics and welding method, applied in the field of welding torches and die castings, can solve the problems of welding wire melting, difficult control, and difficulty in reaching the bottom of the molten pool.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

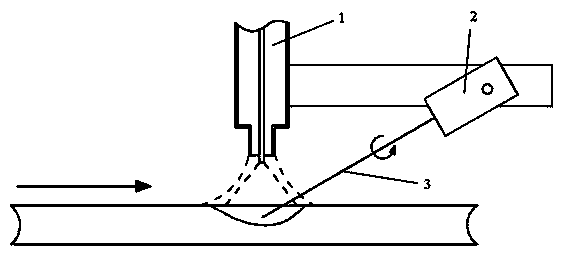

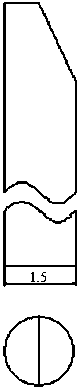

[0024] The object is the die-cast block AZ91D magnesium alloy. While argon tungsten arc welding is welding the die-cast magnesium alloy, the tungsten needle is inserted into the molten pool and moves synchronously with the welding torch 1. The vibration motor drives the tungsten needle to vibrate, and the vibration frequency is 20Hz. The pool is vibrated and disturbed, and the inclination angle of the tungsten needle is 30° to facilitate the escape of gas in the molten pool.

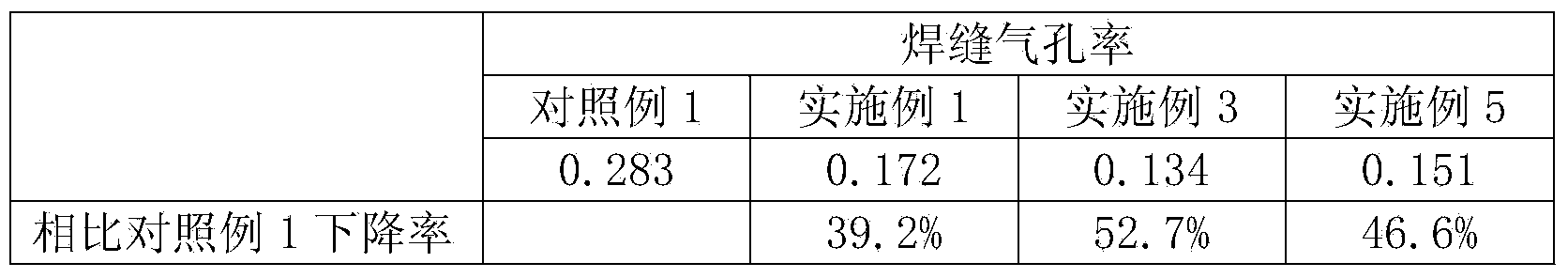

[0025] Experimental results: The calculated weld porosity is 0.172, and compared with the control example 1, the weld porosity decreases by 39.2%.

Embodiment 2

[0027] The object is die-cast block A356 aluminum alloy. While argon tungsten arc welding is used to weld the die-cast aluminum alloy, the tungsten needle is inserted into the molten pool and moves synchronously with the welding torch 1. The vibration motor drives the tungsten needle to vibrate. The vibration frequency is 1000Hz. The pool is vibrated and disturbed, and the inclination angle of the tungsten needle is 30° to facilitate the escape of gas in the molten pool.

[0028] Experimental results: The calculated weld porosity is 0.148, which is 46.4% lower than that of Control Example 2.

Embodiment 3

[0030] The object is the die-cast block AZ91D magnesium alloy. While argon tungsten arc welding is welding the die-cast magnesium alloy, the tungsten needle is inserted into the molten pool and moves synchronously with the welding torch 1. The vibration motor drives the tungsten needle to vibrate, and the vibration frequency is 3000Hz. The pool is vibrated and disturbed, and the inclination angle of the tungsten needle is 30° to facilitate the escape of gas in the molten pool.

[0031] Experimental results: The calculated weld porosity is 0.134, and compared with the control example 1, the porosity decreases by 52.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com