Device and method for measuring crude oil with low air void

The technology of a measuring device and measuring method is applied in the direction of mass flow measuring device, direct mass flow meter, material capacitance, etc. It can solve the problems of poor gas-liquid separation effect, difference, and influence of liquid phase flow measurement accuracy, etc., and achieves simple structure, Ease of implementation and high accuracy of parameter detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

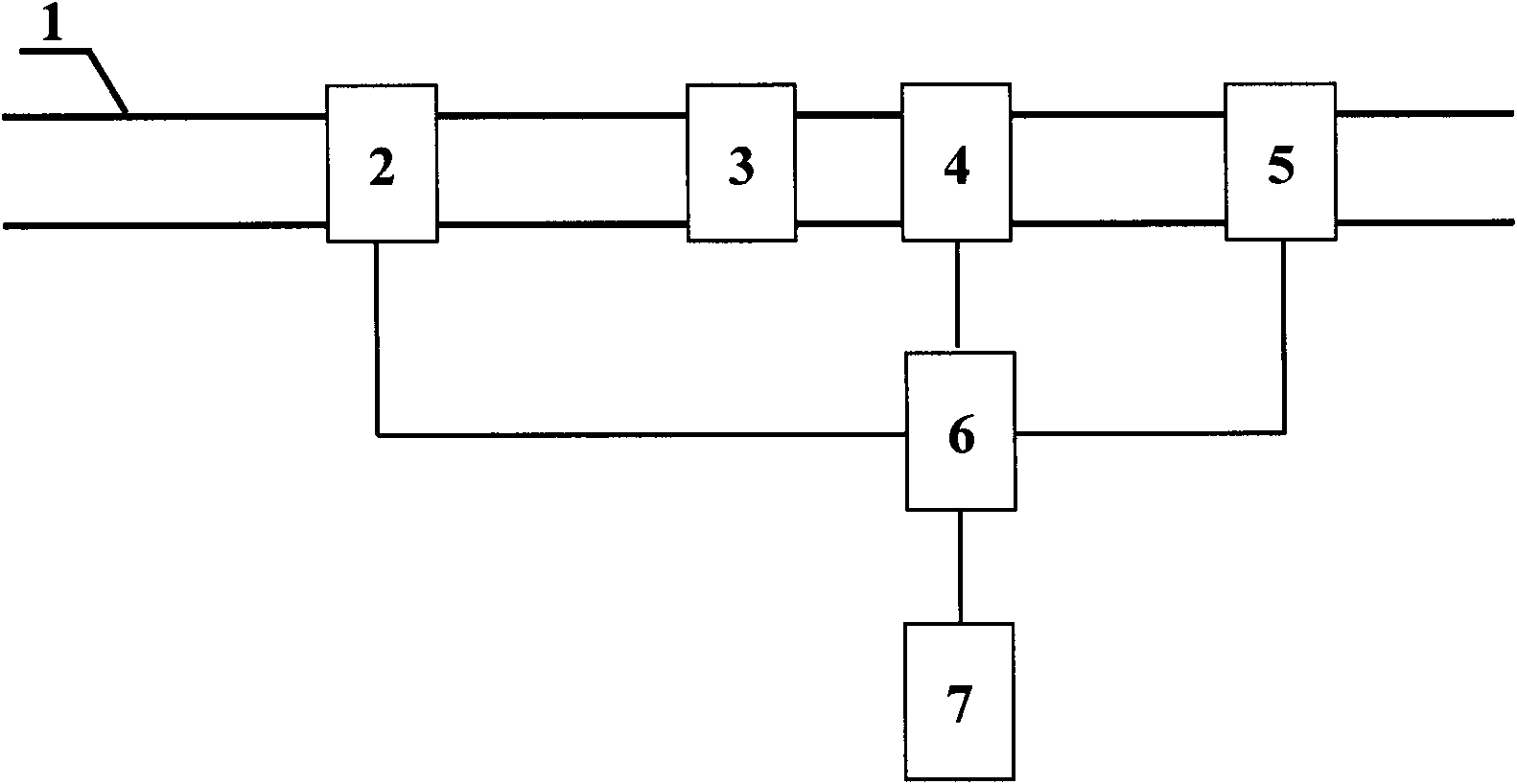

[0015] The crude oil measuring device with low gas content has a metering pipeline (1), on which a capacitance sensor (2), a flow mixer (3), a Coriolis mass flowmeter (4), and a pressure sensor (5) are sequentially arranged on the metering pipeline (1) , the A / D conversion card (6) is connected to the capacitance sensor (2), the Coriolis mass flow meter (4), and the pressure sensor (5), and the computer (7) is connected to the A / D conversion card (6).

[0016] The present invention will be further described below by way of examples.

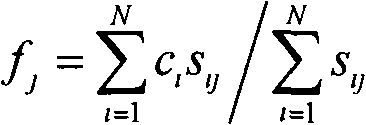

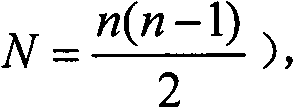

[0017] After the oilfield production fluid is preliminarily separated by the gas-liquid separator, crude oil with low gas content enters the metering pipeline 1, and the capacitance sensor 2 collects the capacitance distribution on the pipeline section, and sends the capacitance measurement signal to the computer 7 through the A / D conversion card 6 . Since the medium to be measured contains gas, the gas is likely to form large bubbles or gas bom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com