Patents

Literature

59results about How to "Feel slippery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ease of closure through tactile/optical means

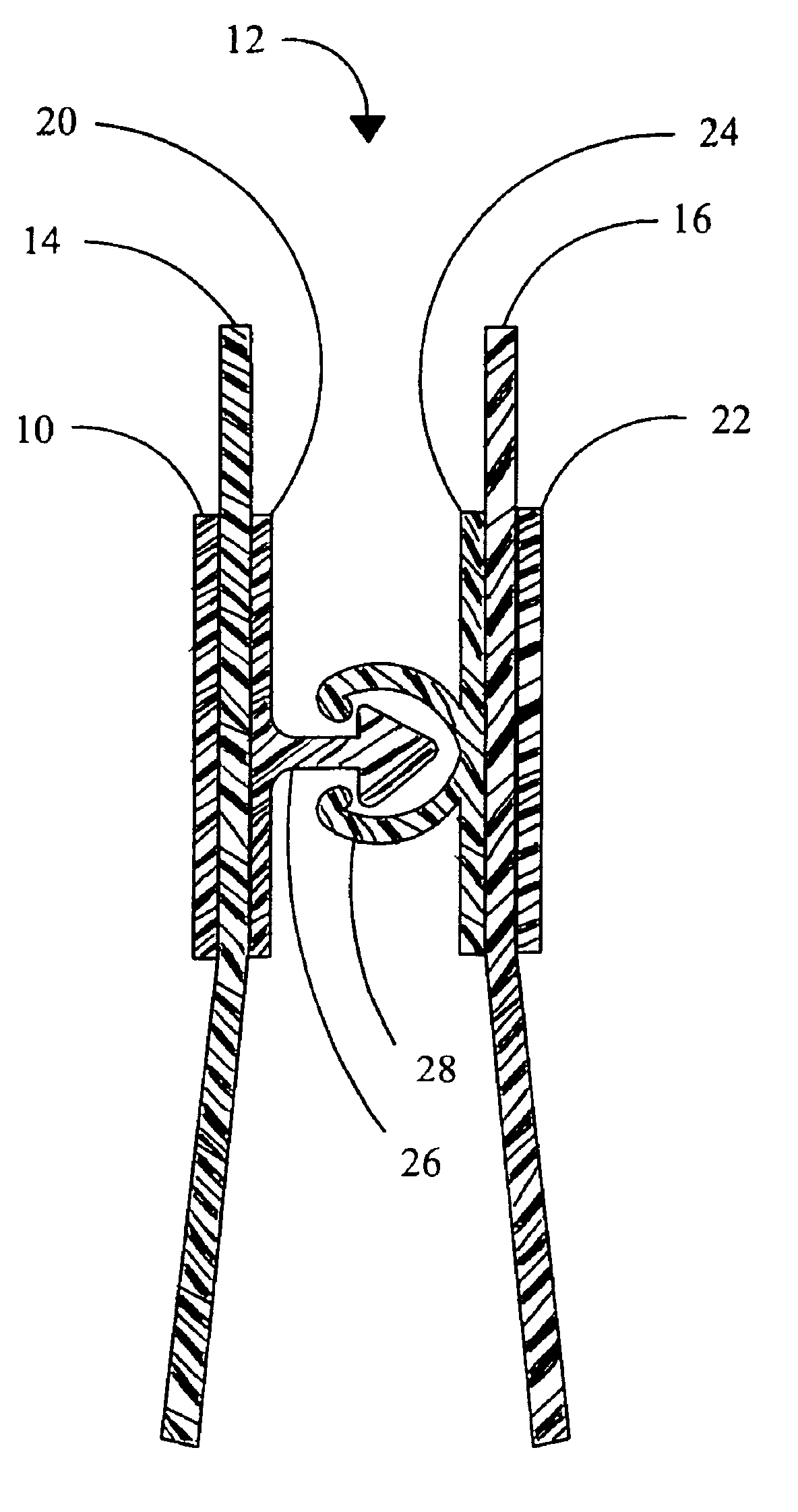

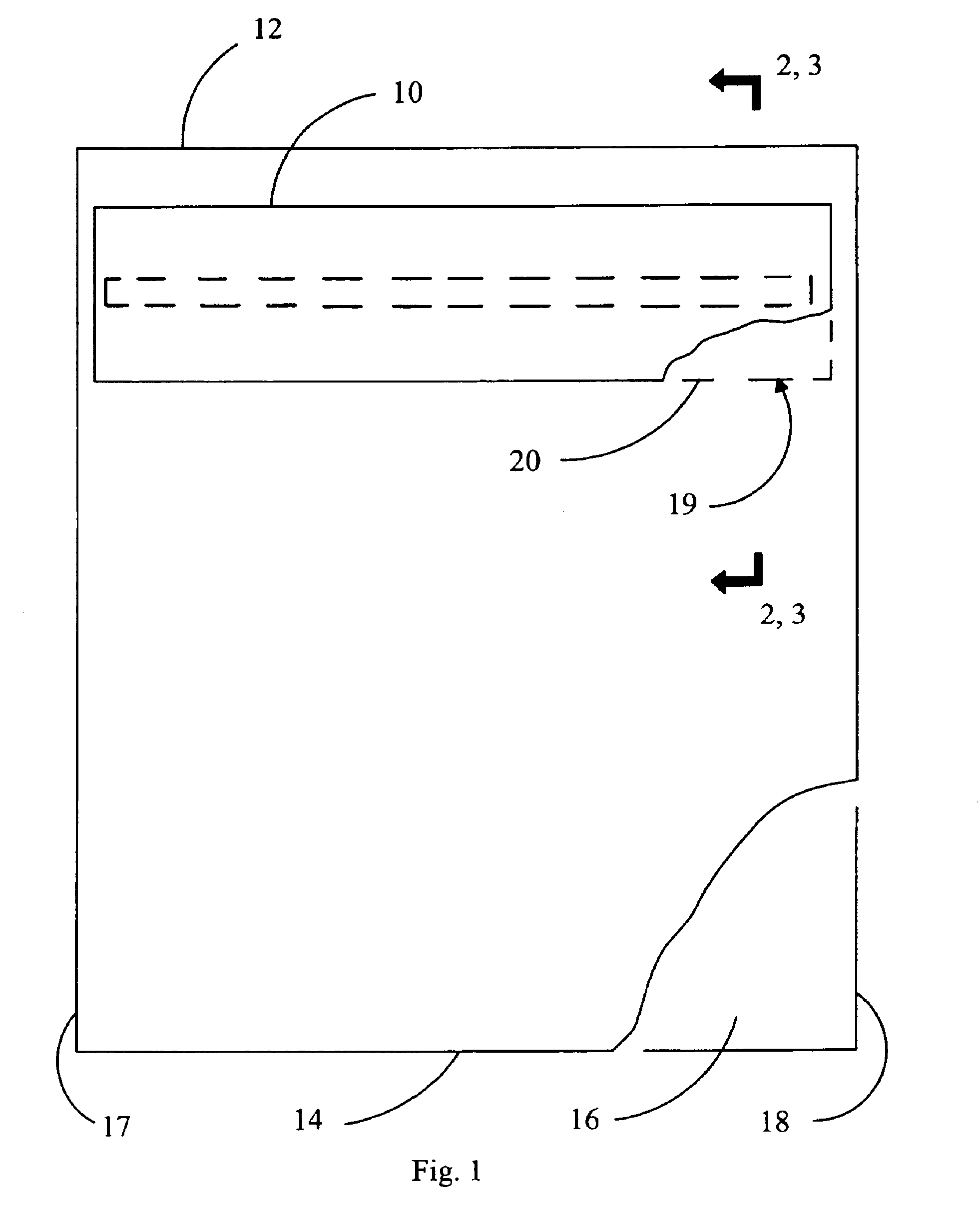

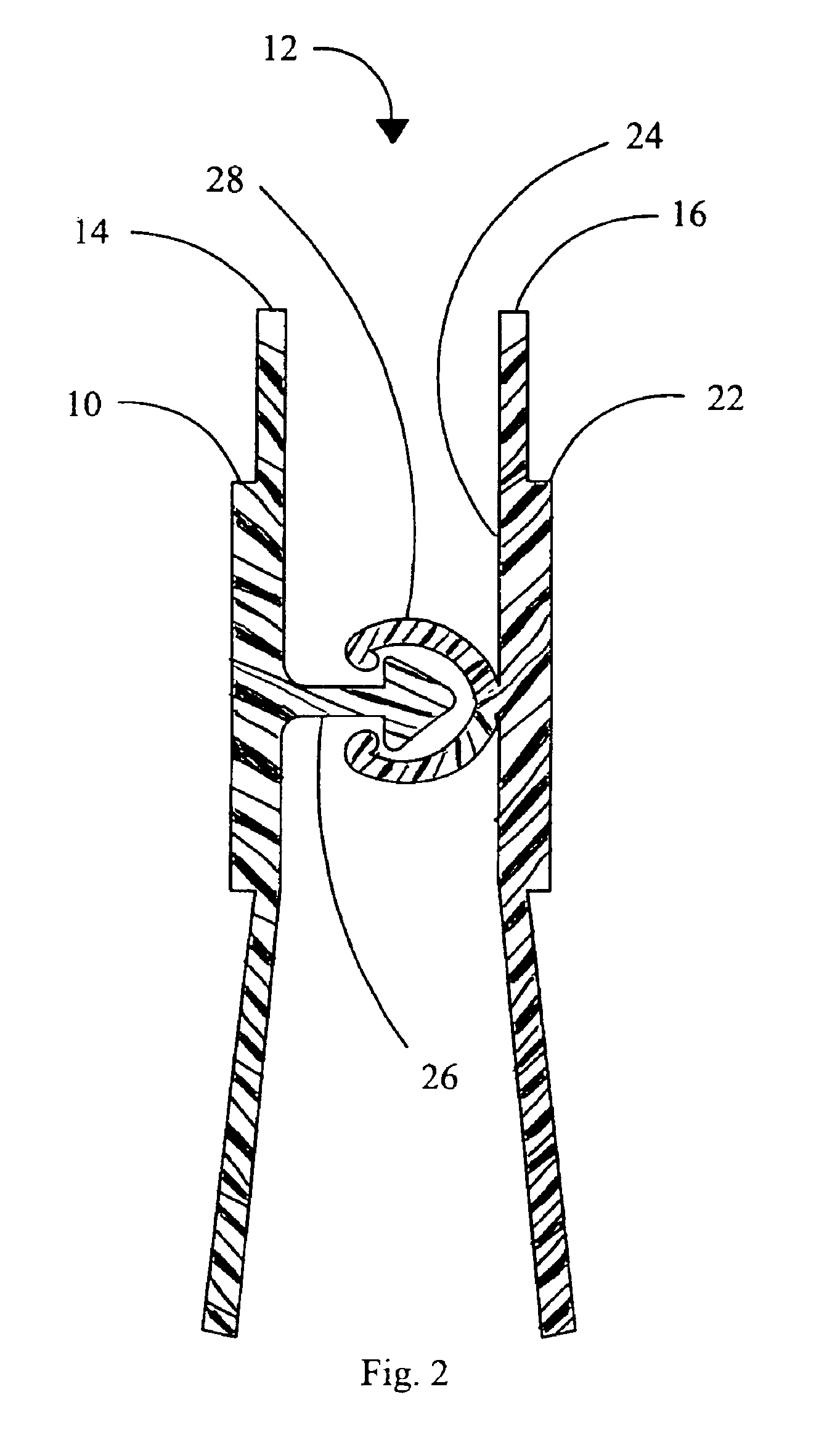

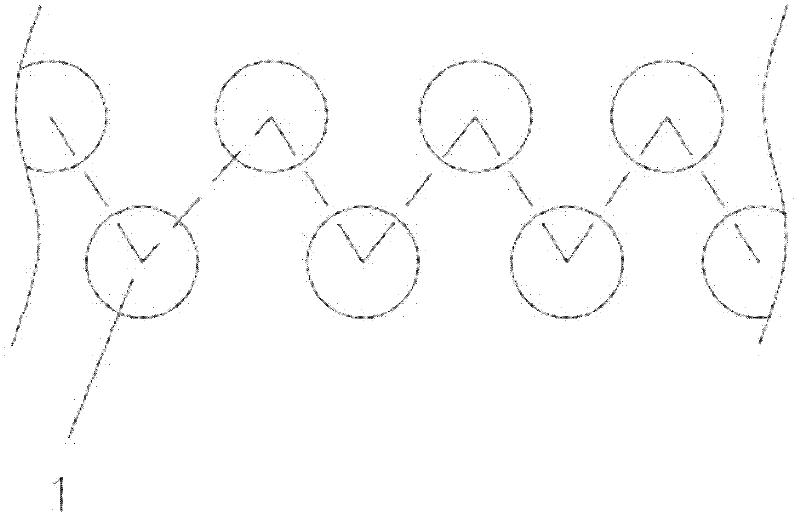

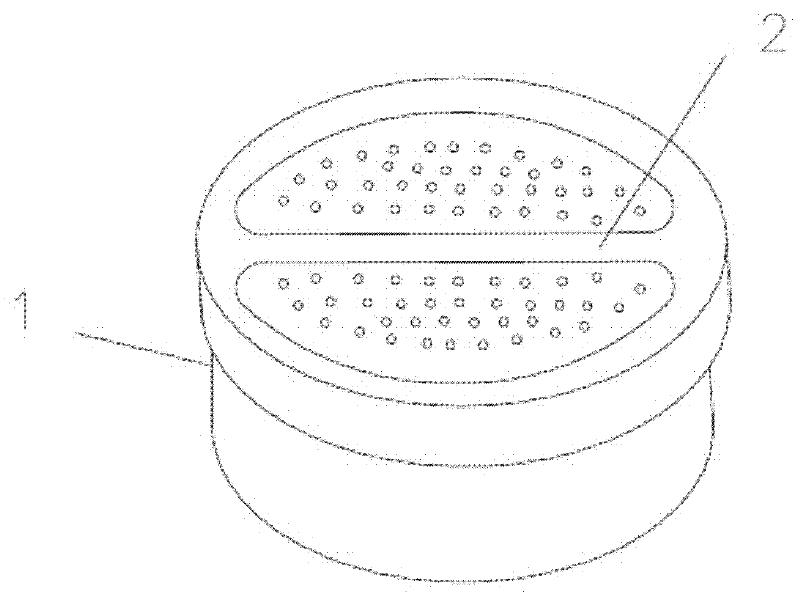

Backing areas (10, 22) are provided for a zipper (19) used in the manufacture of a reclosable bag (12). The backing areas (10, 22) are formed of a material dissimilar to the bag material with the backing areas (10, 22) provided on the walls (14, 16) of the bag (12) in alignment with the zipper (19). The material of the backing areas (10, 22) is dissimilar in that the material has physical characteristics that are noticeable to the tactile feel of the user in regard to the remaining outside areas of the reclosable bag (12). Such physical characteristics include a noticeable difference in surface lubricity, compressibility, obstructions and / or friction. These identified but not exclusive physical characteristics form the backing areas (10, 22) individually or in combination with each other.

Owner:ILLINOIS TOOL WORKS INC

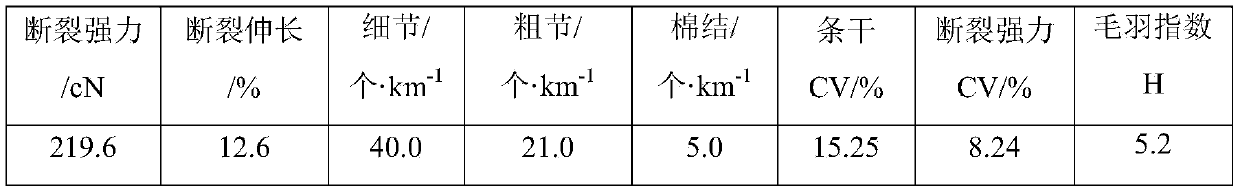

Superfine wool yarn and manufacturing method thereof

InactiveCN101709522AGood anti-pillingImprove effective controlDrafting machinesYarnInternational standardEngineering

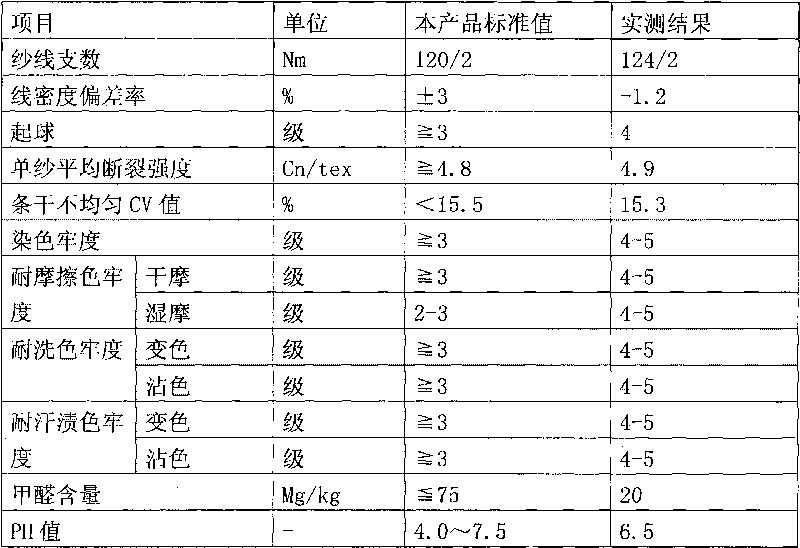

The invention discloses a superfine wool yarn and a manufacturing method thereof. The superfine wool yarn comprises 100-120Nm / 2 of yarn counts, 1050-1200t / m of single twist with a twist direction of Z and 480-550t / m of plied twist with a twist direction of S. The manufacturing method comprises the process steps of wool top recombing, primary silver mixing, secondary silver mixing, quartic gilling, triple roving, spun yarn, spooling, doubling, two-for-one twisting, reeling silk, checking and the like. In the invention, raw materials of the superfine wool are selected, and the reasonable yarn counts and the twist are determined at the same time. By adopting some special measures on the spinning process and optimizing the technological parameters, the excellent and low-consumption superfine wool yarn with the yarn counts of 120Nm / 2, and the yarn levelness of less than 15 percent and anti-pilling of more than or equal to the third level is successfully manufactured; and the number of the cross-section fibers of the fine yarn is only 28, which is far lower than the limit of the number of 36 in the international standard. The invention not only provides a new yarn product with excellent quality and high cost performance, but also provides a beneficial spinning method for sufficiently utilizing and reasonably developing tight wool resources.

Owner:ZHEJIANG ZHONGXIN WOOL TEXTILE

Method for producing pure wool crease-shedding facing material

ActiveCN101270528AIncreased warp and weft elasticityImprove wrinkle resistanceSingeingDyeing processEngineeringWool cloth

The invention relates to a manufacture method for a pure wool anti-crease fabric which includes the following steps of: preparing wool top-top dyeing-double combing-spinning-weaving-grey fabric-subsequent finishing-finished product. The components of the wool top material are 98.2 to 100 percent of pure wool as well as 0 to 1.8 percent of terylene. The top dyeing adopts a lanasol active dye lower temperature colorizing technique; the subsequent finishing includes the steps of: crude finishing-clearing up-singeing-open washing and continuous steaming-washing-open washing and continuous steaming-drying-middle checking-cooked finishing-brushing and cutting hair-elastic finishing-scalding-pot steaming-pre-shrinking. The western-style clothes fabric manufactured by the method has the advantages of elegant quality, smooth hand feeling, comfortable wearing, stiffness and elasticity, breaks through the defect of noble wearing and hard nursing of the clothes of wool cloth, in particular to the difficulties of easy creasing and insufficient shape retention of the high-count thin fabric currently popularizing in the market and promotes the sustainable development of woolen fabrics.

Owner:嵊州雅戈尔毛纺织有限公司

Production method for cashmere/yakwool covering yarn

The invention provides a production method for cashmere / yakwool covering yarns. Cashmere and yakwool fibers are respectively used to weave rough yarns in a wool spinning system. A parallel spinning method is used to weave yakwool / vinylon fascinated yarns by using yakwool rough yarns and vinylon filaments, and then the yakwool / vinylon fascinated yarns are used as core yarns, and the cashmere rough yarns are used as wrapping yarns to weave the covering yarns, and finally, a vinylon dissolution technology is used to remove vinylon, to obtain excellent quality cashmere / yakwool covering yarns. Using the above technology, the cashmere fibers and yakwool fibers can be made into excellent quality covering yarns in high additional value. Especially in the first step and the second step, the yakwool fibers and the cashmere fibers respectively weave rough yarns on a wool spinning system, thereby reducing damages on fibers. In the third step, the parallel spinning method is used to weave the yakwool / vinylon fascinated yarns, thereby improving fluffiness and strength of the yarns. Using the production method, the yakwool just needs to be processed in rough yarns, and the method prevents a procedure in which processing of the yakwool is relatively difficult.

Owner:ZHEJIANG HAONENG TECH CO LTD

Nanometer antibiosis cashmere knit fabric and production method thereof

InactiveCN101967753AImprove long-lasting antibacterial performanceFeel slipperyAnimal fibresYarnAntibiosis

The patent refers to the field of 'treatment of fibres, threads, yarns, fabrics, feathers, or fibrous goods made from such materials'. The invention discloses a nanometer antibiosis cashmere knit fabric which has a moderate price, slippery handfeel and soft gloss and can remove peculiar smell and inhibit the growing of bacteria. The nanometer antibiosis cashmere knit fabric comprises 0.0005 to 0.0025 weight percent of nano silver, 0.01 to 0.1 weight percent of ginkgo leaf extract, and the balance of cashmere, wherein the main antibacterial ingredients of the ginkgo leaf extract comprise ginkgo biloba terpene lactones, ginkgo flavones, and ginkgoic acid. The invention also discloses a production method of the nanometer antibiosis cashmere knit fabric. The method comprises the following steps of: preparing a ginkgo leaf extract / nano silver composite antibacterial agent; treating the cashmere knit fabric with the ginkgo leaf extract / nano silver composite antibacterial agent; and then performing conventional process flow of dehydration, soaking in an adhesive, performing dehydration, rolling and washing in a soft way, drying, and ironing to obtain a finished product. The treated cashmere knit fabric has excellent and lasting antibacterial performance, can effectively inhibit the growing of bacteria when clothes are worn, also can remove peculiar smell and reduce worm damage, does not have toxicity or stimulation to skin, and is safe and clean and protects heath.

Owner:JIANGSU LIANHONG TEXTILE

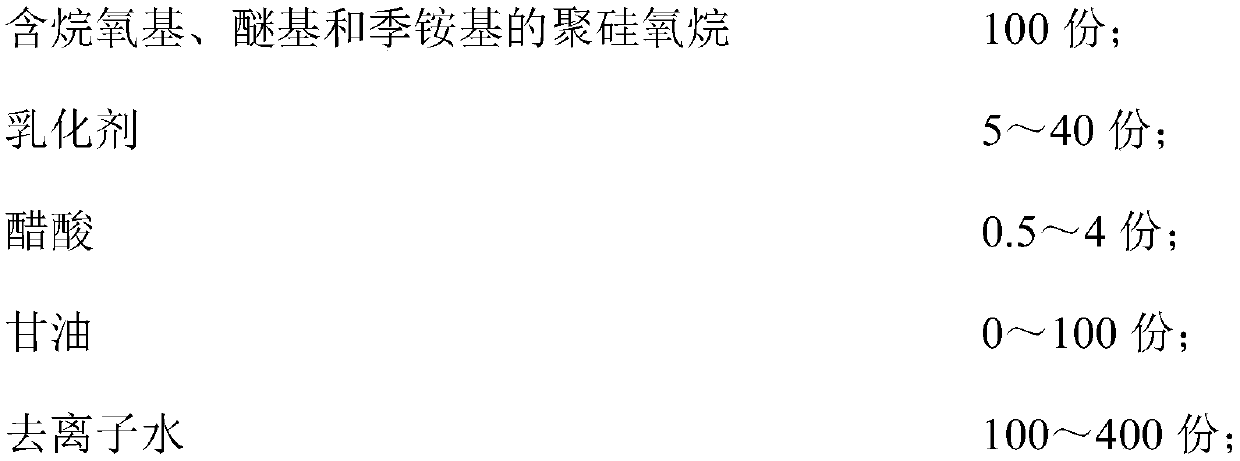

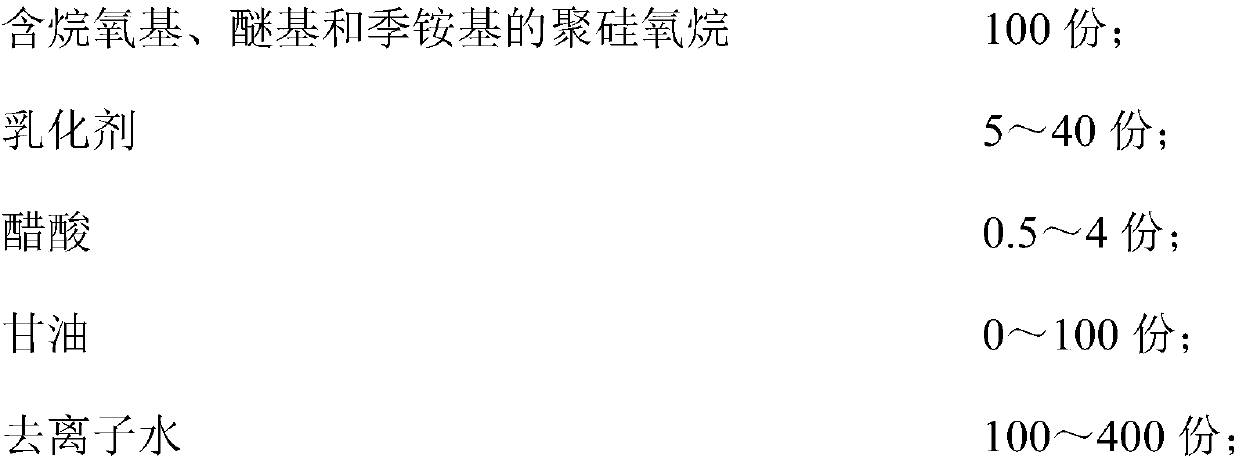

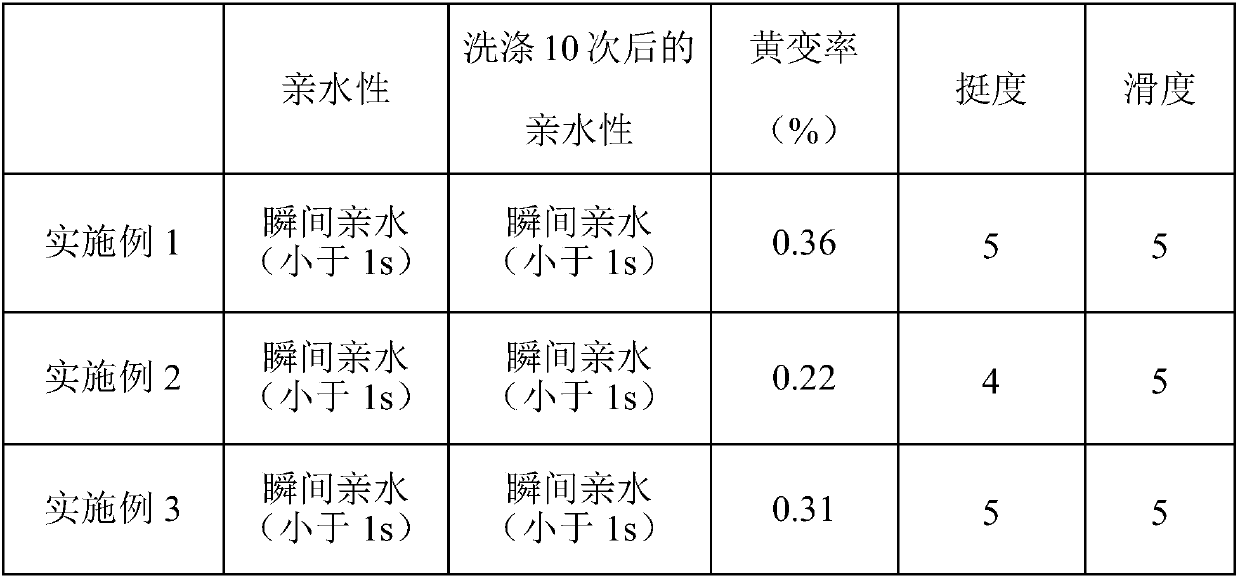

Super-hydrophilic low-yellowing organic silicon softening agent and preparation method thereof

The invention discloses a super-hydrophilic low-yellowing organic silicon softening agent and a preparation method thereof. The preparation method is characterized by including the steps: adding polysiloxane containing alkoxy, ether and quaternary ammonium and emulsifying agents into an emulsifying kettle; stirring mixture for 5-30 min; adding acetic acid to adjust a pH (potential of hydrogen) value to be 5-6; adding glycerin and deionized water to continue to stir mixture for 10-40min to prepare the super-hydrophilic low-yellowing organic silicon softening agent. The prepared organic siliconsoftening agent is good in hydrophilic property, low in yellowing, good in stability, washable and smooth and can reach instant hydrophilic effects (lower than 1s), and yellowing rate is smaller than0.4%. The preparation method is simple, convenient and easy and low in production device requirement, and industrial production is easily achieved.

Owner:FOSHAN XINXIANGXING CHEM

Yarn of blended spinning by combing cotton, spun silk and cashmere and its processing method

The invention relates to combed cotton, spun silk and wool blended yarn and a processing method thereof; the yarn is composed of wool, spun silk and combed cotton; the mass proportion is as follows: 10 percent to 25 percent of wool, 10 percent to 25 percent of spun silk and 35 percent to 65 percent of combed cotton; the performance indexes of the blended yarn meet the following requirements: single-yarn fracture strength: 8.0cN / tex to 16.0cN / tex, single-yarn fracture strength variation coefficient CV: less than or equal to 12.0 percent, yarn evenness variation coefficient CV: 11.0 percent to 17.5 percent; the processing method of the yarn comprises strip making, three-in-one strip combination, roving, spinning, winding and the like. The fabric spun by the yarn has a plurality of advantages of cotton fiber, silk and wool fabric, and the products are smooth to touch, thick and tough. Meanwhile, after process adjustment, the method can greatly save production cost when producing similar high-grade blended yarn on cotton spinning equipment.

Owner:江阴市茂达棉纺厂有限公司

Long wooled tibetan carpet of yak hair or white pile

The invention relates to a Tibetan carpet, in particular to a long yak hair Tibetan carpet made by manually spinning and weaving pure yak hairs. The yarns for weaving warp threads, crossing threads and tufted surfaces of the long yak hair Tibetan carpet are pure yak hair yarns; the weaving density is 40 to 150 rows. The long yak hair Tibetan carpet has the advantages that: as the Tibetan carpet woven by unique yak hair in the Qinghai-Tibet Plateau changes the current situation that the prior Tibetan carpet is only woven by wool yarns, the woven Tibetan carpet keeps the original characteristics of good elasticity and strong warm-preservation; at the same time, as the Tibetan carpet after being woven needs no cropping and only needs to hackle the tufteds in order to extend long hairs, have the effect of simulating fur and make the Tibetan carpet more softer; and as the pure yak hair without dyeing after the cleaning treatment is adopted, the woven Tibetan carpet contains no odour of chemical dye, thereby being more environment-friendly.

Owner:QINGHAI YIYUANXIANG CARPET

Manufacturing method of FDY (fully drawn yarn) fine denier differentiation series products

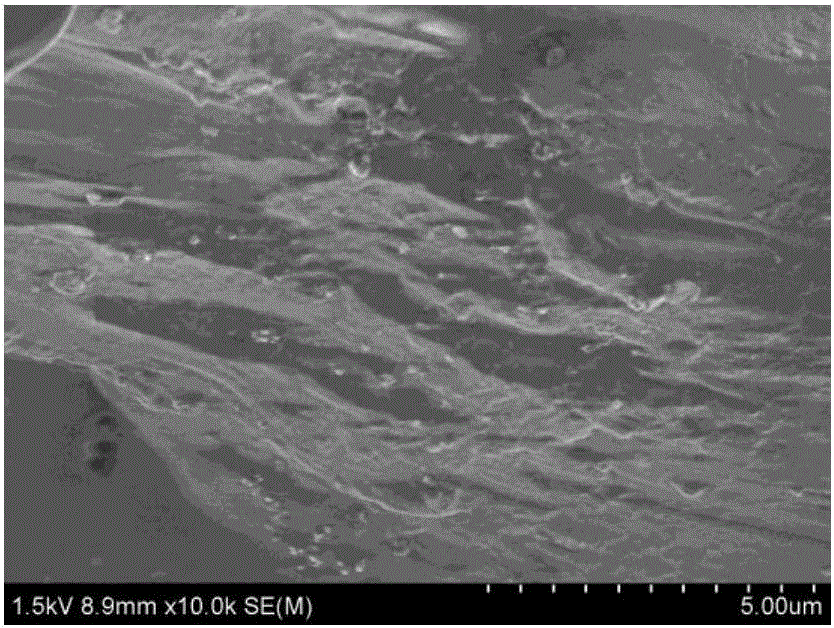

InactiveCN102560701AChanging the internal orientation structure of the moleculeGood compatibilitySpinnerette packsMelt spinning methodsYarnEngineering

The invention discloses a manufacturing method of FDY (full drawn yarn) fine denier differentiation series products, which includes the following production steps of polymerizing in a final-polymerization kettle; distributing by a melt distributor, boosting by a boosting pump; conveying melts; cooling by a cooler, mixing by a static mixer, distributing by a melt distribution valve and spinning in a spinning box; extruding the melts through a metering pump; utilizing a spinning component and a circular blower; cooling and forming; applying oil on double oil nozzles; passing a spinning shaft; setting a pre-network; passing a first heat roll and a second heat roll; setting a main network; passing a yarn guider, a yarn breakage detector and a winder; doffing, dyeing and grading; and performing quality inspection and package, wherein spinneret plates with the ratio L / D of the length (L) to the diameter (D) of 3.56-3.75 are utilized in the step of spinning in the spinning box and staggered in a W-shaped manner, heating devices are arranged on the peripheries of the spinneret plates, the distance between the surface of each spinneret plate and an airless area at the upper end of the cooling blower is set to be 75mm in the step of passing the circular blower. Accordingly, the FDY fine denier differentiation series products manufactured by the manufacturing method are more excellent in quality.

Owner:TONGKUN GRP ZHEJIANG HENGTONG CHEM FIBER

Atmospheric plasma processing method used for fabric topical finish

InactiveCN101117764AEasy to operateShort processUltrasonic/sonic fibre treatmentRegenerating fibersEngineering

A normal-pressure plasma treating method for post-finishing of fabrics is disclosed by the present invention, which relates, in particular, to a normal-pressure plasma treating method for softening and decontaminating finishing of fabrics without chemical assistants and belongs to the technical field of textile processing. The present invention is characterized in that a fabric is positioned between electrodes of a plasma device and treated with corona or glow discharge for 3s-20min by voltage application after the power is switched on,. The fabric can be a natural fiber fabric, a synthesized fabric, a regenerated fiber fabric, a blended fabric of the above fabrics or an interwoven fabric of the above fabrics. The present invention has simple operation and short process and is free of the troublesome steps including padding, pre-baking and baking; without use of chemical assistants or water, the present invention is conducive to environment protection; the fabrics finished with the present invention feels soft and smooth.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

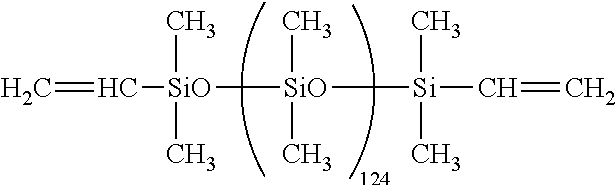

Solventless release coating organopolysiloxane composition and sheet-form substrate having cured release coating

ActiveUS20160244636A1Reduce release forceFlat surfaceCoatingsFilm/foil adhesive release linersPolymer sciencePtru catalyst

This invention relates to solventless release coating organopolysiloxane composition and sheet-form substrate having cured release coating, providing a solventless release coating organopolysiloxane composition having a viscosity of 50 to 3,000 mPa s, comprising (A) 100 parts of an organopolysiloxane fluid having a viscosity at 25° C. of 10 to 1,000 mPa s and alkenyl content of 0.10 to 3.0 wt %; (B) 0.5 to 15 parts of a diorganopolysiloxane having a viscosity at 25° C. of 10,000 to 150,000 mPa s, and 0.05 to 0.30% of alkenyl groups at the pendant position of its siloxane-chain and trialkylsiloxy-terminals; (C) a prescribed quantity of an organohydrogenpolysiloxane; and (D) a hydrosilylation reaction catalyst. Also, a cured release coating-bearing sheet-form substrate that has a cured coating from this solventless release coating organopolysiloxane composition is provided.

Owner:DOW SILICONES CORP +1

High-elongation skin-friendly cashmere yarn

InactiveCN104726982ANo damageExcellent indicatorsBiochemical fibre treatmentDry-cleaning apparatus for textilesYarnPolymer science

The invention discloses a preparation method of high-elongation skin-friendly cashmere yarn. Basically no chemical agents are added in the whole processing process of the high-elongation skin-friendly cashmere yarn. Biological enzymes especially papain and bromelain are fully utilized in the process. Operation is easy, and the optimal parameters of the technique are verified through a large number of experiments. Compared with indexes of cashmere yarn in the prior art, multiple indexes of the prepared cashmere yarn are greatly improved, and especially the advantages of the high elongation and the skin-friendly effect are achieved.

Owner:ZHEJIANG MIHUANG CASHMERE

Production method of yakwool/bamboo fiber blended yarn

The invention relates to a production method of a yakwool / bamboo fiber blended yarn, and the yakwool / bamboo fiber blended yarn is prepared by blending brown yakwool and bamboo fiber, wherein the brown yakwool with the average principal length being 37.4mm, the length discrete degree being 38.3% and the linear density being 4.23dtex is adopted. The method comprises the following steps: (1) preparing yakwool fiber into a yakwool combing sliver by adopting a wool spinning process of raw yakwool pretreatment, worsted carding, first gilling, combing and second gilling; (2) preparing the bamboo fiber into a bamboo fiber sliver by adopting a cotton spinning process of opening picking and cotton carding; (3) blending the yakwool combing sliver and the bamboo fiber sliver through first drawing of cotton spinning, then carrying out third gilling, recombing and regilling of wool spinning, and then carrying out second drawing, roving and spinning of the cotton spinning, thus finally obtaining the yakwool / bamboo fiber blended yarn. According to the production method, the yakwool and the bamboo fiber can be prepared into blended yarns with good quality, and the yarns ensure the yakwool fiber and the bamboo fiber to realize complementary optimization.

Owner:JIANGNAN UNIV

Apocynum mercerization unshrinkable wool blended knited face fabric

The invention involves a kind of bluish dogbane silken luster of mercerized cotton cloth side wool to be enrolled together the knitting lining. Bluish dogbane the silk shrinkproof wool knitting lining belongs to the everyday use health care lining area of technology. Bluish dogbane silken luster of mercerized cotton cloth the shrinkproof wool knitting lining, weaves by the fabric blending gauze becomes, its lining is enrolled together the gauze for bluish dogbane and silken luster of mercerized cotton cloth the shrinkproof wool to weave in the same place. The invention has the remarkable bluish dogbane health care function, the wool with bluish dogbane dual maintains warmth the effect; Silken luster of mercerized cotton cloth shrinkproof, feel is smooth; Green environmental protection; Soft, slides glutinous, but the next to the skin is putting on and so on the merit.

Owner:天津市天益华泰科技发展有限公司

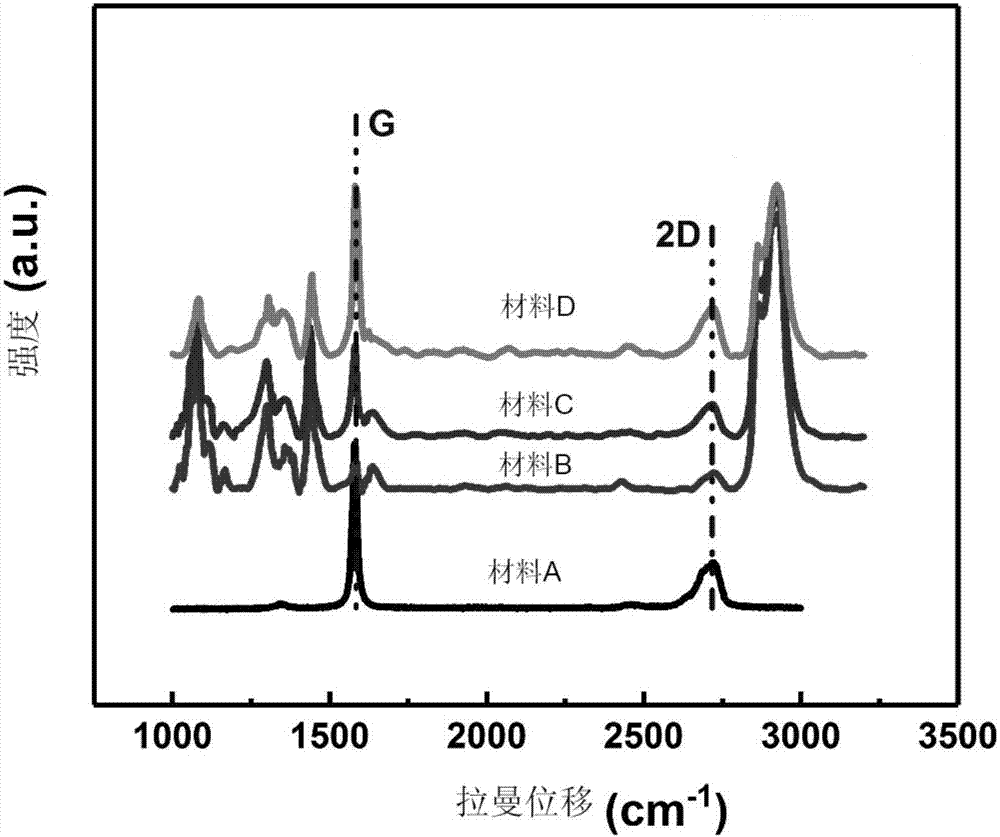

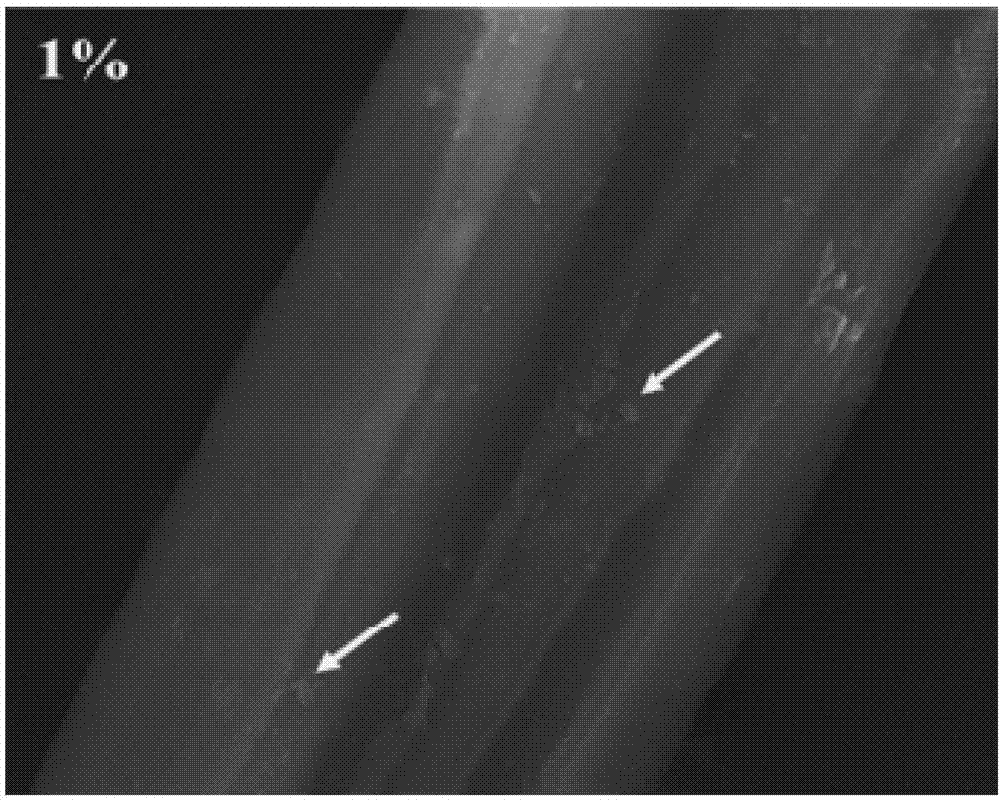

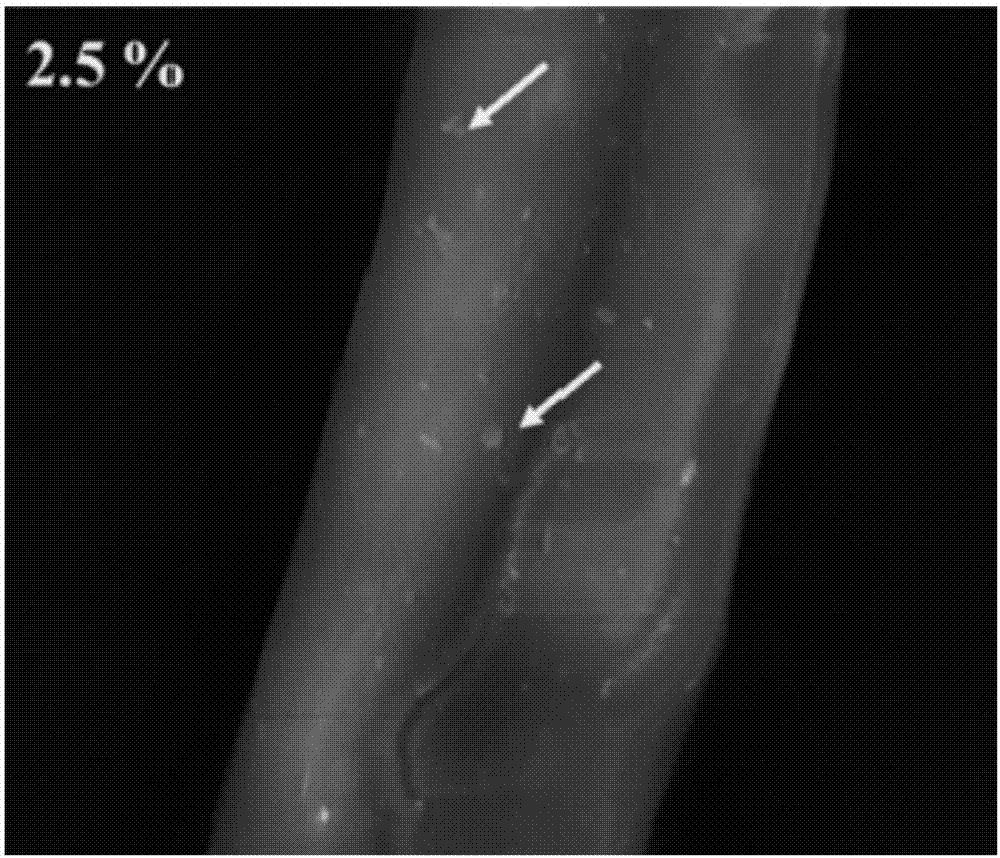

Novel functional graphene composite fiber, and preparation method and application thereof

InactiveCN107488891AGood antibacterial effectImprove antistatic performanceConjugated synthetic polymer artificial filamentsYarnFiberGraphene nanoplatelet

The invention provides a novel functional graphene composite fiber, and a preparation method and an application thereof. The preparation method comprises the following steps: 1, adding graphene nano-sheets into a molten polymer material, and carrying out melt mixing to uniformly mix the graphene nano-sheets with the polymer material in order to obtain a mixture A, wherein 100 wt% of the mixture A contains 20-30 wt% of the graphene nano-sheets; 2, granulating the mixture A to obtain graphene composite master batches; and 3, carrying out melt mixing and spinning on the graphene composite master batches and the polymer material to obtain the novel functional graphene composite fiber, wherein 100 wt% of the novel functional graphene composite fiber contains 1-4 wt% of the graphene nano-sheets. The invention also provides the novel functional graphene composite fiber prepared through the preparation method. The graphene composite fiber has certain strength, softness and hygroscopicity.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Blended fabric containing platinum fiber and production process thereof

InactiveCN102677260AMake up for poor wrinkle resistanceMake up for the relatively single lack of health care performanceWoven fabricsYarnPlatinum

The invention discloses a blended fabric containing platinum fiber. The blended fabric comprises the following components in percentage by weight: 30-40% of platinum fiber, 10-20% of VILOFT, 10-20% of spun silk, and 30-40% of cotton fiber. A production process of the lending fabric containing platinum fiber is that the hatchet man speed of an opener is 460-500 turns / min; the cylinder speed is 300-350 turns / min, and the doffer speed is 17-21 turns / min in a hackling process; a head way broken draft times is 1.68-1.72 in a drawing process, and a rear way broken draft times is 1.28-1.32; spun yarn twist multiplier is 370-390 in a spun yarn process, the spindle speed is 10000-13000 turns / min, and the broken draft times is 1.2-1.45; and the serous fluid concentration is 11.5-12.5% in a sizing process. The blending fabric provided by the invention has an excellent visual effect, has soft comfortable tactile impression, and simultaneously has a health care function.

Owner:山东万泰创业投资有限公司

Imitation sharkskin fabric and production method thereof

The invention relates to an imitation sharkskin fabric made by weaving warps and wefts. The imitation sharkskin fabric is characterized in that the wraps include first wraps and second wraps, and the wefts include first wefts and second wefts; the first wraps and first wefts are formed by wrapping a 100 Denier cationic low elastic polyester filament interlaced yarn formed by 48 single fibers and a 40 Denier spandexes through air before twisting; the second warps and second wefts are formed by compounding a 50 Denier polyester drawn yarn formed by 48 single fibers and a 50 Denier polyester pre-oriented yarn formed by 72 single fibers through air before twisting. The invention further discloses a production method of the fabric. Compared with the prior art, the imitation sharkskin fabric has the advantages that raw materials are polyurethane and polyester, so that the fabric has the advantages of wear resistance, wrinkle resistance, dimensional stability, good color fastness and the like; two layered weave, namely one face is in plain weave and the other face is in twill weave, is selected during weaving, and super elasticity and good air permeability are imparted to a fabric in dual directions of the warps and wefts.

Owner:正凯纺织有限公司

Environment-friendly negative ion far-infrared flame-retardant polyester staple fibers and preparation method thereof

InactiveCN106757481ARealization of halogen-free copolymerization flame retardantAvoid reunionSpinning solution de-aeratingFlame-proof filament manufactureEnvironmental resistanceDrying time

The invention discloses environment-friendly negative ion far-infrared flame-retardant polyester staple fibers and a preparation method thereof. The fibers refer to the environment-friendly negative ion far-infrared flame-retardant polyester staple fibers with the permanent release hydroxyl negative ions (H3O2<->), far-infrared normal total emissivity of 00.88 and a limit oxygen index of 36.8%. The preparation method mainly comprises the following steps: taking environment-friendly recycled polyester bottle pieces as raw materials, performing alcoholysis so as to obtain recycled terephthalic acid and ethylene glycol, adding a negative ion far-infrared powder solution and N,N-bis(2-hydroxymethyl) aminoethyl dimethyl phosphate treatment liquid into the reactant, and preparing environment-friendly recycled negative ion far-infrared functional polyester chips; drying the chips, wherein the drying time is not less than 16 hours; performing melt spinning on the dried through a screw extruder, a spinning box, a seven-roller draw machine and other equipment, and drawing and performing after-treatment. According to the polyester staple fibers disclosed by the invention, the negative ion function, far-infrared function, flame-retardant and environmental protection function can be combined together.

Owner:YANSHAN UNIV

Production process of cool-feeling cotton textile applicable to sportswear

InactiveCN111020826AMoisture-absorbing and breathableComfortable to wearWeft knittingBiochemical fibre treatmentYarnCarding

The invention discloses a production process of a cool-feeling cotton textile applicable to sportswear. The production process is characterized by comprising the following steps of S1, carrying out degumming on flax; S2, carrying out antibacterial pretreatment on cotton fibers and flax; S3, enabling the cotton fibers and the flax after being subjected to antibacterial pretreatment, and moisture absorption and sweat releasing fibers to be preliminarily mixed according to a certain blending ratio; S4, carrying out opening and picking, cotton carding, drawing, roving and open-end spinning to prepare a blended moisture absorption and sweat releasing yarn; S5, preparing a super-cool-feeling yarn; and S6, enabling the super-cool-feeling yarn and the blended moisture absorption and sweat releasing yarn to be interwoven into a double-sided mesh knitted fabric. According to the method, multiple kinds of fibers are blended, the fibers complement each other's advantages, and the blended product has variable styles, the moisture absorption and sweat releasing, comfortable and smooth hand feeling characteristics, and three kinds of effects of instantly cooling, realizing cool and dry feeling, and achieving the moisture absorption and sweat releasing property; and the preparation method is simple and reliable, and is suitable for large-scale industrial production.

Owner:义乌市梵洛薇科技股份有限公司

Production method of ultra-soft textile

InactiveCN106223018AImprove water absorptionGood flexibilityBiochemical treatment with enzymes/microorganismsGrip property fibresFiberMechanical property

The invention relates to a production method of an ultra-soft textile. The textile is prepared by weaving 25 to 40 parts of long staples, 5 to 10 parts of bamboo fibers, 10 to 30 parts of modal fibers, 10 to 20 parts of water-soluble PVA (Polyvinyl Acetate) fibers and 3 to 5 parts of viscose negative-ion functional fibers; a product is obtained through carrying out pre-treatment, enzyme treatment, printing, ageing and color fixation and after-treatment processing. Compared with the prior art, the ultra-soft textile has relatively high water absorbability and air permeability; the softness can be improved; meanwhile, a soft touch feeling can be enhanced and the ultra-soft textile has a strong mechanical property and high wearing resistance.

Owner:福建金苑服饰有限公司

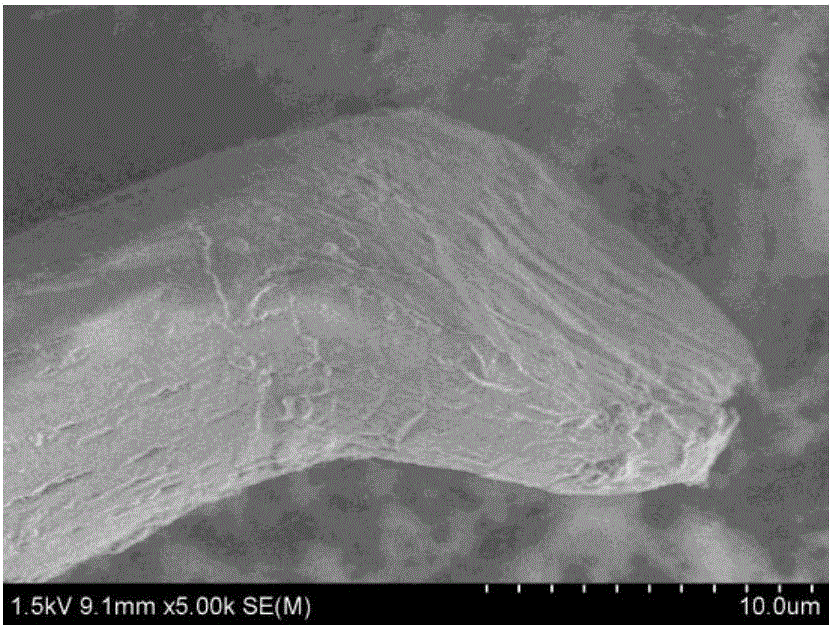

Preparation method of collagen modified superfine acrylic fiber

InactiveCN104264266AGood hygroscopicityGood skin affinityFilament/thread formingArtificial filament heat treatmentPolymer sciencePolymer solution

A preparation method of collagen modified superfine acrylic fiber comprises steps as follows: polyacrylonitrile is dissolved in a solvent, and polyvinylpyrrolidone is added and uniformly stirred to prepare a fiber polymer solution; a collagen solution is added into the fiber polymer solution at the environment of 40 DEG C, magnetically stirred to be uniform and subjected to standing to serve as a spinning solution; and the spinning solution is filled into an injector, spinning is performed under the action of an additional electric field, and spinning fiber is settled in a collecting device by controlling the spinning time and moving a receiving screen and is sintered to obtain the collagen modified superfine acrylic fiber. With adoption of the preparation method, the structural controllability of fabric can be improved, and the modified acrylic fiber touches soft and smooth and has an effect of simulated silk.

Owner:TAICANG SULUN TEXTILE CHEM FIBER

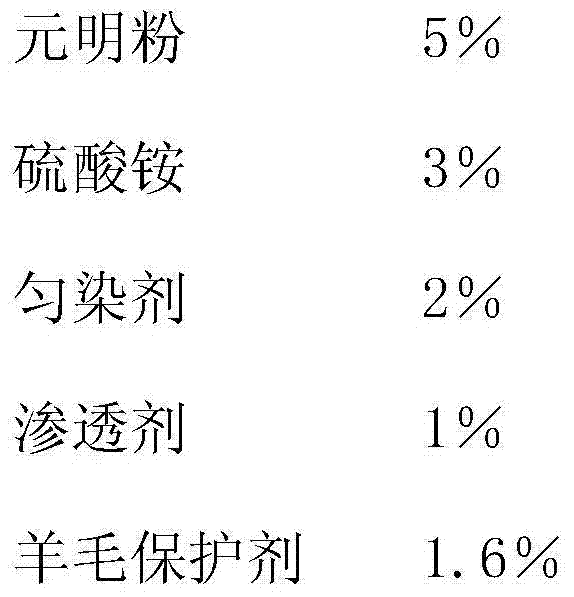

Preparation method of cationic spandex single jersey knitted fabric

InactiveCN105063874AGood three-dimensionalFeel slipperyWeft knittingWarp knittingTextile technologyYarn

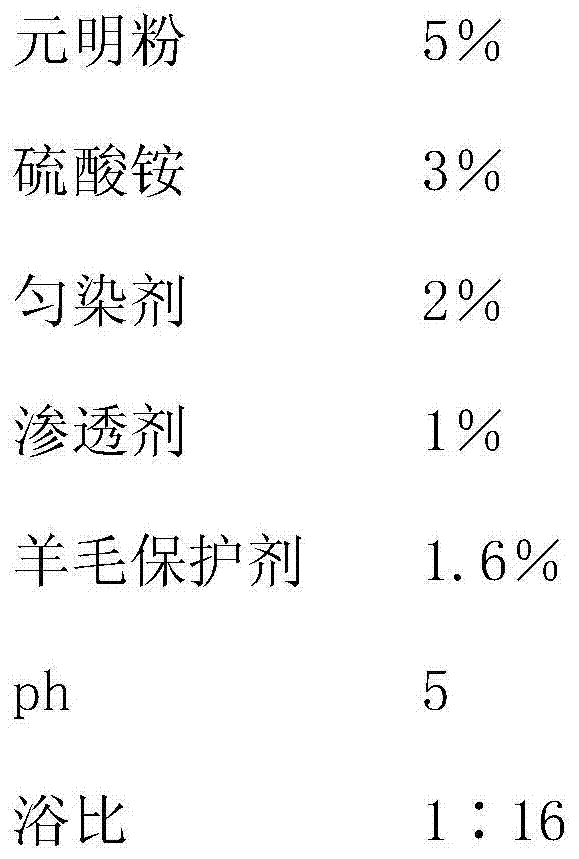

The invention belongs to the field of textile technologies and particularly relates to a preparation method of cationic spandex single jersey knitted fabric. The fabric is composed of 25 wt% of dacron, 70 wt% of acrylic fibers and 5 wt% of spandex. The preparation process includes the steps of yarn forming and fabric pre-treatment. A dyestuff additive used in the fabric pre-treatment process comprises, 0.1-0.3 wt% of cationic blue BG-ED, 0.05-0.10% of cationic red GRL-ED, 0.12-0.25 wt% of cationic yellow 3RL-ED, 0.8-1.3 wt% of glacial acetic acid, 1.5-3.5 wt% of anhydrous sodium sulphate, 0.8-1.5 wt% of ammonium sulfate and the balance water. After the twist of yarn in the fabric yarn forming process is controlled and special dyeing and finishing are conducted, the fabric has the stereoscopic feeling, and a cloth cover is active, not rigid, smooth in hand feeling, good in drooping feeling, breathable and capable of absorbing moisture and releasing sweat. The fabric is easy to dry after being washed, not prone to wrinkling, free of deformation and suitable for being used as summer coat garment materials.

Owner:SHISHI XIANGHUA GRP

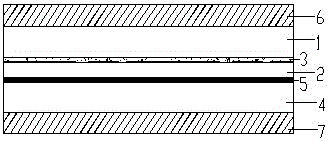

Nano permanent antibacterial antistatic cashmere product and production method thereof

InactiveCN106480712AImprove antibacterial propertiesImprove long-lasting antibacterial performanceAnimal fibresSilica gelBULK ACTIVE INGREDIENT

The invention relates to a nano permanent antibacterial antistatic cashmere product and a production method thereof. The cashmere product comprises 0.005-0.025% (by weight ratio) of nano silver, 0.01-0.1% (by weight ratio) of Artemisia argyi leaf extract and the balance cashmere, wherein the main antibacterial active ingredients of the Artemisia argyi leaf extract include Artemisia argyi terpene lactone, Artemisia argyi flavones and Artemisia argyi acid. The production method includes: a prepared Artemisia argyi leaf extract / nano silver composite antibacterial agent is dissolved into water according to the weight, organic silica gel is added into the solvent according to the weight ratio of 0.01:1, and uniform stirring is carried out for 30 minutes to prepare nano antibacterial coating. The cashmere product comprises cashmere garment upper fabric, a cashmere garment and cashmere garment lower fabric, wherein a nano organosilicon antibacterial layer is arranged between the cashmere garment upper fabric and the cashmere garment, organosilicon antistatic coating is arranged between the cashmere garment and the cashmere garment lower fabric, the outer surface of the cashmere garment upper fabric is provided with the nano antibacterial coating, and the outer surface of the cashmere garment lower fabric is provided with another nano antibacterial coating. Compared with the prior art, the cashmere product has the advantages that the nano moth-proof anti-mite antibacterial coating is added to the outer layer of the fabric on three sides of the cashmere garment, so that the cashmere product has a permanent antibacterial function and a permanent antibacterial antistatic function.

Owner:NANTONG BAOLAI CASHMERE FASHION CO LTD

Method for producing pure wool crease-shedding facing material

ActiveCN101270528BIncreased warp and weft elasticityImprove wrinkle resistanceSingeingDyeing processMaterials scienceWool cloth

Owner:嵊州雅戈尔毛纺织有限公司

A kind of super cool feel polyester fiber blended yarn and spinning method thereof

The invention discloses a novel supercool polyester fiber blended yarn and a method for spinning the blended yarn on cotton spinning equipment. Particularly, the blended yarn consists of 30 to 100 percent of supercool polyester fiber and 70 to 0 percent of other fibers, wherein the other fibers comprise tencel, modal, viscose, cotton, bamboo fiber, polyester and the like. The blended yarn is spun on the cotton spinning equipment by the special process comprising the steps of blowing, cotton carding, drawing, roving, spinning spun yarn and spooling. Various fibers are blended and the advantages of the fibers are complementary. The blended product has variable styles, has the characteristics of hygroscopicity, air permeability, wearing comfortability and smooth and glutinous handfeel, has the effect of cooling instantly, can achieve instant cooling of 1 to 2 DEG C after contacting with skin and achieve cooling temperature difference of 5 to 6 DEG C after being irradiated by sunlight, can absorb and convey sweat moisture on the surface of the skin to the surface of the fabric and diffuse after the skin excretes sweat, and is mainly applied to T-shirt, sportswear, socks and bedclothes.

Owner:SHANGHAI DEFULUN CHEM FIBER

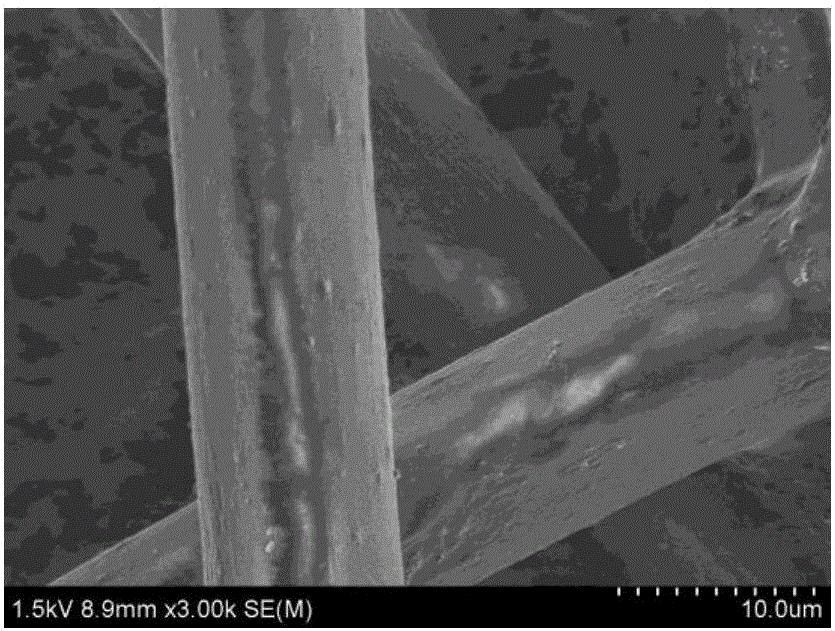

Pearl viscose fiber and preparation method thereof

ActiveCN103374765AFeel slipperySoft touchArtificial filaments from viscoseArtifical filament manufactureFiberEmulsion

The invention discloses a pearl viscose fiber and a preparation method thereof. The pearl viscose fiber is prepared through the following steps: adding a pearl emulsion into a viscose solution, uniformly mixing, filtering, and forming according to a conventional wet spinning and jetting process, thus obtaining the pearl viscose fiber, wherein the mass ratio of the pearl emulsion to the viscose solution is (2:100)-(5:100); and the pearl emulsion is composed of the following components in parts by weight: 20-30 parts of pearl powder, 1-3 parts of isononyl isononanoate, 2-4 parts of sodium alginate, 10-15 parts of pendecamaine, 5-10 parts of potassium dodecyl phosphate, 20-25 parts of Tween-60 and 100-200 parts of water. According to the pearl viscose fiber disclosed by the invention, pearl particles are uniformly distributed over the inside and the external surfaces of the fiber; and the pearl viscose fiber is smooth, soft and cool in hand feeling, is as glossy as silk in appearance, has remarkable anti-ultraviolet effect, and can be blended with cotton, tencel, modal, cashmere, true silk and other raw materials.

Owner:王占霞 +1

Production process of drawing staple and fibre produced by the process

InactiveCN1869294ADamage reliefMeet the technical requirements of the processFibre treatmentEnvironmental resistanceManufacturing technology

The invention relates to a manufacture technology for drawing short fiber. It contains the following steps: combing, jointing and pre-twisting, drawing, washing and drying, gilling, combing, twain needling, balling and the product would be made. The invention has advantages of sliding, nicety, soft, and would not change the natural feature of cashmere. It has great application value and economic value.

Owner:INNER MONGOLIA KINGDEER CASHMERE

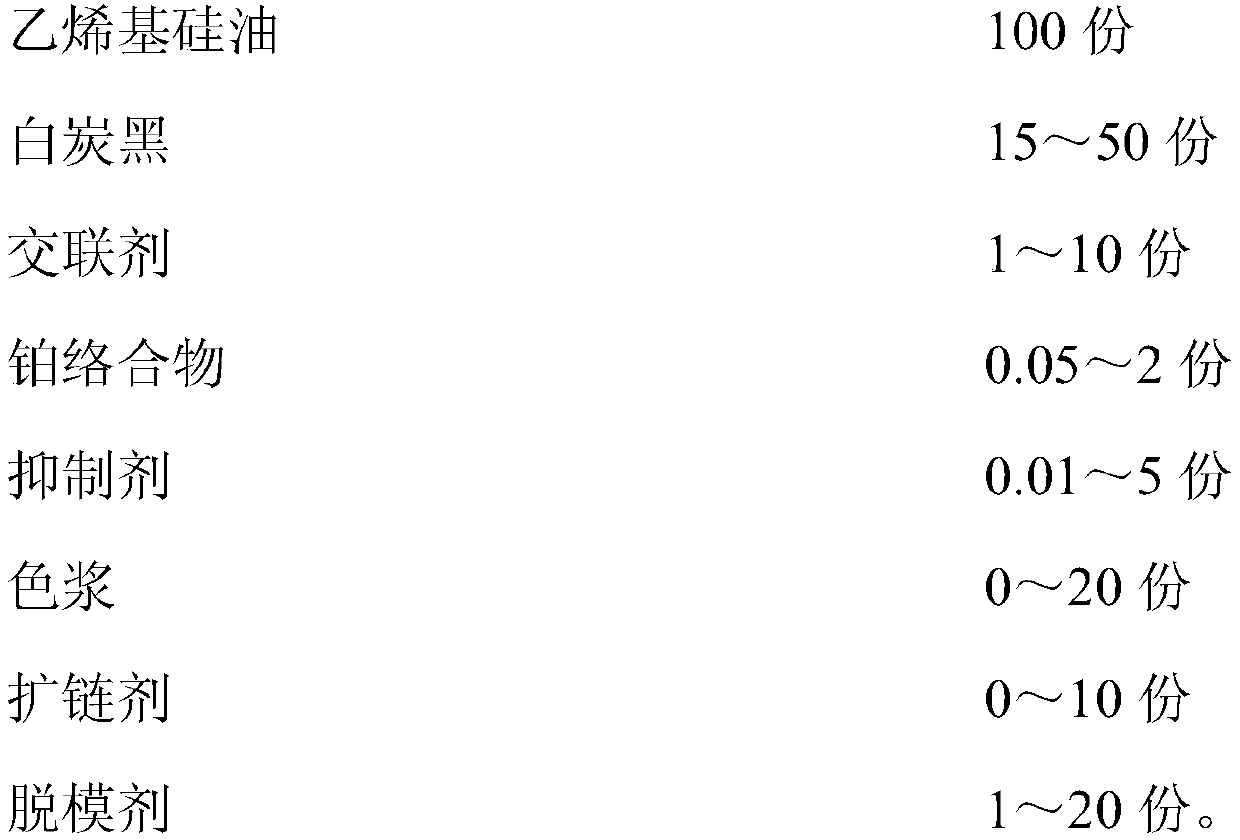

Liquid silicone rubber for artificial leathers

The invention discloses a liquid silicone rubber for artificial leathers. The liquid silicone rubber for the artificial leathers consists of the following components in parts by weight: 100 parts of vinyl silicone oil, 15-50 parts of white carbon black, 1-10 parts of cross-linking agent, and 0.05-2 parts of platinum complex, 0.01-5 parts of inhibitor, 0-20 parts of color paste, 0-10 parts of chainextender, and 1-20 parts of mold release agent. According to the liquid silicone rubber for the artificial leathers, the vinyl silicone oil with a viscosity of 0.5-500 Pa.s is used as a base polymer,and the white carbon black is used as a reinforcing filler, so that the prepared liquid silicone rubber for the artificial leathers has a good fluidity, does not need addition of a solvent for dilution during application, and is more friendly to environment; and methyl silicone rubber is used as an internal mold release agent, so that mold release performance can be significantly improved on a basis of almost not influencing the performance of the liquid silicone rubber, and number of reuse times of a release paper can be improved, and at the same time a slippery touch can be imparted to theartificial leathers.

Owner:CHENGDU GUIBAO SCI & TECH

Pearl viscose fiber and preparation method thereof

ActiveCN103374765BFeel slipperySoft touchArtificial filaments from viscoseArtifical filament manufactureEmulsionPhosphate

The invention discloses a pearl viscose fiber and a preparation method thereof. The pearl viscose fiber is prepared through the following steps: adding a pearl emulsion into a viscose solution, uniformly mixing, filtering, and forming according to a conventional wet spinning and jetting process, thus obtaining the pearl viscose fiber, wherein the mass ratio of the pearl emulsion to the viscose solution is (2:100)-(5:100); and the pearl emulsion is composed of the following components in parts by weight: 20-30 parts of pearl powder, 1-3 parts of isononyl isononanoate, 2-4 parts of sodium alginate, 10-15 parts of pendecamaine, 5-10 parts of potassium dodecyl phosphate, 20-25 parts of Tween-60 and 100-200 parts of water. According to the pearl viscose fiber disclosed by the invention, pearl particles are uniformly distributed over the inside and the external surfaces of the fiber; and the pearl viscose fiber is smooth, soft and cool in hand feeling, is as glossy as silk in appearance, has remarkable anti-ultraviolet effect, and can be blended with cotton, tencel, modal, cashmere, true silk and other raw materials.

Owner:王占霞 +1

Method for preparing superfine acrylic fiber modified by porous collagen

InactiveCN104233498AGood hygroscopicityGood skin affinityMonocomponent synthetic polymer artificial filamentSynthetic polymer filament chemical after-treatmentHydrogen fluoridePolymer science

The invention discloses a method for preparing a superfine acrylic fiber modified by porous collagen, and the method comprises the following steps of: dissolving polyacrylonitrile into a solvent, adding polyvinylpyrrolidone, uniformly stirring them to prepare fiber polymer solution; at 40 degrees centigrade, adding collagen solution into the fiber polymer solution, magnetically stirring to an uniform state and standing, and finally preparing into collagen-modified fiber polymer solution; adding SiO2 nano-particles into the collagen-modified fiber polymer solution, magnetically stirring to the uniform state as spinneret solution; injecting the spinneret solution into an ejector, spinning under the additional electric field, depositing it into a collecting unit by controlling spinning time and moving a receiving screen, and finally calcining; soaking the acrylic fiber containing the SiO2 nano-particles with HF (Hydrogen Fluoride) solution, slowly stirring, cleaning and drying to prepare the superfine acrylic fabric modified by porous collagen. Through the preparation method, fabric is improved in dyeing property, the acrylic fiber has the soft and smooth hand feel and the silk-like effect.

Owner:TAICANG SULUN TEXTILE CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com