Liquid silicone rubber for artificial leathers

A liquid silicone rubber and artificial leather technology, applied in the field of silicone rubber, can solve the problems of short service life, toxic raw materials, harmful to human body, etc., and achieve the effect of improving mold release performance, good fluidity, and increasing the number of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

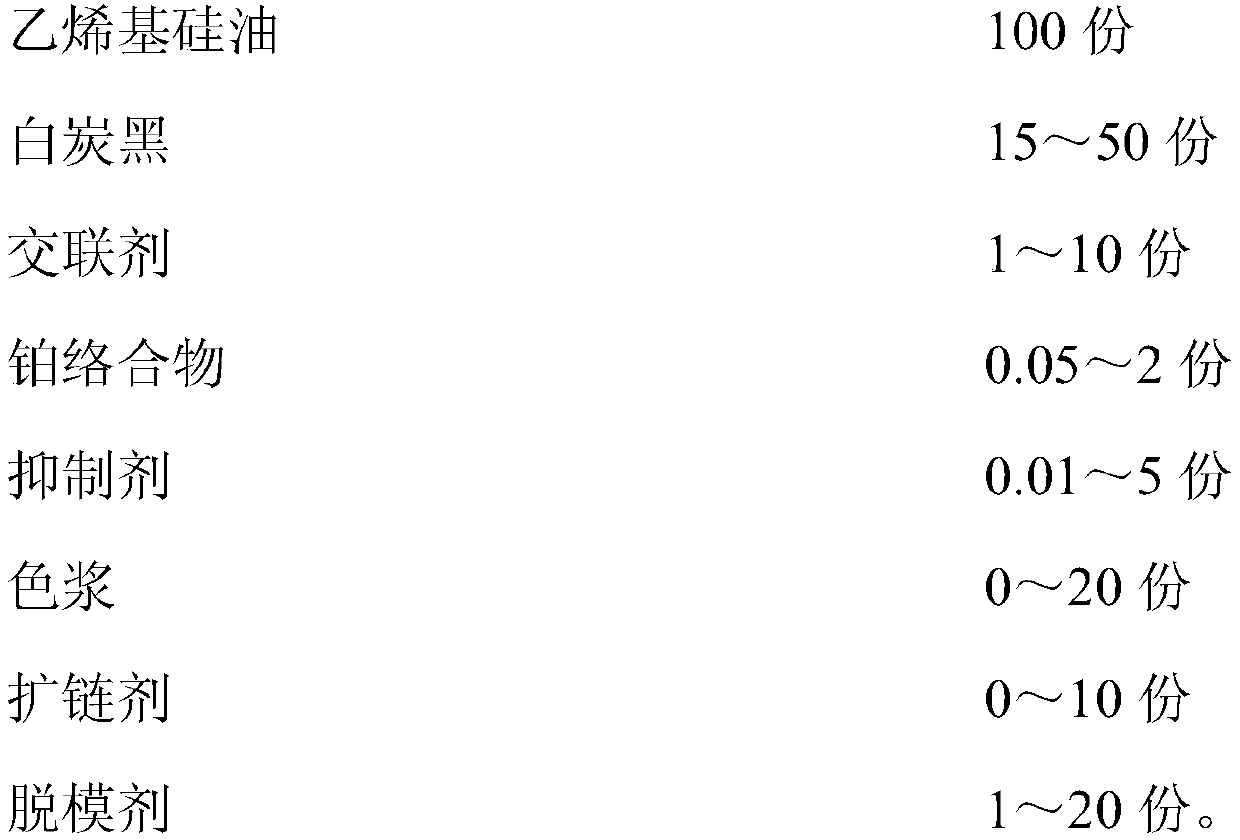

Method used

Image

Examples

Embodiment 1

[0020] Take 100 parts of vinyl silicone oil, 40 parts of white carbon black, 5 parts of crosslinking agent, 0.2 parts of platinum complex, 0.05 parts of inhibitor, 1.5 parts of color paste, 3 parts of chain extender, 4 parts of release agent, and use high-speed Stir evenly with a disperser, then make artificial leather by coating, and vulcanize at 130°C for 5 minutes.

[0021] Among them, the vinyl silicone oil is intermixed with 2Pa·s and 20Pa·s vinyl silicone oil, and the vinyl content is 0.4%. The crosslinking agent is hydrogen-containing silicone oil with a viscosity of 20 mPa·s and a hydrogen content of 0.45%. The inhibitor is methyl butynol. The chain extender is terminal hydrogen-containing silicone oil with a viscosity of 2mPa·s. The release agent is methyl silicone rubber with a viscosity of 5000Pa·s.

Embodiment 2

[0023] Take 100 parts of vinyl silicone oil, 30 parts of white carbon black, 2.5 parts of crosslinking agent, 0.24 parts of platinum complex, 0.1 part of inhibitor, 5 parts of color paste, 6 parts of mold release agent, and use a high-speed disperser to stir evenly, and then The artificial leather is made by coating and vulcanized at 160° C. for 5 minutes.

[0024] Among them, the vinyl silicone oil is intermixed with 6Pa·s and 80Pa·s vinyl silicone oil, and the vinyl content is 0.3%. The crosslinking agent is hydrogen-containing silicone oil with a viscosity of 50 mPa·s and a hydrogen content of 0.8%. The inhibitor is methyl butynol. The release agent is methyl silicone rubber with a viscosity of 4000Pa·s.

Embodiment 3

[0026] Take 100 parts of vinyl silicone oil, 20 parts of white carbon black, 4 parts of crosslinking agent, 0.5 part of platinum complex, 0.05 part of inhibitor, 0.5 part of color paste, 6 parts of mold release agent, stir evenly with a high-speed disperser, and then The artificial leather is made by coating and vulcanized for 3 minutes at 130°C.

[0027] Among them, the vinyl silicone oil is intermixed with 1Pa·s and 300Pa·s vinyl silicone oil, and the vinyl content is 0.15%. The crosslinking agent is hydrogen-containing silicone oil with a viscosity of 100 mPa·s and a hydrogen content of 0.6%. The inhibitor is methyl butynol. The release agent is methyl silicone rubber with a viscosity of 6000Pa·s.

[0028] The artificial leather liquid silicone rubber prepared by above-mentioned embodiment has carried out some performance results as shown in the table below:

[0029]

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com