Patents

Literature

60results about How to "Improve long-lasting antibacterial performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanometer antibiosis cashmere knit fabric and production method thereof

InactiveCN101967753AImprove long-lasting antibacterial performanceFeel slipperyAnimal fibresYarnAntibiosis

The patent refers to the field of 'treatment of fibres, threads, yarns, fabrics, feathers, or fibrous goods made from such materials'. The invention discloses a nanometer antibiosis cashmere knit fabric which has a moderate price, slippery handfeel and soft gloss and can remove peculiar smell and inhibit the growing of bacteria. The nanometer antibiosis cashmere knit fabric comprises 0.0005 to 0.0025 weight percent of nano silver, 0.01 to 0.1 weight percent of ginkgo leaf extract, and the balance of cashmere, wherein the main antibacterial ingredients of the ginkgo leaf extract comprise ginkgo biloba terpene lactones, ginkgo flavones, and ginkgoic acid. The invention also discloses a production method of the nanometer antibiosis cashmere knit fabric. The method comprises the following steps of: preparing a ginkgo leaf extract / nano silver composite antibacterial agent; treating the cashmere knit fabric with the ginkgo leaf extract / nano silver composite antibacterial agent; and then performing conventional process flow of dehydration, soaking in an adhesive, performing dehydration, rolling and washing in a soft way, drying, and ironing to obtain a finished product. The treated cashmere knit fabric has excellent and lasting antibacterial performance, can effectively inhibit the growing of bacteria when clothes are worn, also can remove peculiar smell and reduce worm damage, does not have toxicity or stimulation to skin, and is safe and clean and protects heath.

Owner:JIANGSU LIANHONG TEXTILE

Ferrite antibacterial stainless steel for low-chrome copper-containing dishware and manufacturing method thereof

ActiveCN1827824AExcellent long-lasting antibacterial effectLow content of alloying elementsTemperature control deviceHeat treatment process controlPre treatmentChromium

Disclosed is a ferrite antibacterial stainless steel for low-chrome copper-containing dishware and manufacturing method, wherein the stainless steel matrix comprises (by wt%) Cr 12.0-14.0%, Cu 0.70-2.20%, C <=0.08-0.15, the preparing process comprises pre-processing melted iron, passing through composite revolving furnace, vacuum oxygen decarbonization furnace, refined-smelting ladle furnace, continuous plate blank casting, casting blank annealing, tandem rolling, and annealing in a bell-type furnace.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

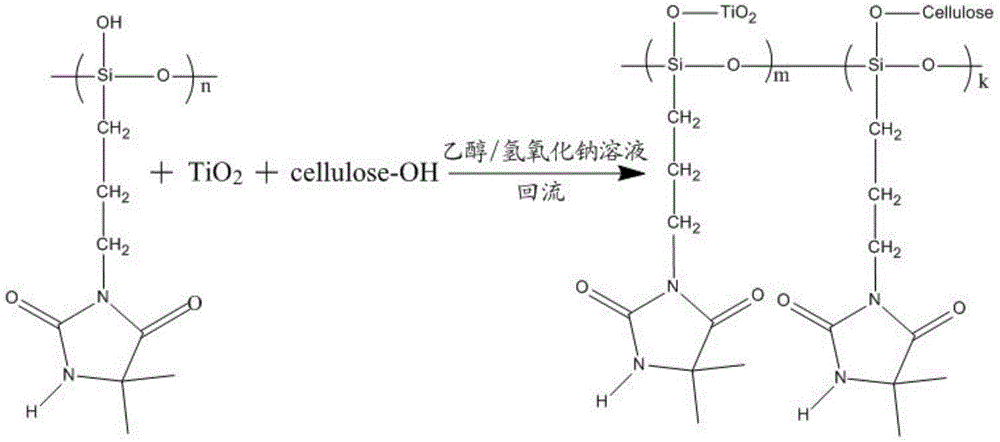

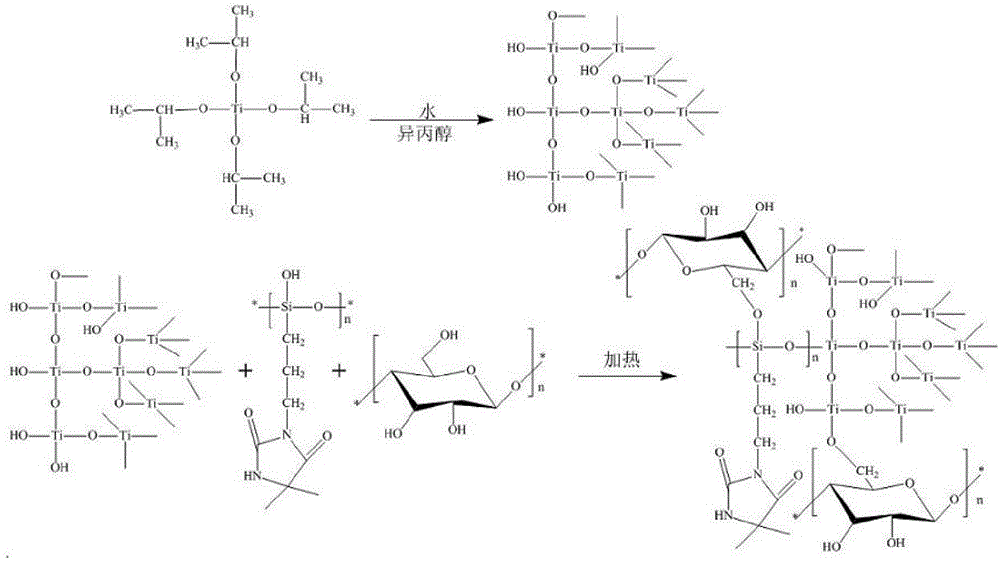

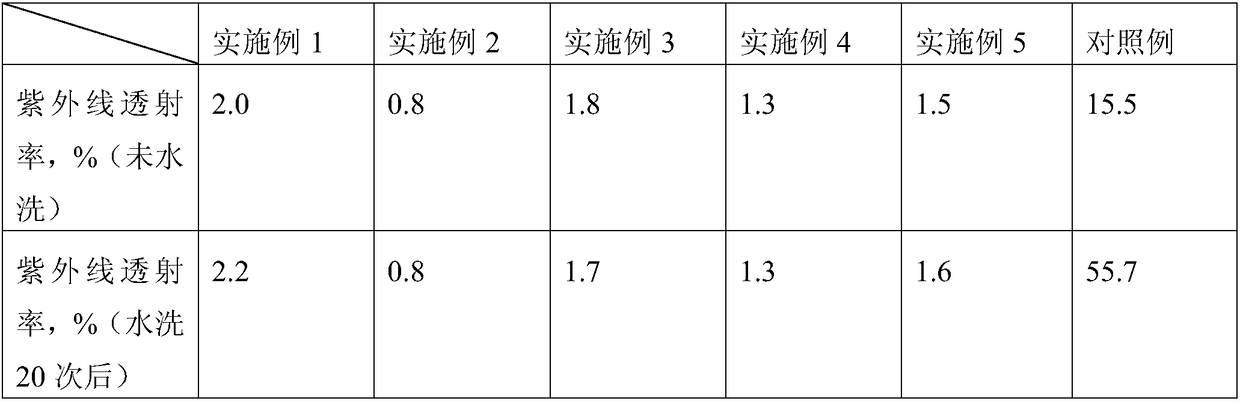

Preparation method of ultraviolet ray resistant antibacterial fabric

ActiveCN104088134ASimple processImproves UV stabilityVegetal fibresAnimal fibresTitanium dioxideFiber

The invention relates to a preparation method of ultraviolet ray resistant antibacterial fabric. The preparation method comprises the following steps of impregnating fiber fabric in finishing liquid for 10-20min, impregnating and padding twice, drying, baking at 90 DEG C -110 DEG C for 30-90min, soaping, washing, airing and chloridizing to obtain the finished product. The process reaction condition is mild, the reaction time is short, the reaction energy consumption is low, the technological process is simple, and synthesized nano-titanium dioxide has high photocatalytic activity.

Owner:JIANGNAN UNIV

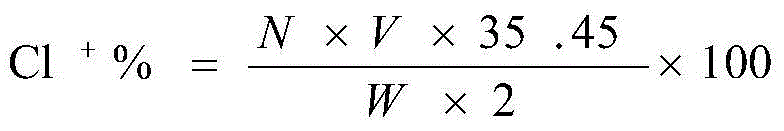

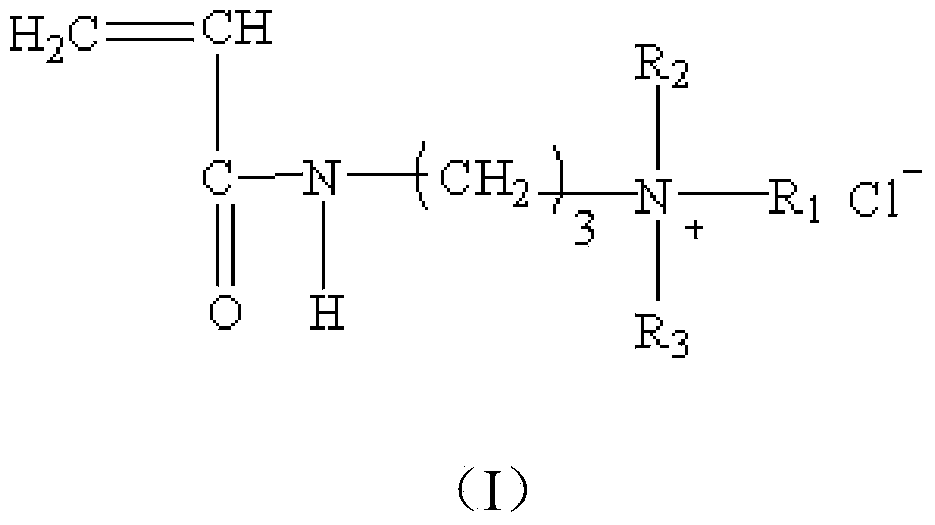

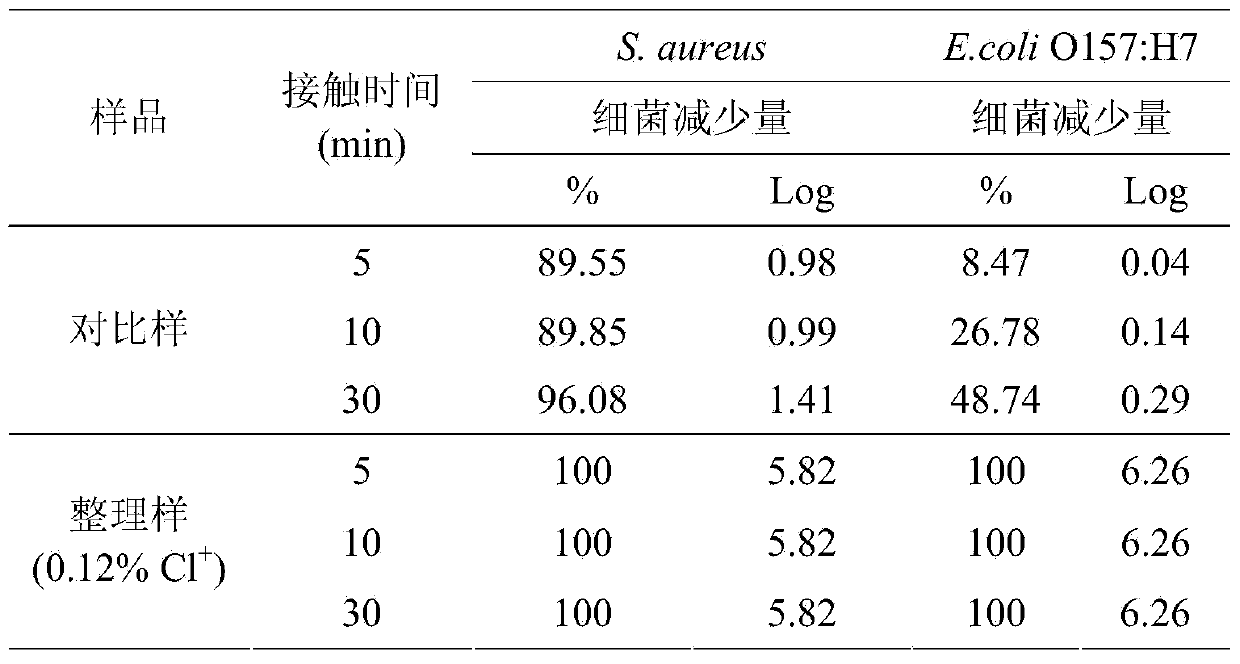

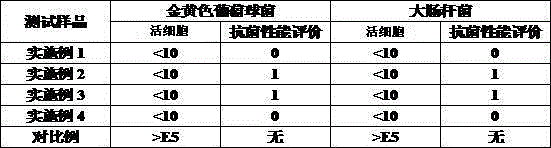

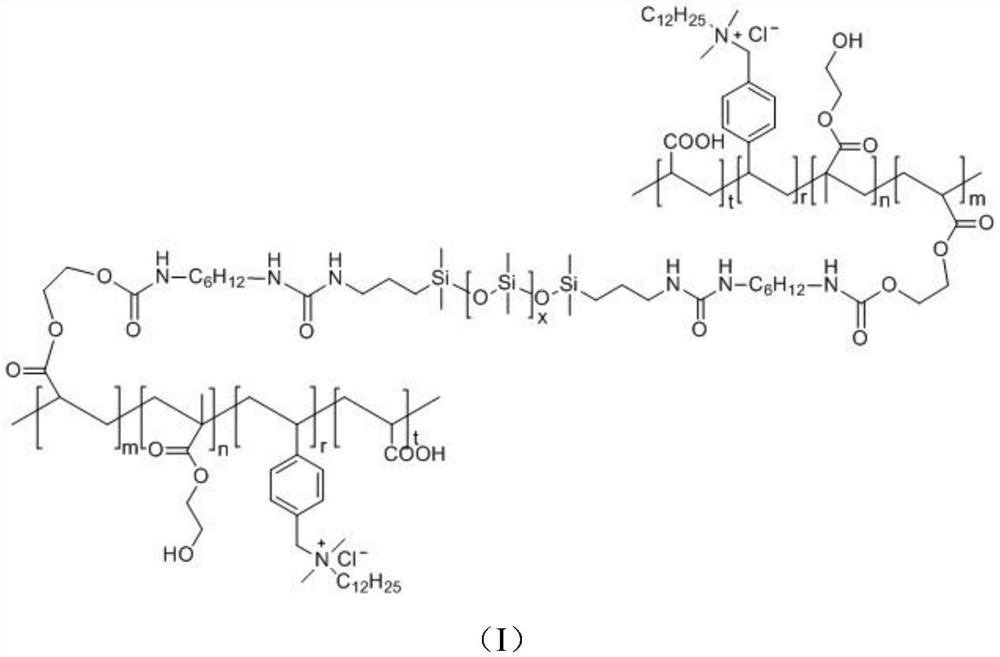

Preparation method of olefine halamine compound grafted antibacterial cotton fabric containing quaternary ammonium groups

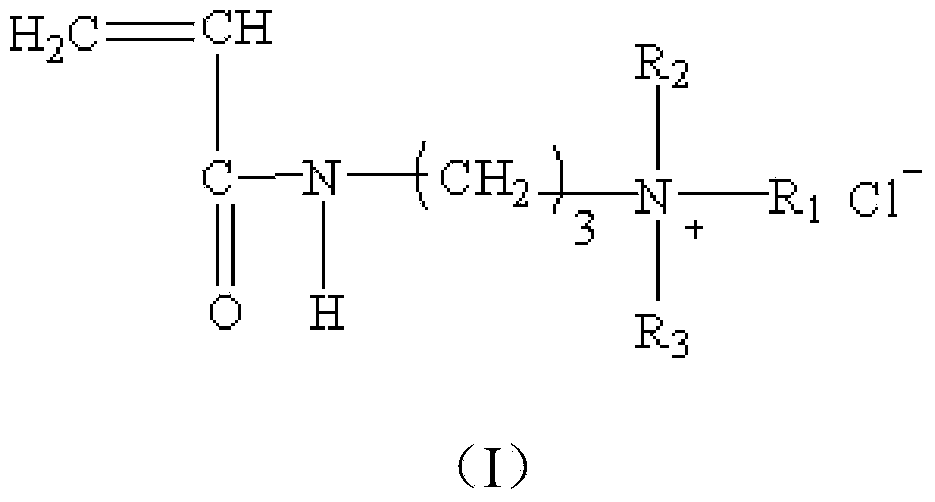

InactiveCN103757906AMild reaction conditionsShort reaction timeVegetal fibresStructural formulaEnergy consumption

The invention discloses a preparation method of olefine halamine compound grafted antibacterial cotton fabric containing quaternary ammonium groups. The method comprises the following steps of: (1) preparing finishing liquid: adding an olefine halamine compound precursor containing quaternary amine groups at the final concentration of 50-150g / L into water, adding an initiator at the final concentration of 0.1-0.4mol / L to prepare the finishing liquid, and (2) antibacterial finishing: putting cotton fabric to be treated in the finishing liquid for reaction at 50-70 DEG C for 1-5h, soaping, washing with water, airing, chloridizing, and obtaining the antibacterial cotton fabric finish product, wherein a chemical structural formula of the precursor is as shown in Formula (I). The method is simple in technology, low in energy consumption and short in time, and an antibacterial test and a fabric strength test show that the prepared antibacterial cotton fabric has excellent antimicrobial property and good wearability, and has an important industrial application value.

Owner:JIANGNAN UNIV

Bagging composite material for fruits and vegetables, preparation method therefor and application of bagging composite material

ActiveCN111820057AGood biocompatibilityEasy to prepareBiocidePlant growth regulatorsSpray coatingAnti bacterial

The invention discloses a bagging composite material for fruits and vegetables, a preparation method therefor and application of the bagging composite material. The composite material comprises the following raw materials in parts by mass: 1-5 parts of film forming matter, 50-90 parts of dispersant, 0.1-2 parts of antibacterial plant essential oil-chitosan based micro-nano capsules, 1-10 parts ofplasticizer, 1-10 parts of nano reinforced particles and 0.5-5 parts of binder. According to the bagging composite material for the fruits and vegetables, the preparation method therefor and the application of the bagging composite material, a safe and efficient emulsifier, plant essential oil with broad bacteriostatic spectrum and high antibacterial property, and chitosan and derivatives thereofare employed, and the bagging composite material for the fruits and vegetables is prepared through effectively constructing long-acting sustained-release micro-nano capsules, i.e., a biological antibacterial agent based on an emulsion template method, and compounding the micro-nano capsules with the chitosan and derivatives thereof and a nano reinforced particle film forming solution; and the obtained composite material can be applied to the fruits and vegetables through a convenient spray coating mode, the slow release of the antibacterial plant essential oil can be achieved, the insect-proofing, antibacterial and freshness-preserving effects of the fruits and vegetables can be effectively improved, and thus, the quality of the fruits and vegetables is improved.

Owner:SOUTH SUBTROPICAL CROPS RES INST CHINESE ACAD OF TROPICAL AGRI SCI

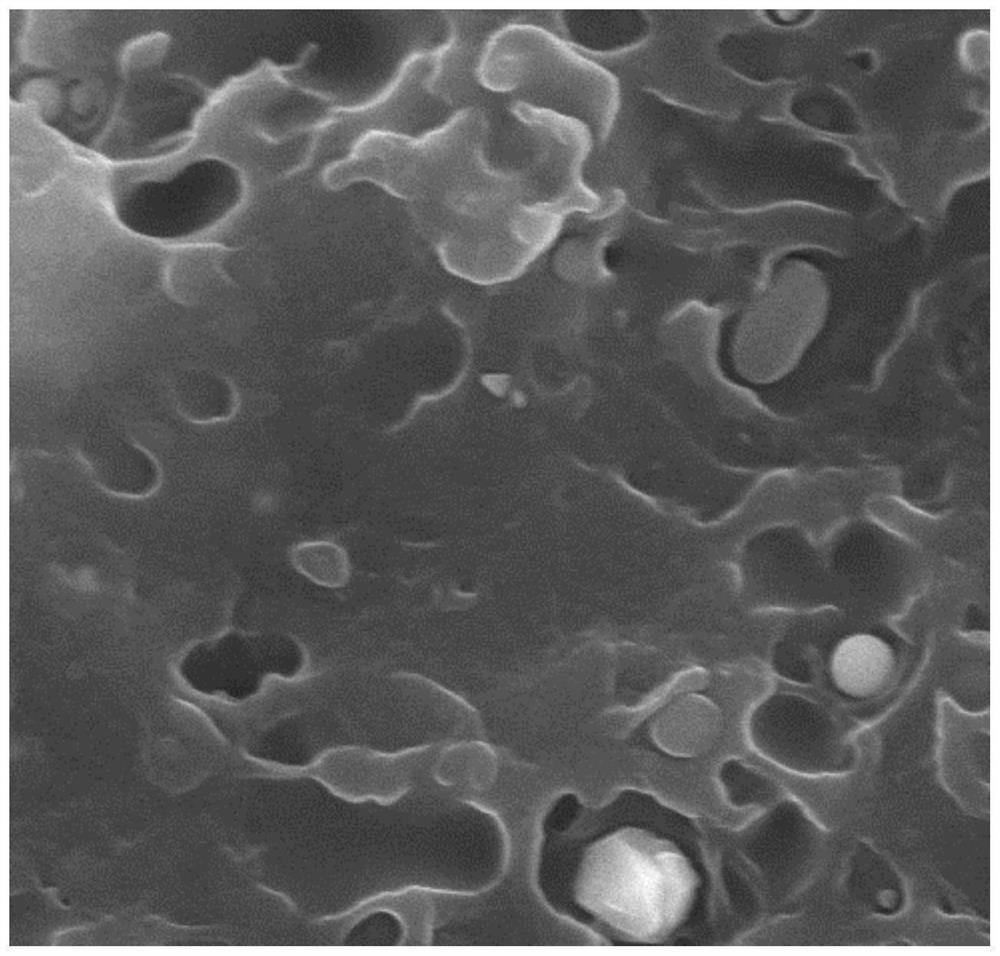

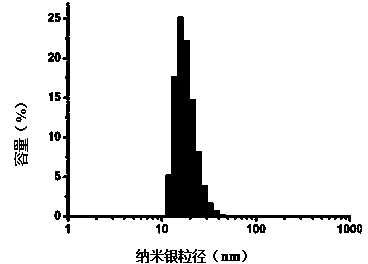

Preparation method of porous nano antibacterial particles and composite nanofiltration membrane, and composite nanofiltration membrane

PendingCN110694493AImprove hydrophilicitySmall apertureSemi-permeable membranesMembranesUltrafiltrationPolyamine

The invention discloses a preparation method of porous nano antibacterial particles and a composite nanofiltration membrane and the composite nanofiltration membrane. The preparation method of the porous nano-antibacterial particle composite nanofiltration membrane comprises the following steps: 1, adding porous copper-coated TiO2 nano-antibacterial particles into a basic solution, and uniformly embedding the porous nano-antibacterial particles into the basic solution through ultrasonic dispersion or strong stirring to prepare a monomer solution; wherein the basic solution is a polybasic acylchloride solution and a piperazine aqueous solution, or a polybasic acyl chloride solution and an aqueous solution of a mixture of piperazine and polyamine; and 2, carrying out interfacial polymerization reaction on the monomer solution on the surface of an ultrafiltration support membrane layer to obtain the porous copper-coated TiO2 nano antibacterial particle composite nanofiltration membrane.The prepared porous copper-coated titanium dioxide nano antibacterial particle composite nanofiltration membrane is large in water flux, high in desalination rate, resistant to bacterial pollution, easy to clean and capable of being widely applied to the application fields of sewage treatment, material concentration, decoloration, desalination of alkaline water or seawater and the like.

Owner:深圳市君脉膜科技有限公司

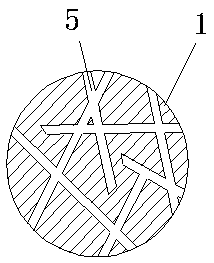

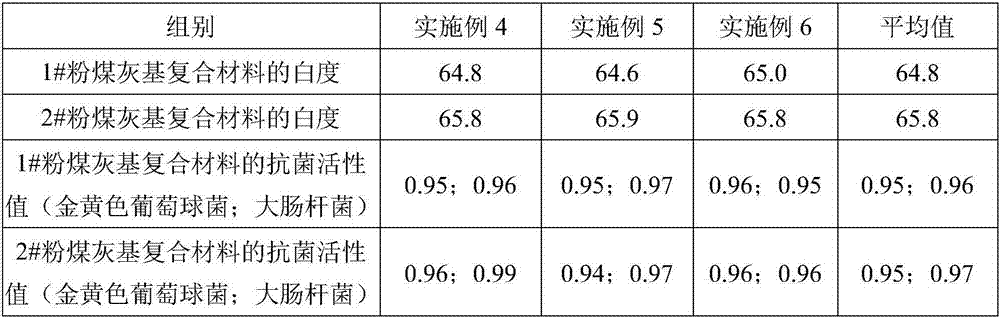

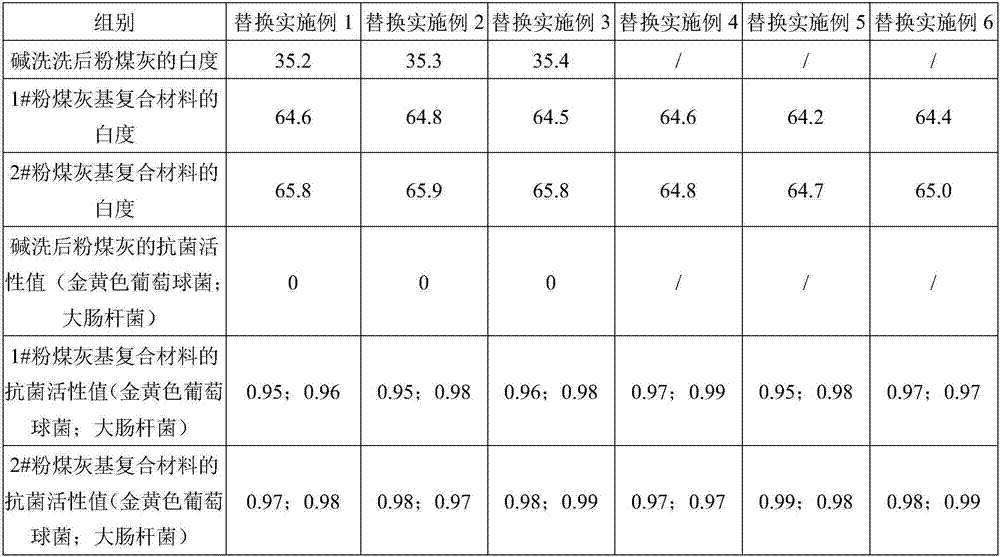

Fly ash based composite material as well as preparation method and application thereof

ActiveCN107383422AIncrease added valueHigh whitenessBiocideAntifouling/underwater paintsZinc hydroxideCore shell

The invention discloses a fly ash based composite material, which is prepared from fly ash and zinc hydroxide or zinc oxide coating the surface of the fly ash. The fly ash based composite material is a material of a core-shell structure using the coal ash as a core and using the zinc hydroxide or zinc oxide as a case; the fly ash based composite material has good whiteness; the application range is greatly expanded; the antibacterial activity value is high; the durable antibacterial performance of the zinc oxide is good; the fly ash based composite material can be used for preparing an antibacterial coating; the coating stability is high. The raw material cost is low; the waste material reutilization can be realized; the added value of the fly ash can be greatly improved; the application prospects are very good.

Owner:ANHUI UNIV OF SCI & TECH

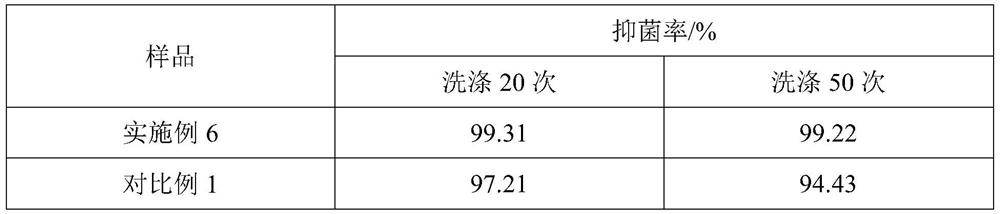

Waterproof antibacterial fabric finishing agent and application thereof

InactiveCN111321594AUniform dense settingImprove long-lasting antibacterial performanceBiochemical fibre treatmentLiquid repellent fibresPolymer scienceAntibacterial agent

The invention relates to the waterproof processing and finishing technology, in particular to a waterproof antibacterial fabric finishing agent and an application thereof. The waterproof antibacterialfabric finishing agent is composed of the following components by weight parts of: 30 to 45 parts of acrylate copolymer, 5 to 10 parts of silica solution, 1 to 8 parts of long-acting antibacterial agent, 1 to 5 parts of dispersant, and 40 to 60 parts of water. In the invention, through adopting the compounded antibacterial agent components, the dispersion and stability of the long-acting antibacterial agent are improved, and at the same time, the long-acting antibacterial effect of the waterproof antibacterial fabric finishing agent is significantly improved. In addition, the waterproof antibacterial fabric finishing agent disclosed by the invention does not contain PFOS(perfluorooctane sulfonate) and PFOA(perfluorooctanoic acid), which is easily biodegraded, has no bioaccumulative properties, is less harmful to the human body, and is a relatively safe and environmentally friendly product.

Owner:京准化工技术(上海)有限公司

Preparation method of functional powder coating

InactiveCN104974635AStrong adhesionLasting effectAntifouling/underwater paintsPaints with biocidesHome applianceSilver ion

The invention discloses a preparation method of a functional powder coating. The powder coating is prepared by adopting melt extrusion and ball-milling crushing; and the anti-bacterial functional powder coating prepared by the invention has the advantages of high antibacterial agent adhesive force and long action time, so that heavy metal pollution possibly caused by silver ion release is overcome, and good and lasting antibacterial effect of the functional powder coating is guaranteed. The powder coating prepared by the invention can be widely applied to the coating of household appliances, bicycles, motor bicycles, outdoor air conditioners, automobile and tractor accessories as well as outdoor products such as forklifts, and has great application value and popularization prospect.

Owner:ANHUI HUAHUI SUYE TECH SHARE CO LTD

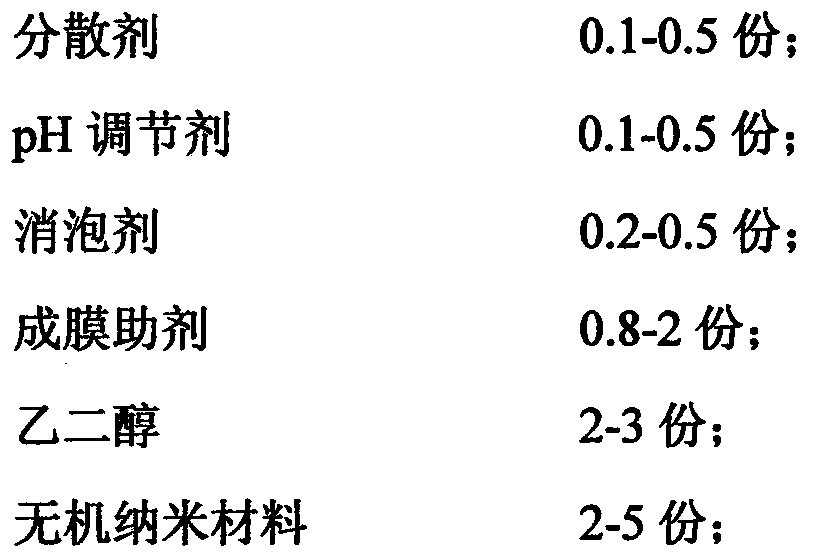

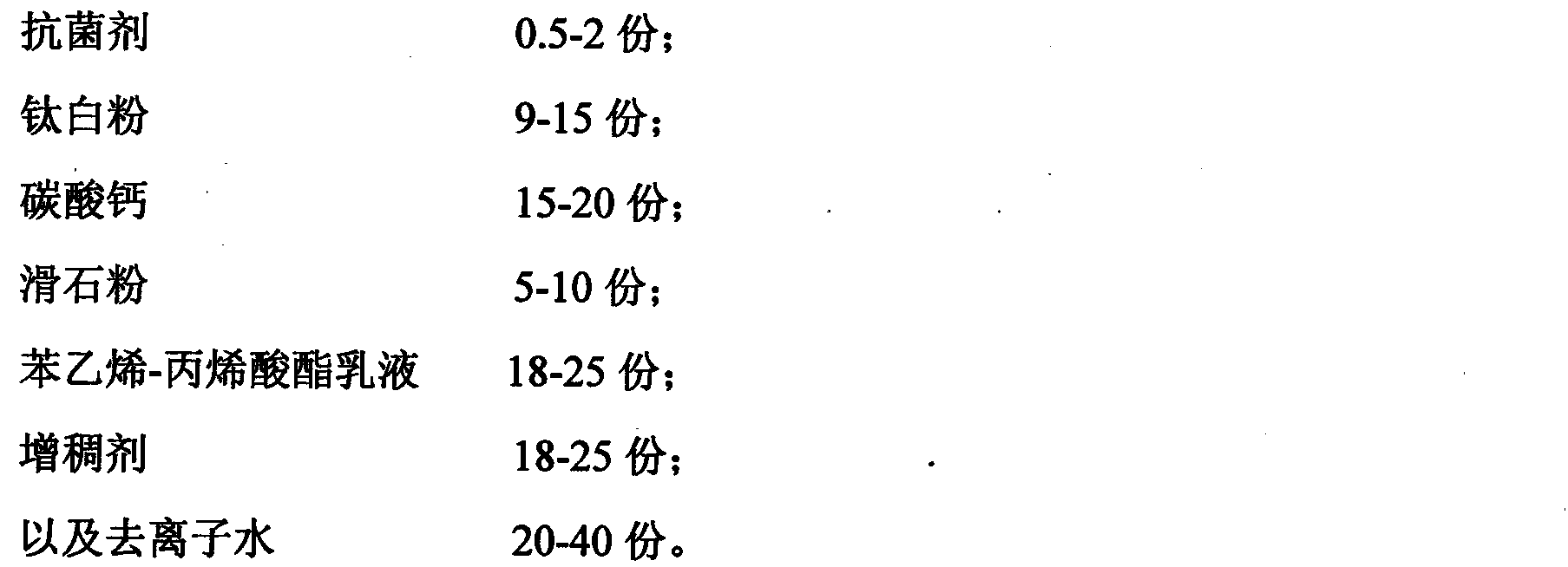

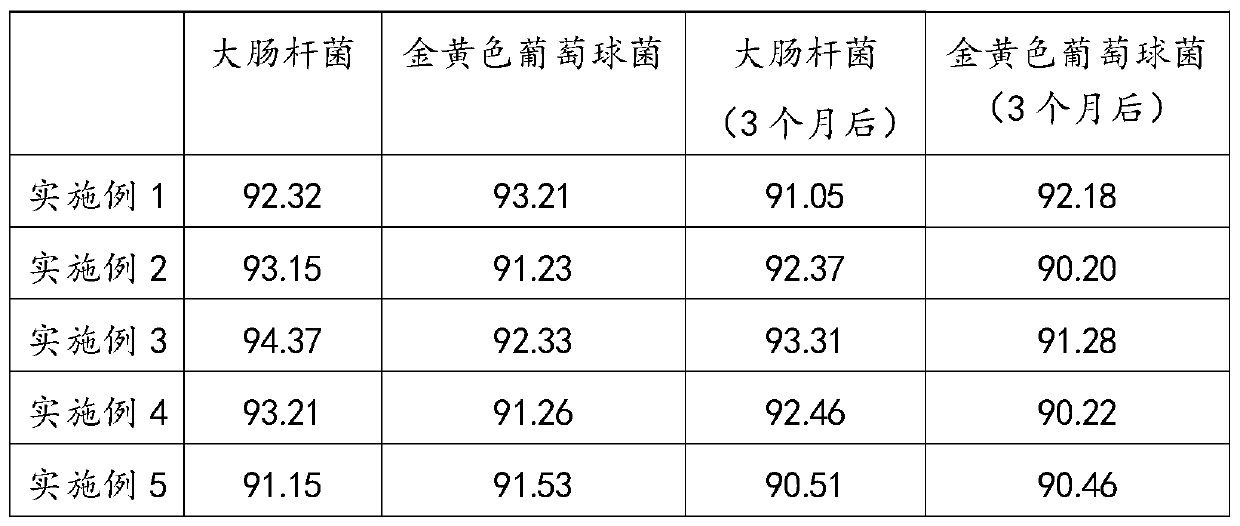

Acrylate antibacterial coating

InactiveCN104263116AGood and long-lasting antibacterial effectEasy to operateAntifouling/underwater paintsPaints with biocidesChemistryEmulsion

The invention discloses an acrylate antibacterial coating. The acrylate antibacterial coating is characterized in that the acrylate antibacterial coating includes the following components in parts by weight: 0.1 to 0.5 part of a disperser, 0.1 to 0.5 part of a pH modifier, 0.2 to 0.5 part of a defoamer, 0.8 to 2 parts of a coalescing agent, 2 to 3 parts of ethylene glycol, 2 to 5 parts of inorganic nano-materials, 0.5 to 2 parts of an antibacterial agent, 9 to 15 parts of titanium dioxide, 15 to 20 parts of calcium carbonate, 5 to 10 parts of talcum powders, 18 to 25 parts of styrene-acrylate emulsion, 18 to 25 parts of a thickener, and 20 to 40 parts of deionized water; preferably, the disperser is sodium hexametaphosphate. The inorganic nano-materials are used for modification of the antibacterial performance of coatings, that is, the materials are used for modification of an ordinary acrylate coating, so as to achieve the nano-modified coating; the acrylate antibacterial coating has the advantages of easy acquisition of the raw materials, environment friendliness, harmlessness to human bodies, good and lasting antibacterial effect and the like, and can effectively prevent the growth and reproduction of escherichia coli, staphylococcus aureus and other bacteria.

Owner:SHANGHAI ZHONGLI AUTO PARTS

Method for preparing antibacterial masterbatches by using discarded and/or waste plastic as raw materials

The invention belongs to the technical field of discarded and / or waste plastics, and particularly relates to a method for preparing antibacterial masterbatches by using discarded and / or waste plasticsas raw materials. The method includes the steps that (1) sorting, cleaning and drying of discarded and / or waste plastics are performed; through primary crushing, fine crushing and twin-screw extrusion, discarded and / or waste plastic masterbatches are obtained; and (2) a first surface modification agent is added to the discarded and / or waste plastic masterbatches, and the obtained modified discarded and / or waste plastic masterbatches are mixed with antibacterial-agent-loaded fly ash through high temperature and high speed modification, then a second surface modification agent is added, high-temperature and high-speed processing and the two-screw extrusion are performed, and the obtained masterbatches are subjected vacuum-drying at low temperature and sealed and packaged. The problems existing in the process of recycling waste are utilized, the antibacterial agent is added to the discarded and / or waste plastics to obtain antibacterial plastic masterbatches, and the antibacterial plasticmasterbatches can be conveniently added to other plastics later to make antibacterial plastics.

Owner:ANHUI UNIV OF SCI & TECH +1

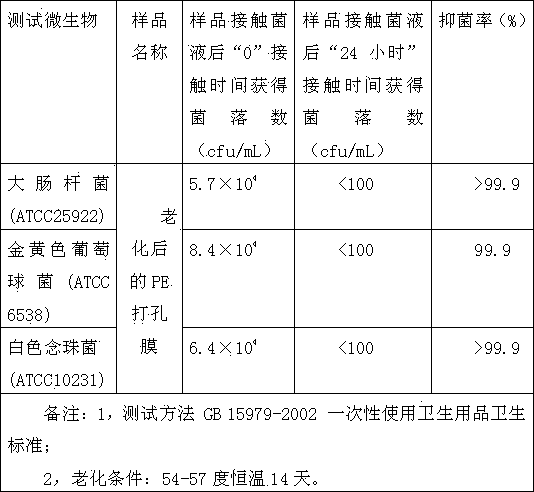

Antibacterial PE (Poly Ethylene) punched film, preparation process thereof and hygienic product therefrom

InactiveCN103432619AImprove long-lasting antibacterial performanceGood antibacterial effectAbsorbent padsBandagesPhosphoric acidAnti bacterial

The invention relates to an antibacterial PE (Poly Ethylene) punched film, which is used as a permeable layer on the surface of a hygienic product and is prepared from the following components in percentage by weight: 2-6% of antibacterial master batch, 0.1-0.3% of antioxidant, 1-5% of whitening master batch, 4-5% of PE punched film penetrant and 85-90% of polyethylene plastic, wherein the antibacterial master batch comprises the following components in percentage by weight: 10-20% of zirconium phosphate silver-loaded antibacterial powder and 80-90% of polyethylene plastic; and the whitening master batch is polyethylene master batch in which the percentage by weight of titanium dioxide is 48-52%. Since the inorganic silver antibacterial agent is added in the preparation process of the PE punched film, the prepared PE punched film and the hygienic product have the excellent long-lasting antibacterial effect; experiments prove that the antibacterial ratio can be up to 99.9%; furthermore, the PE punched film is nontoxic and harmless and is free from irritation and completely accords with national health standards; and the adverse effects on human-body health are eliminated. The invention discloses a preparation process of the PE punched film and the hygienic product prepared from the PE punched film.

Owner:XIAMEN JINDA IND

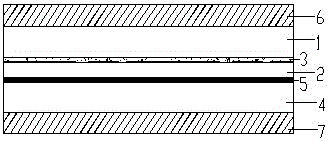

Nano permanent antibacterial antistatic cashmere product and production method thereof

InactiveCN106480712AImprove antibacterial propertiesImprove long-lasting antibacterial performanceAnimal fibresSilica gelBULK ACTIVE INGREDIENT

The invention relates to a nano permanent antibacterial antistatic cashmere product and a production method thereof. The cashmere product comprises 0.005-0.025% (by weight ratio) of nano silver, 0.01-0.1% (by weight ratio) of Artemisia argyi leaf extract and the balance cashmere, wherein the main antibacterial active ingredients of the Artemisia argyi leaf extract include Artemisia argyi terpene lactone, Artemisia argyi flavones and Artemisia argyi acid. The production method includes: a prepared Artemisia argyi leaf extract / nano silver composite antibacterial agent is dissolved into water according to the weight, organic silica gel is added into the solvent according to the weight ratio of 0.01:1, and uniform stirring is carried out for 30 minutes to prepare nano antibacterial coating. The cashmere product comprises cashmere garment upper fabric, a cashmere garment and cashmere garment lower fabric, wherein a nano organosilicon antibacterial layer is arranged between the cashmere garment upper fabric and the cashmere garment, organosilicon antistatic coating is arranged between the cashmere garment and the cashmere garment lower fabric, the outer surface of the cashmere garment upper fabric is provided with the nano antibacterial coating, and the outer surface of the cashmere garment lower fabric is provided with another nano antibacterial coating. Compared with the prior art, the cashmere product has the advantages that the nano moth-proof anti-mite antibacterial coating is added to the outer layer of the fabric on three sides of the cashmere garment, so that the cashmere product has a permanent antibacterial function and a permanent antibacterial antistatic function.

Owner:NANTONG BAOLAI CASHMERE FASHION CO LTD

Long-acting antibacterial dressing and preparation method thereof

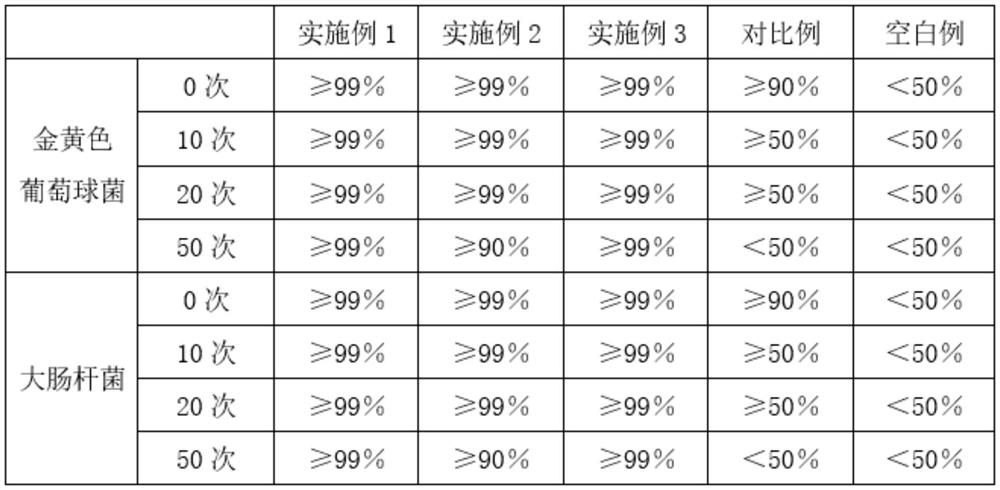

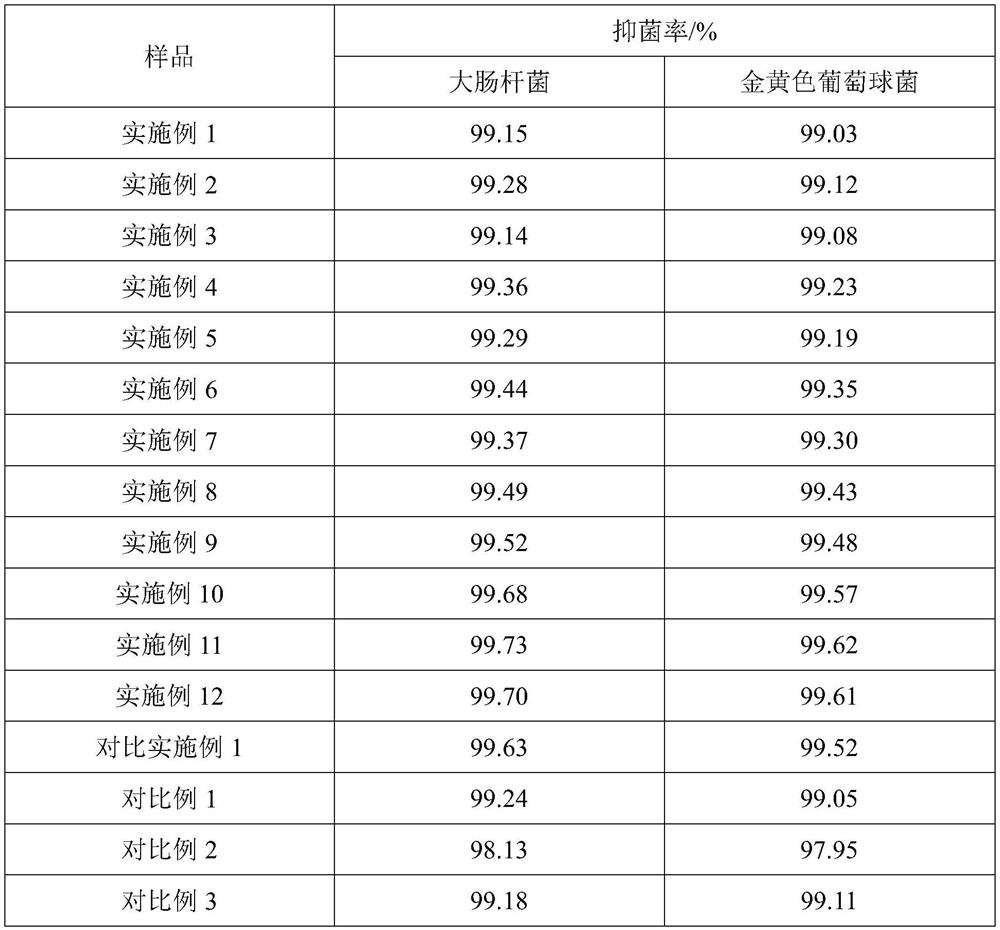

PendingCN111620988AGood skin adhesionImprove long-lasting antibacterial performanceAbsorbent padsBandagesPolymer science(Hydroxyethyl)methacrylate

The invention discloses a long-acting antibacterial dressing and a preparation method thereof. The preparation method comprises the step that a vinyl-terminated polysiloxane reaction monomer and a quaternary ammonium salt reaction monomer are prepared and subjected to free radical polymerization with acrylic acid and hydroxyethyl methacrylate, so the polysiloxane elastomer dressing with a cross-linked structure is prepared. According to the invention, a system contains a large number of polar groups (amide, carboxyl groups, hydroxyl groups and substituted ureido groups), so the elastomer dressing has good skin adhesion and percolate absorptivity; quaternary ammonium salt molecules are connected into an elastomer in a chemical crosslinking mode, so the dressing is endowed with a good and lasting antibacterial effect, and the elastomer dressing has potential application in wet dressings.

Owner:张玉花

Antibacterial finishing agent for fiber yarns and cloth and preparation method of antibacterial finishing agent

The invention discloses an antibacterial finishing agent for fiber yarns and cloth and a preparation method of the antibacterial finishing agent. The antibacterial finishing agent is composed of the following components in parts by weight of 1-10 parts of modified tourmaline nano powder, 0.2-2 parts of poly(diallyl dimethyl ammonium chloride), 0.5-5 parts of hydroxyethyl cellulose and 100 parts of deionized water. The prepared antibacterial finishing agent is safe to human bodies and free of toxic and side effects, and tourmaline can emit oxygen negative ions and infrared rays and has a beneficial effect on human health; and the antibacterial finishing agent disclosed by the invention has relatively strong reusability, and can play a long-lasting strong antibacterial role.

Owner:DONGGUAN SHIHAO NEW MATERIAL BIOTECHNOLOGY CO LTD

Antibacterial thermal underwear and production process thereof

InactiveCN112501763AImprove stabilityGuaranteed dispersion stabilityWeft knittingHollow filament manufactureYarnFiber

The invention relates to the field of clothes, and particularly discloses antibacterial thermal underwear and a production process thereof. The antibacterial thermal underwear comprises a surface layer, wherein the surface layer is formed by blending various fibers including antibacterial fibers, and the antibacterial fibers are nano-silver / chitosan / polylactic acid composite fibers; the preparation method of the antibacterial thermal underwear comprises the following steps of S1, spinning, namely, blending various fibers including the antibacterial fibers to prepare blended yarns; S2, weaving,namely, weaving the blended yarns by adopting a single-sided and double-sided alternate weaving mode to weave gray cloth; S3, napping, namely, napping the skin-friendly surface of the gray cloth to obtain napped gray cloth; S4, dyeing, namely, dyeing the napped gray cloth; and S5, sewing, namely, sewing the dyed napped gray cloth to prepare a finished product of the thermal underwear. The thermalunderwear prepared by the invention has good lasting antibacterial property.

Owner:武汉猫人云商科技有限公司

Breathable waterproof anti-ultraviolet fabric and preparation method and application thereof

InactiveCN108660580AHigh strengthImprove wear resistanceBiochemical fibre treatmentWoven fabricsPolyesterUltraviolet

The invention relates to the field of outdoor fabrics, in particular to a breathable waterproof anti-ultraviolet fabric, and further relates to a preparation method and application of the breathable waterproof anti-ultraviolet fabric. The fabric is made from an anti-ultraviolet gray fabric with coated nano-silver on the surface, wherein the anti-ultraviolet gray fabric is formed by, by weight, 40-50 parts of ultraviolet modified PVC, 30-40 parts of polypropylene and 10-20 parts of polyester through mixed weaving. The preparation technology is simple and easy to implement, the materials for usage are conventional in the field and cheap, and the made fabric not only has the properties of high strength, abrasion resistance and others, but also has the properties of good water prevention, airbreathing and ultraviolet resistance, and also has the excellent properties of bacterium resistance and bacterium restraining.

Owner:深圳市好美佳智能家居股份有限公司

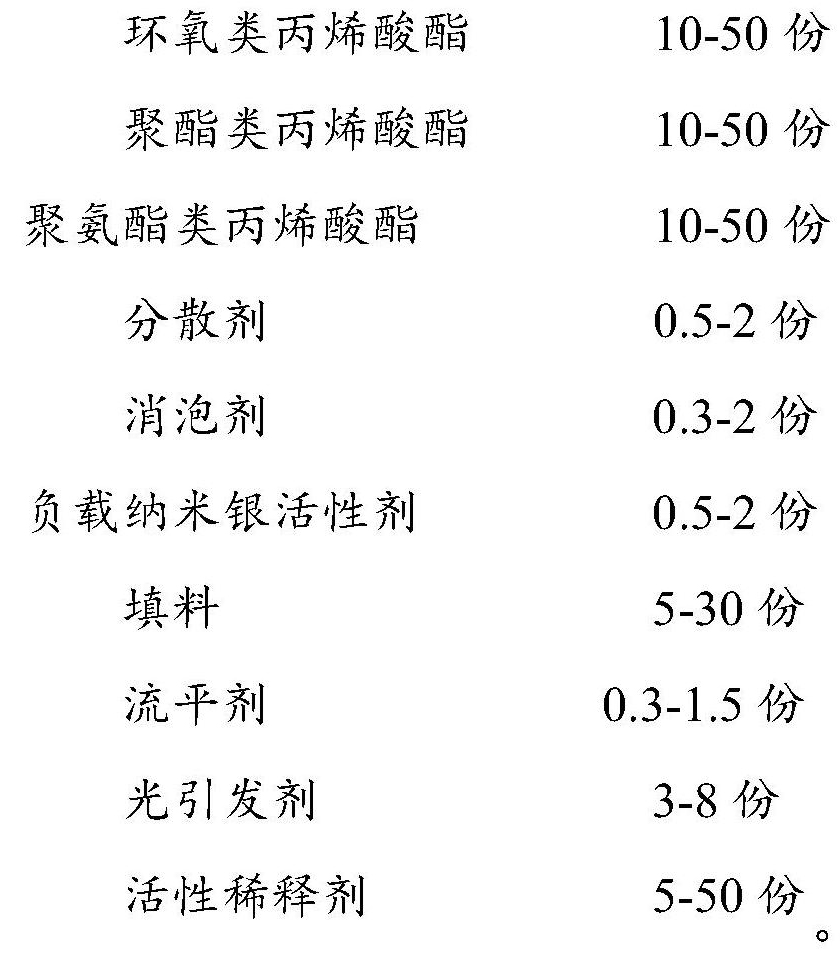

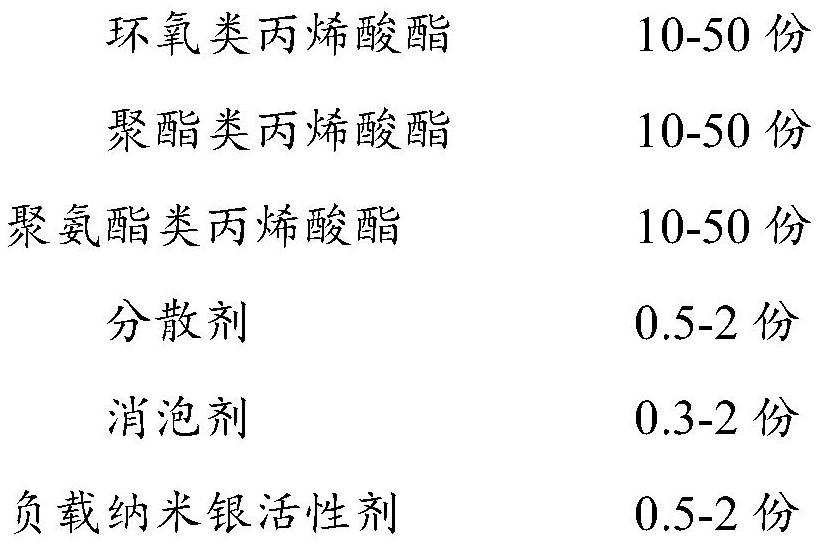

Efficient antibacterial and antiviral two-in-one odorless radiation curable coating and preparation method thereof

InactiveCN112143350ALong-lasting antibacterial and antiviral effectReduce coating odorAntifouling/underwater paintsPaints with biocidesPolyesterPolymer science

The invention relates to an efficient antibacterial and antiviral two-in-one odorless radiation curable coating and a preparation method thereof. The efficient antibacterial and antiviral two-in-one odorless radiation curable coating is prepared from the following components in parts by weight: epoxy acrylate, polyester acrylate, polyurethane acrylate, a dispersing agent, an antifoaming agent, a nano-silver-loaded active agent, a filler, a leveling agent, a photoinitiator and an active diluent. According to the invention, only one antibacterial and antiviral active agent is selected to achieveefficient and lasting antibacterial and antiviral effects; the photoinitiator disclosed by the invention can reduce the odor of a coating film and achieve an odor removal effect; during construction,various curing means such as UV curing and LED curing can be adopted; the efficient antibacterial and antiviral active agent is a nano-silver active agent loaded on glass beads, can control slow release of silver ions, and has good lasting antibacterial property.

Owner:三棵树(上海)新材料研究有限公司

Ferrite antibacterial stainless steel for low-chrome copper-containing dishware and manufacturing method thereof

ActiveCN100386461CFlexible structureAdaptableTemperature control deviceHeat treatment process controlOxygenCopper

Disclosed is a ferrite antibacterial stainless steel for low-chrome copper-containing dishware and manufacturing method, wherein the stainless steel matrix comprises (by wt%) Cr 12.0-14.0%, Cu 0.70-2.20%, C <=0.08-0.15, the preparing process comprises pre-processing melted iron, passing through composite revolving furnace, vacuum oxygen decarbonization furnace, refined-smelting ladle furnace, continuous plate blank casting, casting blank annealing, tandem rolling, and annealing in a bell-type furnace.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

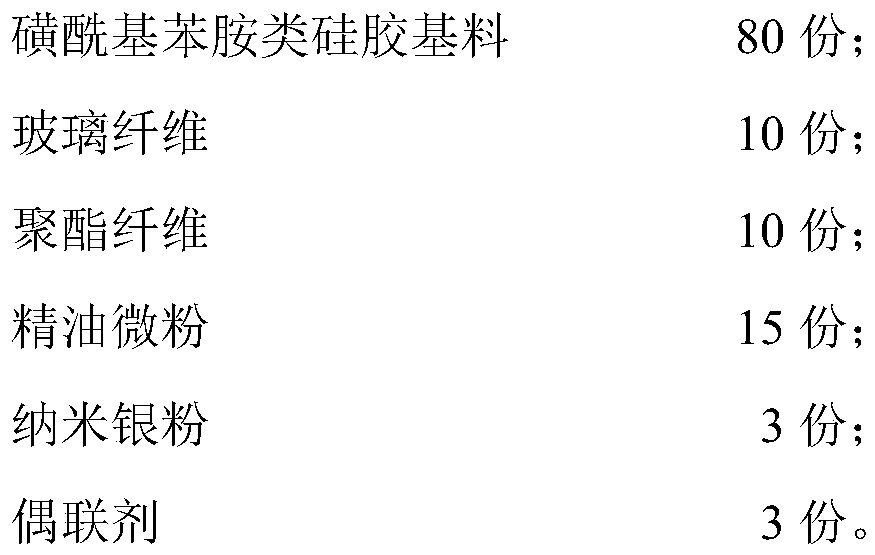

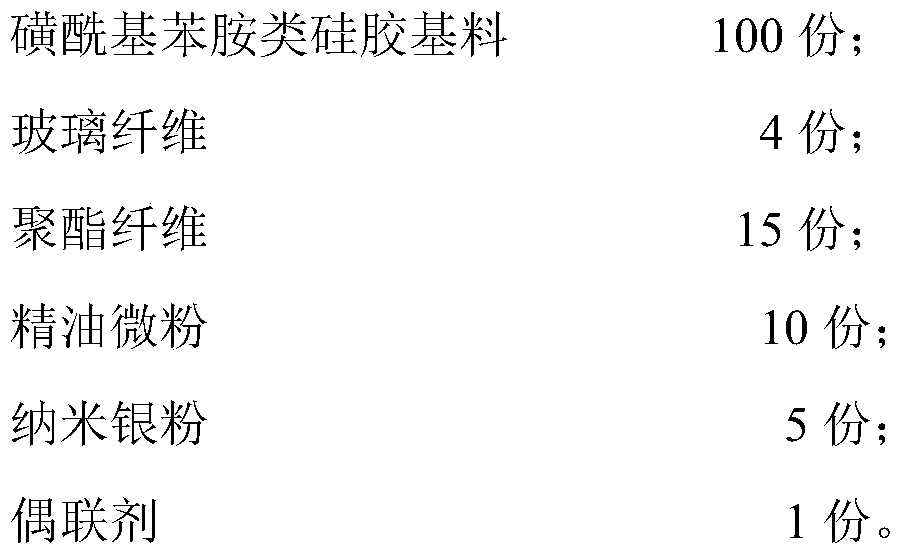

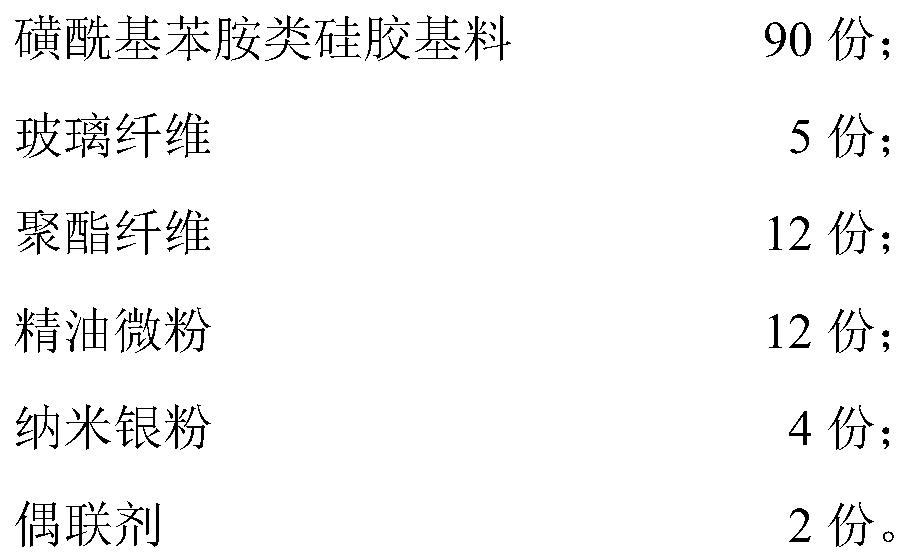

Medical antibacterial silica gel material

PendingCN111040456AImprove long-lasting antibacterial performanceImprove thermal stabilityPolyesterFiber

The invention discloses a medical antibacterial silica gel material. The medical antibacterial silica gel material comprises, by weight, 80-100 parts of a sulfonyl aniline silica gel base material, 4-10 parts of a glass fiber, 10-15 parts of a polyester fiber, 10-15 parts of essential oil micropowder, 3-5 parts of nano-silver powder and 1-3 parts of a coupling agent. Antibacterial components are introduced through the essential oil micropowder and the nano-silver powder, and the sulfonyl aniline silica gel base material is used as a silica gel main body material, so that the long-acting antibacterial property of the silica gel material is effectively improved, and meanwhile, the medical antibacterial silica gel material has good thermal stability, antifouling property and mechanical property.

Owner:FOSHAN UNIVERSITY

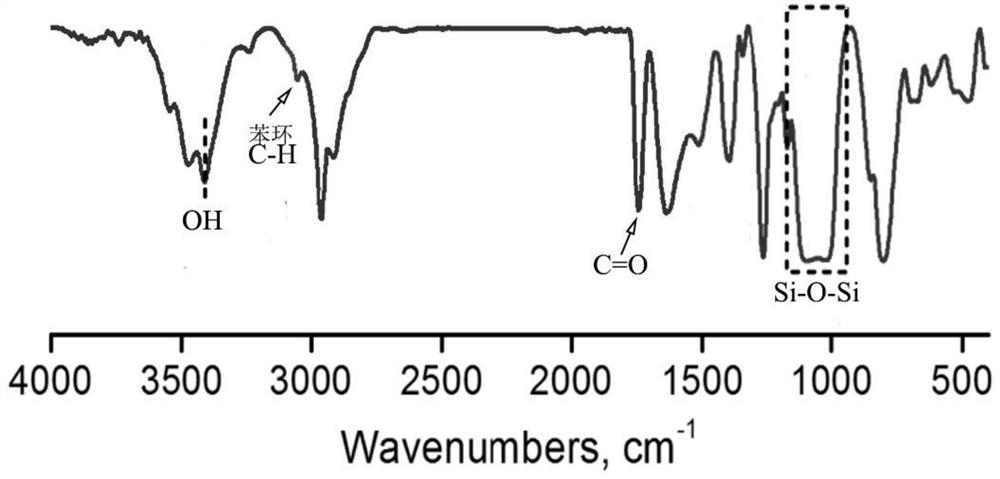

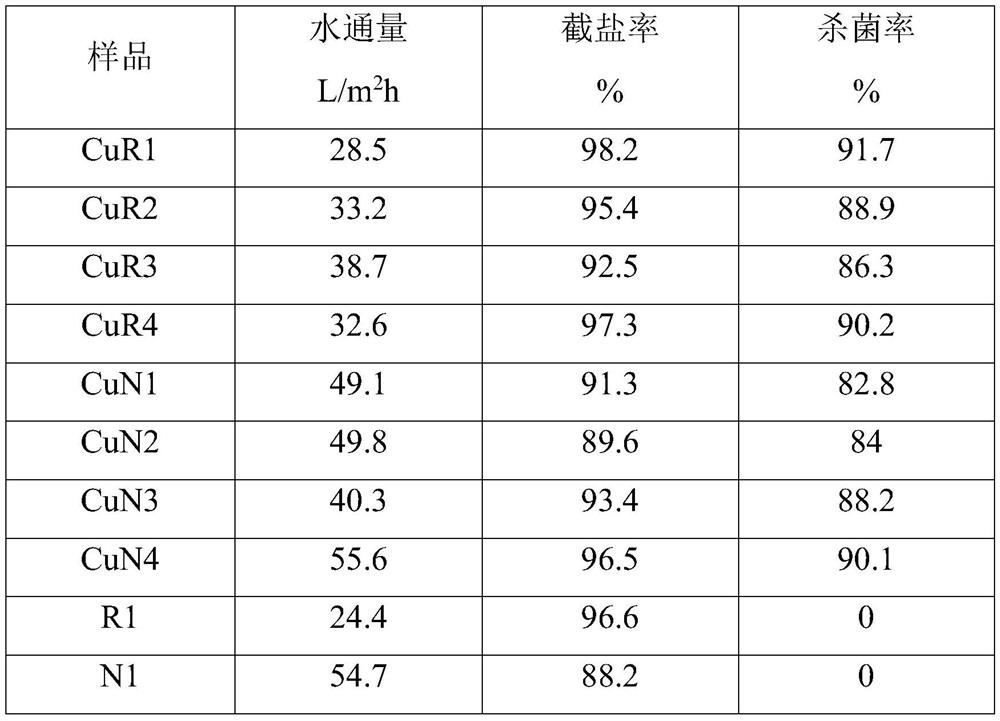

Copper-containing antibacterial thin-layer composite film as well as preparation method and application thereof

PendingCN112516812AImprove long-lasting antibacterial performanceLong-term bactericidal effectMembranesSemi-permeable membranesPolyamideCopper oxide

The invention discloses a copper-containing antibacterial thin-layer composite film as well as a preparation method and application thereof. The composite film comprises an enhancement layer, a supporting layer and a separation layer, wherein the separation layer is located on one surface of the supporting layer, the enhancement layer is located on the other surface of the supporting layer, the supporting layer is a polymer porous membrane, the separation layer is a polyamide separation layer loaded with copper hydroxide, and the mass content of elemental copper in the separation layer is 0.5-10 wt%. The preparation method comprises the following steps: firstly, preparing a polyamine solution and a polyacyl chloride solution of copper hydroxide; and sequentially contacting the supporting layer with the polyamine solution and the polyacyl chloride solution of copper hydroxide, and carrying out heat treatment. The copper-containing antibacterial thin-layer composite film prepared according to the invention has the advantages of lasting antibacterial performance, simple preparation process, suitability for mass production and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

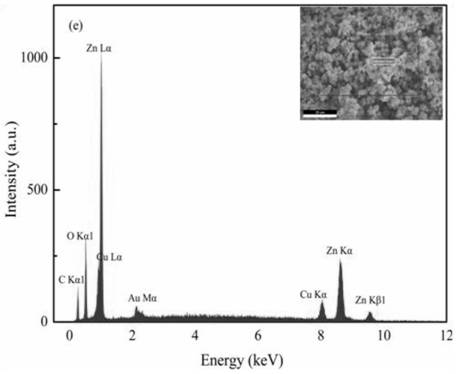

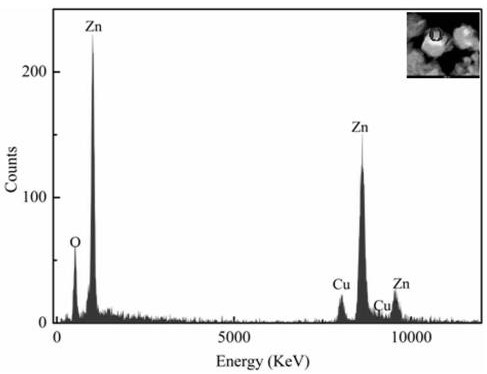

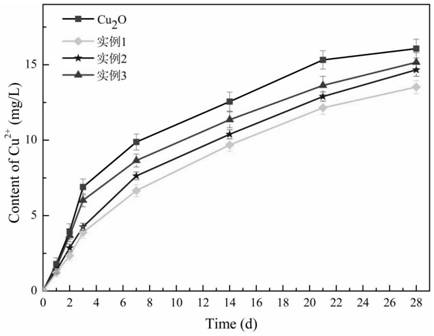

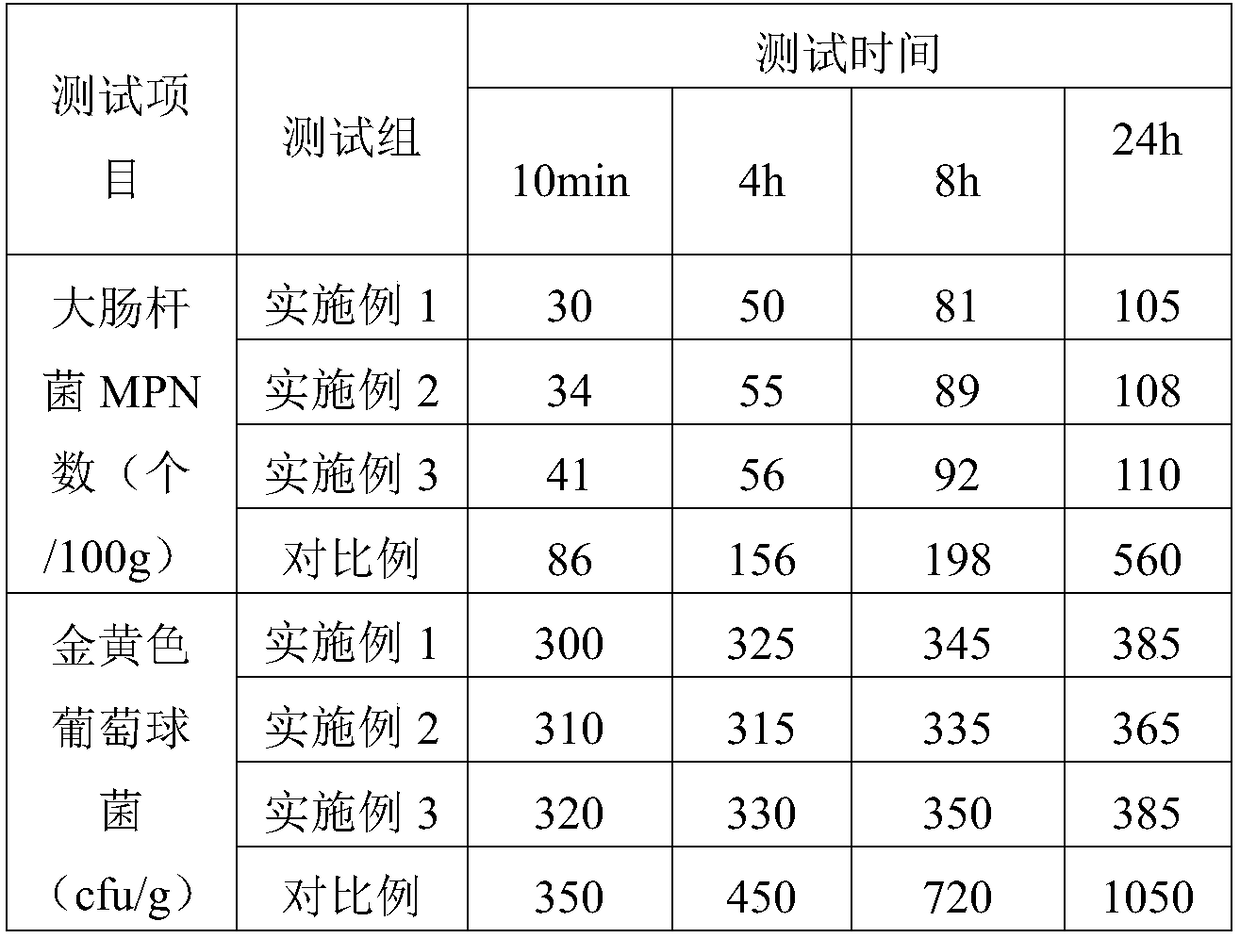

Preparation method of cuprous oxide-zinc oxide core-shell antibacterial material

InactiveCN113349220ASolve the violent releaseFix instabilityBiocideFungicidesPhysical chemistryAnti bacterial

The invention discloses a preparation method of a cuprous oxide-zinc oxide core-shell antibacterial material. The method comprises the following steps: preparing cubic cuprous oxide by a liquid phase reduction method, and coating the cuprous oxide with zinc oxide by a precipitation method to obtain the durable antibacterial core-shell antibacterial material. The material prepared by the invention combines the characteristics of N-type semiconductor zinc oxide and P-type semiconductor cuprous oxide, and the problems of sudden release, instability, short antibacterial timeliness and the like of the cuprous oxide are solved by wrapping the cuprous oxide with the zinc oxide, so that the cuprous oxide-zinc oxide core-shell antibacterial material prepared by the method has a good application prospect in the antibacterial field.

Owner:KUNMING UNIV OF SCI & TECH

Antibacterial post treatment method of latex gloves

InactiveCN108690212AComfortable to wearImprove long-lasting antibacterial performanceAntifouling/underwater paintsPaints with biocidesChemistryPost treatment

The invention discloses an antibacterial post treatment method of latex gloves. After latex base materials are added into a glove model, a low-temperature plasma treatment process is performed; afterthe treatment, through a series of technical flow process, a semifinished product is obtained; next, the semifinished product is put into an antibacterial sorting agent prepared from 55 percent of antibacterial plant extracts, 10 percent of nanometer silver ion solutions, 1 percent of povidone solution and the balance deionized water to be treated; after the semifinished product is taken out and is washed by water, drying treatment is performed by using a vacuum drying process; next, a latex glove finished product is obtained. The latex gloves prepared after the treatment by the antibacterialpost treatment method provided by the invention have the advantages that the wearing feeling and the touch feeling are comfortable; the excellent and durable antibacterial capability is realized.

Owner:镇江华扬乳胶制品有限公司

Nanometre Ag antibacterial aqueous woodware paint and its preparation method

InactiveCN100387666CSolve technical problems that are difficult to applyImprove securityAntifouling/underwater paintsPaints with biocidesWater basedAdjuvant

Disclosed is a nano Ag antibacterial aqueous woodware paint and its preparation method, wherein the paint comprises (by weight ratio) water-based resin 700-900, delustring agent 0-20, wetting agent 1-10, levelling agent 1-5, defoaming agent 1-15, thickening agent 2-20, hand feeling agent 20-100, nano silver antibacterial agent 0.01-100, film forming adjuvant 5-100, water 0-300. The paint has the function of broad spectrum disinfection.

Owner:SAT INT GROUP

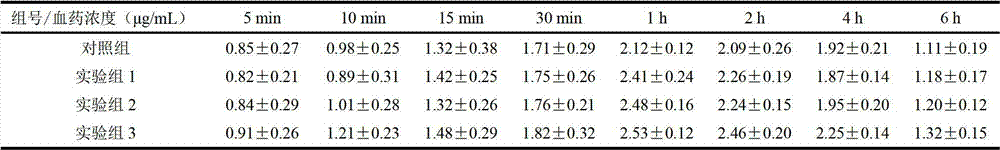

Doxycycline hydrochloride for livestock compound injection and preparation method thereof

InactiveCN102846649AEnhance long-lasting antibacterial effectLong-acting treatmentAntibacterial agentsTetracycline active ingredientsChemistryMagnesium

The invention discloses a doxycycline hydrochloride compound injection for livestock and a preparation method thereof, and belongs to the field of drugs for livestock. Per 100mL of the injection mainly comprises the following components, by weight: 5-10 g of doxycycline hydrochloride, 3-5 g of azithromycin, 20-30 g of propylene glycol, 15-25 g of alpha-pyrrolidone, 8-10 g of anhydrous ethanol, 1-2 g of PVP K30, 5-6 g of magnesium oxide, 0.3-0.5 g of sodium formaldehyde sulfoxylate, 3.2-3.5 g of ethanol amine, and the balance of water for injection. According to the invention, doxycycline hydrochloride and azithromycin are compounded to fully play quick-acting antibacterial activity of azithromycin on the basis of realizing long-acting antibacterial effect of doxycycline hydrochloride; drug concentration in body is effectively maintained during the application period, so as to realize efficient, quick-acting and long-acting treatment effect of the drug, and to avoid the inconvenience caused by repeated dosing by veterinary; and the prepared injection has stable quality, and has accurate and fast curative effect on livestock diseases caused by acute moderate and severe infection.

Owner:ZHENGZHOU HOUYI PHARMA

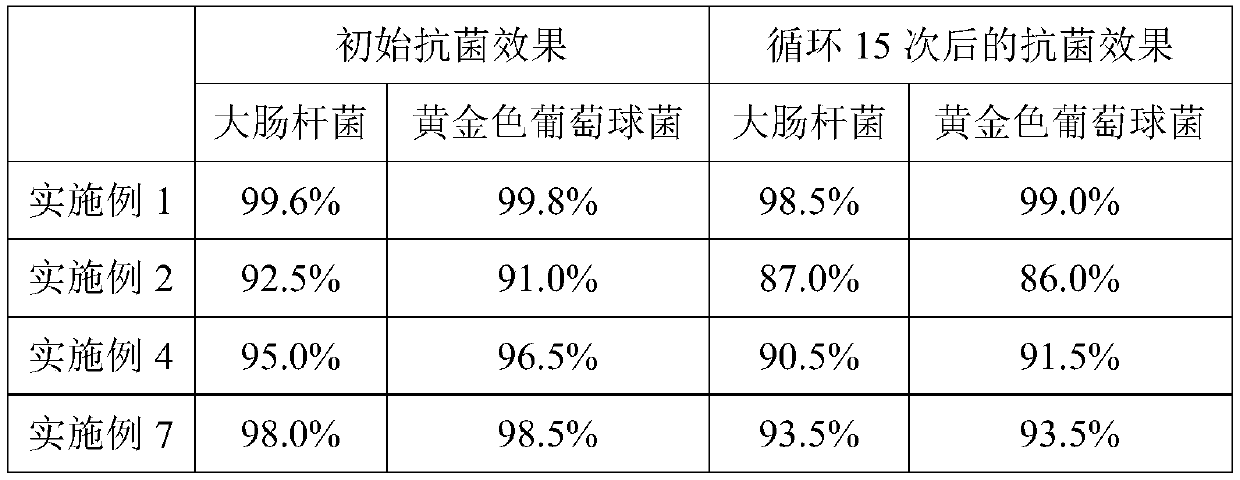

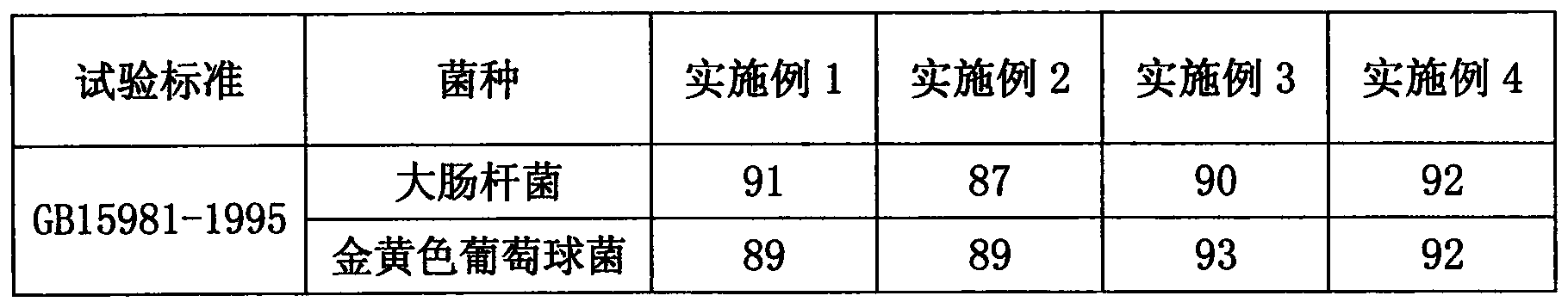

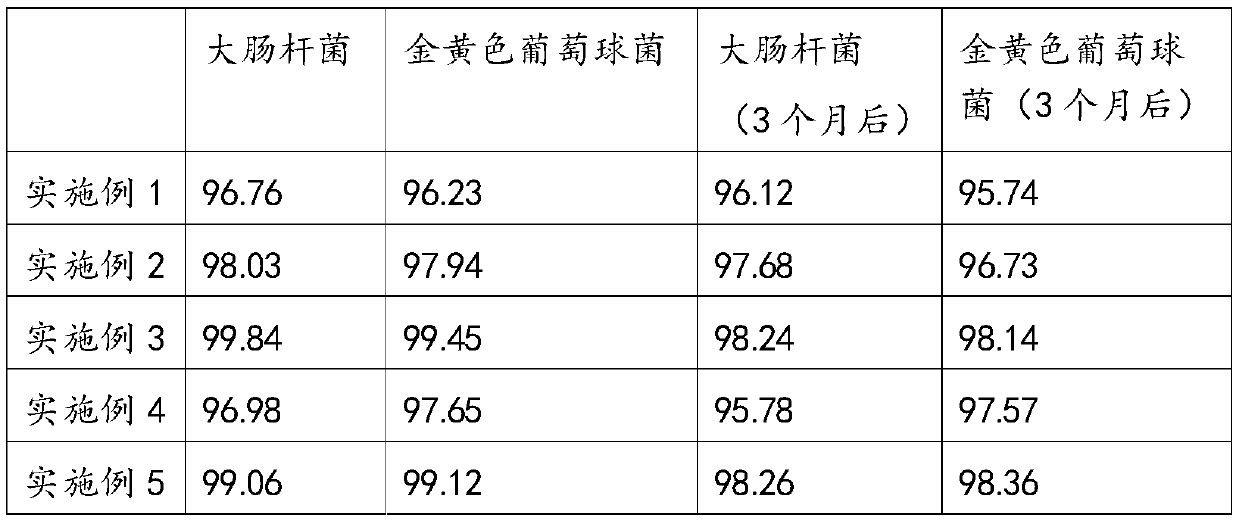

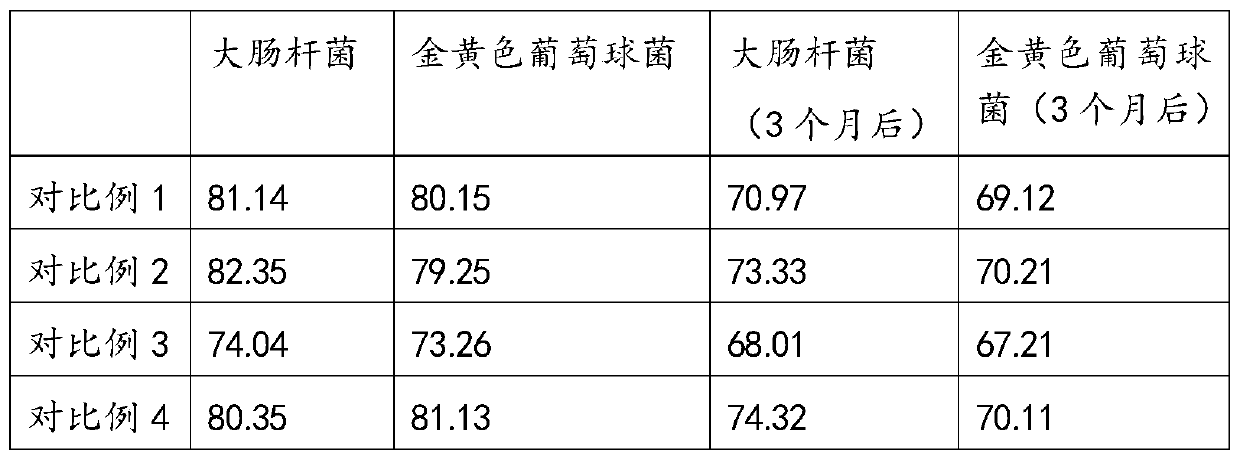

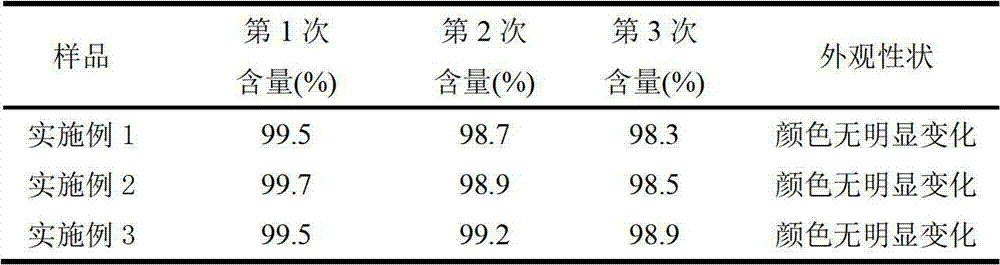

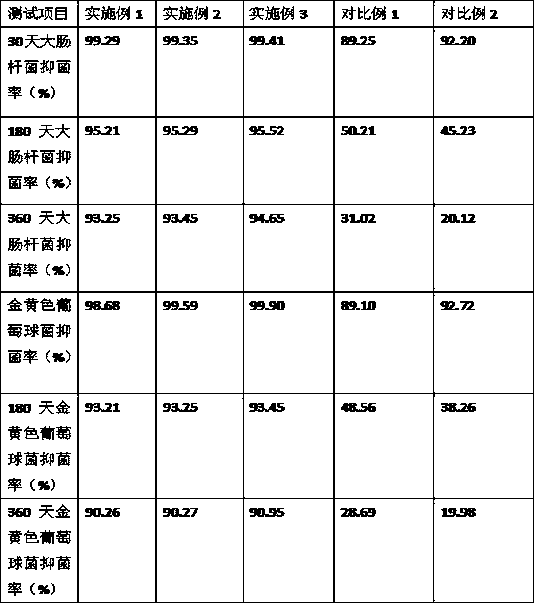

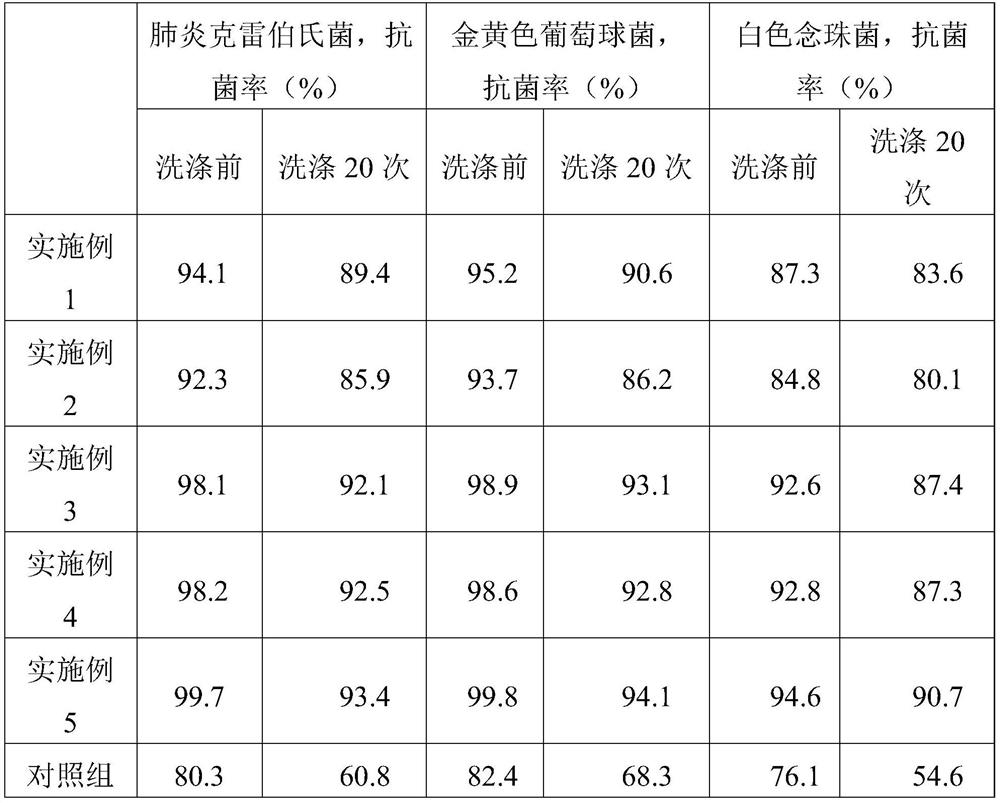

Long-acting antibacterial fabric rich in silver ion fibers and preparation method of long-acting antibacterial fabric rich in silver ion fibers

InactiveCN110699822ASmall molecular weightImprove antibacterial propertiesConjugated cellulose/protein artificial filamentsWoven fabricsFiberPolymer science

The invention belongs to the technical field of textile material preparation and relates to a long-acting antibacterial fabric rich in silver ion fibers and a preparation method of the long-acting antibacterial fabric rich in silver ion fibers. The method includes: firstly, subjecting oak bark fibers and citric acid to mixed soaking, and defiberizing preliminarily; secondly, mechanically defiberizing through a wooden hammer to obtain degummed oak bark fibers; thirdly, soaking the oak bark fibers in N-methylmorpholine solution to obtain pre-modified fibers; fourthly, mixing the pre-modified fibers with water, performing high-temperature high-pressure cooking, mixing with mussel mucin solution, adding catechol oxidase, and performing reaction to obtain modified oak bark fibers; fifthly, mixing the modified oak bark fibers with sodium polyphosphate and silver nitrate solution, and performing reaction to obtain self-made sliver ion fibers; finally, compounding the silver ion fibers, polyurethane fibers and viscose fibers to finally obtain the long-acting antibacterial fabric rich in silver ion fibers. According to detection data in a table as shown in the specification, the long-actingantibacterial fabric has remarkable antibacterial effects and long antibacterial action, thereby having a promising application prospect.

Owner:吴芳

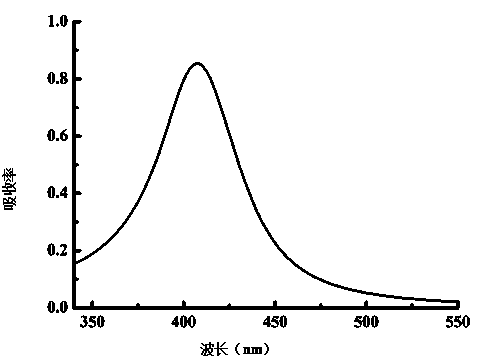

Hydrophobic durable antibacterial polypropylene composite material and preparation method thereof

PendingCN114213755AImprove long-lasting antibacterial performanceGood antibacterial effectPolymer scienceOctene

The invention relates to a hydrophobic durable antibacterial polypropylene composite material and a preparation method thereof. The hydrophobic lasting antibacterial polypropylene composite material provided by the invention comprises the following components in parts by mass: 75-100 parts of polypropylene; 5-15 parts of functional hydrophobic master batch; 0.3-0.8 part of a silver ion antibacterial agent taking phosphate glass as a carrier; 1-3 parts of silicone oil; and 0.5-1 part of an auxiliary agent. The functional hydrophobic master batch comprises an ethylene-octylene copolymer, low-density polyethylene, PTFE (Polytetrafluoroethylene) and a hydrophobic agent in a mass ratio of (15-20): 100: 15: (5-15). The polarity of the surface of the prepared polypropylene compound is improved, and due to the structural characteristics of the composite polypropylene material, the antibacterial property in the material can continuously migrate to the surface, so that the condition that an antibacterial agent loses efficacy in a complex environment is overcome.

Owner:上海日之升科技有限公司

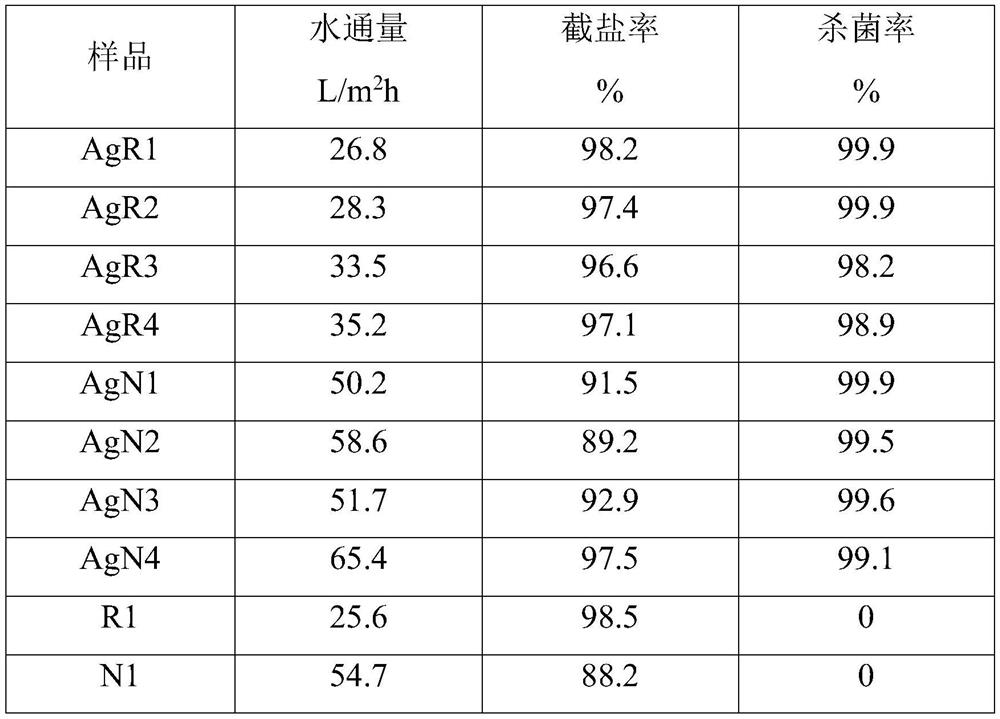

Method for preparing antibacterial polyester by use of plant nano-silver

The invention discloses a method for preparing antibacterial polyester by use of plant nano-silver. The method comprises the following steps of: performing surface structure modification pretreatment on the polyester fiber / fabric pretreated by refining liquid by a low-temperature plasma or alkali de-weighting method; and placing the product in plant nano-silver hydrosol for impregnation treatment, or soaking the pretreated polyester fiber / fabric in a silver-ammonia solution, and then transferring to a plant leaf extract liquid-soluble starch composite solution for impregnation treatment to obtain the antibacterial polyester fiber or fabric prepared by use of plant nano-silver. According to the invention, through surface structure modification of polyester, the adsorption capacity of the polyester to nano-silver particles or silver ions is enhanced, the adsorption quantity is obviously increased, and the nano-silver can be attached for a long time without loss; and the obtained polyester fiber / fabric shows excellent and lasting antibacterial performance, and the wet absorption and air permeability, the anti-static ability, the dyeing performance and the like are obviously improved.

Owner:SUZHOU UNIV

Silver-containing antibacterial thin-layer composite film as well as preparation method and application thereof

PendingCN112516811AImprove long-lasting antibacterial performanceLong-term bactericidal effectMembranesSemi-permeable membranesPolyamideMass content

The invention discloses a silver-containing antibacterial thin-layer composite film as well as a preparation method and application thereof. The composite film comprises an enhancement layer, a supporting layer and a separation layer, wherein the separation layer is located on one surface of the supporting layer, the enhancement layer is located on the other surface of the supporting layer, the supporting layer is a polymer porous membrane, and the separation layer is a polyamide separation layer loaded with a silver-containing compound, wherein the mass content of the elemental silver in theseparation layer is 0.1-10 wt%. The preparation method comprises the following steps: firstly, preparing a polyamine solution and a polyacyl chloride solution of a silver compound; and sequentially contacting the supporting layer with the polyamine solution and the polyacyl chloride solution containing the silver compound, and carrying out heat treatment. The silver-containing antibacterial thin-layer composite film prepared according to the invention has the advantages of lasting antibacterial performance, simple preparation process, suitability for mass production and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Women's shoes with antibacterial soles

InactiveCN113278209AImprove long-lasting antibacterial performanceExcellent long-lasting wear resistanceSolesPolymer scienceVulcanization

The invention discloses women's shoes with antibacterial soles. The soles are prepared from the following raw materials: butadiene rubber, an acrylonitrile-butadiene-styrene terpolymer, diphenylmethane diisocyanate, 1, 2-polyethylene, dioctyl phthalate, a wear-resistant agent, a foaming agent, a coupling agent, a cross-linking agent, an assistant cross-linking agent, zinc stearate, octadecanoic acid, tert-butylhydroquinone, carbodiimide, zinc oxide, sulfur, a vulcanization accelerator, an antibacterial agent and antiskid filler. The prepared women's shoes with the antibacterial soles are excellent and durable in antibacterial property and wear resistance, and also have good anti-skid property and mechanical property.

Owner:新泰华(惠州)制鞋科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com