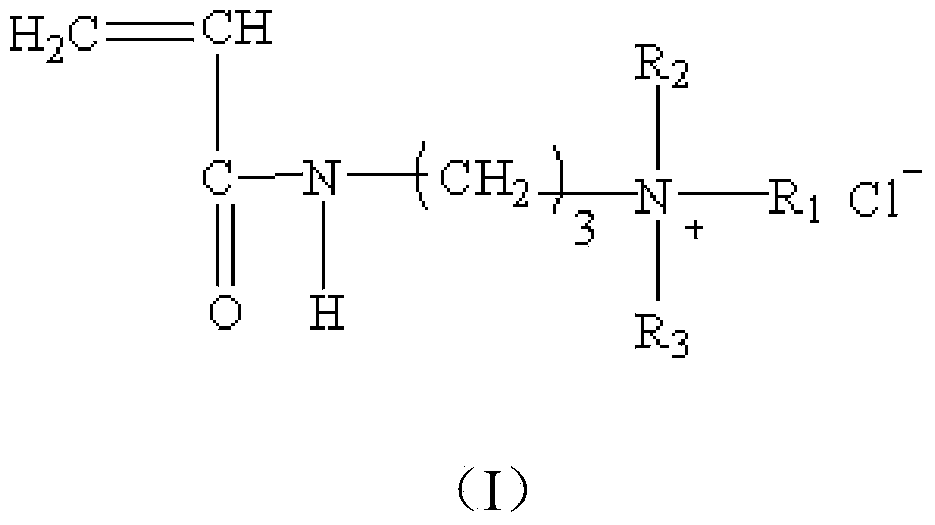

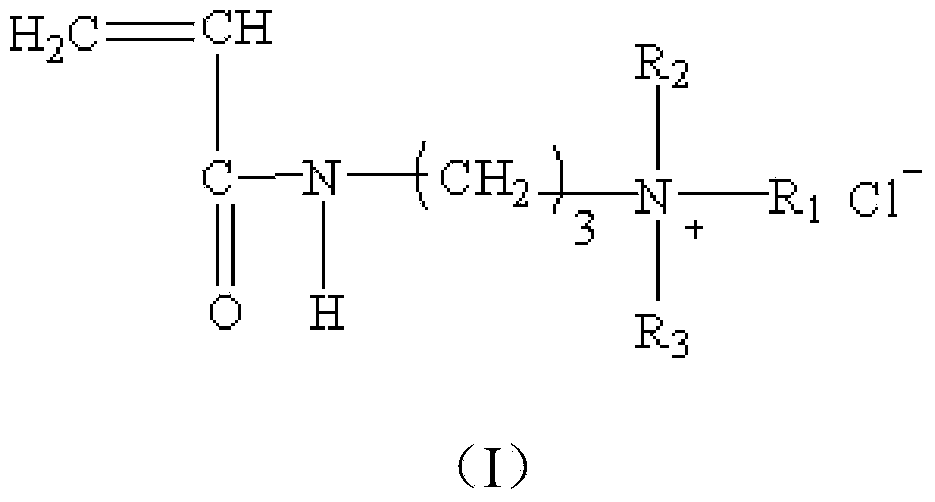

Preparation method of olefine halamine compound grafted antibacterial cotton fabric containing quaternary ammonium groups

A technology of quaternary ammonium groups and olefins, which is applied in the field of preparation of antibacterial cotton fabrics, can solve the problems of increased finishing and wastewater treatment costs, reduced tensile fracture strength of fabrics, and high finishing temperature of haloamine compounds, so as to reduce the cost of antibacterial finishing. Short time, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add (3-acrylamidopropyl) trimethylammonium chloride that final concentration is 100g / L to water, add the initiator sodium persulfate that final concentration is 0.1mol / L again, configure finishing liquid; The fabric is placed in the finishing solution, reacted at 60°C for 3 hours, and then washed with detergent for 15 minutes to remove unreacted monomer substances on the surface, then washed with clean water to remove the detergent on the surface of the fabric, after drying, wash with 10wt% sodium hypochlorite solution Chlorination for 1 hour, washing and drying to obtain the finished antibacterial cotton fabric. After testing, the effective chlorine content of the finished fabric is 0.06%.

Embodiment 2

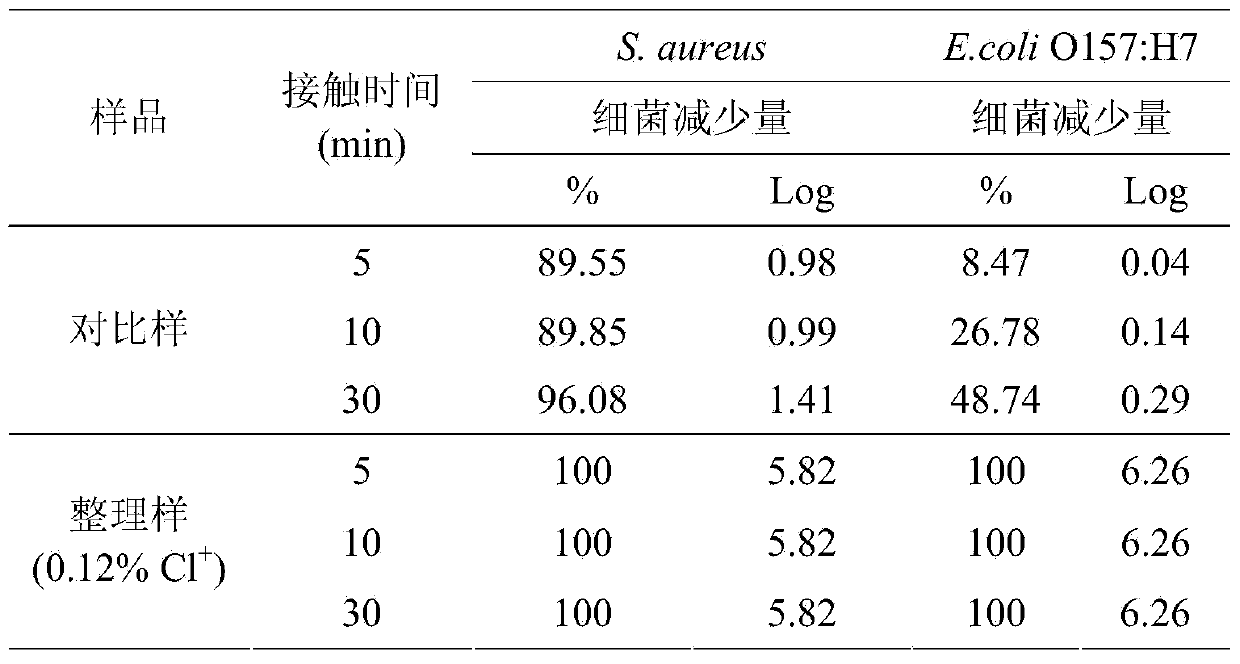

[0024] Add (3-acrylamidopropyl) trimethylammonium chloride that final concentration is 100g / L in water, add the initiator potassium persulfate that final concentration is 0.3mol / L again, configure finishing liquid; The fabric is placed in the finishing solution, reacted at 60°C for 3 hours, and then washed with detergent for 15 minutes to remove unreacted monomer substances on the surface, and then washed with clean water to remove the detergent on the surface of the fabric. After drying, chlorinated with 10wt% sodium hypochlorite solution for 1 hour, washed and dried to obtain the finished antibacterial cotton fabric. After testing, the effective chlorine content of the finished fabric was 0.12%.

Embodiment 3

[0026] Add (3-acrylamidopropyl) trimethylammonium chloride that final concentration is 100g / L in water, add the initiator potassium persulfate that final concentration is 0.4mol / L again, configure finishing liquid; The fabric is placed in the finishing solution, reacted at 70°C for 3 hours, and then washed with detergent for 15 minutes to remove unreacted monomer substances on the surface, and then washed with clean water to remove the detergent on the surface of the fabric. After drying, chlorinated with 10wt% sodium hypochlorite solution for 1 hour, washed and dried to obtain the finished antibacterial cotton fabric. After testing, the effective chlorine content of the finished fabric is 0.10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com