Preparation method of functional powder coating

A powder coating and functional technology, which is applied in the preparation of functional powder coatings, can solve the problems of poor adhesion of inorganic antibacterial agents, harm to human health, heavy metal pollution, etc., and achieve good antibacterial effect, scientific compatibility and strong adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

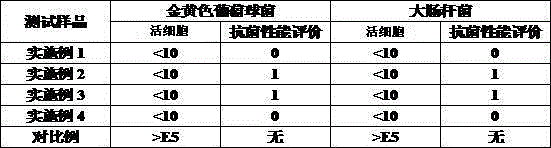

Examples

Embodiment 1

[0025] The formula of functional powder coating is as follows:

[0026] Phenolic modified epoxy resin 40%, bisphenol A epoxy resin 25%, curing agent 3%, accelerator 1%, leveling agent 1%, pigment 2%, filler 26%, antioxidant 1%, inorganic Antimicrobial 1%.

[0027] The curing agent in the formula is PSG-01 phenolic curing agent, the accelerator is dimethylimidazole, the leveling agent is BD-3376 leveling agent, and the filler is ultrafine barium sulfate and CaCO 3 Mixed according to the mass ratio of 2:1, the antioxidant is composite antioxidant JY-215, and the inorganic antibacterial agent is nano-silver inorganic antibacterial agent RHA-1.

[0028] When preparing, weigh all the components except the inorganic antibacterial agent, and pre-mix the raw materials; melt and extrude the pre-mixed materials, extrusion parameters: 100°C in the first zone and 100°C in the second zone, screw speed 45HZ ; The above-mentioned extruded material is cooled, followed by coarse crushing to ...

Embodiment 2

[0030] A functional powder coating, the parts by weight and preparation method of each component in the formula are the same as in Example 1, compared with Example 1, the components in the formula have the following differences:

[0031] The curing agent in the formula is PSG-02 phenolic curing agent, the accelerator is dimethylimidazole, the leveling agent is a mixture of butyl cellulose and hydroxymethyl cellulose in a weight ratio of 2:1, and the antioxidant is Compound antioxidant JY-255.

Embodiment 3

[0033] The formula of a kind of functional powder coating is as follows:

[0034] Phenolic modified epoxy resin 40%, bisphenol A epoxy resin 25%, curing agent 3%, accelerator 1%, leveling agent 1%, pigment 2%, filler 26.5%, antioxidant 1%, inorganic Antimicrobial agent 0.5%.

[0035] The selection and preparation method of each component in the formula are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com