Antibacterial thermal underwear and production process thereof

A technology of thermal underwear and antibacterial fiber, applied in the field of clothing, can solve the problems of thermal underwear antibacterial effect reduction, insufficient stability of silver particles, easy to fall off, etc., achieve excellent stability, ensure stability, and improve the effect of antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

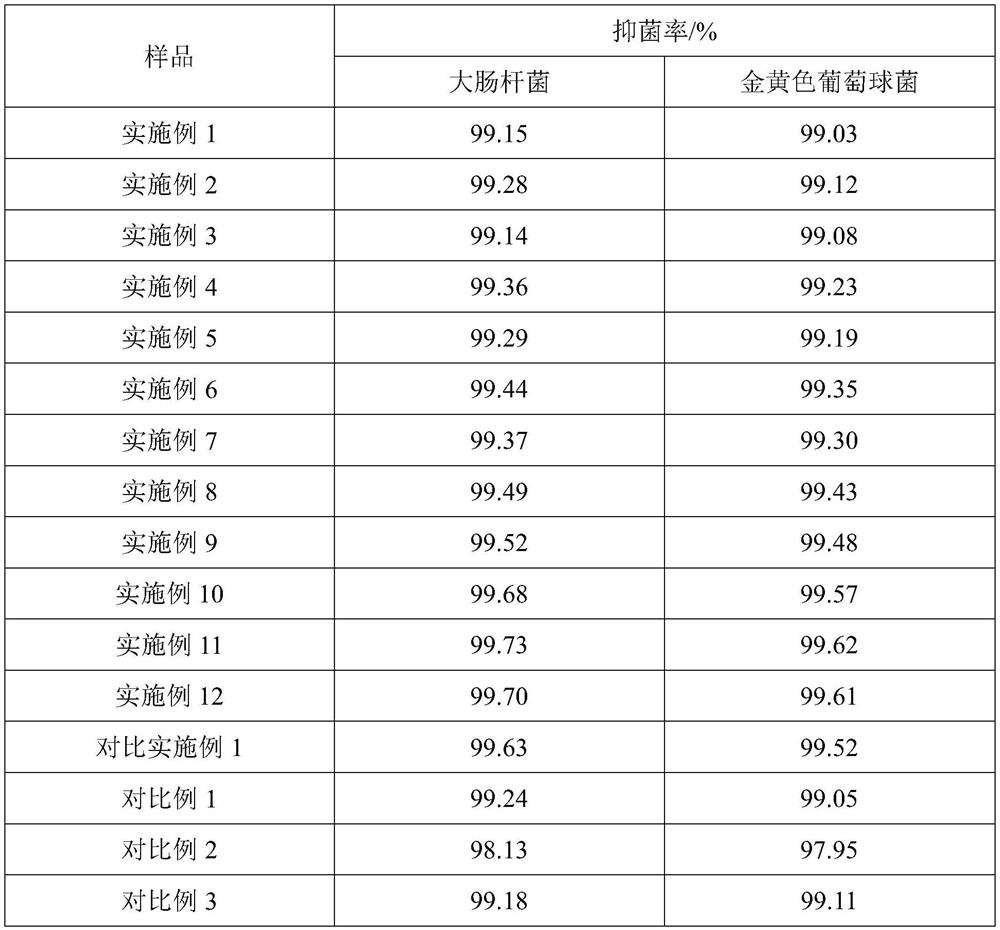

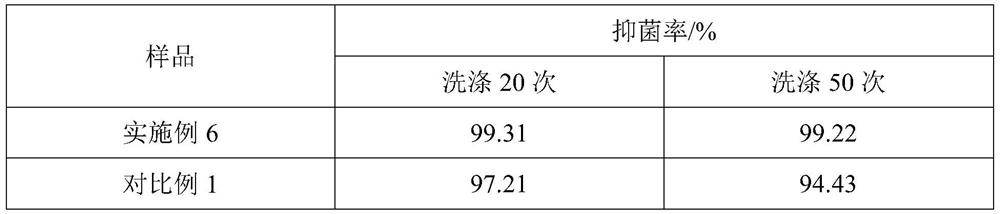

Examples

preparation example 1

[0037] The preparation method of nano-silver / chitosan / polylactic acid composite fiber is: 1) polylactic acid resin is sliced, and after carrying out vacuum drying, is heated to molten state, makes molten liquid; 2) chitosan is dissolved in 0.5% acetic acid aqueous solution, and stir evenly to obtain a chitosan solution; 3) add the amino nano-silver solution and the chitosan solution to the melt, and stir evenly to obtain a blend, the amino nano-silver solution, the shell The mass ratio of polysaccharide solution to polylactic acid melt is 0.1:0.4:1; 4) Extrude, filter, spin, cool, and stretch the blend to obtain nano silver / chitosan / poly Lactic acid composite fiber.

preparation example 2

[0039] The preparation method of nano-silver / chitosan / polylactic acid composite fiber is: 1) polylactic acid resin is sliced, and after carrying out vacuum drying, is heated to molten state, makes molten liquid; 2) chitosan is dissolved in 0.5% acetic acid aqueous solution, and stirred evenly to obtain a chitosan solution, uniformly disperse nano-titanium dioxide into the chitosan solution, the mass ratio of nano-titanium dioxide to chitosan solution is 0.5:1.7, to obtain nano-titanium dioxide / chitosan dispersion; 3) amino nano-silver solution and nano-titanium dioxide / chitosan dispersion are added in the molten liquid, stir evenly, make blend, amino nano-silver solution, nano-titanium dioxide / chitosan dispersion The mass ratio to the polylactic acid melt is 0.1:0.4:1; 4) The blend is extruded, filtered, spun, cooled, and stretched to prepare nano-silver / chitosan / polylactic acid composite fibers.

preparation example 3

[0041]The preparation method of the nano-silver / polylactic acid composite fiber is as follows: 1) slice the polylactic acid resin, and after vacuum drying, heat to a molten state to obtain a melt; 2) add the amino nano-silver solution into the melt, and stir evenly , to obtain a blend, the mass ratio of the amino nano-silver solution to the polylactic acid melt is 0.5:1; 3) the blend is extruded, filtered, spun, cooled, and stretched to obtain a nano-silver / Polylactic acid composite fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com