Patents

Literature

74results about How to "Guaranteed dispersion stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

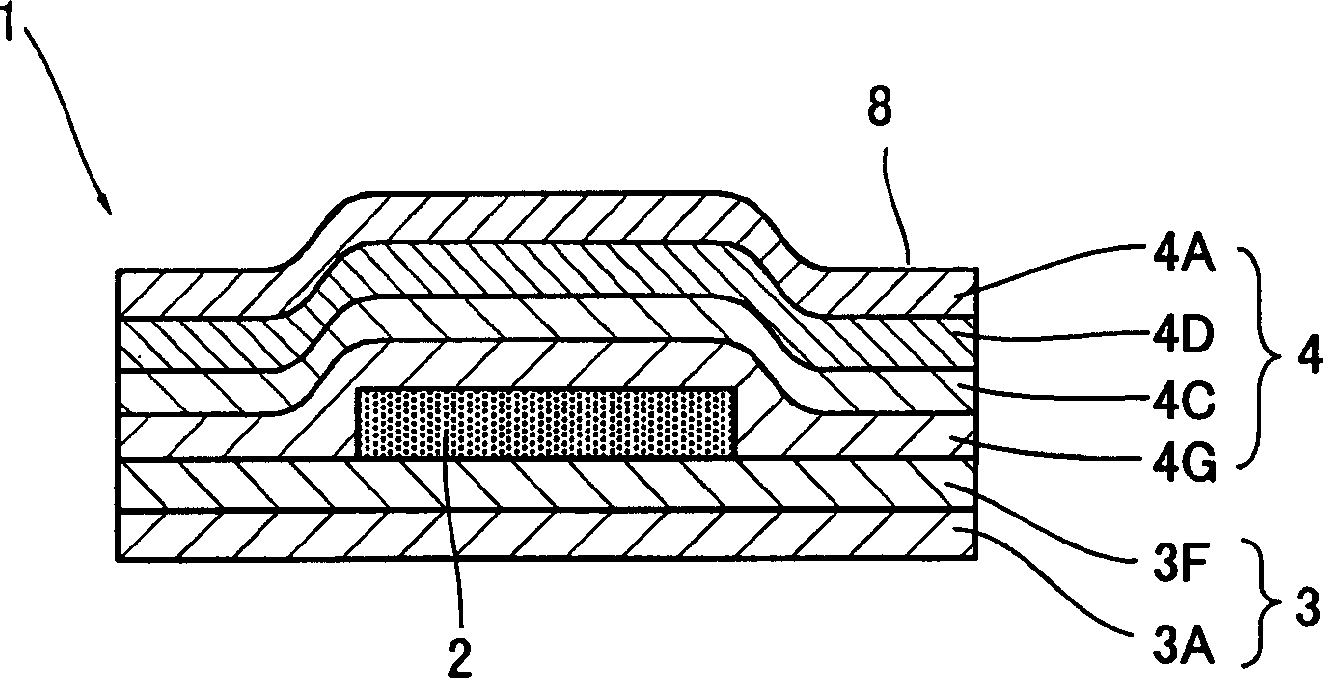

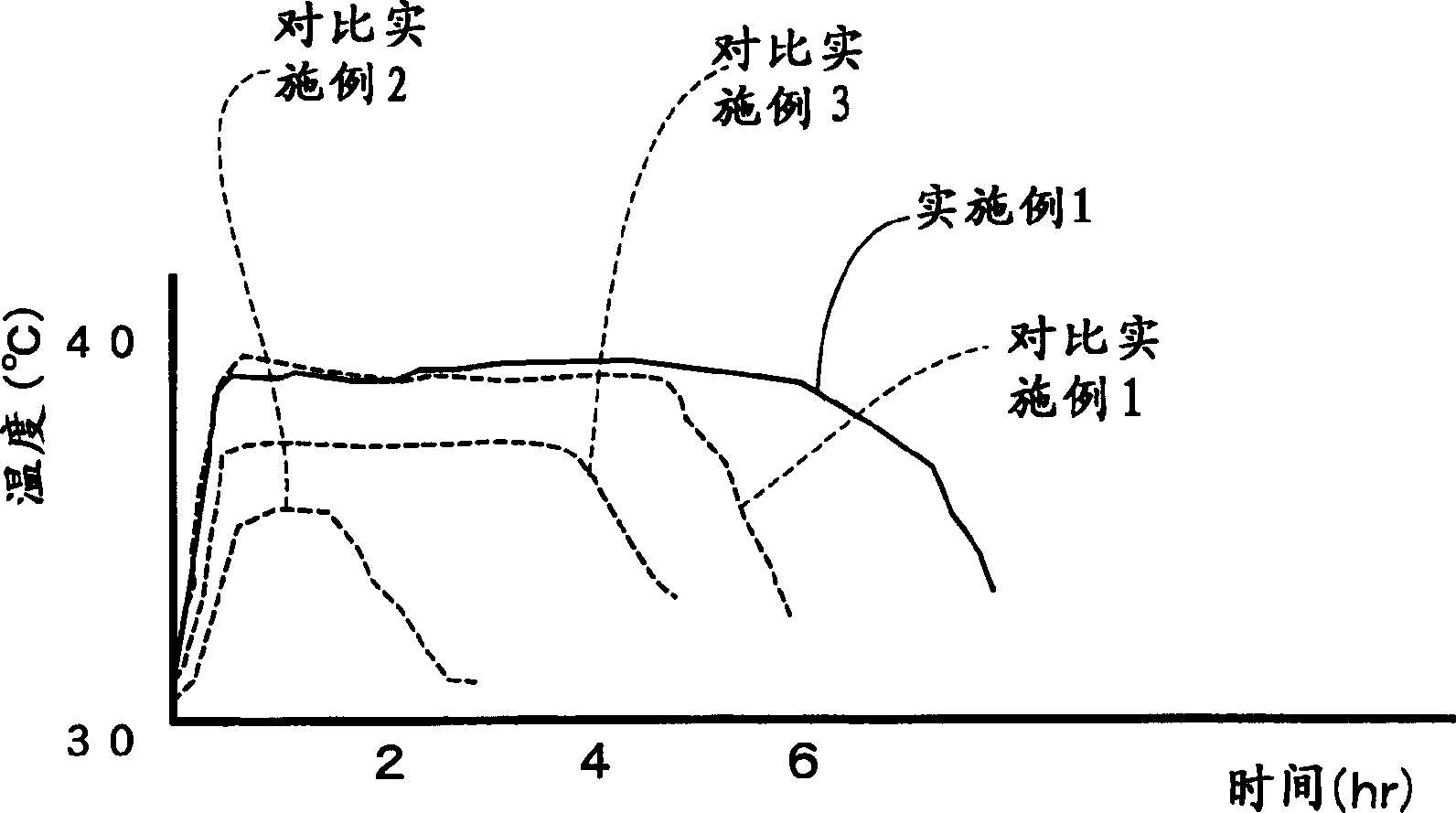

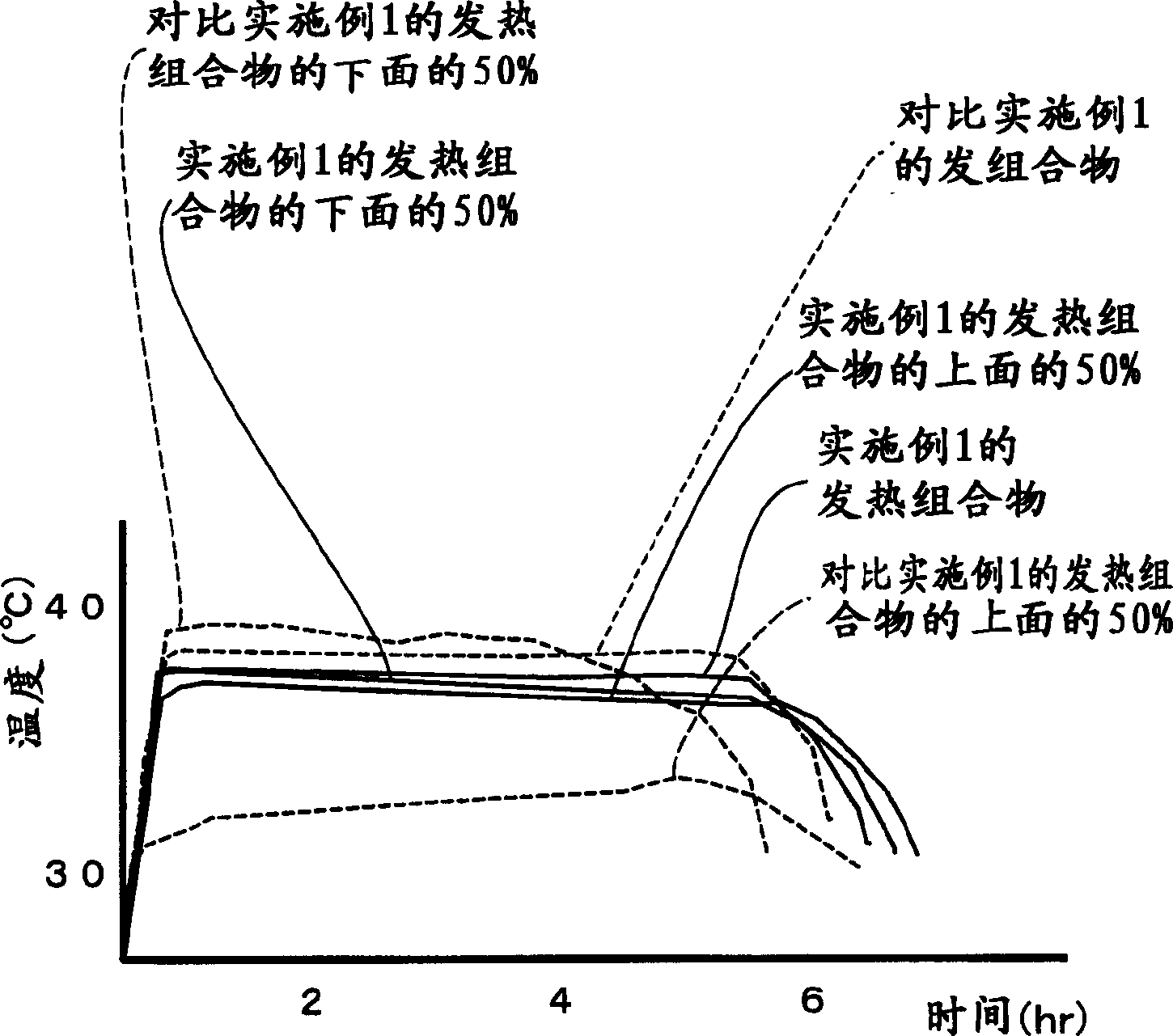

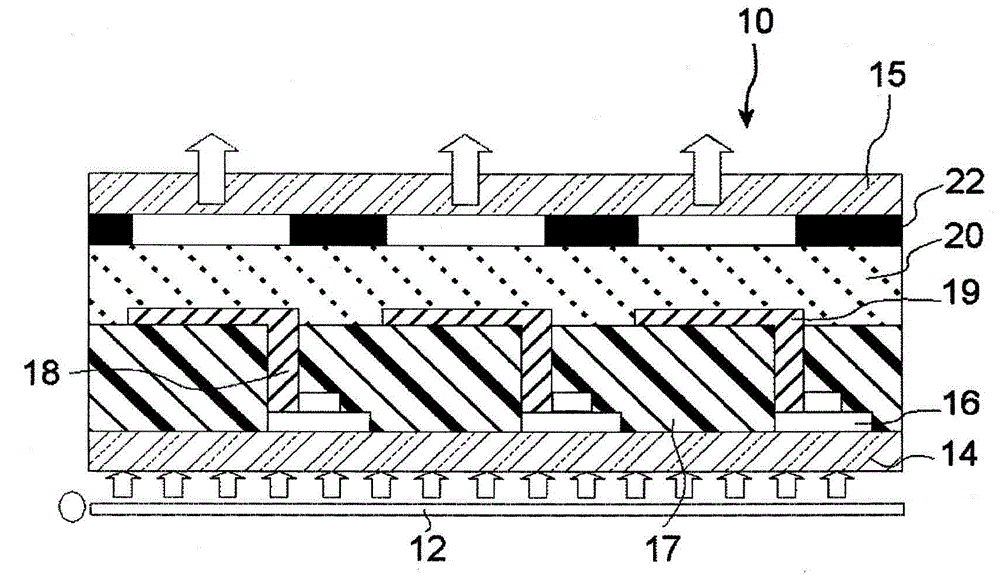

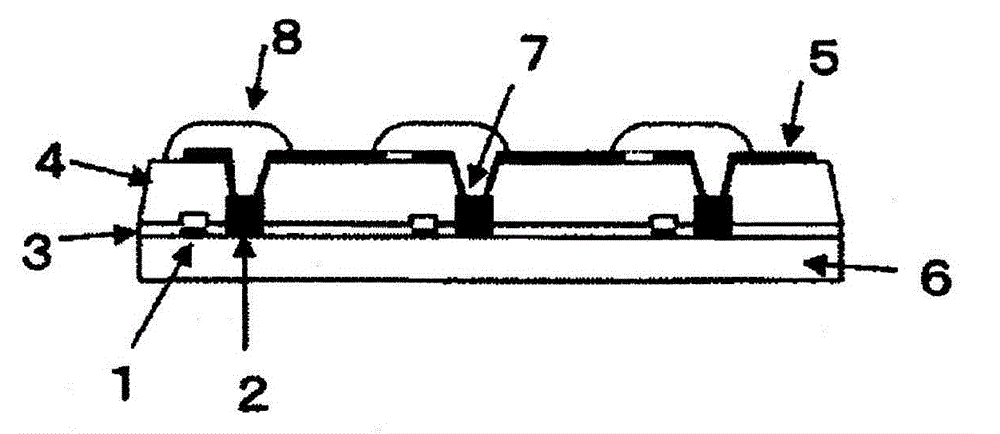

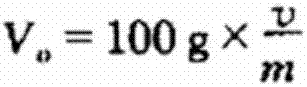

Exothermic composition and exothermic article using composition, and method for producing exothermic article

InactiveCN1491271AAccurate Guaranteed QuantityHas dispersion stabilityExothermal chemical reaction heat productionHeat-exchange elementsDispersion stabilityChemical composition

It relates to a heat-generating composition having such dispersion stability that withstands continuous molding, and has excellent drainage property, excellent heat-generating characteristics, excellent molding property and excellent shape retaining property, without becoming viscous, and relates to a heat-generating body using the same and a process for producing the heat-generating body. It contains, as essential components, a heat-generating substance generating heat upon reaction with oxygen, a carbon component, an oxidation promoter and water, characterized in that the composition further contains a water separation-preventing stabilizer in a proportion of from 0.001 to 0.25 part by mass per 100 parts by mass of the heat-generating composition, and has a water mobility value of from 7 to 40 and a separation degree of from 0 to 30.

Owner:MYCOAL

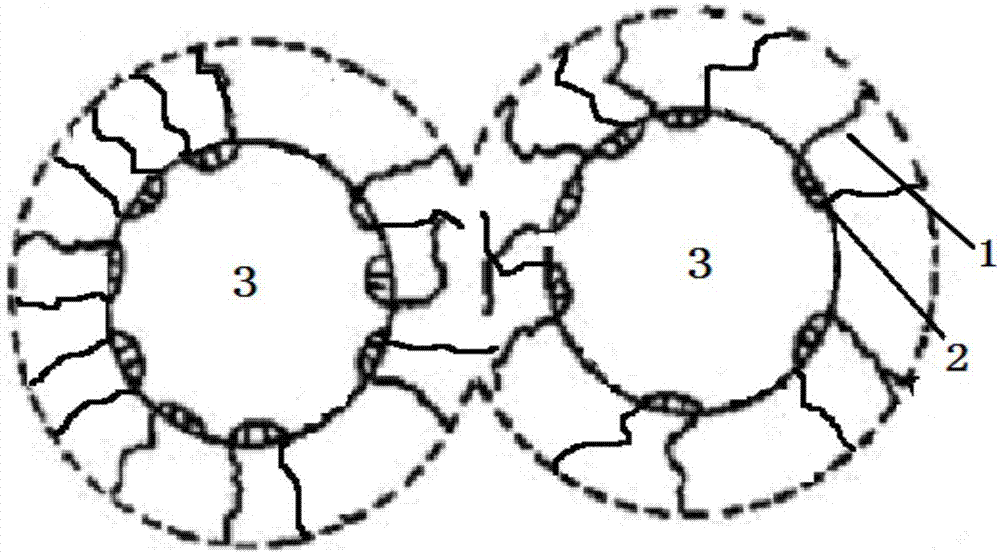

Double-foaming cellular concrete and production method thereof

The invention discloses double-foaming cellular concrete and a site production construction method thereof. The volume weight of the double-foaming cellular concrete ranges from 100 KG / M<3> to 400 KG / M<3>; the heat conduction coefficient is as little as 0.020 W / M.DEG C, and the intensity is up to 5 MPa. The double-foaming cellular concrete can be widely applied to the production of light-weight heat preservation materials such as roof heat preservation materials and external wall heat preservation materials and hanging pieces such as light-weight building hanging beams, and has the purposes of the filling of light-weight hollow bricks and hollow building covers; more importantly, the double-foaming cellular concrete can be applied to the construction of underwater facilities. The site production construction method for the double-foaming cellular concrete is simple in technology and simple and convenient to operate; by special equipment, full-automatic integrated productions, such as automatic foaming, metering and proportioning, are effectively realized; upon automatic control, the production construction of the double-foaming cellular concrete is finished highly efficiently at low cost.

Owner:河南华泰新材科技股份有限公司

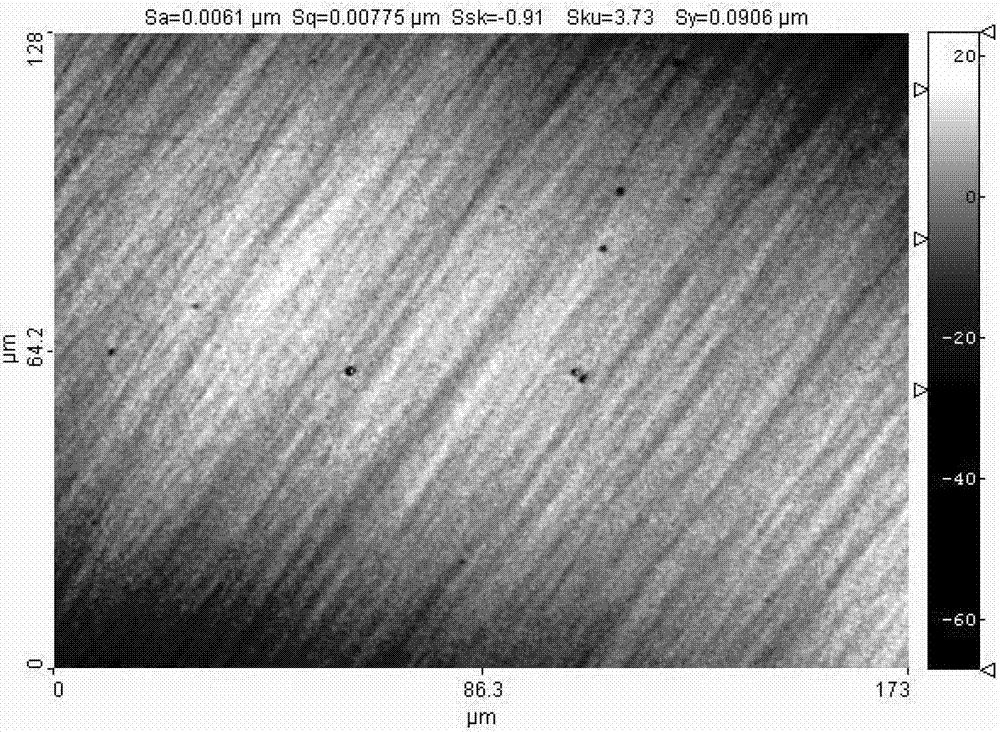

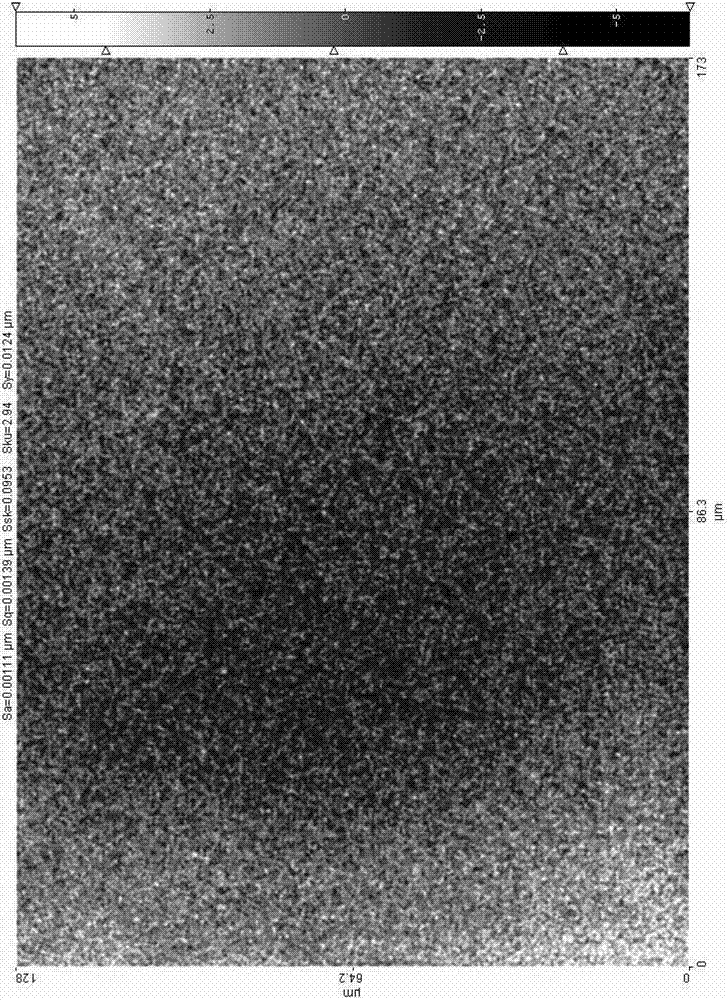

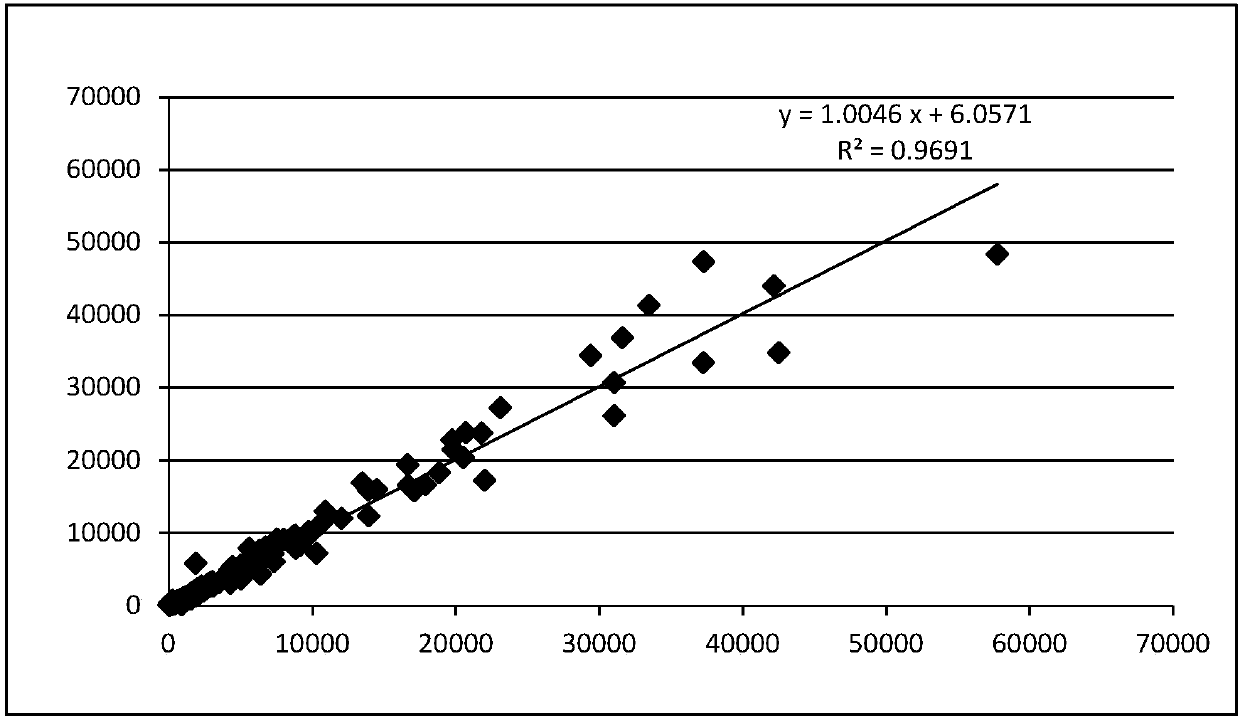

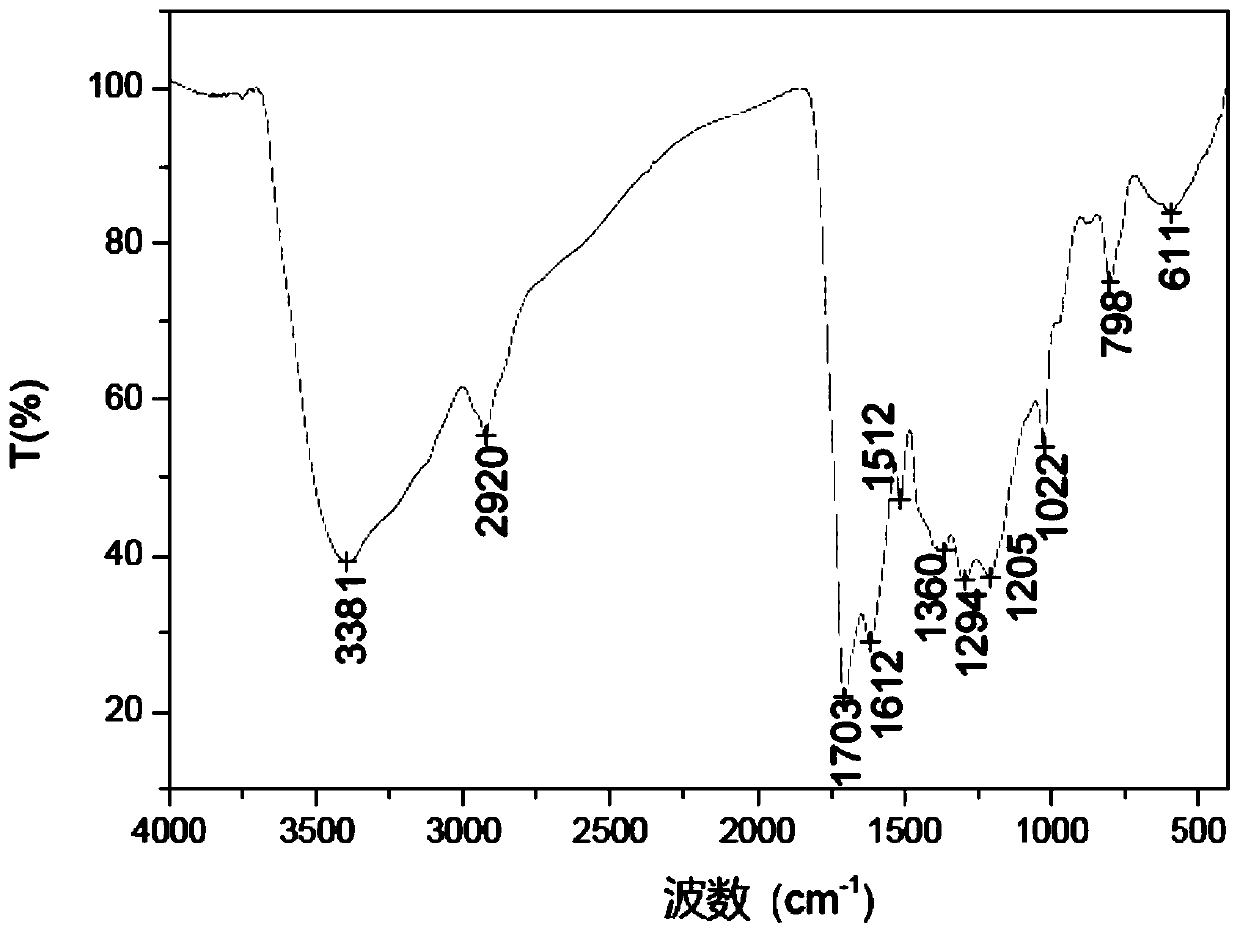

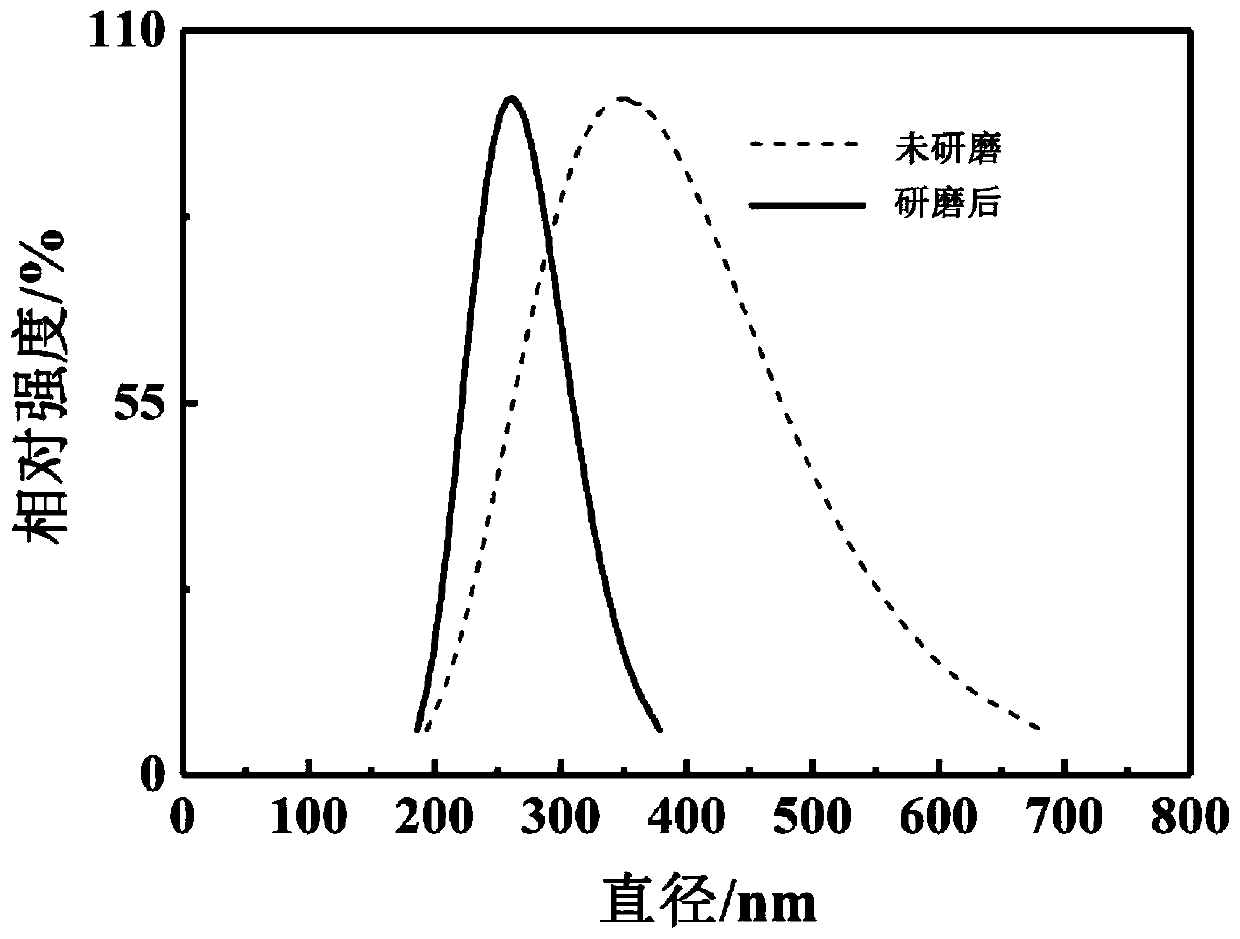

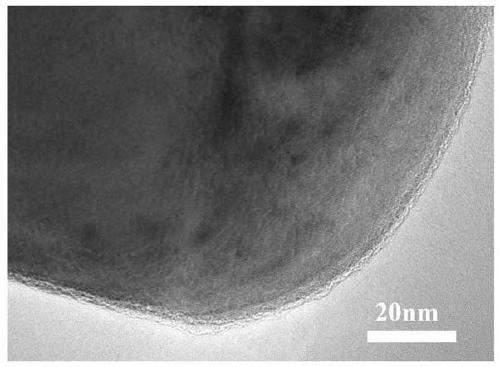

Barium titanate chemico-mechanical polishing aqueous composition and its application

ActiveCN102786879AImprove removal rateReduce concentrationPolishing machinesPolishing compositions with abrasivesBarium titanateSorbent

The invention relates to a barium titanate chemico-mechanical polishing aqueous composition and its application. Specifically, the barium titanate chemico-mechanical polishing aqueous composition comprises: 1-20 wt%, preferably 8-15 wt% of an abrasive; 0.5-10 wt%, preferably 1-3 wt% of a complexing agent; and 0.01-5 wt%, preferably 0.1-1 wt% of a surface adsorbent, wherein the barium titanate chemico-mechanical polishing aqueous composition has a pH value of 8.0-12.0, preferably 10.0-11.5. The barium titanate chemico-mechanical polishing aqueous composition provided in the invention can be effectively applied to a barium titanate substrate chemico-mechanical polishing process, thereby being able to effectively obtain a polished barium titanate layer with a high polishing rate and high surface quality.

Owner:TSINGHUA UNIV

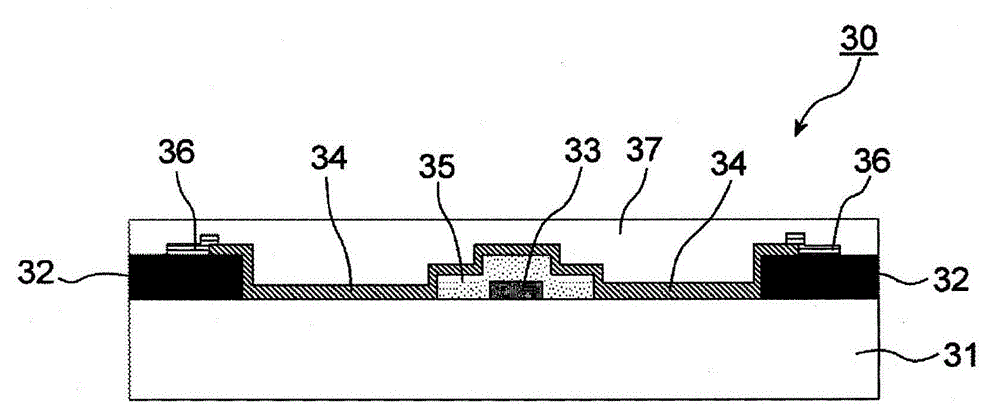

Toner for electrostatic charge developing, production method thereof, developer for electrostatic charge developing using the same, and image forming method

ActiveUS20060216627A1High resolutionGuaranteed dispersion stabilityDevelopersElectrographic processes using charge patternPolyolAlcohol

A toner for electrostatic charge developing prepared by a production method including aggregating one or more kind of particles in a raw material dispersion including the particles to form aggregated particles, and coalescing the aggregated particles by heating. At least one kind of the particles is resin particles including an amorphous polyester resin synthesized by copolymerizing one or more polyvalent carboxylic acids and two or more polyhydric alcohols; at least one of the polyvalent carboxylic acids is polyvalent carboxylic acid having a sulfonic acid group; two of the polyhydric alcohols are an ethylene oxide adduct of bisphenol A and a propylene oxide adduct of bisphenol A; and the following equation (1) is satisfied. 10 / 90≦BPA(EO) / BPA(PO)≦90 / 10 Equation (1) In the equation (1), BPA(EO) represents a total mole amount of the ethylene oxide adduct of bisphenol A used in synthesis of the amorphous polyester resin, and BPA(PO) represents a total mole amount of the propylene oxide adduct of bisphenol A used in synthesis of the amorphous polyester resin.

Owner:FUJIFILM BUSINESS INNOVATION CORP

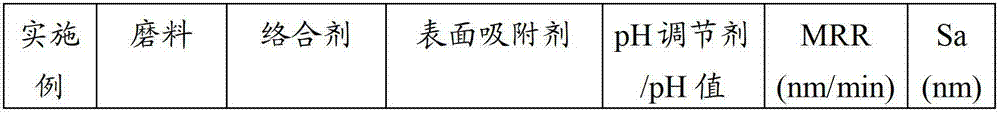

NT-ProBNP detection kit and using method thereof

ActiveCN107656071ADetection speedSimplify operation stepsDisease diagnosisBiological testingChemistryEnzyme

The invention discloses an NT-ProBNP detection kit. The NT-ProBNP detection kit comprises a calibrator, a cleaning solution, a substrate solution, a pretreatment solution, an enzyme conjugate workingsolution and a magnetic bead conjugate working solution; the pretreatment solution contains pyridine, the enzyme conjugate working solution contains NT-ProBNP antibody labeled by enzyme, and the magnetic bead conjugate working solution contains magnetic beads labeled by the NT-ProBNP antibody. The NT-ProBNP detection kit can accurately measure NT-ProBNP in a whole blood sample, the lowest limit detection of the kit is 20 pg / ml, the linearity range is 20-5,000 pg / ml, the detection sensitivity is high, the linearity range is wide, and the result is accurate. The invention further discloses a using method of the NT-ProBNP detection kit. The NT-ProBNP detection kit is simple in using step, the detection time of an NT-ProBNP is shortened, and quick and sensitive detection of the NT-ProBNP is achieved.

Owner:NANTONG EGENS BIOTECH

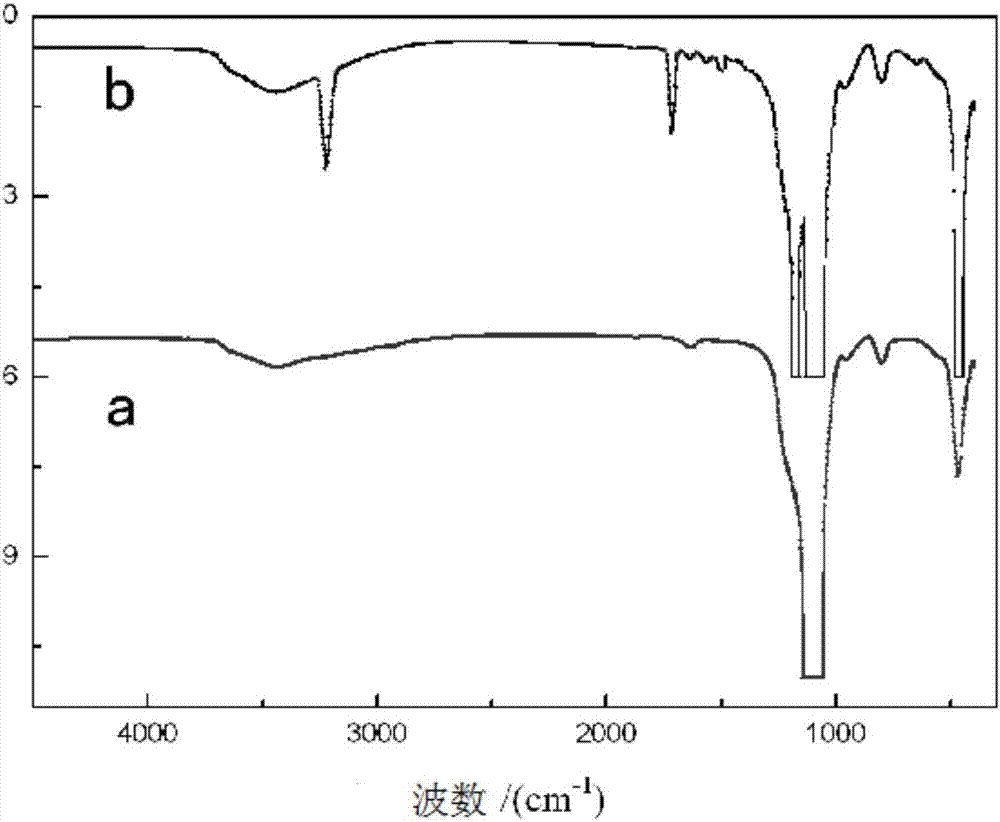

Application of carbon microspheres serving as blocking agent for high-temperature water-based drilling fluid and high-temperature water-based drilling fluid

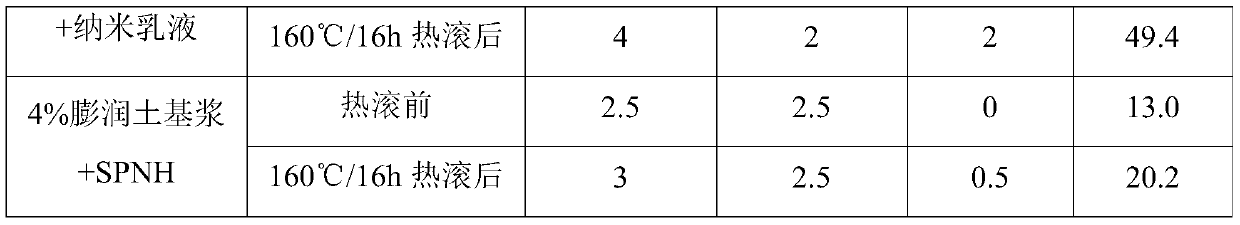

ActiveCN110105941AImprove performanceGood dispersionNano-carbonDrilling compositionWater basedMicrosphere

The invention relates to the field of oilfield chemistry, and discloses application of carbon microspheres serving as a blocking agent for high-temperature water-based drilling fluid and the high-temperature water-based drilling fluid. The average particle size of the carbon microspheres is 50-50,000 nanometers, the total number of oxygen-containing functional groups is greater than or equal to 0.2 mmol / g, and the carbon microspheres serving as the blocking agent for the high-temperature water-based drilling fluid are good in blocking performance at the high temperature of 200 DEG C and friendly to the environment.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

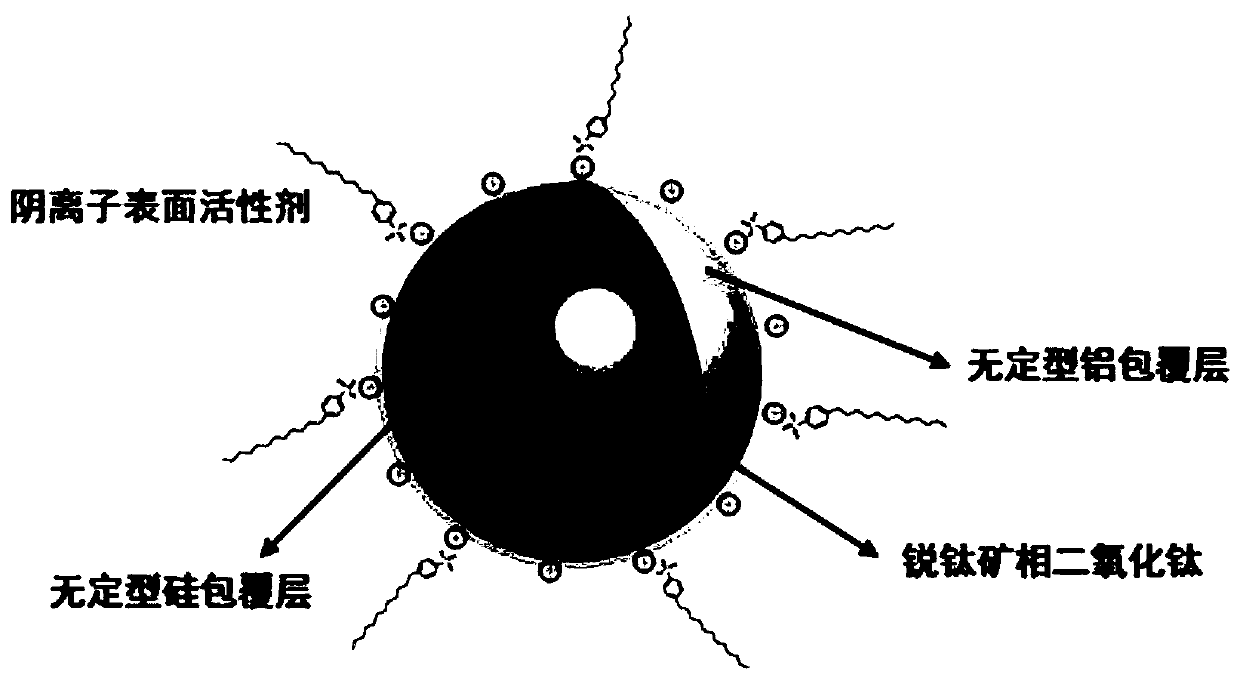

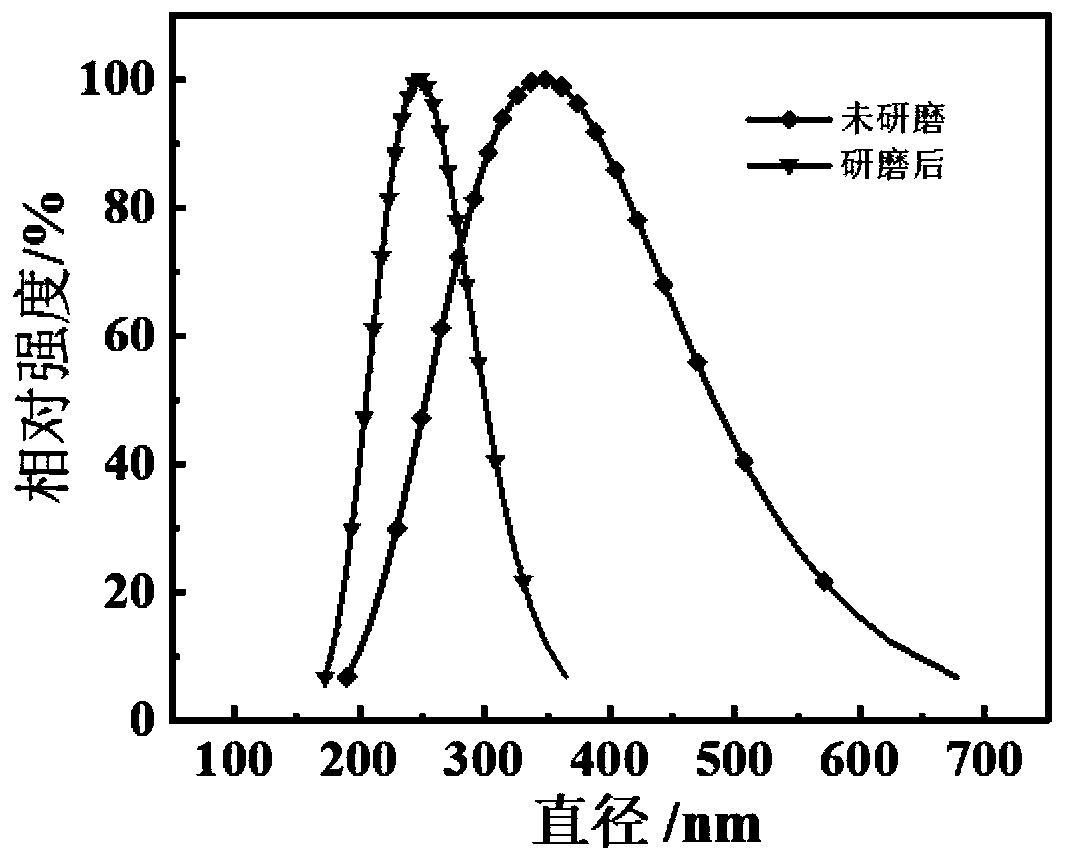

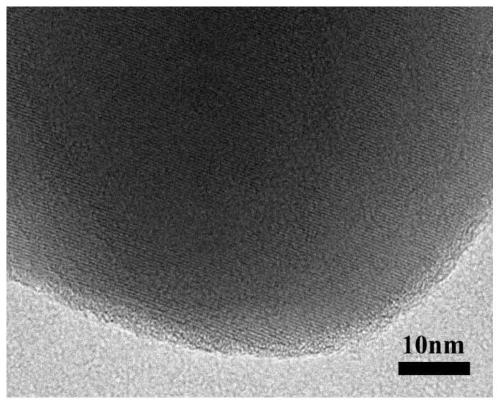

Low-cost titanium dioxide matting agent for polyamide fibers, and preparation and application thereof

InactiveCN110358329AChange surface electrical propertiesReduce photocatalytic activityPigment treatment with non-polymer organic compoundsArtifical filament manufactureWhite powderAmorphous silicon

Owner:DONGHUA UNIV +1

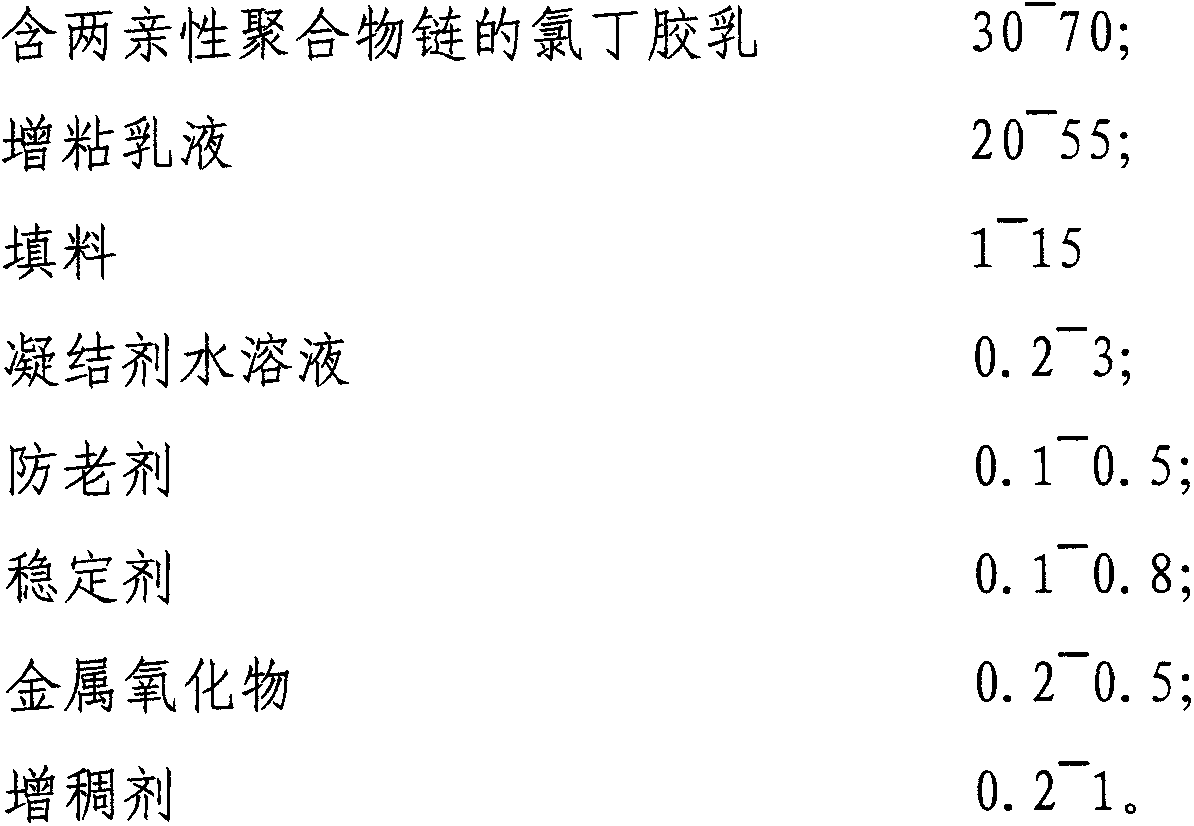

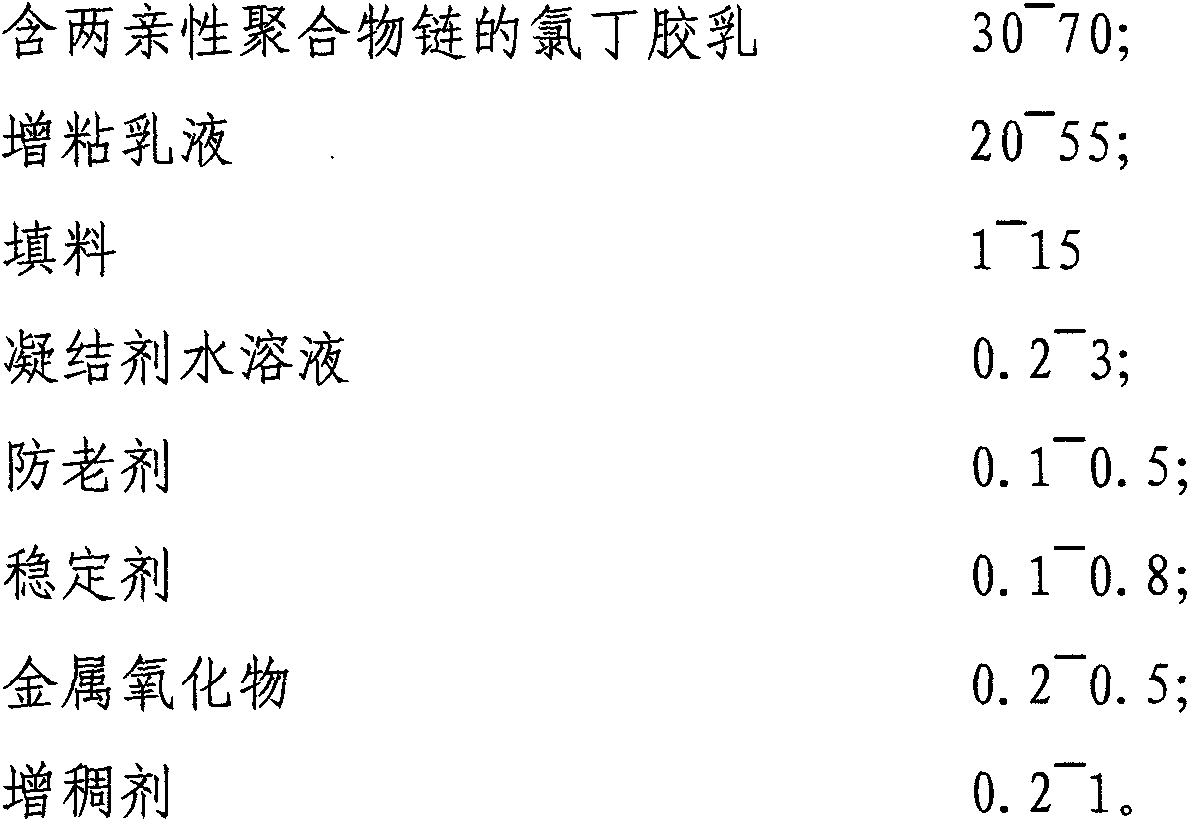

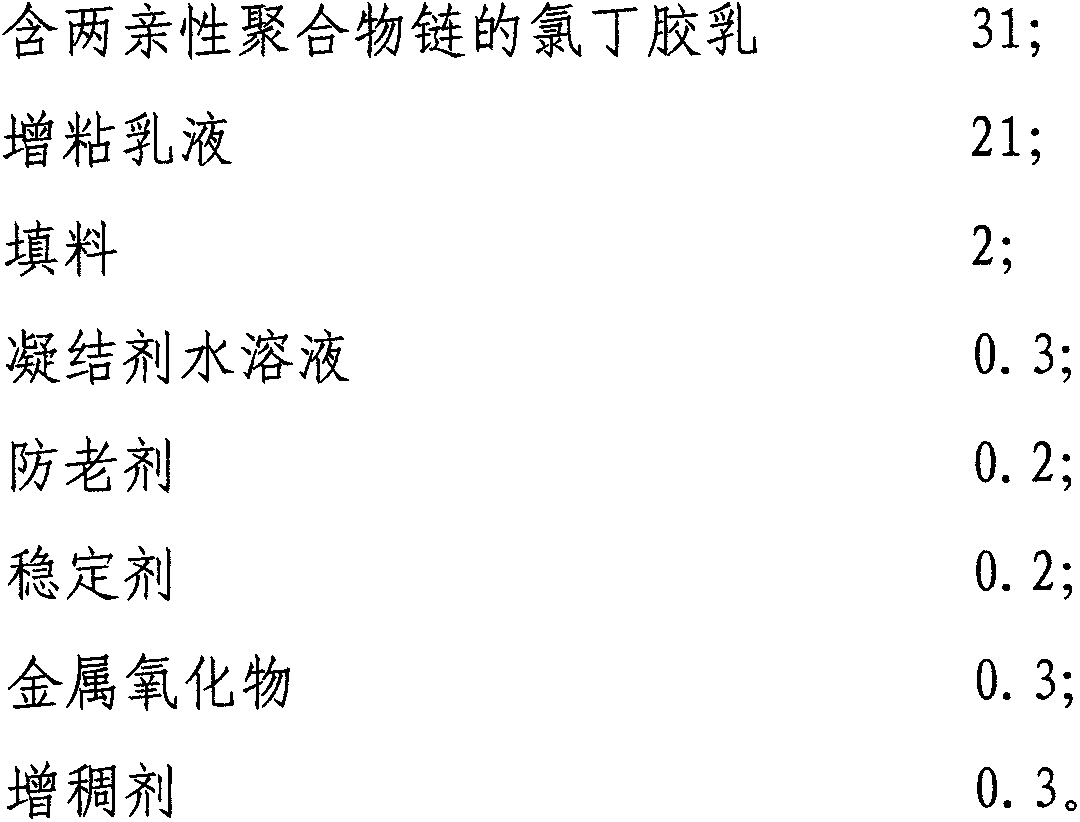

Amphiphilic polymer chain-containing neoprene latex adhesion agent and preparation method thereof

ActiveCN103740304AImprove initial tackImprove dispersion stabilityNon-macromolecular adhesive additivesRosin adhesivesAminoethyl methacrylateDispersion stability

The invention discloses an amphiphilic polymer chain-containing neoprene latex adhesion agent. The adhesion agent comprises the following components in parts by weight: an amphiphilic polymer chain-containing neoprene latex, a tackifying emulsion, a filler, a coagulating agent aqueous solution, an anti-aging agent, a stabilizer, a metal oxide and a thickening agent. With a neoprene latex as a matrix and with methyl methacrylate, methacrylic acid and N,N-dimethyl aminoethyl methacrylate as graft monomers, the amphiphilic polymer chain-containing neoprene latex is prepared by an emulsion graft polymerization reaction. The invention also discloses a preparation method of the amphiphilic polymer chain-containing neoprene latex adhesion agent. The problems of poor storage stability and small initial viscous force are solved, the neoprene latex can be simultaneously skillfully endowed with dispersion stability and demulsification cohesion, and at the same time, the dispersion stability and the initial viscous force of the neoprene latex are improved; and the grafted type neoprene latex adhesion agent has wide application range, high adhesion strength, and remarkable economic benefits and social benefits.

Owner:GUANGDONG TAIQIANG TECH IND CO LTD

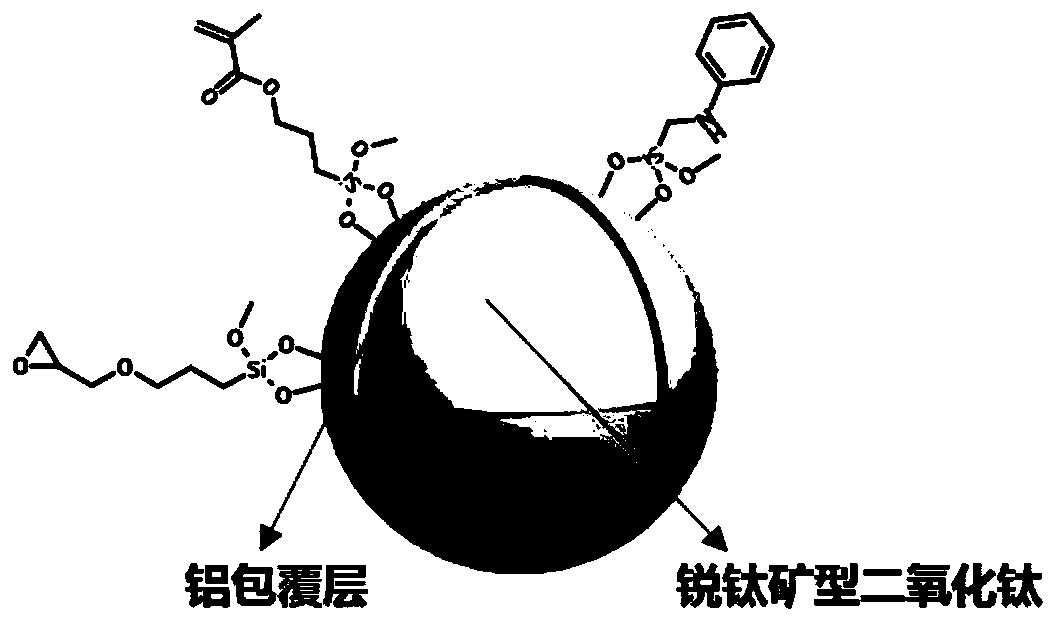

Preparation method of delustering agent for chinlon chemical fibers

PendingCN109852104AGuaranteed dispersion stabilityEffectively closedFibre typesPigment treatment with organosilicon compoundsIndustrial scaleAnatase titanium dioxide

The invention relates to a preparation method of a delustering agent for chinlon chemical fibers. The preparation method comprises the following steps: preparing anatase titanium dioxide ultrafine powder; preparing aluminum coated titanium dioxide slurry; and carrying out surface grafting modification by a coupling agent method. The prepared flatting agent for the chinlon chemical fibers has excellent flatting performance, good dispersion stability, low photocatalytic activity and good compatibility with the chinlon fibers. The preparation method is simple in process, mild in reaction condition and suitable for industrial large-scale production; by-products are easy to recycle, sewage treatment is easy and convenient and the process cost is effectively reduced.

Owner:DONGHUA UNIV +1

Foam concrete capable of pumping and chemically foaming and production method of foam concrete

The invention discloses foam concrete capable of pumping and chemically foaming and an on-site construction production method. The foam concrete comprises the following materials in parts by weight: 75-500 parts of concrete, 20-120 parts of an active mixing material, 40-300 parts of water, 15-50 parts of an adjusting agent, 30-90 parts of a foaming agent and 2-10 parts of a micro foam agent. The volume weight of the prepared foam concrete is 100-600kg / M<3>; the heat conductivity coefficient of the foam concrete is as low as 0.020W / M.DEG C; the strength of the foam concrete can reach 5Mpa. By virtue of the production method, the advantages of cast-in-situ physical foaming and chemical foaming make an organic combination to form a novel construction method; the production method is relatively high in production efficiency, flexible to operate and relatively wide in application; the foam concrete can be made into high-strength product materials with different shapes; the heat-insulating construction of buildings can be effectively completed with high efficiency and low cost.

Owner:河南华泰新材科技股份有限公司

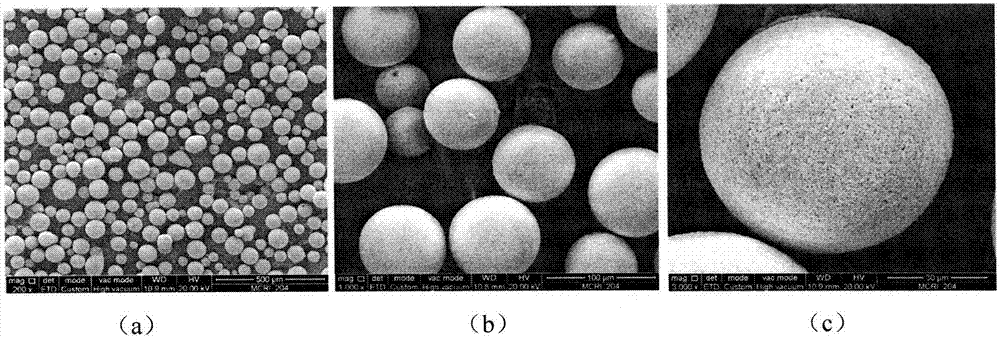

Silicon carbide composite powder as well as preparation method and application thereof

The invention discloses silicon carbide composite powder as well as a preparation method and application thereof. A granulation method of the silicon carbide composite powder comprises the following steps: (1) uniformly mixing beta-SiC micropowder with water and a dispersing agent in a mass ratio of (0.1-0.2) to 1 to (0.03-0.08), putting the mixture into a sand mill, and carrying out circularly grinding, so as to obtain nano-beta-SiC slurry, wherein the average grain diameter of the beta-SiC micropowder is not more than 1.5 micron; (2) adding micron-scale alpha-SiC and a bonding agent into the nano-beta-SiC slurry, and uniformly stirring, so as to obtain mixed slurry, wherein the mass of micron-scale alpha-SiC is 0.8-0.9 of the mass of the mixed slurry, and the mass of the bonding agent is 0.03-0.05 of the mass of the mixed slurry; and (3) conveying the mixed slurry into a spray granulation machine through a peristaltic pump, so as to obtain silicon carbide composite granulated powder. By introducing nano-scale beta-SiC, the sintering temperature can be decreased, the tenacity and strength of ceramic can be increased, and more importantly, nano-scale beta-SiC can be gradually converted into alpha-SiC in a uniform phase during the sintering, so that the stability of the use performance of the silicon carbide ceramic is not degraded.

Owner:XIAN BOER NEW MATERIAL CO LTD

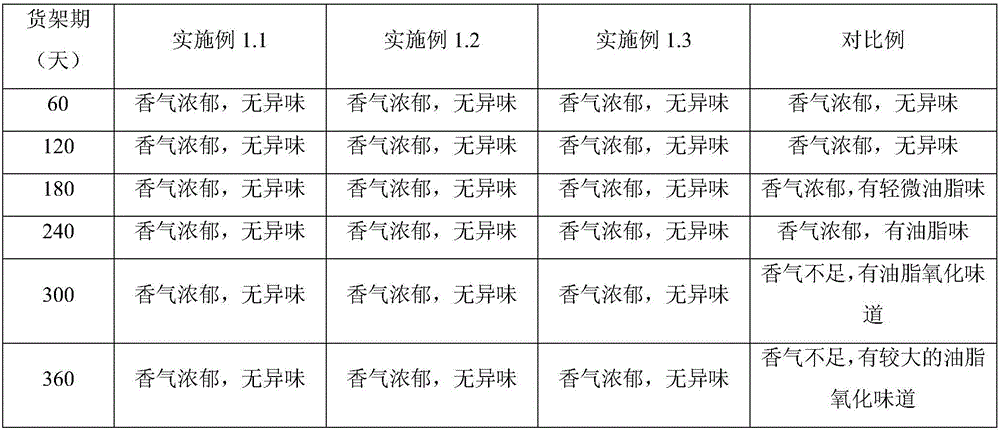

Mixed congee assisting people to lower cholesterol

InactiveCN105831570AAdd accessoriesImprove sexual functionFood ingredient functionsPhytosterol estersBlood lipids

The invention provides a mixed congee assisting people to lower cholesterol. The phytosterol ester is added into the mixed congee, while the conjugated linoleic acid and phospholipid are compounded. The dispersion stability of the functional material is guaranteed by means of the synergistic effect in functionality of phytosterol ester, conjugated linoleic acid, phospholipid, and coarse cereals in the mixed congee such as oat; and the specific soup compound operation in preparation, so that the obtained mixed congee has good effects on lowering cholesterol, adjusting the blood lipids, and maintaining cardio cerebrovascular health. Moreover, the dispersibility and stability of phytosterol ester in the mixed congee is guaranteed, and the organoleptic and physicochemical indexes of the mixed congee in the expiration date are guaranteed to meet the requirement.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

cTnI detection kit and using method thereof

ActiveCN107918022AAccurate measurementStrong specificityDisease diagnosisBiological testingMagnetic beadWhole blood sample

The invention discloses a cTnI detection kit which comprises a calibration product, a cleanout fluid, a substrate solution, a pretreatment liquid, an enzyme conjugate working solution and a magnetic bead conjugate working solution, wherein the pretreatment liquid contains imidazole; the enzyme conjugate working solution contain an enzyme labeled cTnI antibody; and the magnetic bead conjugate working solution contains cTnI antibody labeled magnetic beads. The cTnI detection kit can realize accurate determination of cTnI in a whole blood sample, the detection steps are simplified, and the detection efficiency is improved. The lowest detection limit of the kit is 0.02ng / ml, the linear range is 0.02-50ng / ml, the detection sensitivity is high, the linear range is wide, and the detection resultis accurate. The invention further discloses a using method of the cTnI detection kit. The using method is simple in using steps, the detection time of the cTnI is effectively shortened, and rapid andsensitive detection of the cTnI is realized.

Owner:NANTONG EGENS BIOTECH CO LTD

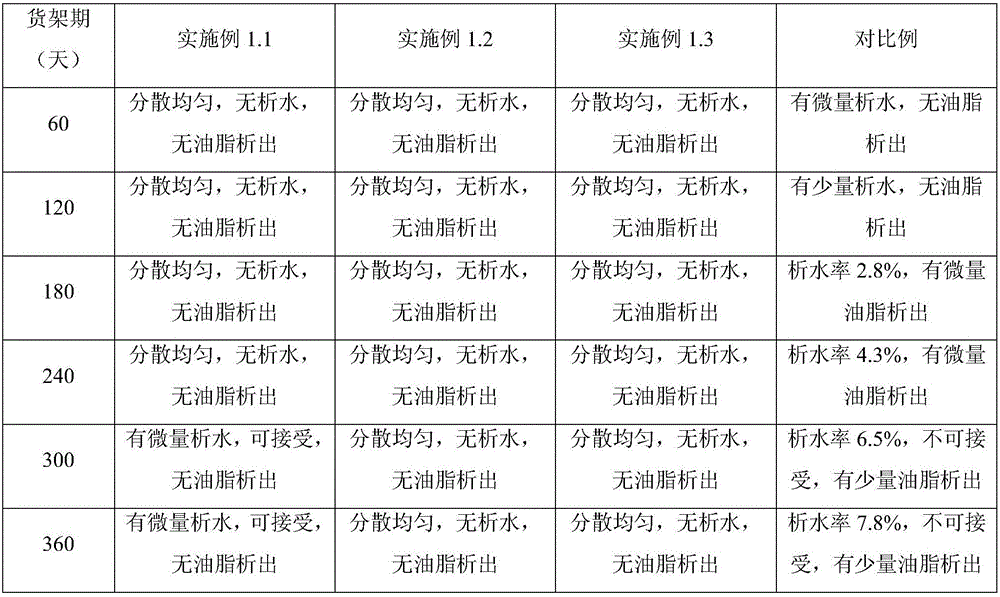

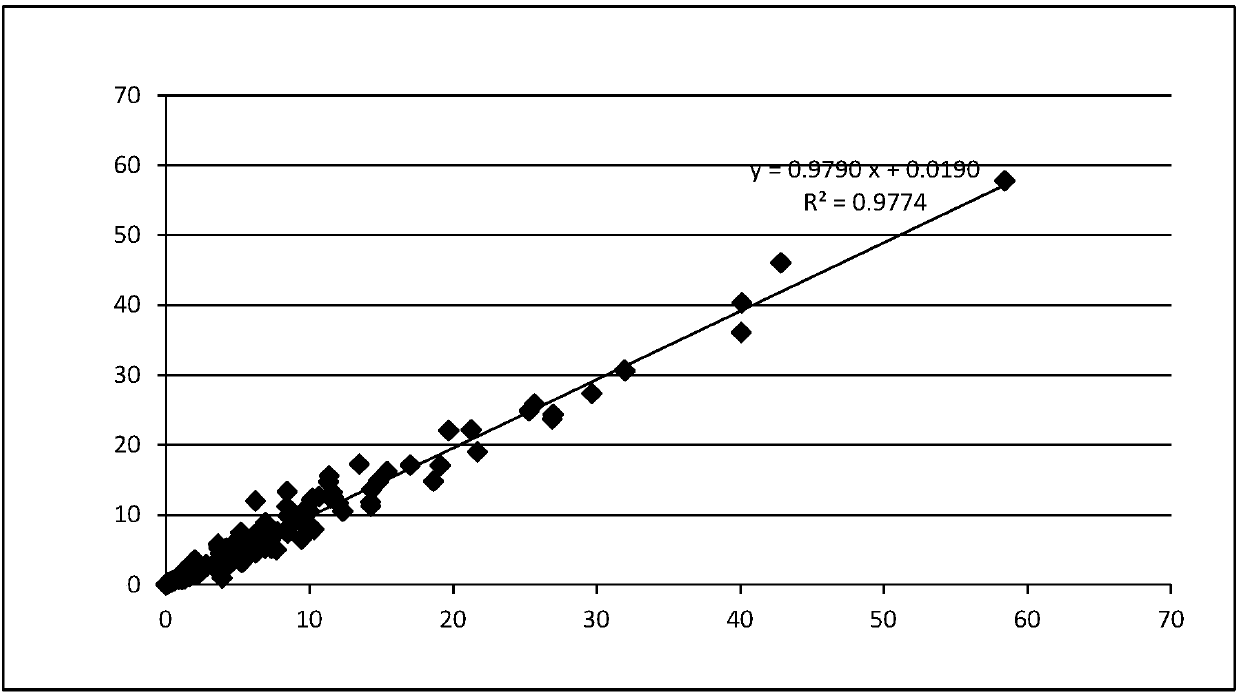

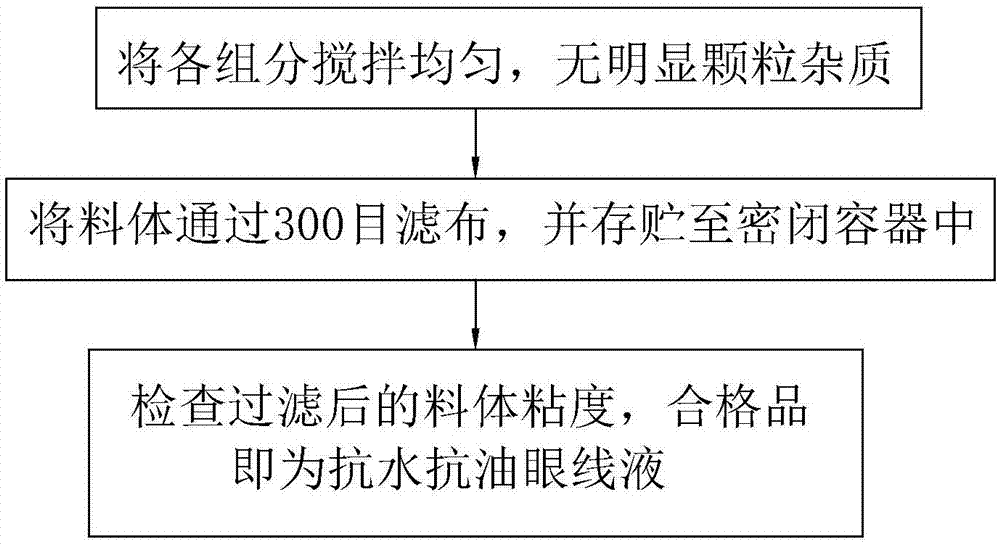

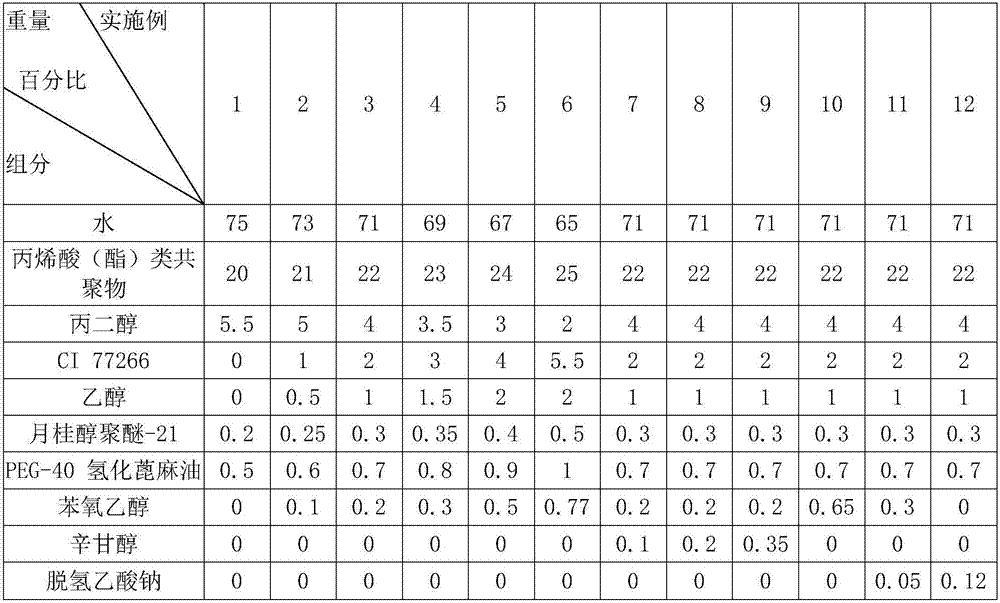

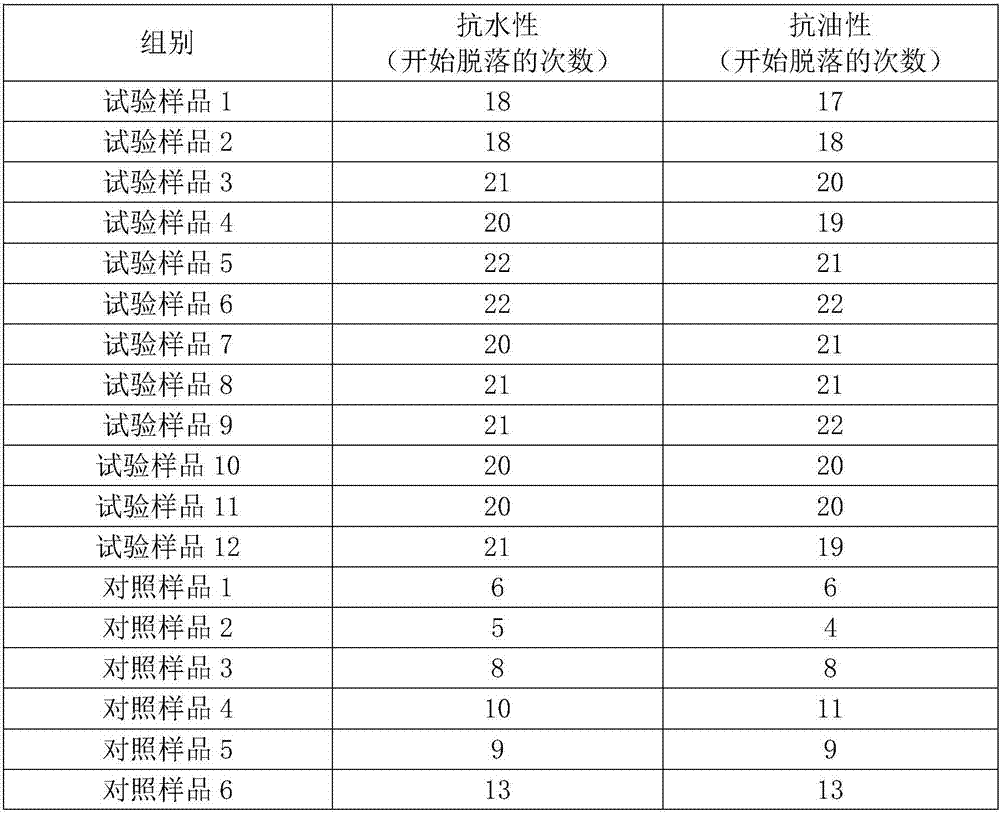

Water-resisting and oil-resisting liquid eyeliner and preparation method thereof

InactiveCN107496211AReduce the amount addedGuaranteed dispersion stabilityCosmetic preparationsMake-upDispersion stabilityPreservative

The invention discloses a water-resistant and oil-resistant eyeliner and a preparation method thereof, belonging to the technical field of cosmetics. Wherein the liquid eyeliner comprises the following components by weight percentage: 65-75% of water; 20-25% of acrylic acid (ester) copolymer; 2-5.5% of humectant; 0-5.5% of coloring agent; 0-2% of ethanol; Alcohol-21 0.2-0.5%; PEG-40 Hydrogenated Castor Oil 0.5-1%; Preservative 0-0.77%. The present invention adopts acrylic acid (ester) copolymer as a dispersant, cooperates with laureth-21 and PEG-40 hydrogenated castor oil, and greatly reduces the two surfactants of laureth-21 and PEG-40 hydrogenated castor oil The added amount of the product improves the water resistance and oil resistance of the product, and at the same time ensures the dispersion stability of the material. The liquid eyeliner is not easy to smudge after application and has good durability.

Owner:上海禾雅化妆品有限公司

Dispersion composition, and curable composition, transparent film, microlens and solid-state imaging element using same, and polymer compound

ActiveCN104640932AHigh refractive indexLow viscosityCoatingsPhotosensitive materials for photomechanical apparatusRefractive indexSolvent

PROBLEM TO BE SOLVED: To provide a dispersion composition which has excellent dispersibility even when an inorganic ultrafine particle is packed densely and also has a low viscosity, a high refractive index and excellent surface characteristics of the film surface after coating and a curable composition, a transparent film, a micro-lens and a solid-state imaging device using the dispersion composition.SOLUTION: A dispersion composition comprises a metal oxide particle (A) of primary particle sizes of 1-100 nm, a polymer compound (B) of formula (1) having a weight average molecular weight of 10,000 or smaller and a solvent (C).

Owner:FUJIFILM CORP

Preparation method for electric property-controllable organic pigment dispersion

ActiveCN104098927AGuaranteed dispersion stabilityStrong hydrophobic attractionOrganic dyesAcetic acidPigment dispersion

The invention relates to a preparation method for electric property-controllable organic pigment dispersion, and belongs to the technical field of textile dyeing and finishing. The preparation method is characterized by comprising the following steps: adding a certain quantity of cellulase into water to ensure that the mass concentration of zymoprotein is 0.1 to 1 g / L; adjusting the pH of the mixed solution to be 7; adding an organic pigment of which the mass is 10 to 20 times of that of the zymoprotein; treating the liquid in a phacofragmentation condition for 30 to 40 min; adjusting the pH of the dispersion liquid to be 3 to 10 with acetic acid or sodium hydroxide as required. The preparation method has the advantages that the organic pigment dispersion prepared according to the method is stable; the electric property of the organic pigment dispersion can be adjusted and controlled by adjusting the pH value of the dispersion liquid.

Owner:德沐新材料科技苏州有限公司

CK-MB detection kit and use method thereof

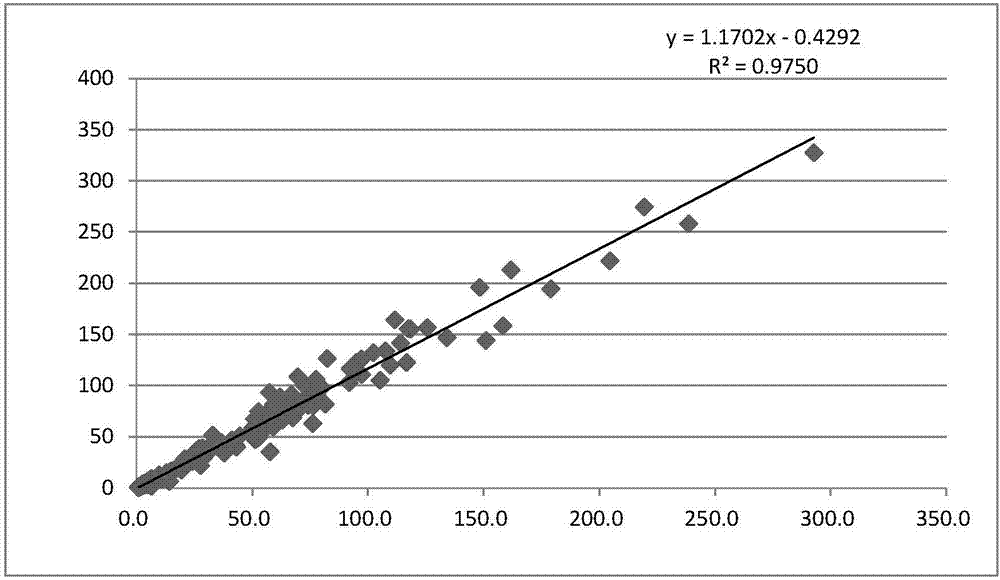

The invention discloses a CK-MB detection kit which comprises calibrator, cleaning fluid, a substrate solution, a pretreatment solution, an enzyme conjugate working solution and magnetic bead conjugate working solution, wherein the pretreatment solution contains imidazole, the enzyme conjugate working solution contains an enzyme marked CK-MB antibody, and the magnetic bead conjugate working solution contains CK-MB antibody marked magnetic beads. By means of the CK-MB detection kit, accurate measurement of CK-MB in a whole blood sample can be achieved, detection steps are simplified, and a detection efficiency is improved. The lowest detection limit of the kit is 1ng / ml, a linearity range is 1 to 300ng / ml, detection sensitivity is high, the linearity range is wide, and detection results areaccurate. The invention further discloses a use method of the CK-MB detection kit. Use steps of the use method are simple, CK-MB detection time is effectively shortened, and quick and flexible detection of the CK-MB is benefit to achieve.

Owner:NANTONG EGENS BIOTECH CO LTD

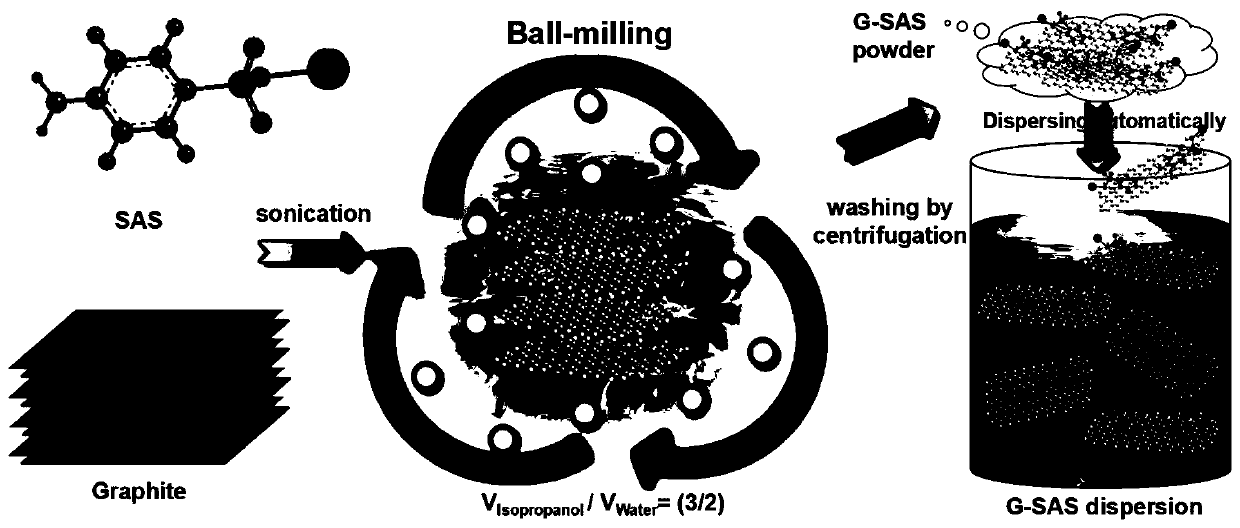

Nano titanium dioxide modified graphene oxide rolling liquid and preparation method thereof

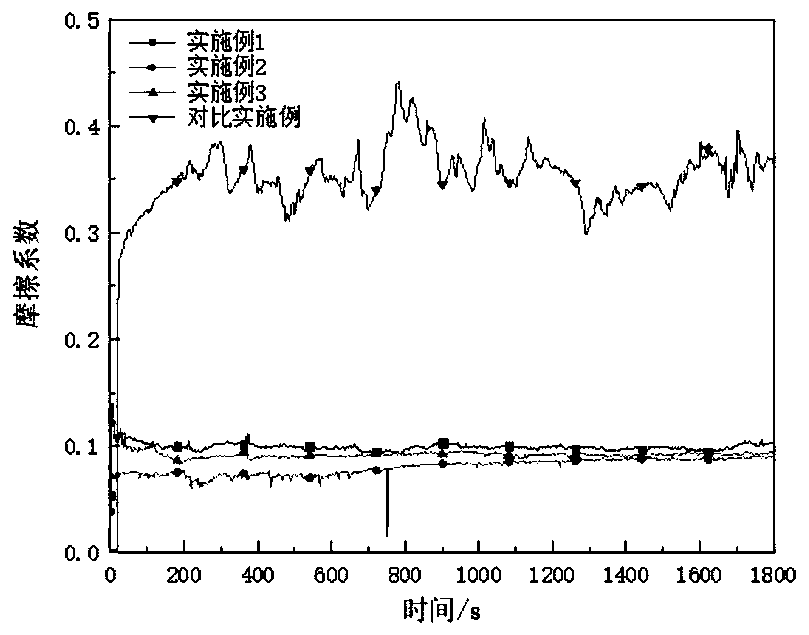

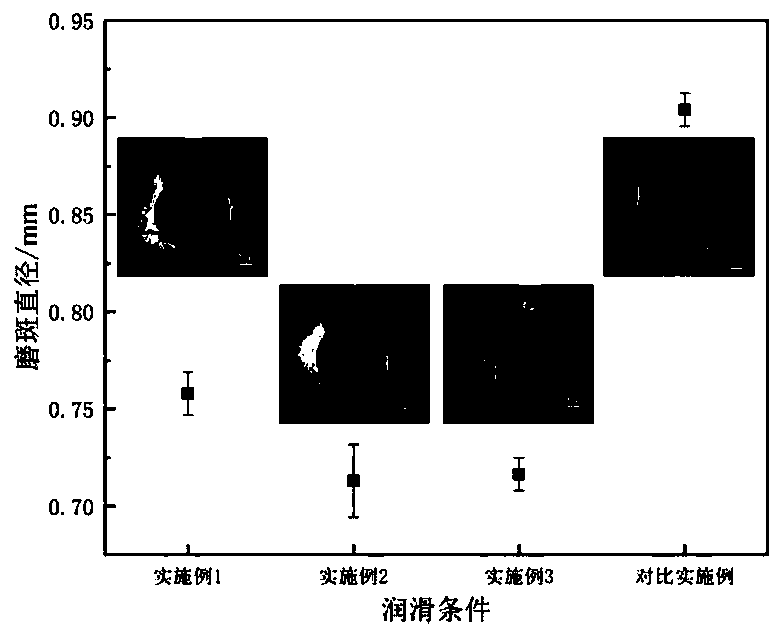

InactiveCN111171936AImprove defectsGuaranteed dispersion stabilityLubricant compositionGlycerolComposite nanoparticles

The invention relates to a nano titanium dioxide modified graphene oxide rolling liquid and a preparation method thereof. The rolling liquid is composed of nano titanium dioxide modified graphene oxide, oleic acid, triethanolamine, water-based borate, glycerin and deionized water. Oleic acid, triethanolamine, glycerol and water-based borate are sequentially added into deionized water, and are completely dissolved to obtain a primary solution; a graphene oxide-titanium dioxide nano composite material prepared by an improved solvothermal method is added into the primary solution, and ultrasonicdispersion is carried out by using an ultrasonic cell disruptor to avoid agglomeration or layering among nano particles, thereby obtaining the uniform and stable water-based nano rolling liquid. The nano titanium dioxide is used for modifying the graphene oxide, so that the tribology and the rolling lubricating property of the graphene oxide are enhanced while the dispersion stability of the graphene oxide is enhanced. Through deposition of the graphene oxide-titanium dioxide composite nanoparticles, a carbonaceous lubricating film and a carbonaceous protective film can be formed on the surface of the steel plate so as to obtain better rolled surface quality.

Owner:UNIV OF SCI & TECH BEIJING

Modification method of nano white carbon black

InactiveCN107266939AIncrease space densityImprove adsorption strengthPigment treatment with macromolecular organic compoundsDispersityIn situ polymerization

The invention provides a modification method of highly dispersed nano white carbon black used as rubber filler. According to the method, unsaturated acrylate polar monomers and acrylamide polar monomers are compounded, arylethene monomers are pre-emulsified, and highly dispersed nano white carbon black is prepared with an in-situ polymerization method. The method not only solves the problem that nano white carbon black is prone to agglomeration, but also solves the problem that nano white carbon black is agglomerated again due to long-term storage, nano white carbon black is endowed with super dispersity, and long-term storage stability is guaranteed. The modification method has the characteristics that fewer monomers are used, environmental pollution is small, the operation method is simple, the method is suitable for industrial production, and the like.

Owner:PETROCHINA CO LTD

Color curable composition and method of preparing the same, color filter and method of producing the same, and solid-state image pick-up device

InactiveCN102482508AImprove dispersionGuaranteed dispersion stabilityMethine/polymethine dyesOptical filtersOrganic solventColor gel

Owner:FUJIFILM CORP

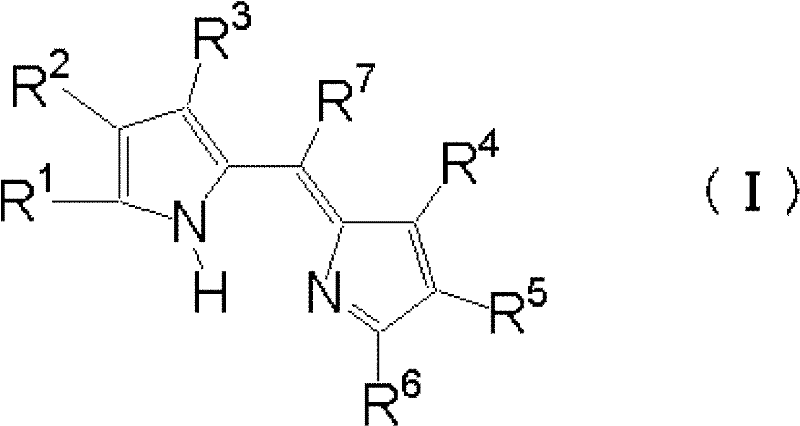

Colouring phototonus composition for color filter, color filter, manufacturing method thereof and liquid crystal display device

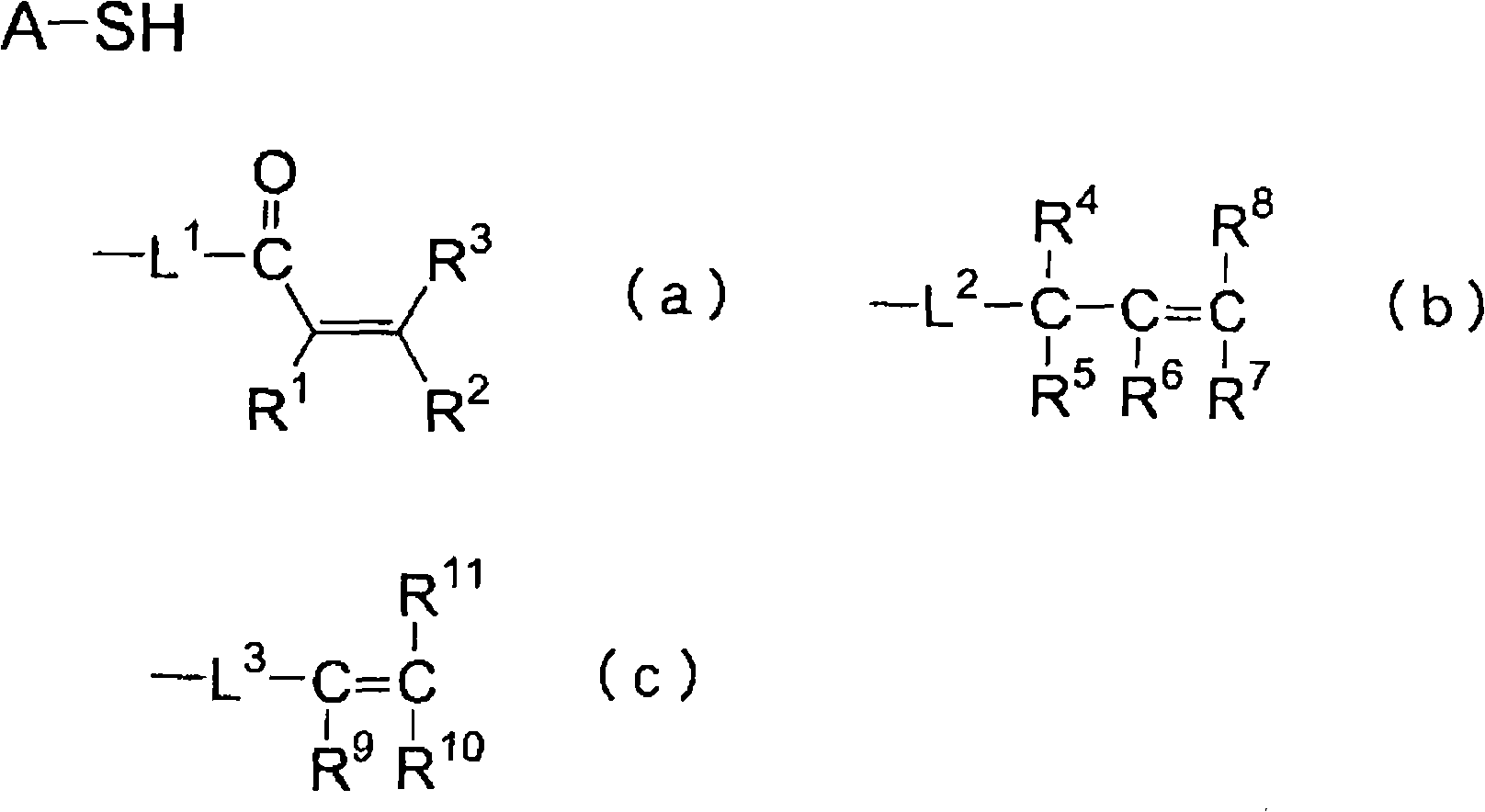

InactiveCN101261446AInhibition of alkali solubilityFormation effect is goodMonoazo dyesMethine/polymethine dyesSolubilityDouble bond

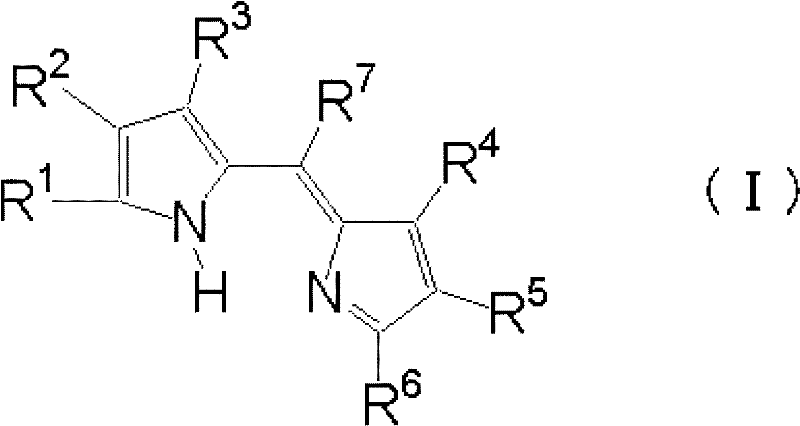

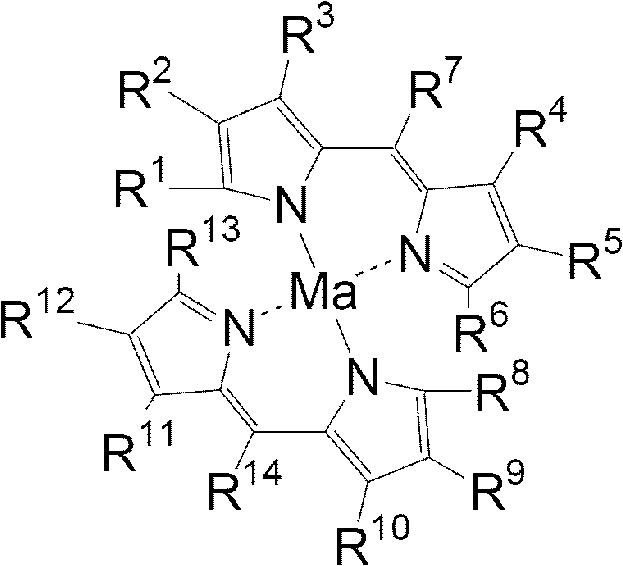

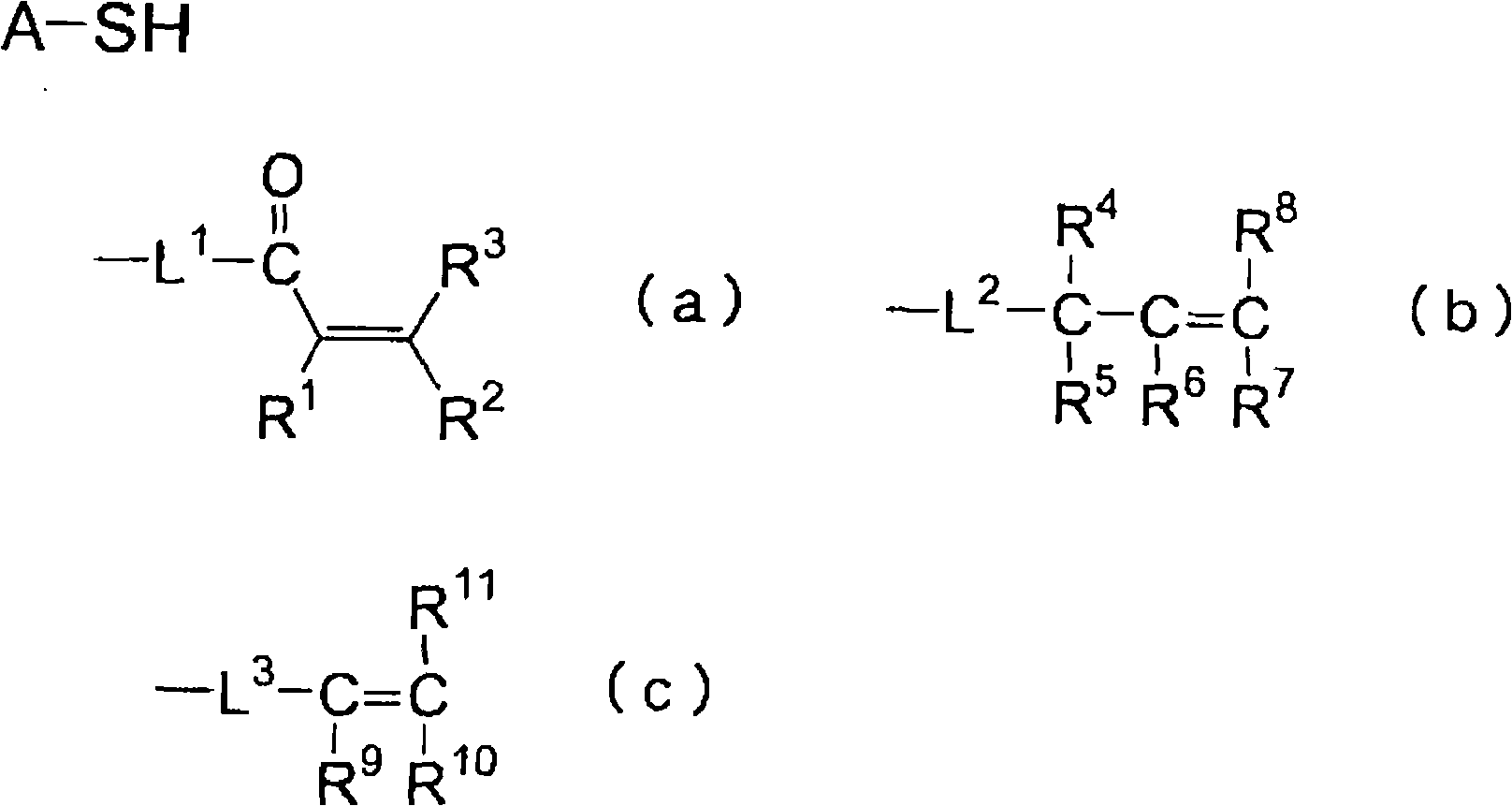

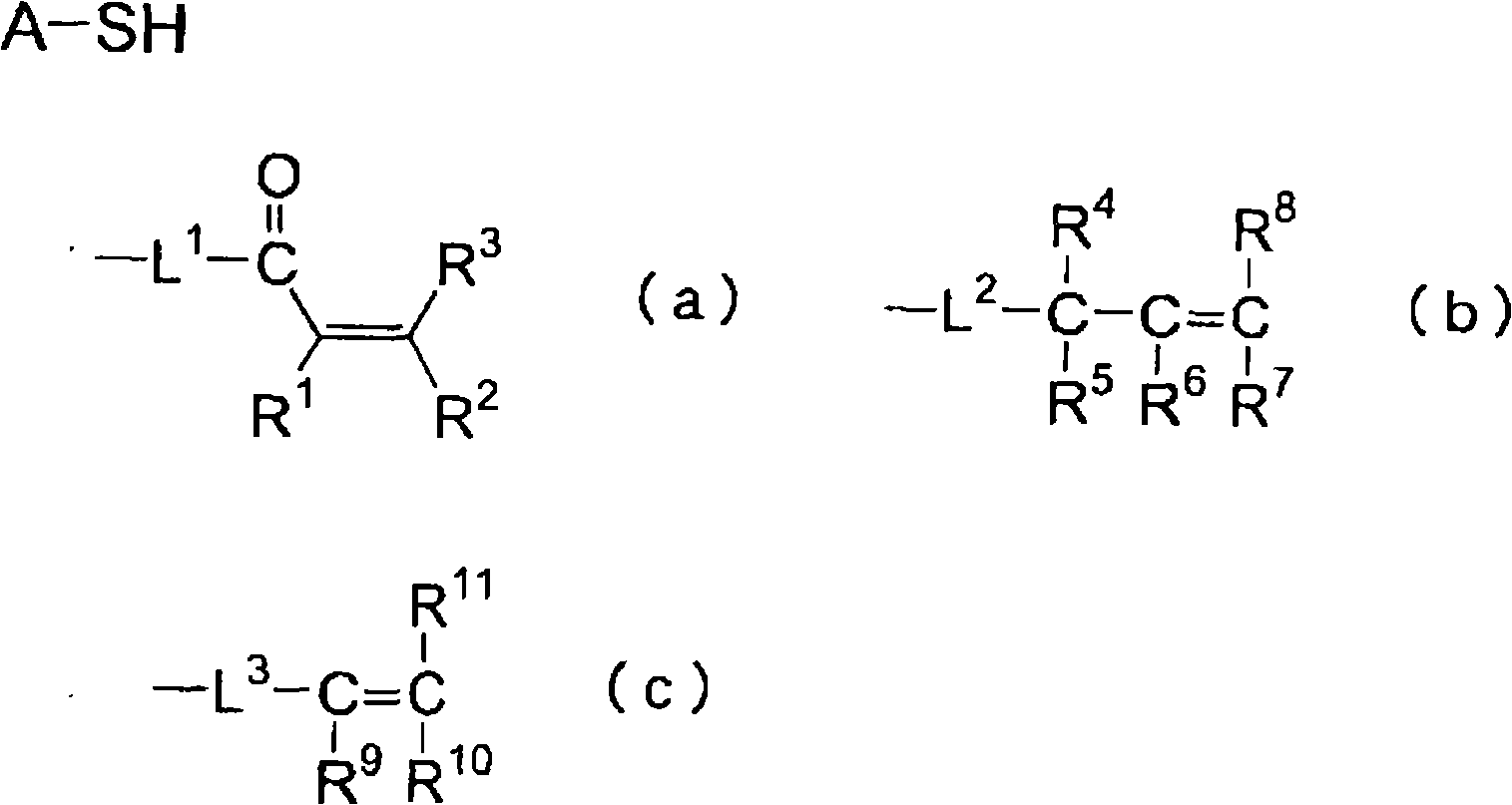

The invention provides a coloring photosensitive composition for a color filter, the color filter, a manufacturing method thereof and a liquid crystal display device. The composition can obtain sufficient deep solidifying property on exposure for forming a coloring pattern with excellent development solubility, development latitude and pattern forming property, and realizing high contrast. The composition includes (A) a thiol compound represented by the formula (I), (B) a six-aryl-link imidazole compound, (C) a polymerism compound with alkenes unsaturated double bonds compound, (D) a dye and (E) a dye dispersant. In formula (I), A is a heterocyclic with a group that is represented by any of formula (a)-(c). In formula (a)-(c), L<1>, L<2>, L<3> represent single bond, oxygen atom, sulfur atom, -N(R<12>)-, phenylene, or linkage group combined with more than two groups independently; R<1>-R<12> represent hydrogen atom or organic group with one valence independently.

Owner:FUJIFILM CORP

A waterborne coating composition used for exterior walls of buildings and a preparing method thereof

InactiveCN107353802AImprove waterproof performanceHigh tensile strengthPolyurea/polyurethane coatingsPliabilityMechanical property

The invention discloses a water-based paint composition for building exterior walls and a preparation method thereof, comprising the following raw materials in parts by weight: 30-35 parts of water-based polyurethane emulsion, 25-29 parts of polyacrylate, 26-31 parts of isocyanate, polyether 25‑30 parts, 16‑20 parts of sodium methyl silicate, 11‑14 parts of sodium carbonate, 10‑15 parts of talc powder, 11‑16 parts of mica powder, 12‑17 parts of titanium dioxide, 8‑12 parts of sodium tripolyphosphate 9-13 parts of polyoxyethylene fatty acid ester, 7-11 parts of sodium polyacrylate, 6-10 parts of tricresyl phosphate, 5-9 parts of ethylene glycol butyl ether, 4-8 parts of tetrachloroisophthalonitrile , 3-7 parts of ethylene glycol, 5-8 parts of terpineol, 30-34 parts of deionized water; including the following steps: S1: water-based polyurethane emulsion, polyacrylate, isocyanate, polyether, sodium methyl silicate and deionized water in a blender. The invention has excellent waterproof performance, high tensile strength and good flexibility, and also has excellent mechanical properties, low cost, high yield and no pollution to the environment.

Owner:天津市金三鑫水性涂料科技有限公司

Light foamed soil for high speed railway station maintenance and change filling

The invention discloses a light foamed soil for high speed railway station maintenance and change filling. The light foamed soil contains the following composition materials by weight: 240-280 parts of cement, 60-80 parts of an active mixed material, 120-140 parts of water, 2-6 parts of an expansive agent, 10-18 parts of a foam stabilizing agent, 6-12 parts of a foaming agent, 3-10 parts of a water repellent, and 4-8 parts of a micro-foam agent. The light foamed soil also includes ceramsite lightweight aggregate with an adding amount accounting for 10%-35% of the total volume. The obtained light foamed soil has the characteristics of compact filling, good foam stabilizing effect, high strength, difficult cracking and good flexibility, is lighter than general civil engineering materials, can avoid environment destruction caused by high fill and high cut and the like when applied to filling engineering construction, and under the circumstance of ensuring constant load, can greatly enhance the filling height, reduce the influence of filling on the foundation, and has very obvious load decreasing effect under the circumstance of insufficient ground bearing capacity.

Owner:河南华泰新材科技股份有限公司

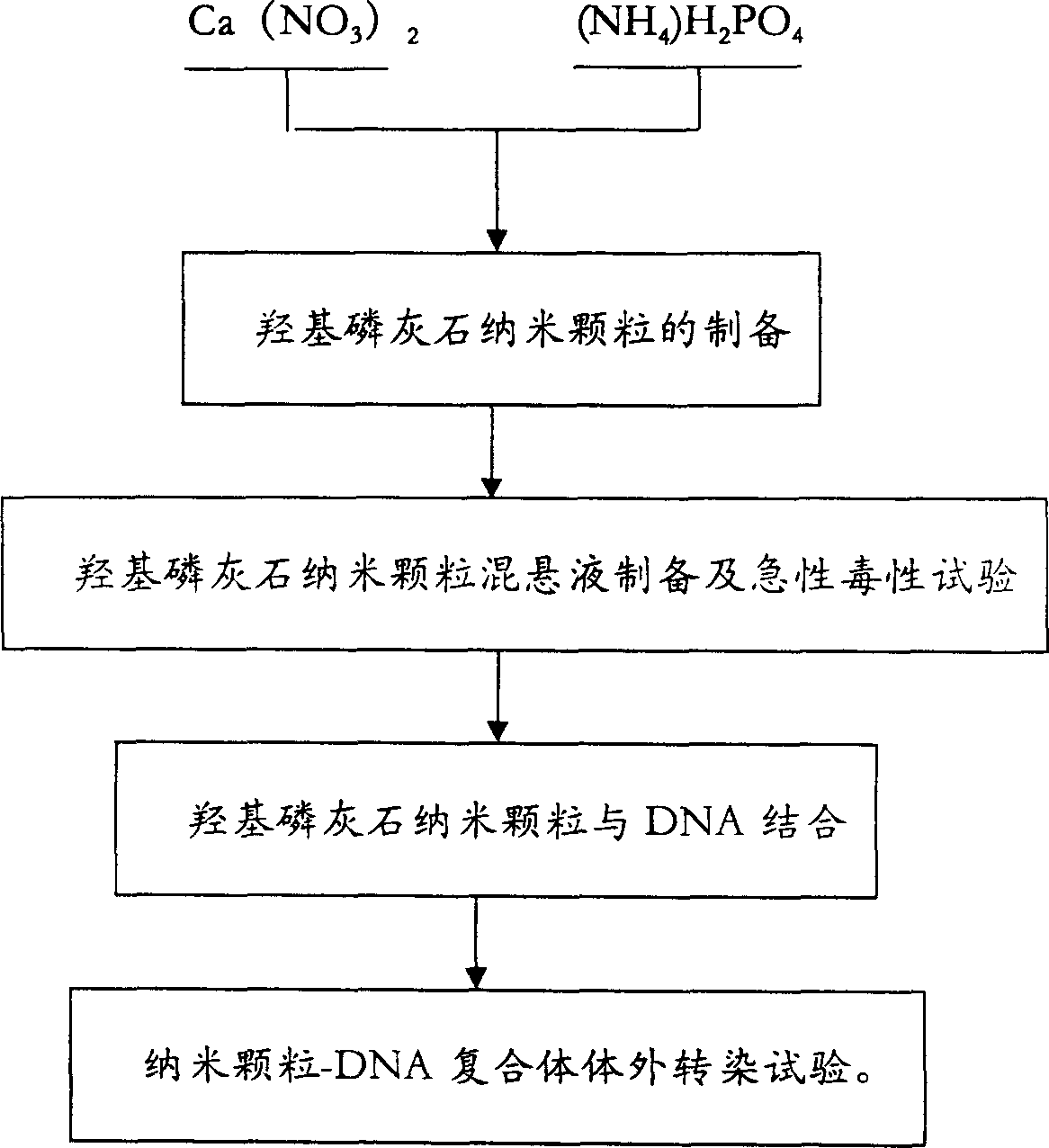

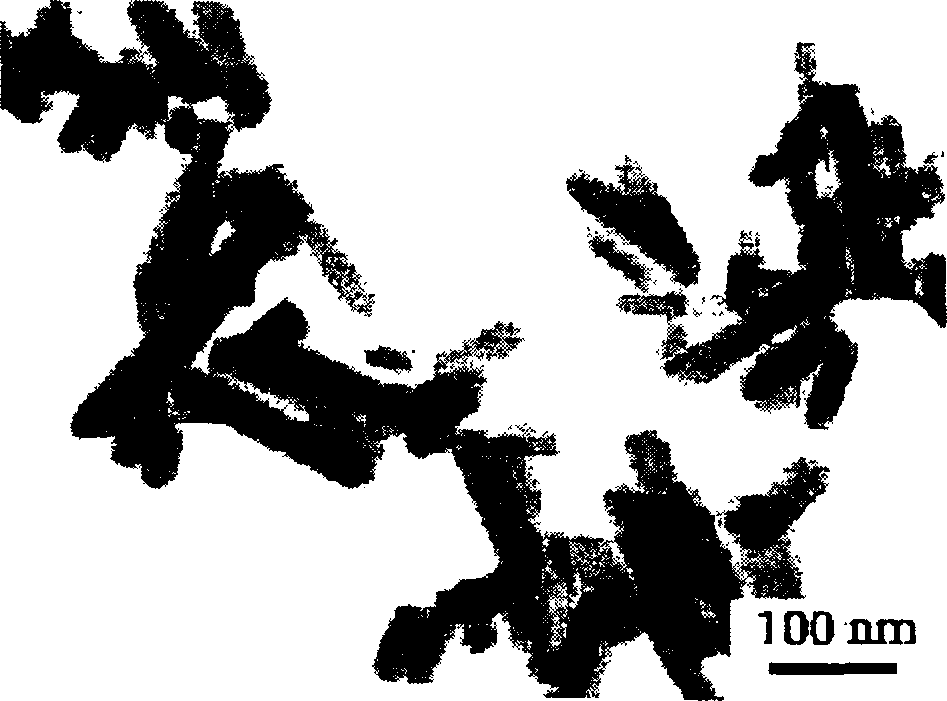

Production of gene carrier and use thereof

InactiveCN1712070AGood biocompatibilityEnhanced ability to carry DNAGenetic material ingredientsGene therapyNanoparticleBiocompatibility Testing

A process for preparing the gene carrier includes such steps as proportionally mixing Ca(NO3)2 solution with (NH4)H2PO4 solution at 1500 rpm, and treating the obtained deposit at 200 deg.C and 200 rpm under 200 mv for 4 hr to obtain hydroxy apatite nanoparticles, which can be used as biologic ceramic material with high biocompatibility.

Owner:CENT SOUTH UNIV

Building external wall temperature-change-resistant anti-oxidative color coating

InactiveCN106381045AHigh tensile strengthGood flexibilityPolyurea/polyurethane coatingsAluminium hydroxidePOLYOXYETHYLENE ETHER

The invention discloses a building external wall temperature-change-resistant anti-oxidative color coating, which is prepared from the following raw materials in parts by weight: 20 to 25 parts of carboxylic waterborne polyurethane, 19 to 24 parts of pure silicon resin emulsion, 11 to 16 parts of cobalt blue, 10 to 15 parts of mill base, 8 to 12 parts of bentonite, 7 to 11 parts of mica powder, 6 to 10 parts of kaolin, 5 to 9 parts of talcum powder, 12 to 14 parts of sodium carbonate, 9 to 11 parts of sodium tripolyphosphate, 10 to 12 parts of polyoxyethylene aliphatic ester, 8 to 10 parts of sodium polyacrylate, 13 to 16 parts of sheet zinc powder, 7 to 11 parts of aluminum hydroxide, 5 to 8 parts of silicon nitride, and 30 to 35 parts of deionized water. A preparation method comprises the following steps of S1, adding the carboxylic waterborne polyurethane, the pure siliconresin emulsion, the cobalt blue, the mill base and the deionized water into a stirrer, and stirring with the stirring speed of 30 to 40rpm for 20 to 30min at the temperature of 40 to 50 DEG C; S2, adding the sheet zinc powder, the aluminum hydroxide and the silicon nitride for stirring with the stirring speed of 100 to 150rpm for 5 to 10min. The building external wall temperature-change-resistant anti-oxidativecolor coating provided by the invention has excellent temperature alternating resistance and oxidation resistance, has high tensile strength and favorable flexibility, and is simple in preparation process, convenient to use, and low in cost.

Owner:CHENGDU PUJIANG KEXIAN TECH

Novel environment-protection stereo brocade modified coating

This invention discloses one kind of new environmental three-dimensional brocade modified dope, it contains water, dispersant, wetting agent, bead burnishing powder, defoamer, alcohol ester - 12, anticorrosion disinfectant, thickening agent, pH conditioner, parent metal, 2% hydroxide ethylol cellulose solution and 801 modified rubber, the weight share of each related ingredient respectively is: Water is 15-18, dispersing agent is 0.2, wetting agent is 0.1, bead burnishing powder is 9-10, defoamer is 0.4, the alcohol ester - 12 is 0.8-2, anticorrosion disinfectant is 0.1-0.2, thickening agent is 0.1-1, pH conditioner is 0.2, parent metal is 38-45, 2% hydroxide ethylol cellulose solution is 5-10 and 801 modified rubber is 15-25. This dope can spray the needed design, which has an effect of the wallpaper and the mural, and make the luster bright, which has the three-dimensional brocade effect.

Owner:沈双平

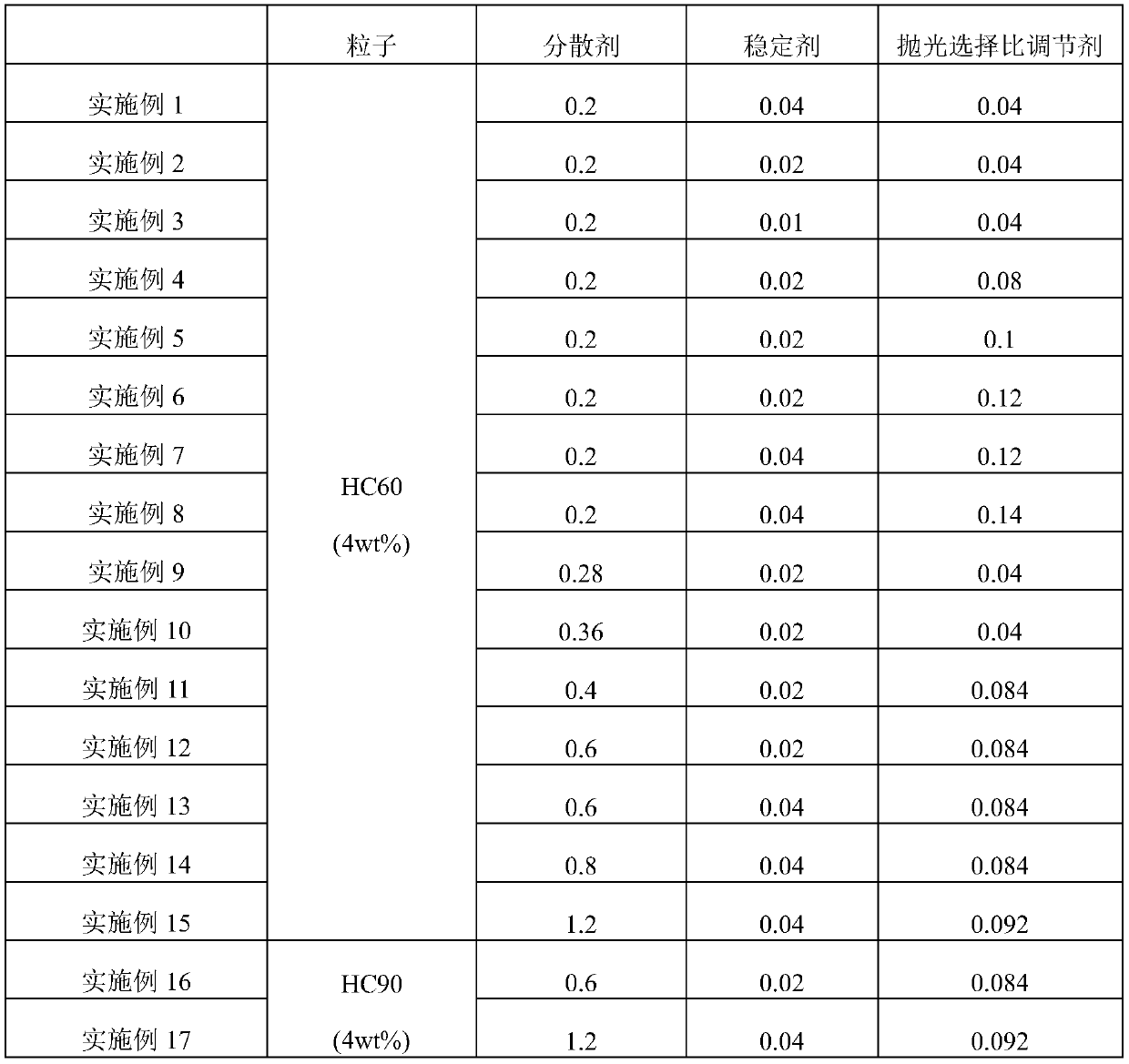

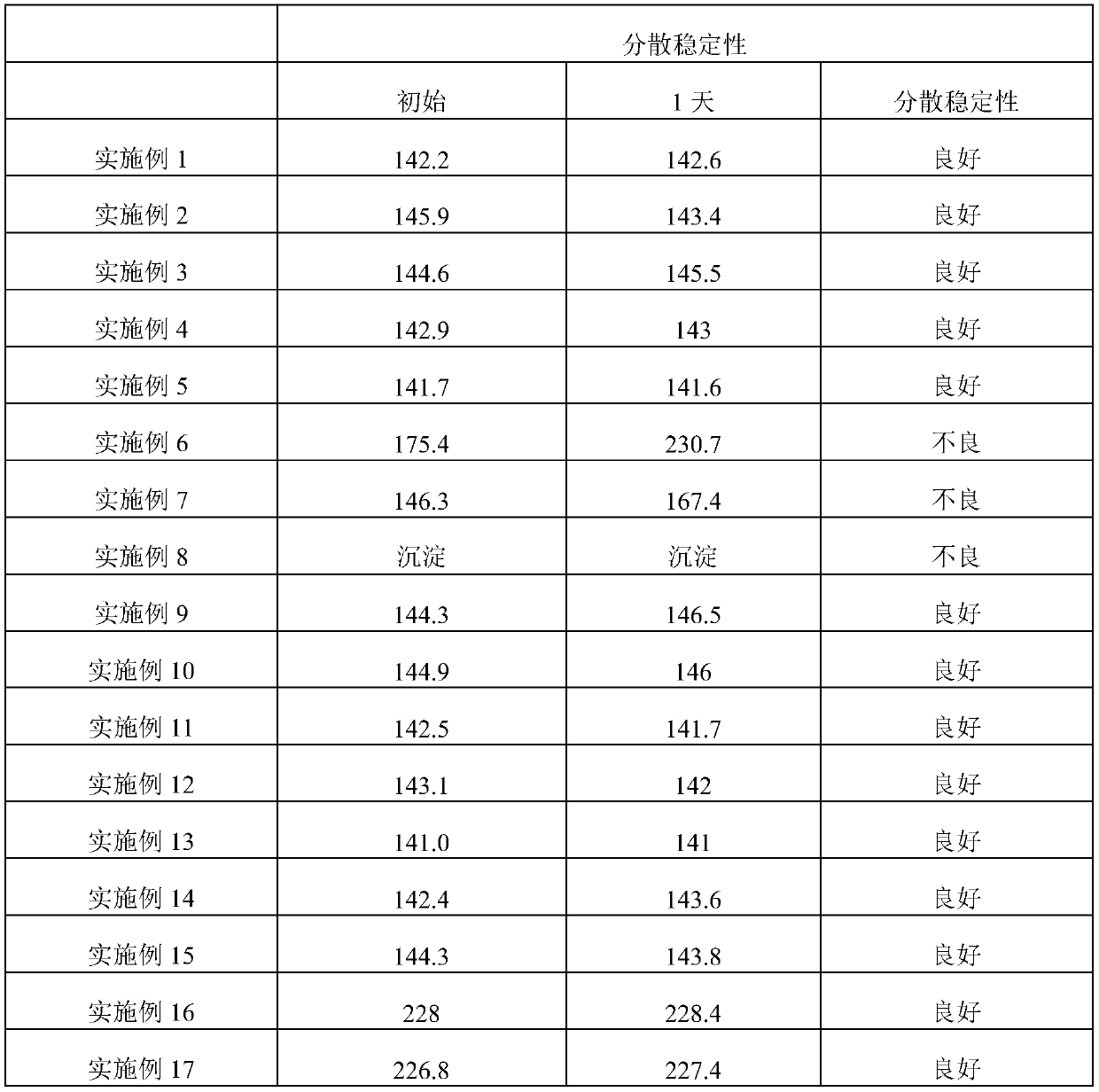

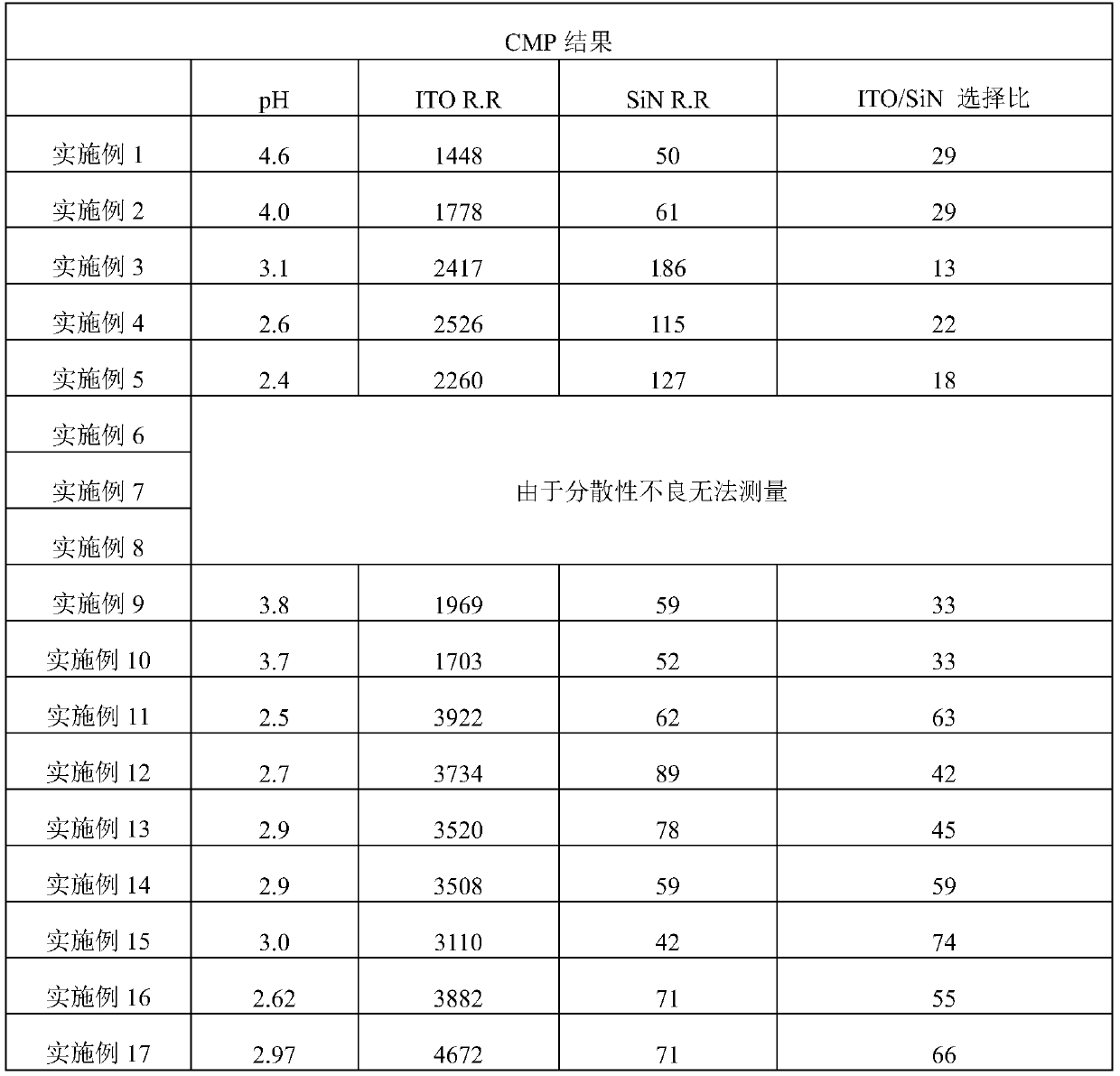

Polishing slurry composition

ActiveCN110903766ARealize automatic stop functionGuaranteed dispersion stabilityOther chemical processesSemiconductor/solid-state device manufacturingOrganic acidSlurry

Owner:K C TECH

Beta 2-microglobulin assay kit and preparation method thereof

The invention discloses a beta 2-microglobulin assay kit and a preparation method thereof. The kit comprises a reagent A, a reagent B and a calibration product, wherein the reagent A is prepared from the following raw materials in parts by weight: 25-30 parts of a buffer solution, 20-25 parts of sodium azide, 15-20 parts of a stabilizer and 11-16 parts of a surface activator; the reagent B is prepared from the following raw materials in parts by weight: 23-27 parts of latex particles combined with anti-human beta 2-microglobulin antibody, 21-24 parts of sodium azide and 25-30 parts of the buffer solution; the calibrator is prepared from the following raw materials in parts by weight: 15-18 parts of beta 2-microglobulin, 21-24 parts of the buffer solution and 16-21 parts of the stabilizer; the buffer solution comprises the following raw materials in parts by weight: 17-22 parts of tris(hydroxymethyl) aminomethane, 30-35 parts of deionized water and 11-20 parts of hydrochloric acid. The preparation method for the beta 2-microglobulin assay kit comprises the following steps: mixing tris(hydroxymethyl) aminomethane with deionized water, uniformly stirring, adding hydrochloric acid and regulating the PH value to be 7-9. The beta 2-microglobulin assay kit has excellent sensitivity for analysis, precision degree and accuracy, is relatively great in measurement range, is simple to prepare, is convenient to use, and is low in cost.

Owner:安徽同致生物工程股份有限公司

Graphene conductive ink and preparing method thereof

InactiveCN110204962AProcess stabilityImprove conductivityMaterial nanotechnologyGrapheneAlcoholAdhesive

Owner:HUAQIAO UNIVERSITY

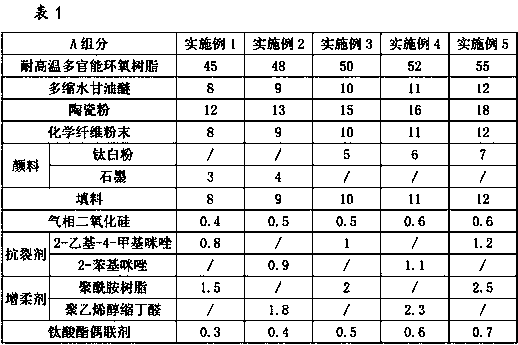

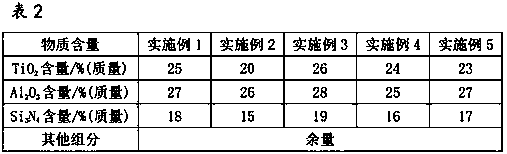

Strong acid-base resistant composite ceramic anticorrosive coating and preparation method thereof

ActiveCN108753107AImprove bonding fastnessIncrease coating thicknessAntifouling/underwater paintsPaints with biocidesFiberEpoxy

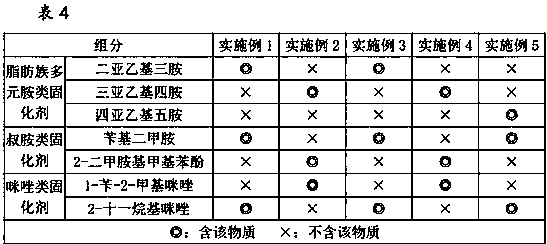

The invention discloses a strong acid-base resistant composite ceramic anticorrosive coating, relates to the technical field of anticorrosive coatings and preparation of the coatings, and aims at solving the problem in the prior art that the anticorrosive coating needs multiple coating to achieve the desired thickness and has poor abrasion resistance. The coating includes components A and components B. The components A include the following by weight: 45-55 parts of high temperature resistant multifunctional epoxy resin, 8-12 parts of polyglycidyl ether, 12-18 parts of ceramic powder, 8-12 parts of chemical fiber powder, 3-7 parts of pigment, 8-12 parts of filler, 0.4-0.6 part of anti-settling agent, 0.8-1.2 parts of anti-cracking agent, 1.5-2.5 parts of softening agent and 0.3-0.7 parts of coupling agent; the components B are formed by mixing aliphatic polyamine curing agent, tertiary amine curing agent and imidazole curing agent according to the ratio of 1:0.8:0.5 by mass. A preparation method of the above anticorrosive coating is disclosed correspondingly. The coating prepared by the method has the advantages of high coating thickness, high compactness, good abrasion resistanceand good acid and alkali resistance.

Owner:苏州群鹰防腐材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com