Graphene conductive ink and preparing method thereof

A technology of conductive ink and graphene, which is applied in the field of graphene, can solve problems such as hindering the application of liquid phase exfoliation, expensive metal consumables, and complicated processes, and achieve excellent printing adaptability, excellent electrical conductivity, and high electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] According to the technical scheme disclosed by the present invention, the following operations are carried out:

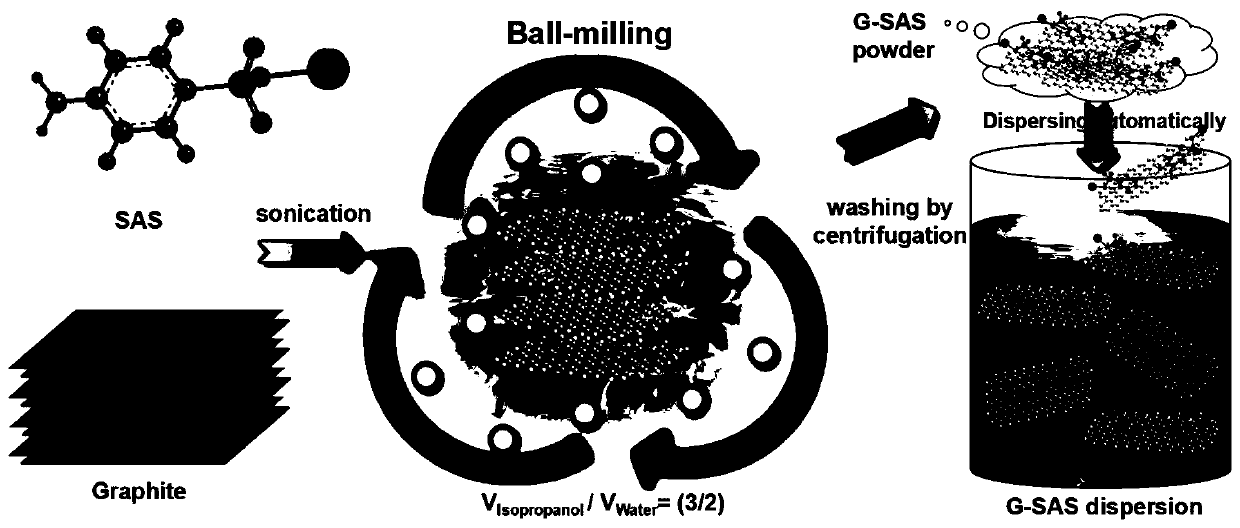

[0037](1) Accurately weigh the following raw materials in parts by mass: 10 g of 8000-mesh natural flake graphite, 10 g of sodium p-aminobenzenesulfonate, 240 mL of isopropanol, and 160 mL of distilled water, and ultrasonically mix the raw materials of the above components to obtain a grinding liquid;

[0038] (2) Put the obtained grinding liquid into a basket mill and pass through a zirconia ball mill with a particle diameter of 2.5 mm for 24 hours at a speed of 2000 rpm, and feed into cooling water for circulating cooling;

[0039] (3) Take out the upper material after grinding from the grinder barrel, and use isopropanol / water (V 异丙醇 / V 水 =3 / 2) The solvent carries out centrifugal washing 5 times to the material, finally obtains the self-stable dispersed graphene nanomaterial, and the specific preparation process is as follows figure 1 shown;

[0040] (...

Embodiment 2

[0045] According to the technical scheme disclosed by the present invention, the following operations are carried out:

[0046] (1) Accurately weigh the following raw materials by mass: 10 g of 8000-mesh natural flake graphite, 5 g of sodium p-aminobenzenesulfonate, 240 mL of isopropanol, and 160 mL of distilled water, and ultrasonically mix the raw materials of the above components to obtain a grinding liquid;

[0047] (2) Put the obtained grinding liquid into a basket mill and pass through a zirconia ball mill with a particle diameter of 2.5 mm for 24 hours at a speed of 2000 rpm, and feed into cooling water for circulating cooling;

[0048] (3) Take out the upper material after grinding from the grinder barrel, and use isopropanol / water (V 异丙醇 / V 水 =3 / 2) The solvent carries out centrifugal washing 5 times to the material, finally obtains self-stabilizing dispersed graphene nanomaterials, and its preparation process is as follows figure 1 shown;

[0049] (4) Accurately we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com