Polishing slurry composition

A composition, slurry technology, used in polishing compositions containing abrasives, other chemical processes, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 15

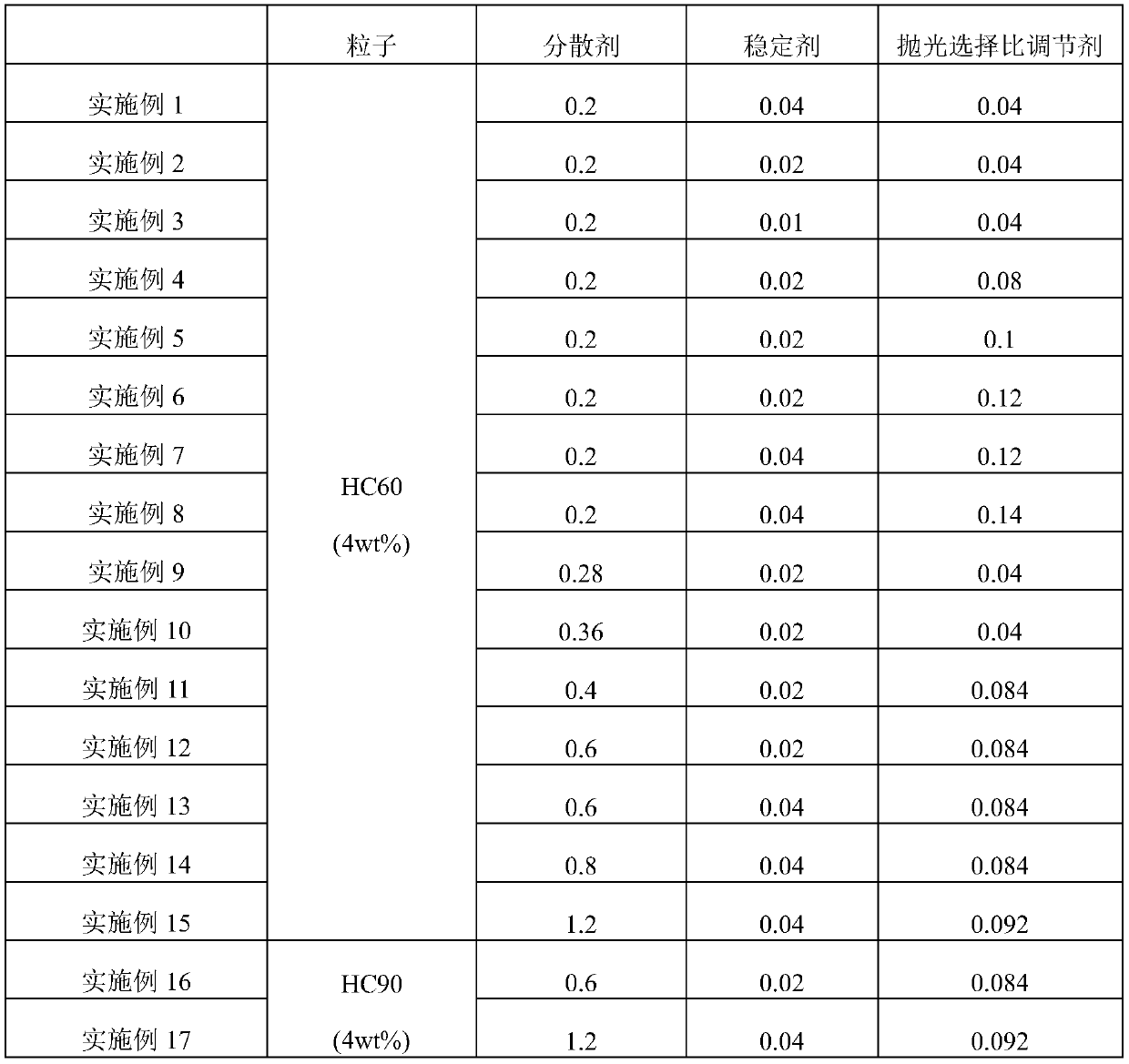

[0067] According to Table 1, the average particle size of primary particles is 4% by weight of colloidal ceria (HC-60, Solvay company) of 60nm (BET measurement), picolinic acid (Picolinic acid) as dispersant, polyethyleneimine (PEI, Polyethyleneimine) was used as a stabilizer, and oxalic acid (Oxalic acid) was mixed with ultrapure water as a polishing selectivity regulator, and a polishing slurry composition was prepared based on Table 1.

Embodiment 16 and Embodiment 17

[0069] In said embodiment 1, the colloidal ceria particle (HC-90, Solvay company) that the average particle size of polishing particle uses primary particle is 90nm (BET measurement), except that, other conditions are identical, prepare according to table 1 Polishing slurry composition.

[0070] 【Table 1】

[0071]

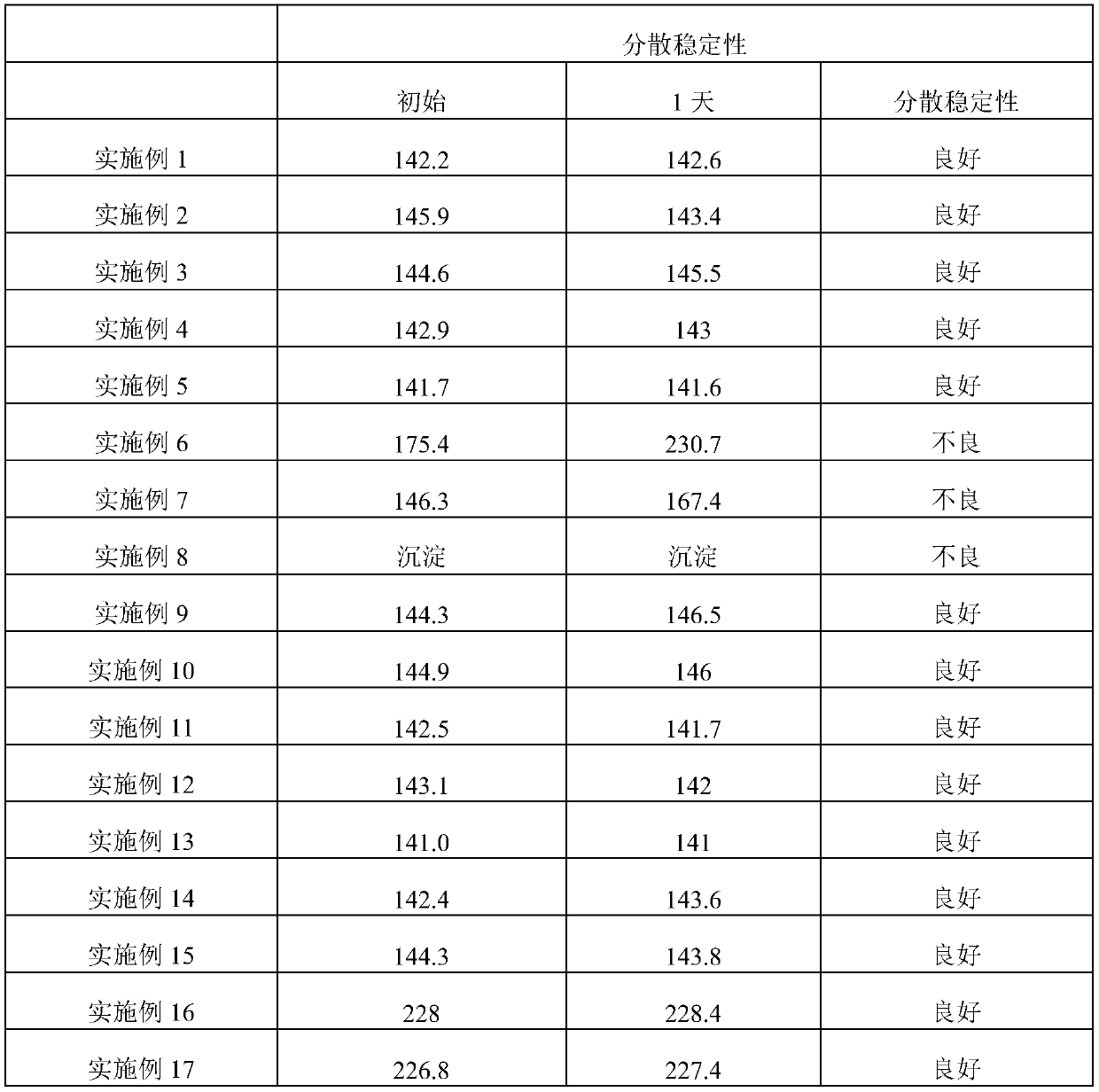

[0072] (1) Evaluation of dispersion stability

[0073] In order to evaluate the dispersion stability of the slurry composition of the example, the particle size was measured on the 0th day and the first day respectively, and the stability over time was measured.

[0074] 【Table 2】

[0075]

[0076] Referring to Table 2, Examples 1 to 5 and Examples 9 to 17 show good dispersion stability even if oxalic acid, which acts as an ITO etchant, is added. And have low dispersion stability.

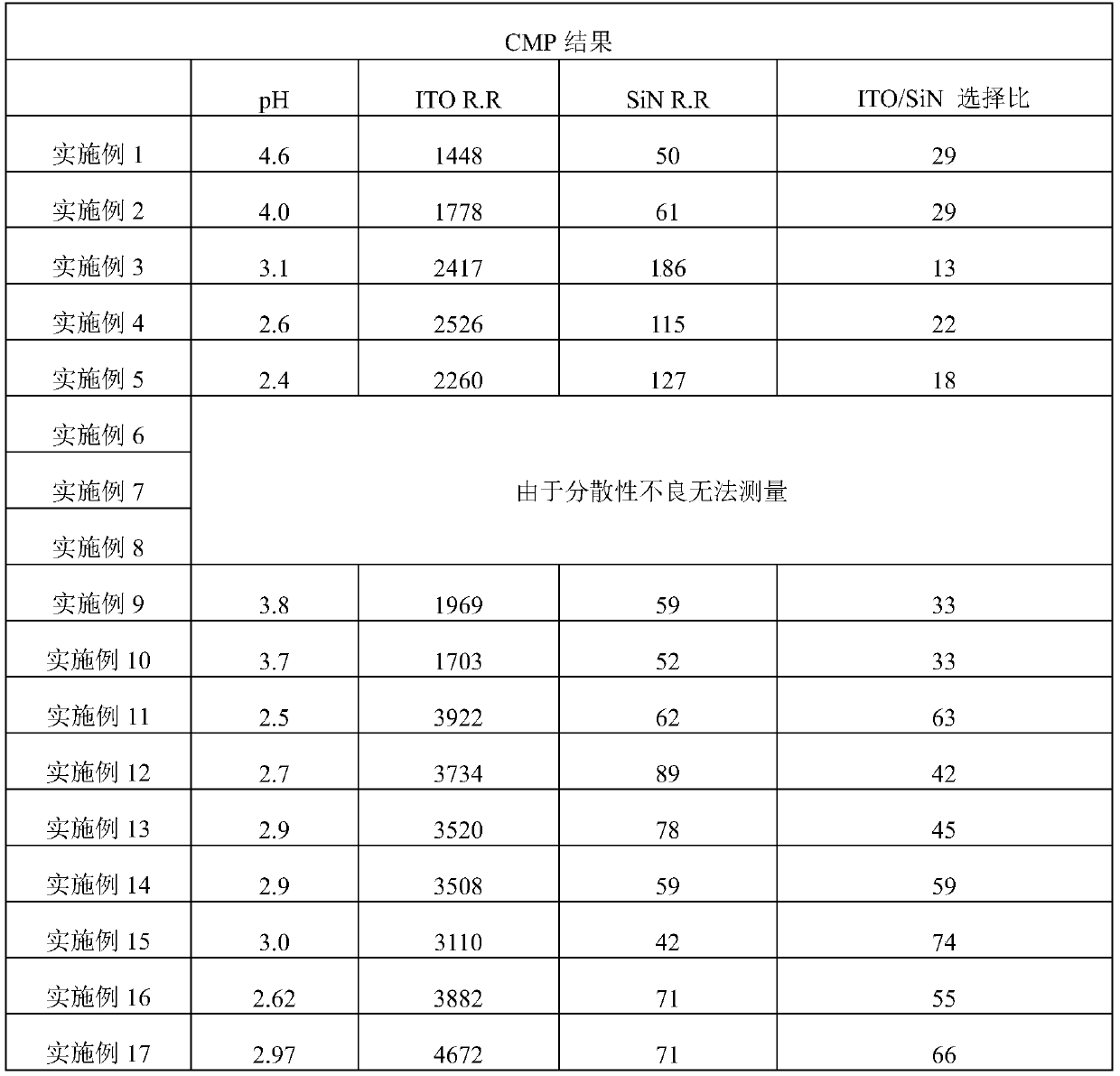

[0077] (2) Evaluation of polishing characteristics

[0078] Using the polishing slurry composition of the example, the substrate containing the ITO film and the SiN film was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com