Dual-purpose lathe capable of machining large-aperture and deep hole at a time

A large-diameter, deep-hole technology, applied in metal processing equipment, turning equipment, manufacturing tools, etc., can solve the problems of low degree of automation of lathes, unqualified processing quality, complicated operation steps, etc., to achieve high work efficiency and improve pass rate. , the effect of reducing the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

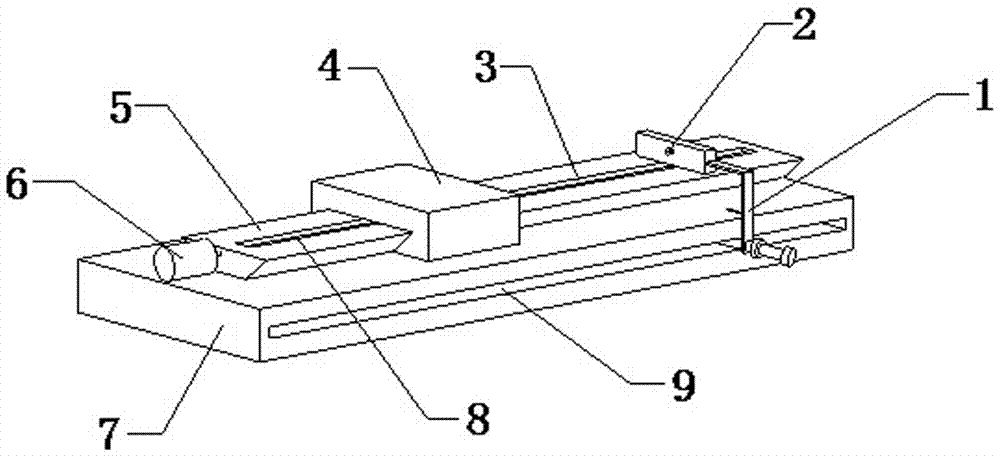

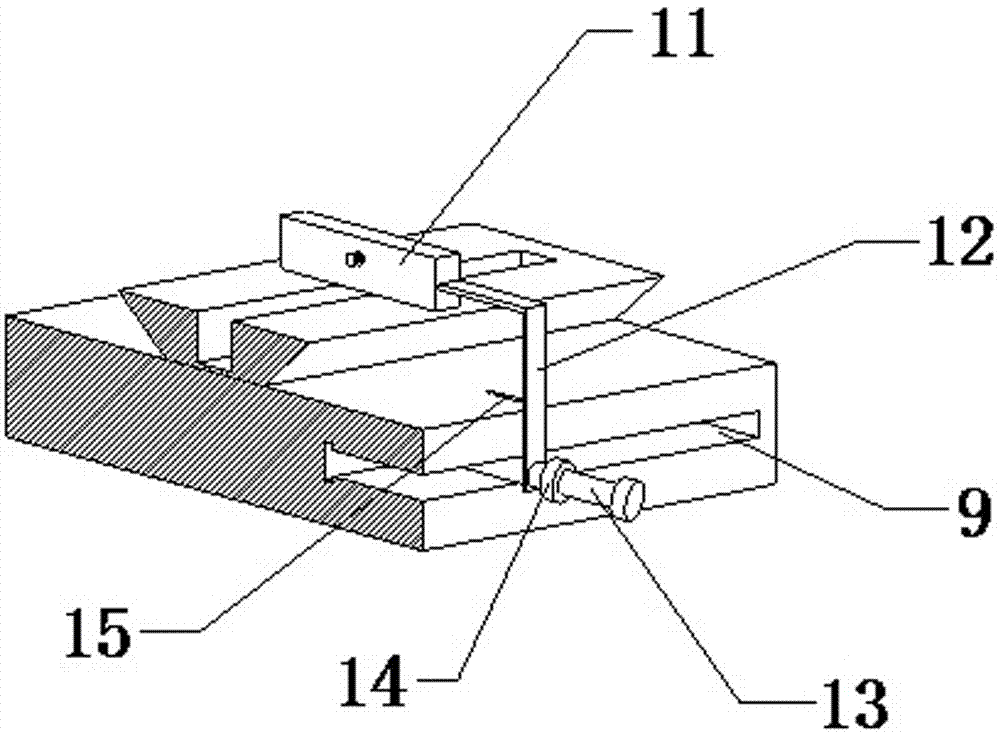

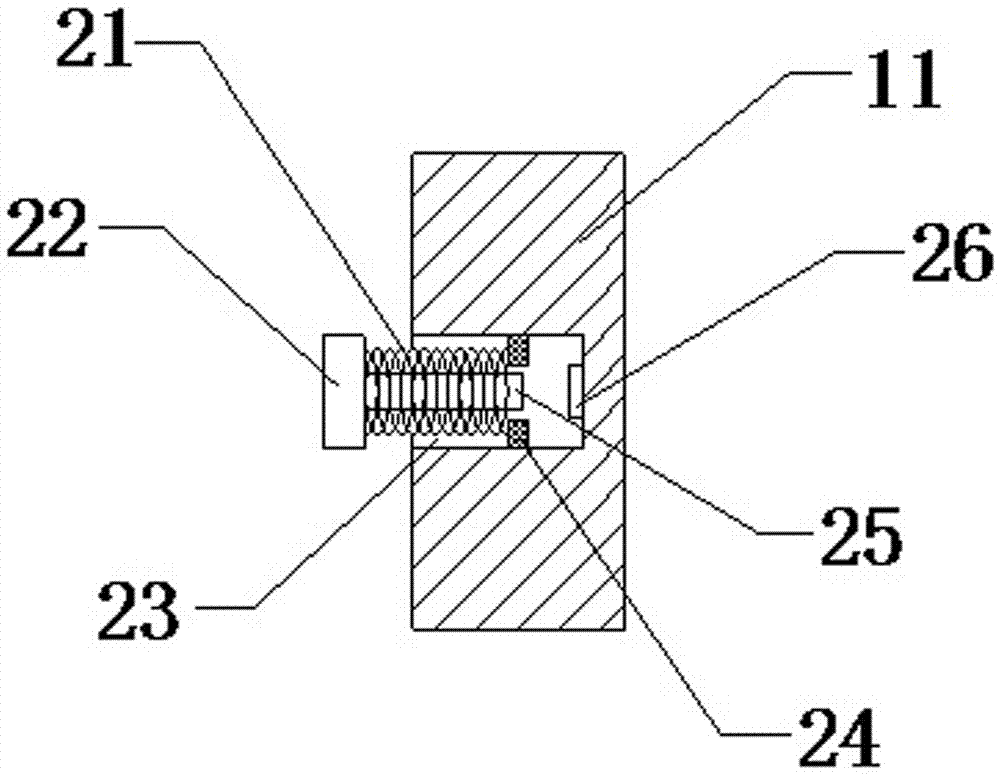

[0020] see Figure 1-Figure 3 , the present invention provides a technical solution: a dual-purpose lathe capable of processing large apertures and deep holes at one time, including a device main body, an aperture determination mechanism 1 and a self-stopping mechanism 2, the device main body includes a chute-3, a tool holder 4, Slide rail 5, servo motor 6, base 7, screw rod 8 and chute 2 9, slide rail 5 is assembled on the upper end surface of base 7, tool holder 4 is assembled on slide rail 5, screw rod 8 is assembled in chute 1 3 , chute one 3 is offered at slide rail 5 upper end faces, and chute two 9 is offered at base 7 front end faces, and servo motor 6 is arranged on slide rail 5 left sides, and screw mandrel 8 left ends connect servo moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com