Self-locking car stopper in can

A car stopper and self-locking technology, which is applied in transportation and packaging, lifting equipment in mines, etc., can solve problems such as hindering mine production and dangerous efficiency, and achieve the effect of simple structure, ensuring safety and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and embodiments.

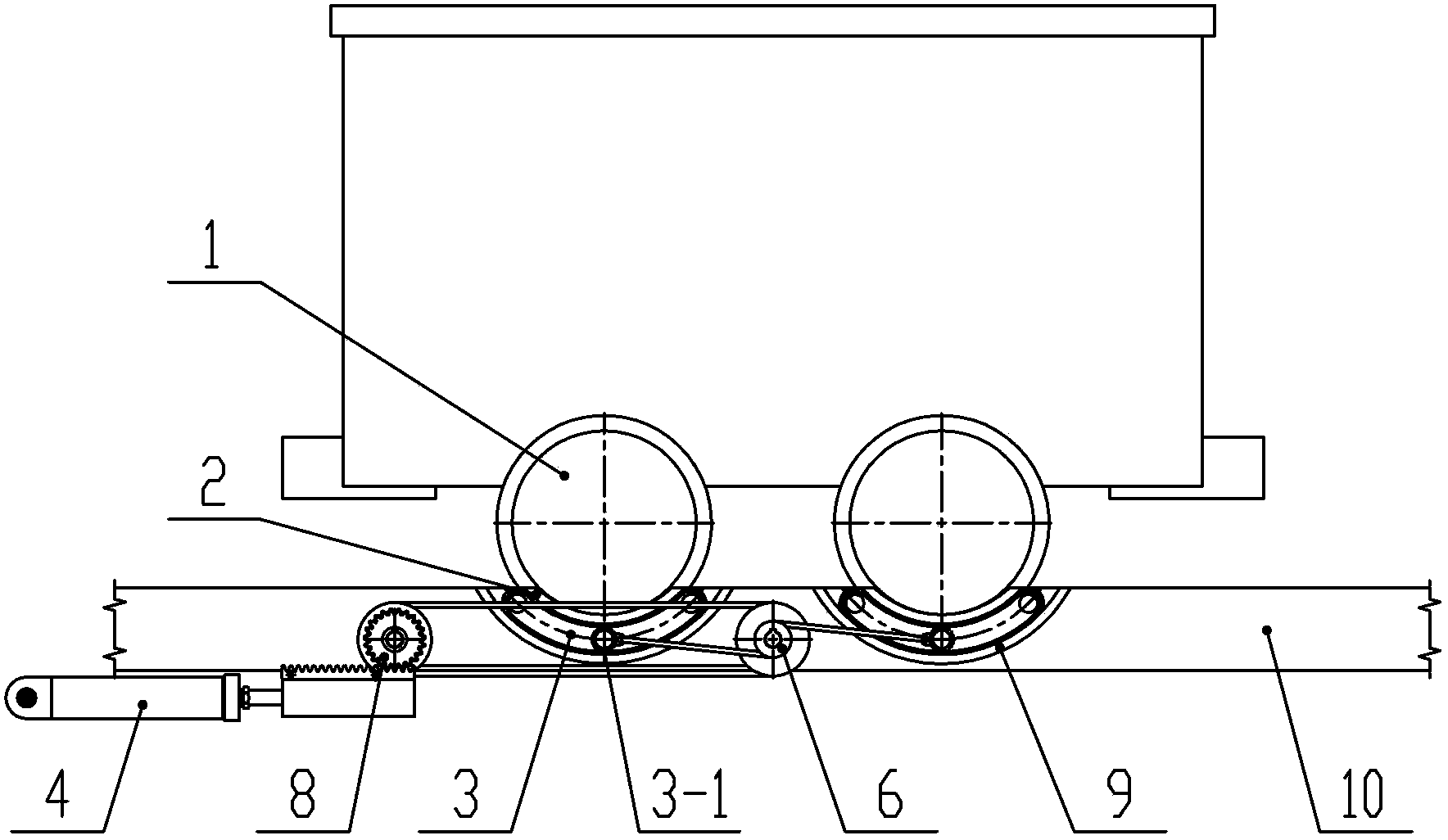

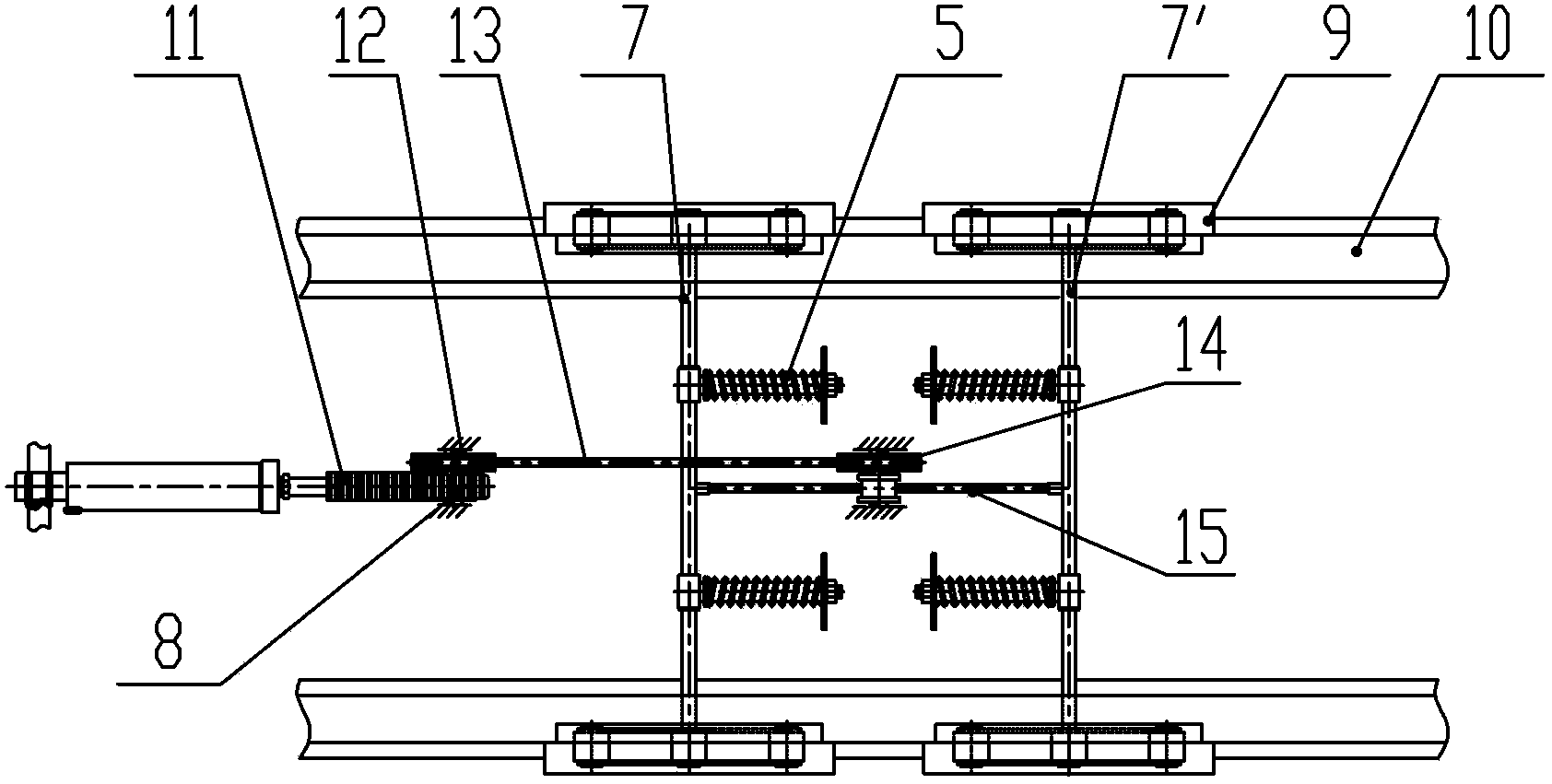

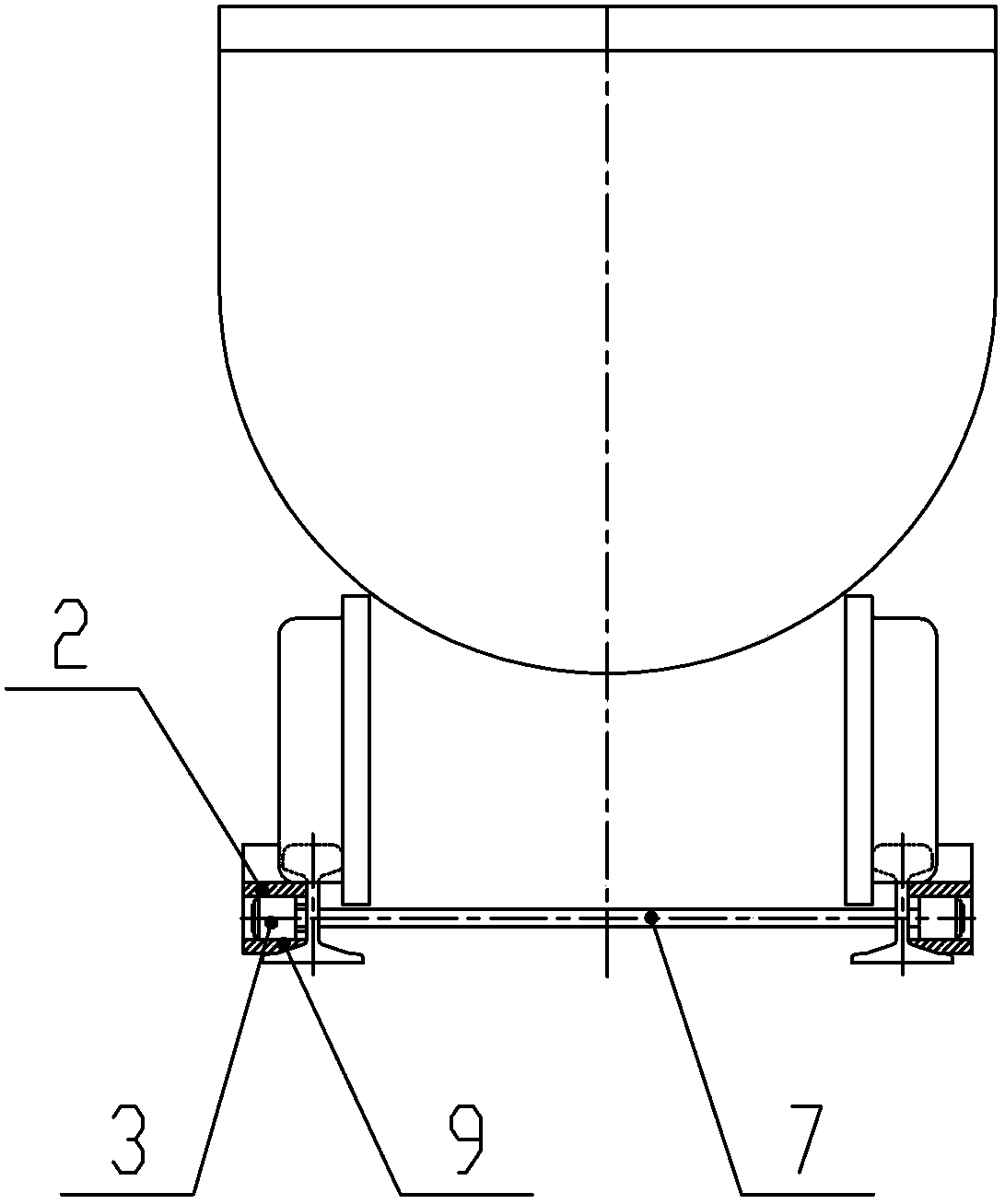

[0015] as attached figure 1 , figure 2 , image 3 The self-locking vehicle arrester in the tank shown includes two rails 10 laid in parallel on the lower part of the cage, and is characterized in that two groups of symmetrical arc-shaped grooves are arranged on the two rails 10, The center distance of the two groups of arc-shaped grooves is equal to the center distance of the two groups of wheels 1. The arc-shaped grooves include the grooved car-blocking rail 2 and the grooved rail support plate 9 fixed on the track 10. The grooved anti-vehicle rail 2 is directly in contact with the wheel 1, and an arc-shaped self-locking anti-vehicle body 3 is movably installed in the space between the grooved rail support plate 9 and the grooved anti-vehicle rail 2. The synchronous beam I7 of the anti-vehicle body is installed between the two self-locking anti-vehicle bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com